TABLE OF CONTENTS

DESCRIPTION PAGE

Warranty.......................................................................................................................................2

Unpacking .................................................

..

.................................................................................2

Assembly......................................................................................................................................2

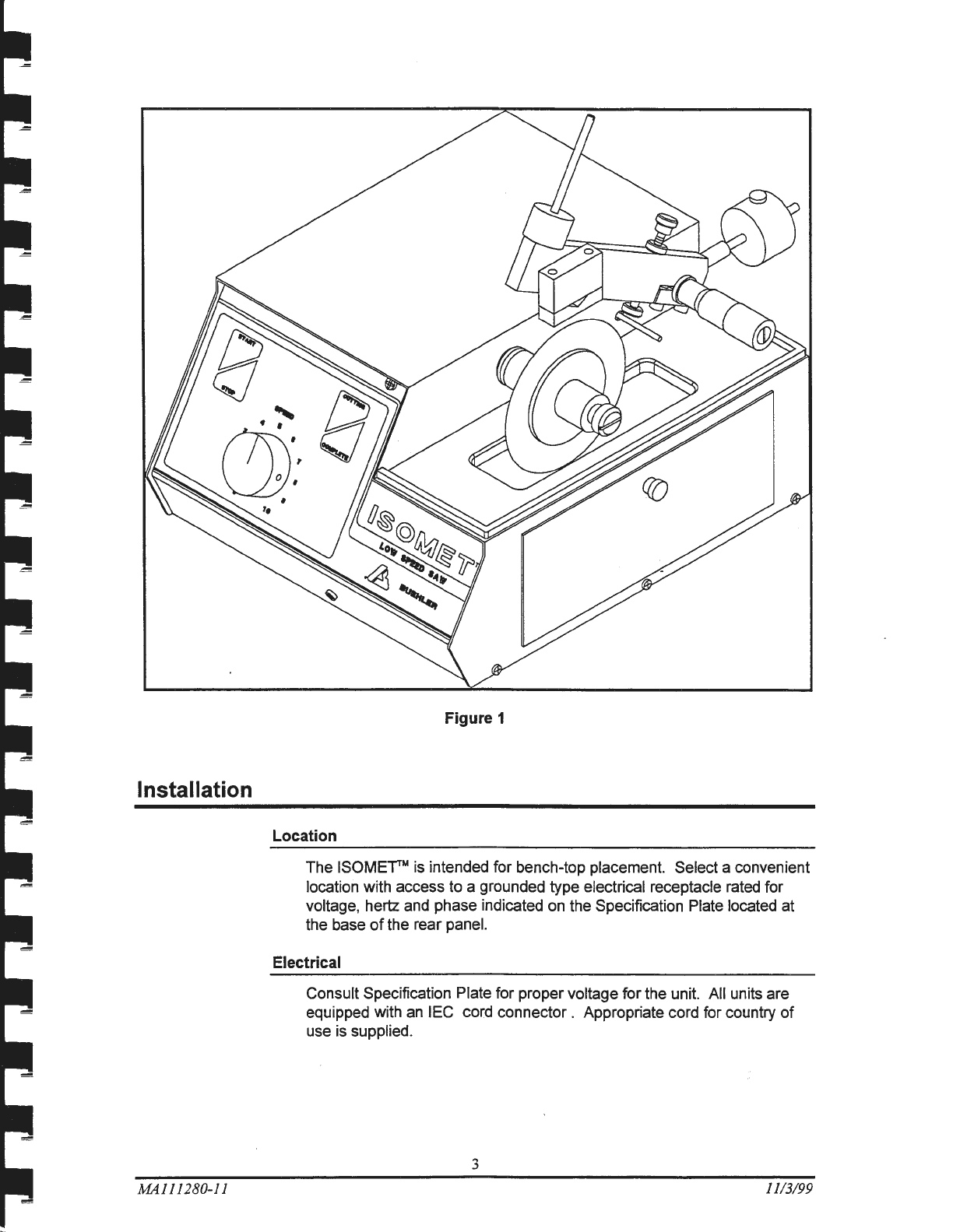

Installation ....................................................................................................................................3

Location....................

..

..............................................................

..

.....................................3

Electrical.......................................

..

...

....

