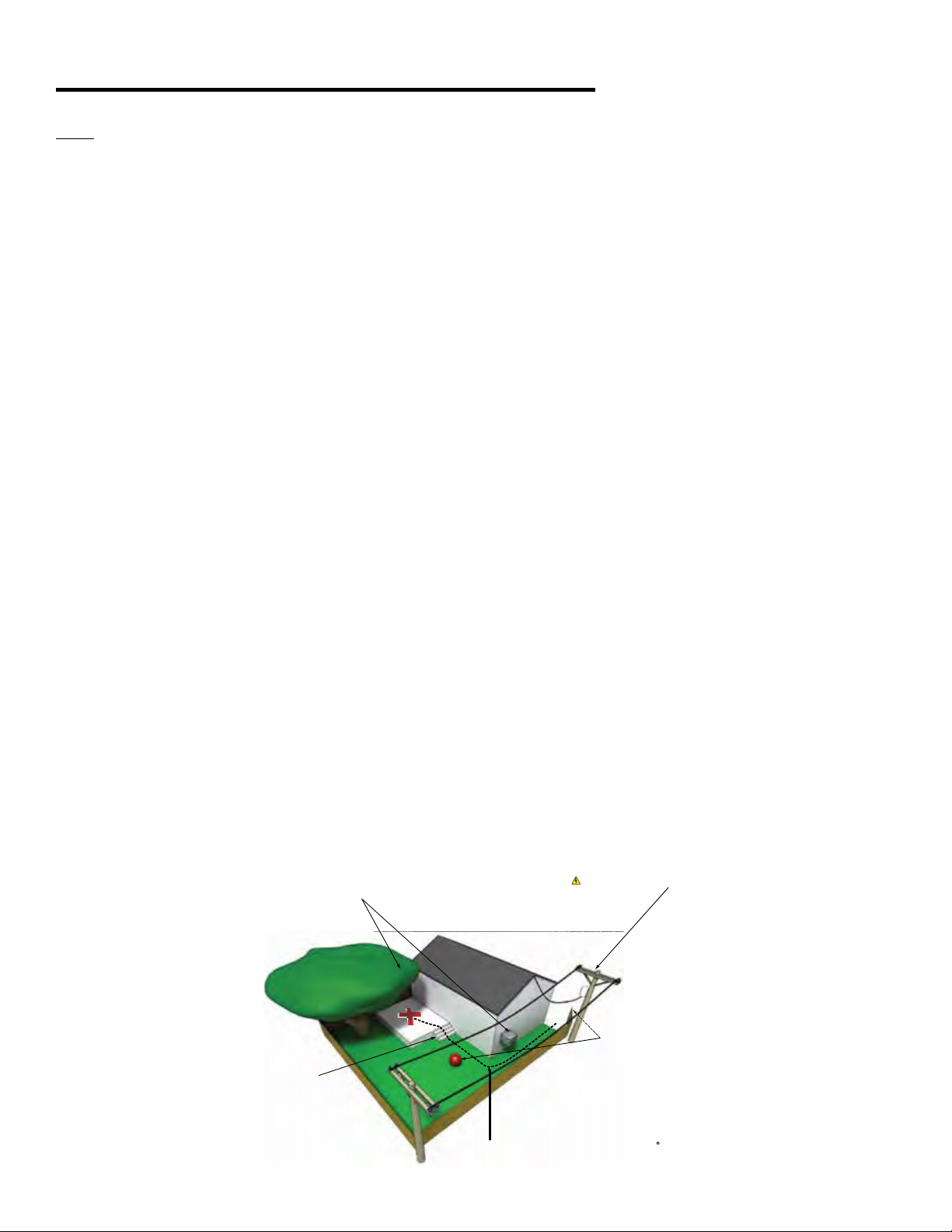

Spa Location

Service Access: Some people choose to install tile, stone, or

custom wood around their spas. If you are installing your spa with

custom trimming, remember to allow access for service. Should

your spa need service, a technician may need to remove the spa’s

equipment compartment door or side panels, or access the spa

from beneath. Also, it is always best to design special installations

so the spa can still be moved, or lifted from the ground.

