Table of contents

1 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.1 User qualification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Proper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Improper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4 Safety warnings and safety signs used in this manual . . . . . . . . . . . . . . . . . . 6

2.5 Product safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.5.1 General hazards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.5.2 Personal protective equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.5.3 Built-in safety elements and measures . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.6 General safety rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Materials used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Description of function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Functional principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5 Putting into operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1 Installation site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.2 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

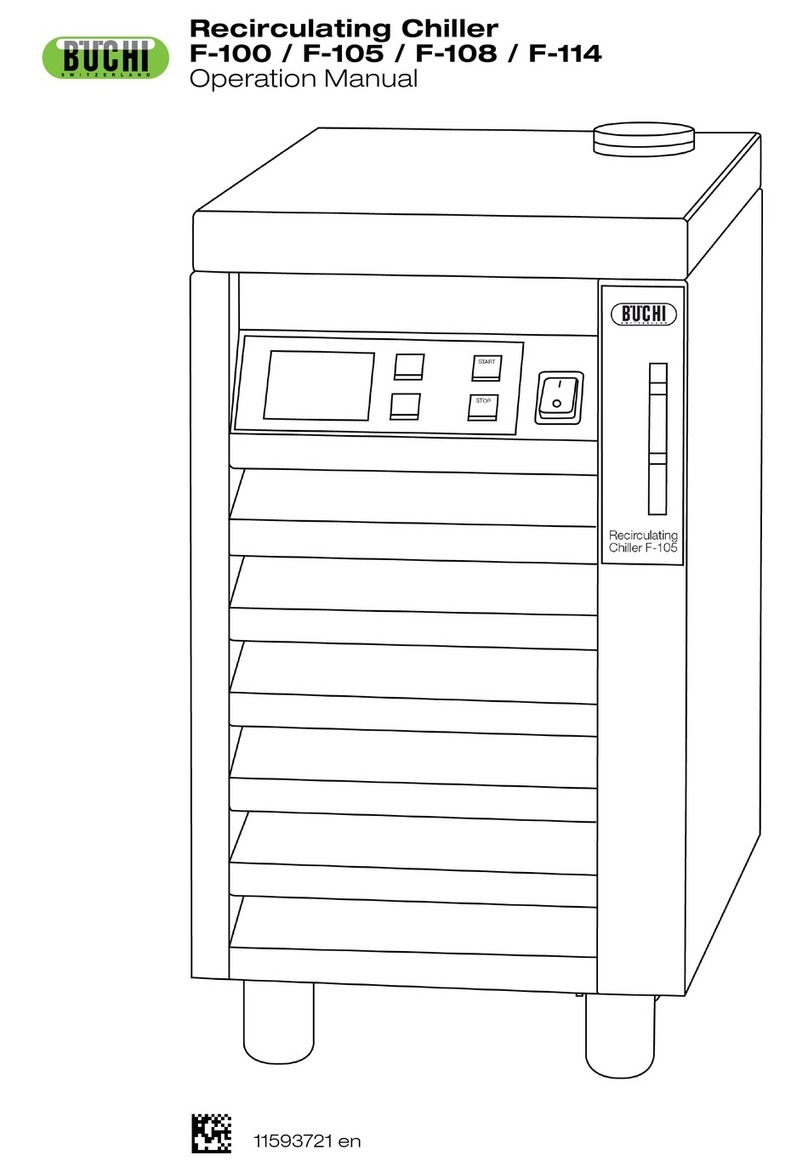

6.1 Operating controls and housing . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.2 Preparing for use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.2.1 Installing the hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.2.2 Filling the chiller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.3 Start operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.4 No BUCHI vacuum controller connected to the system . . . . . . . . . . . . . . . 21

6.5 Working with BUCHI vacuum controller . . . . . . . . . . . . . . . . . . . . . . . 22

7 Maintenance and repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.1 Customer service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.2 General inspection and cleaning instructions. . . . . . . . . . . . . . . . . . . . . 24

8 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8.1 Error message display (only F-105) . . . . . . . . . . . . . . . . . . . . . . . . . 25

8.2 Malfunctions and their remedies. . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9 Shutdown, storage, transport and disposal . . . . . . . . . . . . . . . . . . . . . . . . 26

9.1 Storage and transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

9.2 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

10 Spare parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

10.1 Enclosed parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

10.2 Instrument configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

10.3 Spare parts, optional accessories . . . . . . . . . . . . . . . . . . . . . . . . . . 30