..........................................................................3

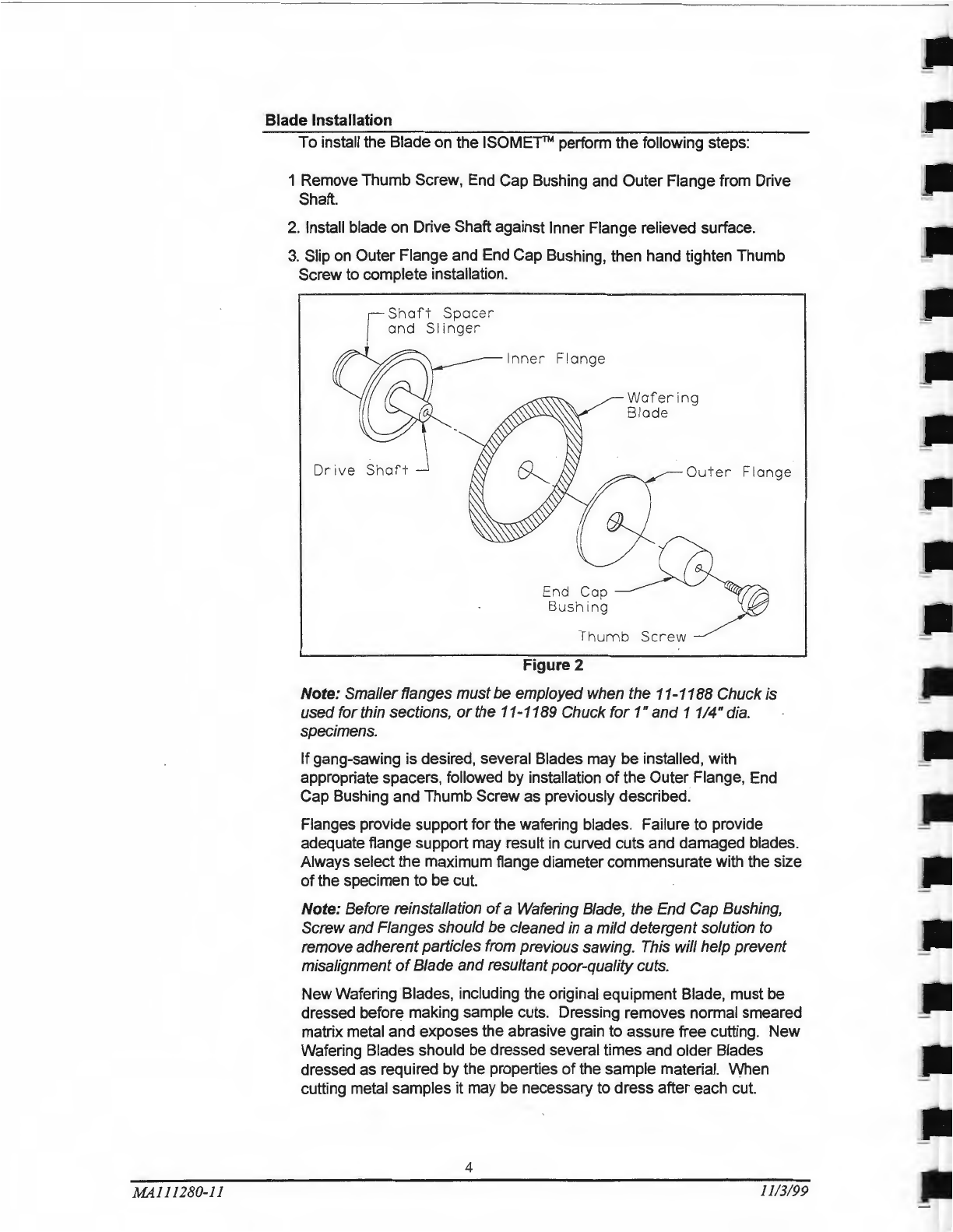

Blade Installation.............................................................................................................4