Access to Circuit Breakers: For service purposes, allow

easy access to the circuit breakers in the electrical service panel

(permanently connected models), or to the interrupter switch on

the end of the power cord (cord-connected models).

Electrical Safety Requirements: e installation of all

spas must be in accordance with national and local wiring rules

and with applicable permits consistent with local regulations. A

licensed Electrician must perform the electrical installation and

GFCI test procedure. Each Bullfrog Spa is manufactured and

tested to a standard that provides maximum protection against

electrical shock.

Improper wiring may prevent the spa from operating safely which

could result in electrical shock, injury, or death. Improper wiring

could also lead to a malfunction of the spa’s equipment and risk

of re. When considering a location for your spa, consult with a

licensed Electrician pertaining to the following:

Overhead Power Lines: Based upon the national and local

wiring rules that apply to your area, you will need to install your

spa at the required minimum horizontal and vertical distances

from all power lines.

Service Disconnect: Based upon your area, a disconnect

device must be incorporated into the xed wiring in accordance

with national and local wiring rules. If the national and local

wiring rules permit, a GFCI or RCD Sub-Panel may be used

to substitute the service disconnect, providing that it is located

within the same parameters.

Electrical Outlets, Switches and Devices: Based upon

the national and local wiring rules that apply to your area, you

must install your spa at the required minimum distance from all

electrical outlets, switches, and devices.

Bonding: Based upon the national and local wiring rules that

apply to your area, the Control System Box located inside the

equipment compartment of your spa must be bonded to all metal

equipment, handrails, xtures, enclosures, pipe, or conduit that

are located within the maximum specied distances. e bonding

is to be connected to the ground lug connector on the exterior

surface of the Control System Box and all metal items previously

described.

Equipment Compartment Access: Make sure the spa is

positioned so access to the equipment compartment will not be

blocked.

All other national and local rules that may be applicable.

Water Drainage: Your spa contains an equipment

compartment, which houses all of its electrical components.

Allowing water into the equipment compartment can damage

the electronics, or may result in tripping your spa’s circuit

breaker. If installing the spa in a SpaVault, below ground level,

or where water may accumulate it is the owner’s responsibility to

ensure that water will drain adequately so as not to damage spa

equipment. For normal installations at ground level choose a site

where water will drain away from the spa.

Use of a Cover-Lifting Mechanism: If using a cover-

lifting mechanism, allow up to 18 inches (.61m) of clearance

behind the spa. Check with your authorized Bullfrog Spas

Dealer for the exact clearance requirements for the cover-lifting

mechanism.

Spa Foundation

General Guidelines: Select a structurally sound at surface

that is reasonably level to serve as your spa’s foundation. A

foundation that shifts or settles may cause stress to the spa shell.

e foundation that your spa rests on must have a weight bearing

load capability of supporting the weight of your spa, its water, and

the people using it. e maximum lled weight of a spa can be

as much as 6,000 lbs. (2,800kg), plus the weight of the occupants

that use the spa (for the weight bearing load requirements as

well as the maximum lled weight of your spa, refer to the Spa

Technical Specications Chart or contact your local authorized

Bullfrog Spas Dealer).

If your spa’s pad is slightly sloped it may not aect the

performance of the spa or its structure, however, there should

be no dips, sags, or unevenness in the pad. Most patios are

built to slope away from the house for drainage purposes. ere

should be no more than a 1/2” (1cm) slope in an 8 ft (2m) run.

