16 17

TROUBLESHOOTING GUIDE

PROBLEM 1

PROBLEM 3

PROBLEM 4

PROBLEM 5

PROBLEM 5

PROBLEM 2

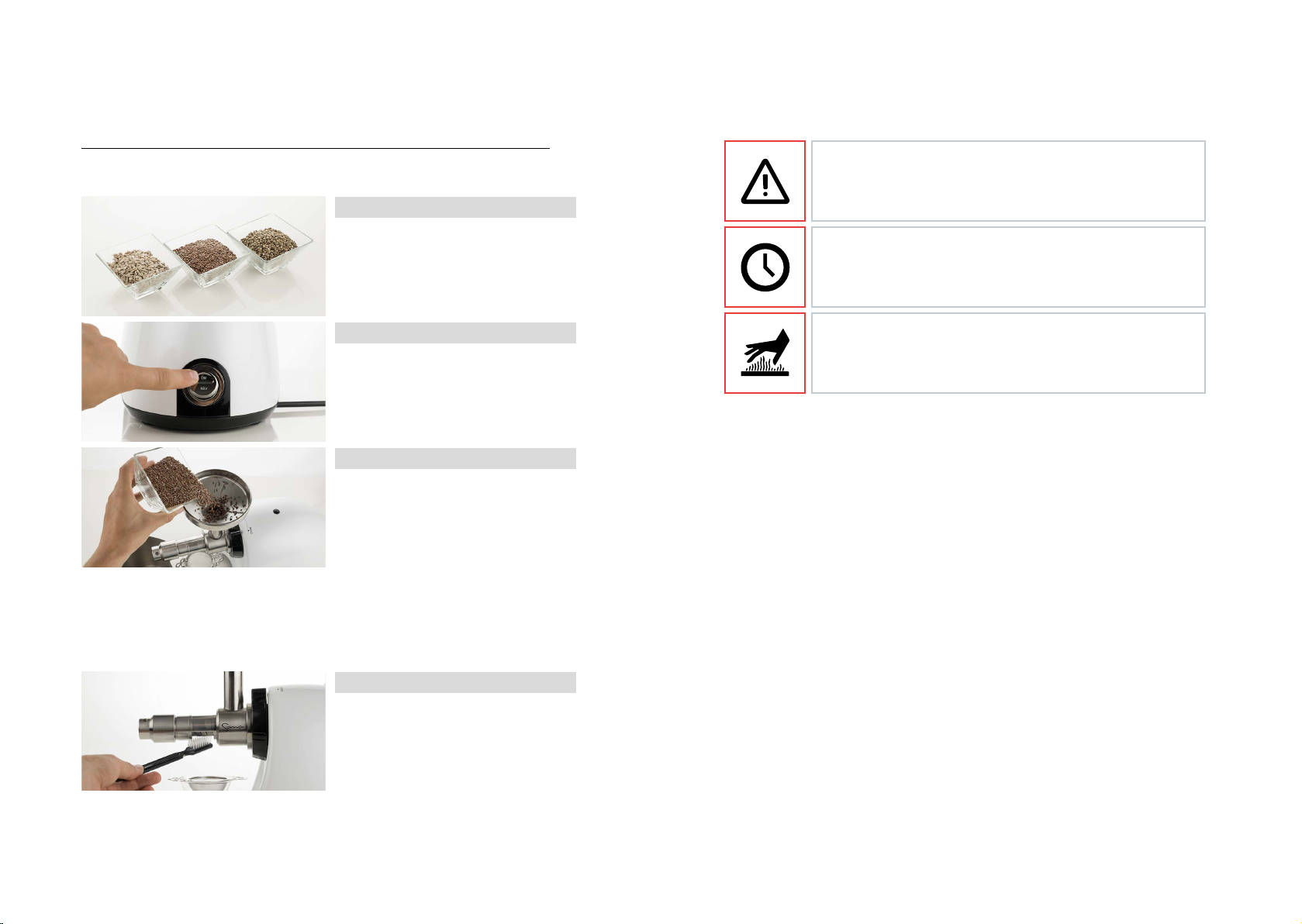

1. Are the grooves on the working unit unobstructed? From time to time, it may be

necessary to clean the grooves during the oil extracting process. For that purpose,

there is a special cleaning brush included in the Sana Oil Extractor set. In case you

notice that the oil is running slower than before, or isn‘t running at all, clean the grooves

using the provided brush.