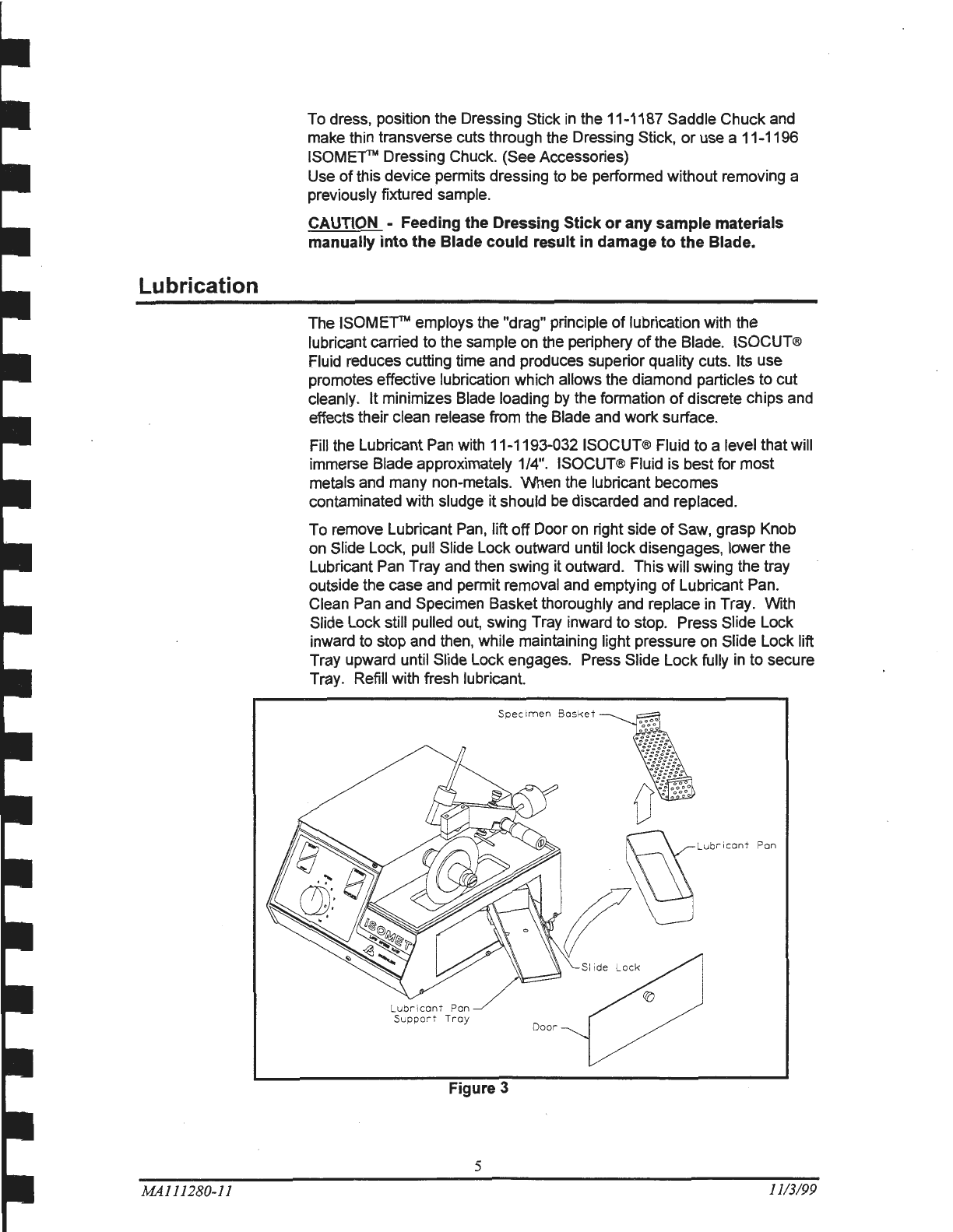

Lubrication

..

...............................................

..

.

..

..............................................................................5

Operation...........................

..

.........................................................................................................6

Loading the Saw..............................................................................................................6

Adjustment

of

Cut-OffSwitch Mechanism.......................................................................6