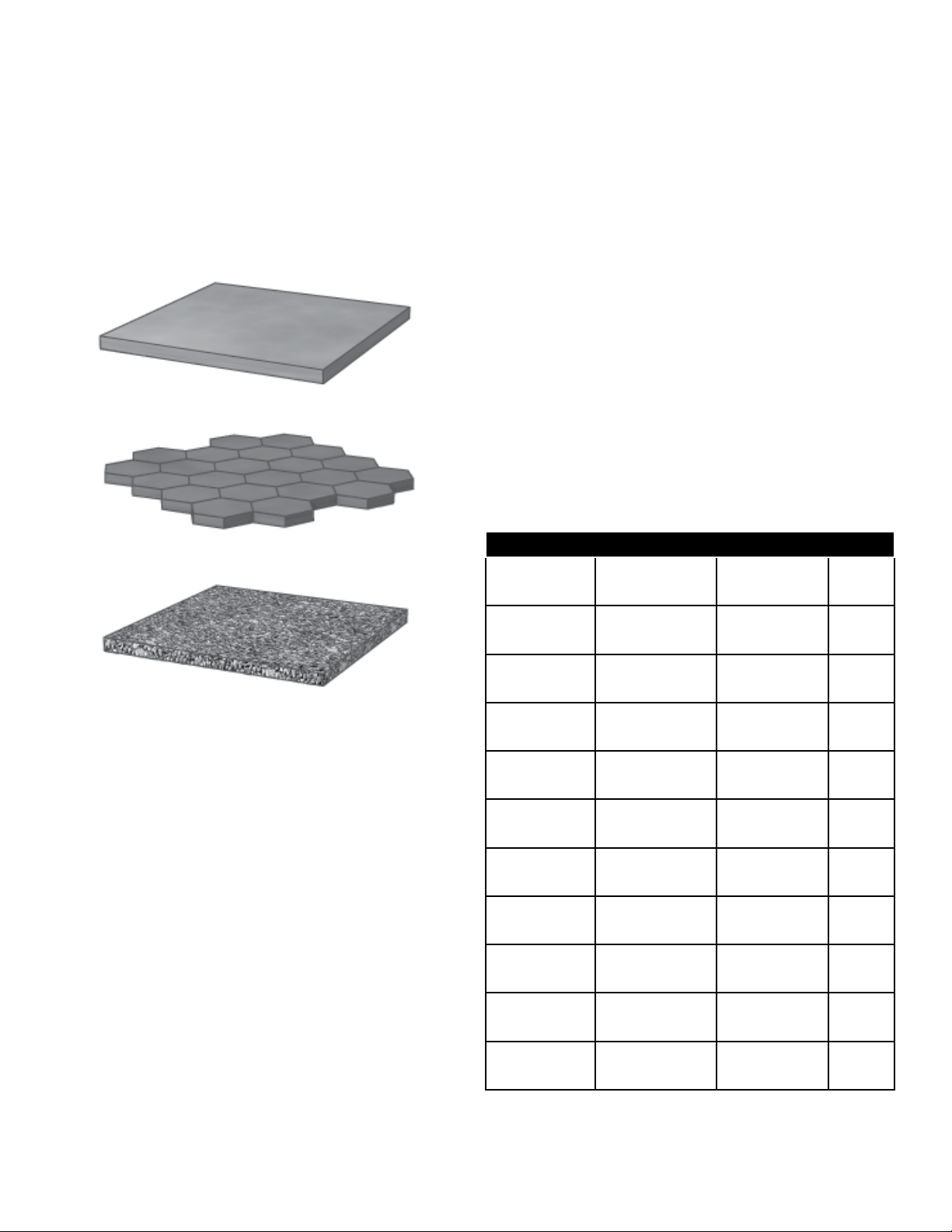

Recommended ooring materials include a concrete pad, concrete

pavers or bricks, pea gravel, or crushed rock 1.5” (4cm) or less, or

a reinforced deck. Additionally, your authorized Bullfrog Spas

Dealer may sell or recommend pre-formed spa pads.

NOTE: Concrete foundations should be a minimum of 4

inches (10cm) thick and should be reinforced with either rebar or

mesh. For electrical grounding purposes, the rebar or mesh should

be attached to a bond wire (see Electrical Requirements and

Installation Instructions).

WARNING: To prevent serious damage to your spa, it is

important that the spa foundation be supported by a at, stable,

and consistent subsurface. Bullfrog Spas International highly

recommends consulting a qualied, licensed contractor prior to

the installation of any spa foundation. For assistance, contact your

authorized Bullfrog Spas Dealer.

WARNING: Because your spa pad must provide continuous

support for the entire base of the spa, you should never level

it with shims. If it is necessary to level your spa, make sure the

entire spa’s structure is fully supported, both in the center as well

as the outer edge. When leveling your spa, there should be no

voids beneath it. Contact your authorized Bullfrog Spas Dealer

before making any leveling adjustments. Structural damage to the

spa resulting from incorrect installation, placement on an

inadequate foundation, or improper leveling will void the 2

spa’s warranty.