3

Safety Instructions...................................................................................................................4

IMPORTANT SAFETY INSTRUCTIONS................................................................................4

FOR SAFETY DURING OPERATION....................................................................................4

FOR SAFETY WHEN SERVICING or MAINTAINING MACHINE 4

Unpacking Instructions ...........................................................................................................4

Inspection...............................................................................................................................4

Electrical.................................................................................................................................4

Batteries.................................................................................................................................4

Operator Responsibility..........................................................................................................4

Machine Overview....................................................................................................................5

Machine Overview - Front......................................................................................................5

Machine Overview - Rear.......................................................................................................5

Controls .................................................................................................................................6

Bail Handle.........................................................................................................................6

Handle Adjustment Knobs..................................................................................................6

Key Switch..........................................................................................................................6

Direction Switch..................................................................................................................6

Squeegee Lift Lever...........................................................................................................6

Battery / Fault Gauge.........................................................................................................6

Speed Control ....................................................................................................................6

Charge Status Indicator......................................................................................................6

Optional Hour Meter...............................................................................................................7

Circuit Breakers......................................................................................................................7

Battery Compartment.............................................................................................................7

Diagnostic Code Guide ..........................................................................................................8

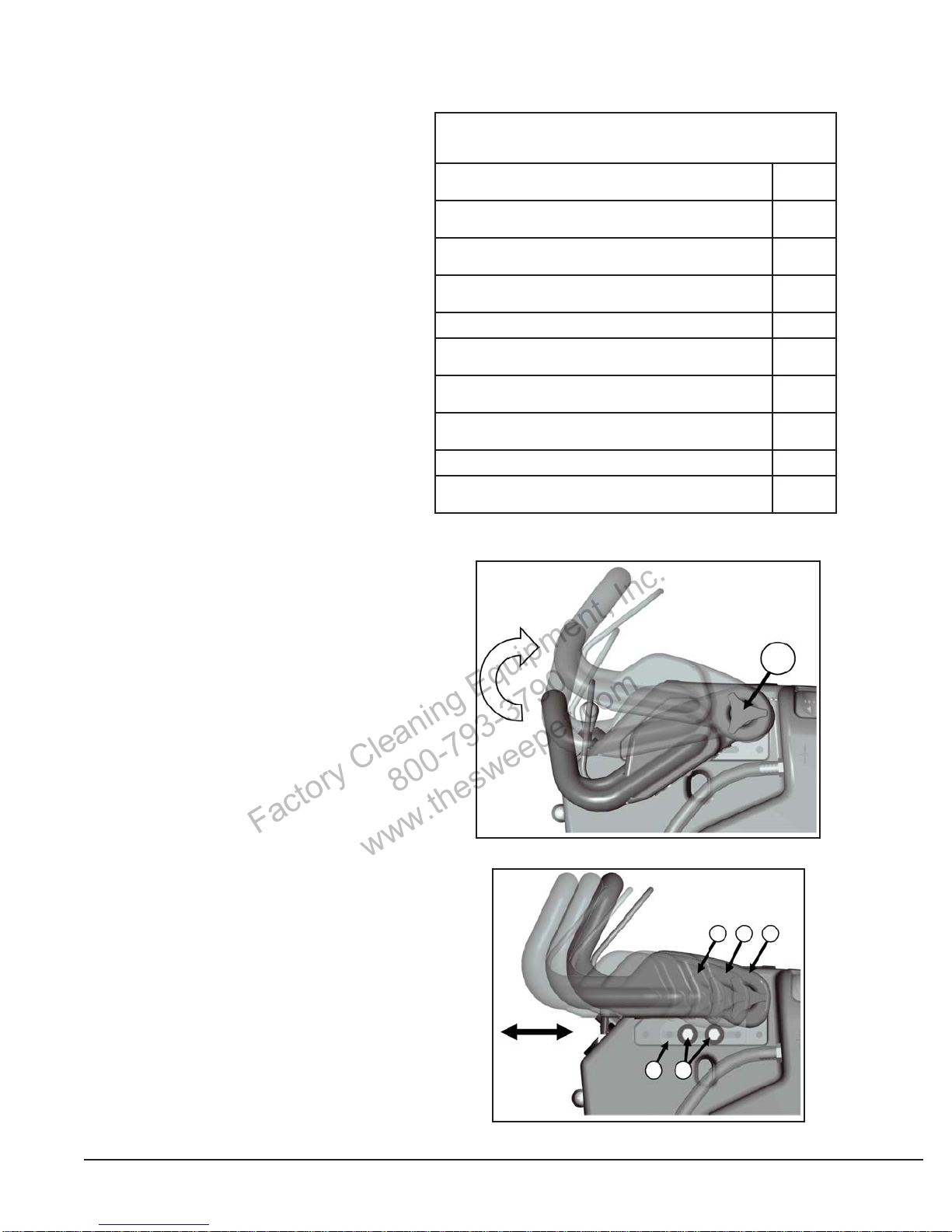

Handle Adjustment.................................................................................................................8

Angle Adjustment ...............................................................................................................8

Horizontal Adjustment ........................................................................................................8

Solution Tank Drain Hose.......................................................................................................9

Solution Level Indicator..........................................................................................................9