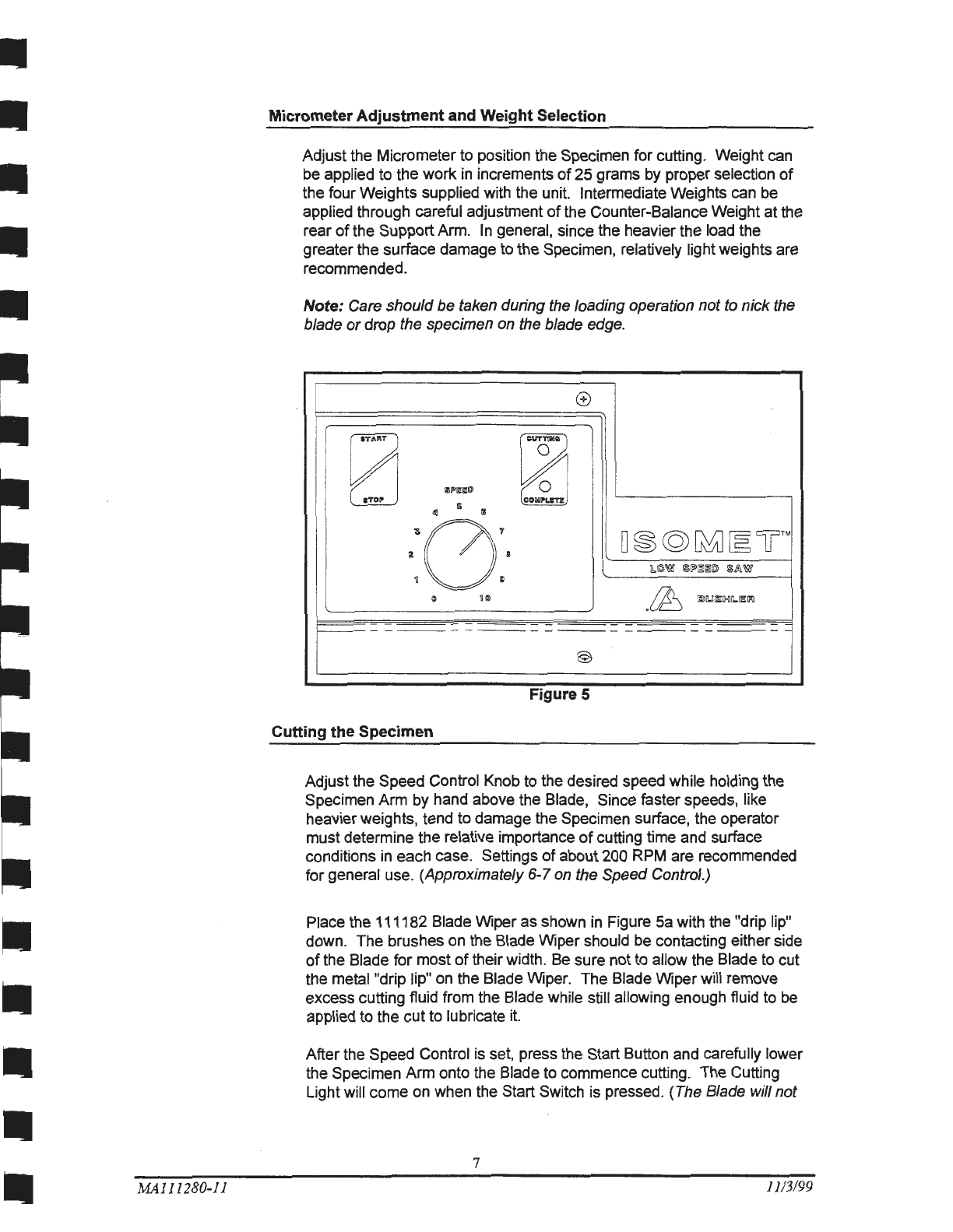

MicrometerAdjustment and Weight Selection ................................................................7

Cutting the Specimen......................................................................................................7

Maintenance...............

..

........................

..

.......................................................................................9

Motor

or

Drive Belt Replacement...........................

..

.......................................................9

Micrometer Screw Adjustment ..................................................................

~

.....................

11

Replacement

or

Exchange

of

Micrometers.....................................................................

11

General Specifications ....................................................

...

..

.......

..

...............

..

.................12

Hot Cell

or

Glove Box Use ...........................................................................................................12

Exploded Assembly Drawings......................................................................................................13

Electrical Connection Drawing ......................................

..

...

.........

..

.

...

...........................................20

Packaging Drawing ..................................................

..

.......................

....

.......................................

21

Parts List ......................................................................................................................................22

Accessories and Supplies.....................................................................................·.......................24

ISOCUT ®Wafering Blades ............................................

..

............................

....

................26

Notes: ....................................................

....

....................

..

.............................................................28

MA111280-11 1113199