2. Please note that some seeds, especially nuts or dried coconut shreds, give little oil

while being pressed. This is normal, as these kinds of materials are far less oily than

produce such as flaxseed or sesame seeds (of good quality).

3. Perhaps the seeds you are trying to extract oil from are too old and dry inside (there is

very little oil left inside of them). Buy your seeds somewhere else, until you find a good

source. For details on this topic, see page 7.

1. If you are attempting to extract oil from pumpkin seeds or nuts, maybe you haven’t

crushed them suciently enough, or a bigger piece had blocked the press. Switch

the motor into reverse mode for 2-3 seconds. Wait until you hear it stop, then switch it

on again and see if the problem has been solved. It may be necessary to repeat this

step 2-3 times. If you tried this and the machine still isn‘t working, try disassembling the

press and cleaning out any seeds or husks from the auger and working unit. Assemble

the press once again and make sure the produce has been prepared for extraction

according to the guidelines from page 9. Remember that some materials require

crushing or removing their husks.

2. (This does not apply to milk thistle seeds) Maybe you have put too little produce into

the press, which results in insucient internal pressure for the oil to be extracted. Try

putting some more material into the press.

1. Check whether correct regulating ring has been used. Every kind of seed and nut

which can be extracted in the Sana Oil Extractor has a recommended regulating ring to

use during the extraction process - for more details see page 8.