Solution Fill Filter....................................................................................................................9

Screened Float.....................................................................................................................10

Screened Float Removal..................................................................................................10

In-Line Solution Filter Assembly...........................................................................................11

Rear Squeegee ...................................................................................................................11

Cleaning the Squeegee....................................................................................................11

Changing the Squeegee Blades.......................................................................................11

Squeegee Blades ............................................................................................................12

Angle Adjustment ............................................................................................................12

Squeegee Blades ............................................................................................................12

Height Adjustment ...........................................................................................................12

Brush Deck Maintenance.....................................................................................................12

Brush Loading / Unloading ..................................................................................................13

Brush Deck Maintenance.....................................................................................................13

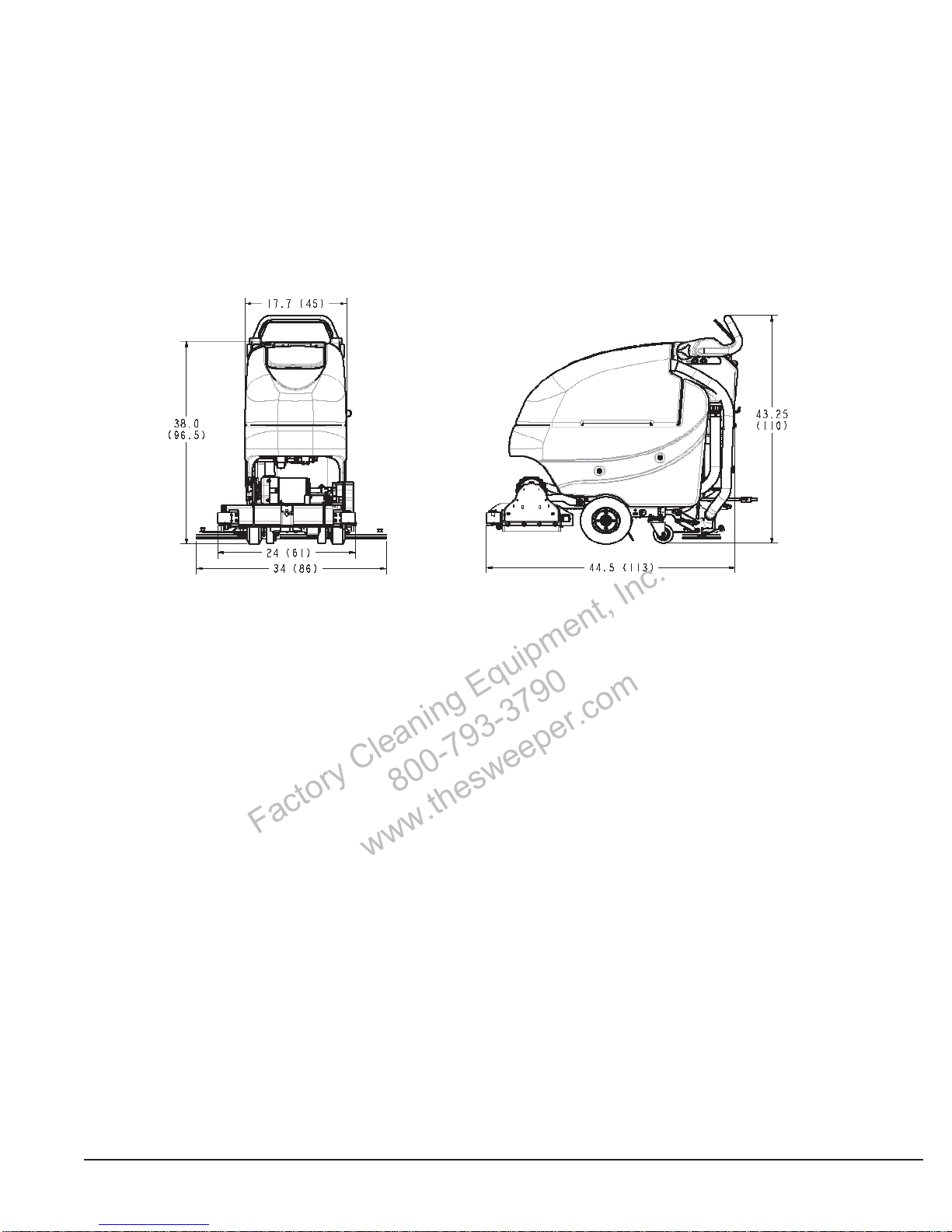

The Floor Scrubber Cylindrical.............................................................................................14

Machine Operation.................................................................................................................15

To Turn ON Machine: ...........................................................................................................15

To Turn ON Vacuum:............................................................................................................15

To Turn ON Brush Motor: .....................................................................................................15

To Turn on Cleaning Solution:..............................................................................................15

Direction Switch:...................................................................................................................15

Speed control:......................................................................................................................15

Driving:.................................................................................................................................15

To Charge Batteries:.............................................................................................................15

Hour Meter (Optional):..........................................................................................................15

After Use .................................................................................................................................15

Maintenance............................................................................................................................16

Troubleshooting.......................................................................................................................17

Table Of Contents

Factory Cleaning Equipment, Inc.

800-793-3790

www.thesweeper.com