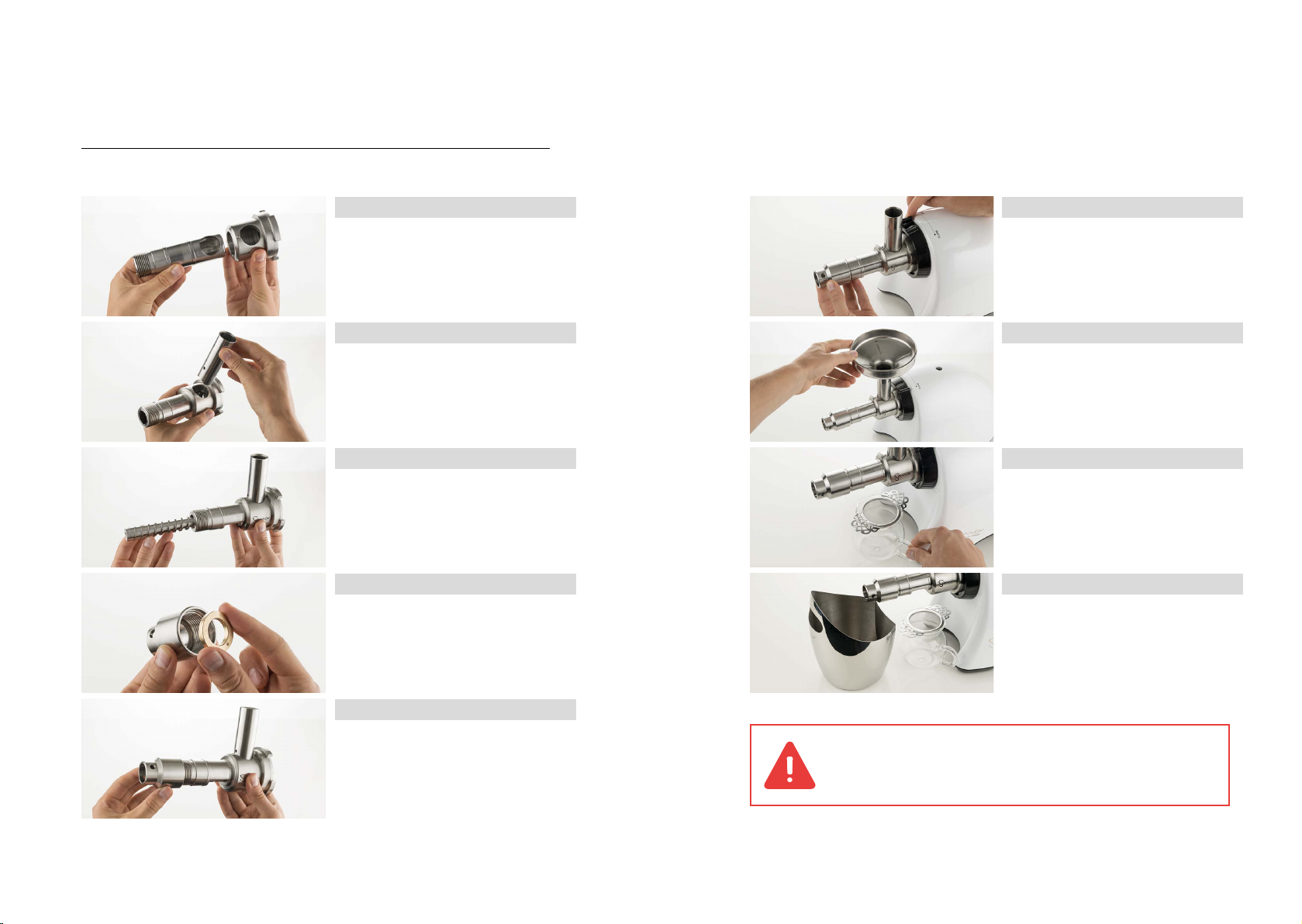

2. Check whether the extractor has been assembled properly. In case of doubt,

disassemble the machine and then put it back together while carefully following the

instructions from page 10.

1. Check whether the auger has been properly inserted into the working and mounting

units. If properly assembled, the auger‘s end should be fully mounted in the juicer‘s

hexagonal slot. If not, disassemble the extractor and assemble it once again according

to the instructions on pages 10-11.

1. Some amount of squeaking is normal when extracting flax seeds. The squeaking

should disappear after a couple of minutes or during the next extraction

2. If the squeaking doesn‘t disappear, check if the proper regulating ring has been used.

For instructions see page 8.

1. Check whether a proper regulating ring has been used for processing the particular

type of seeds or nuts. For every type of nut or seed there is a recommended regulating

ring - for details see page 7.

2. Check whether the oil extractor has been properly assembled. If you’re not sure,

disassemble the machine and reassemble it while carefully following the instructions

from page 9.

3. If the machine has been properly assembled according to the instructions, and the

oil still isn‘t running, there is a high possibility that the material you are trying to press

is too dry inside. Unfortunately, there is always the chance of purchasing low-quality

seeds in shops. Don‘t be disheartened by this. Try buying your supplies somewhere

else until you find a good source. For details on this topic, see page 6.

4. From time to time, it might be necessary to clean the grooves during the oil extracting

process. For that purpose there is a special cleaning brush included in the set. In case

you notice that the oil is running slower than before, or isn‘t running at all, try cleaning

the grooves using the brush.

The oil is running very slowly or is not dripping at all.

The oil isn‘t coming out, the seeds are not going in, and the

pressings aren‘t coming out the extractor.

The oil is not dripping and the pressings coming out of the

extractor‘s front cap are not suciently dry or crushed.

The motor is working but the auger isn‘t rotating.

There is a loud squeaking noise during the oil extraction process.

The oil isn‘t running, even though the seeds are being collected and

processed by the extractor. The pressings are coming out of the

extractor through its front cap like they should.