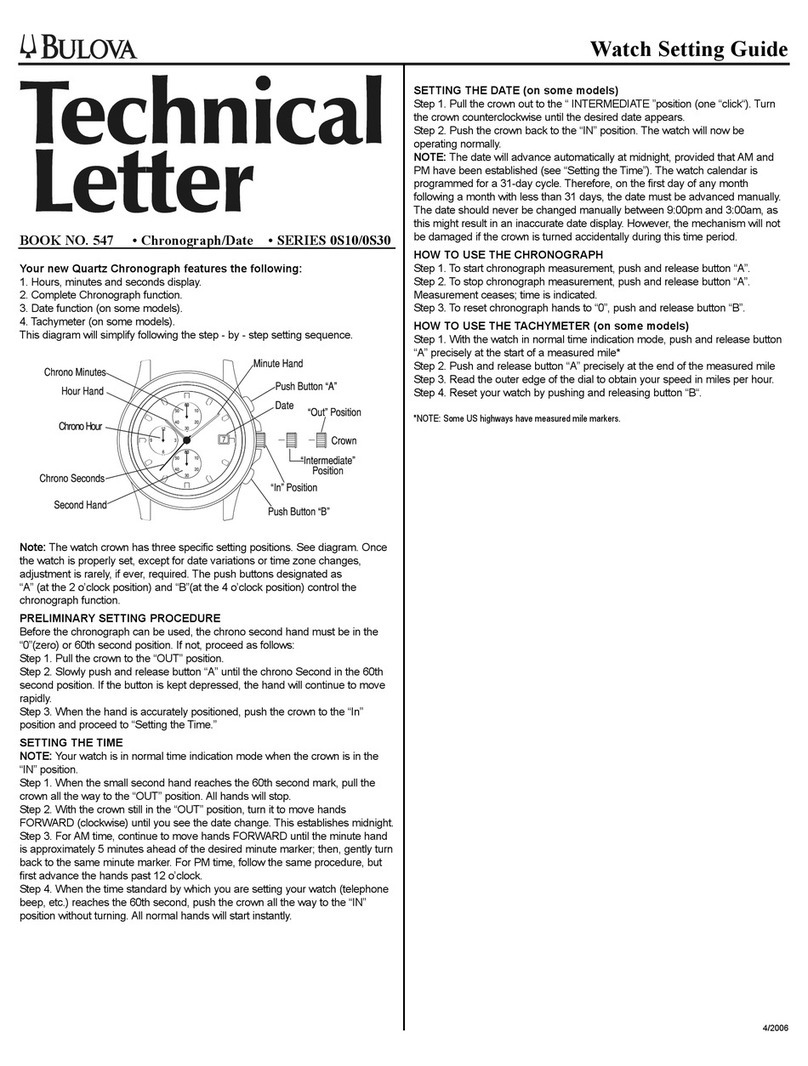

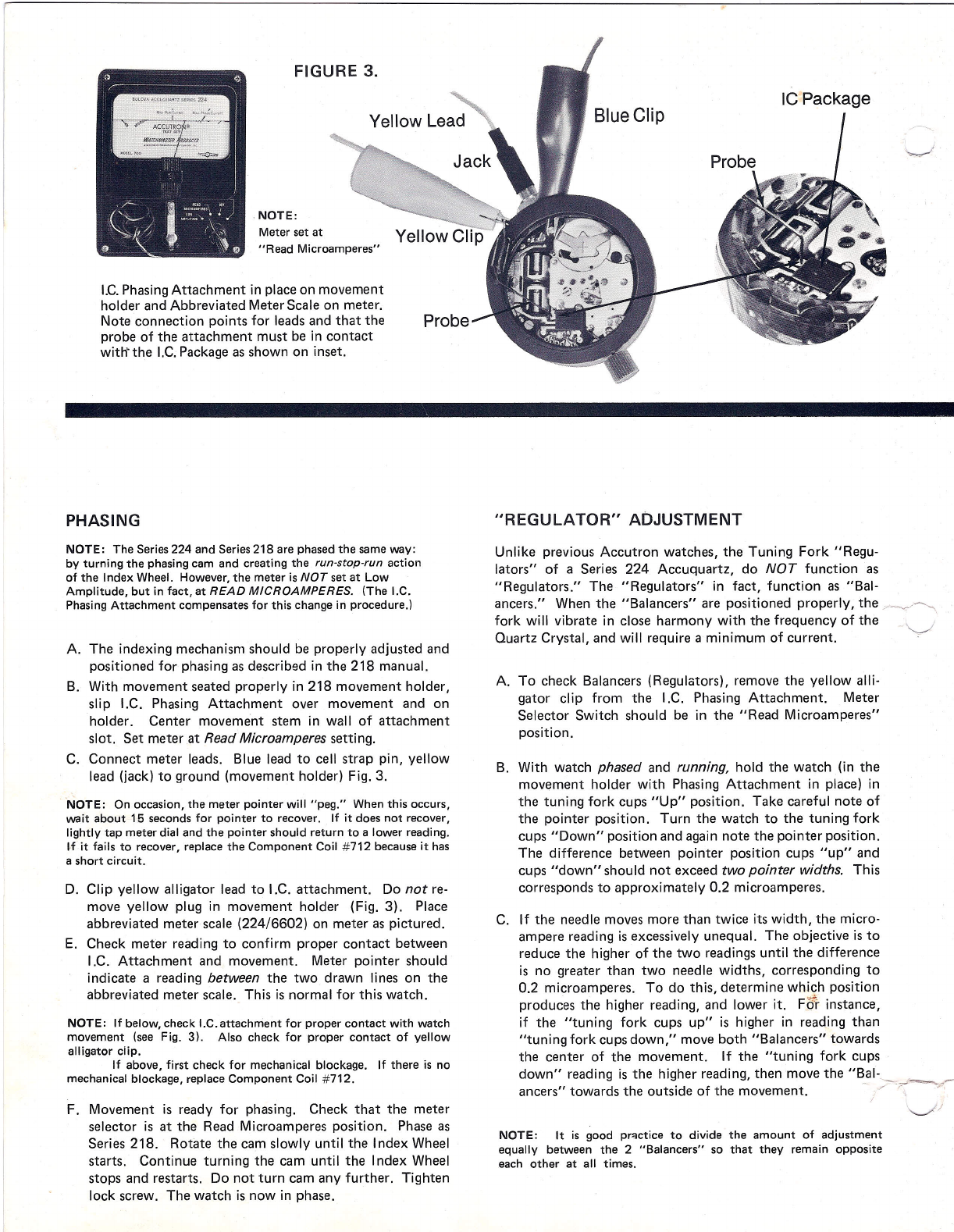

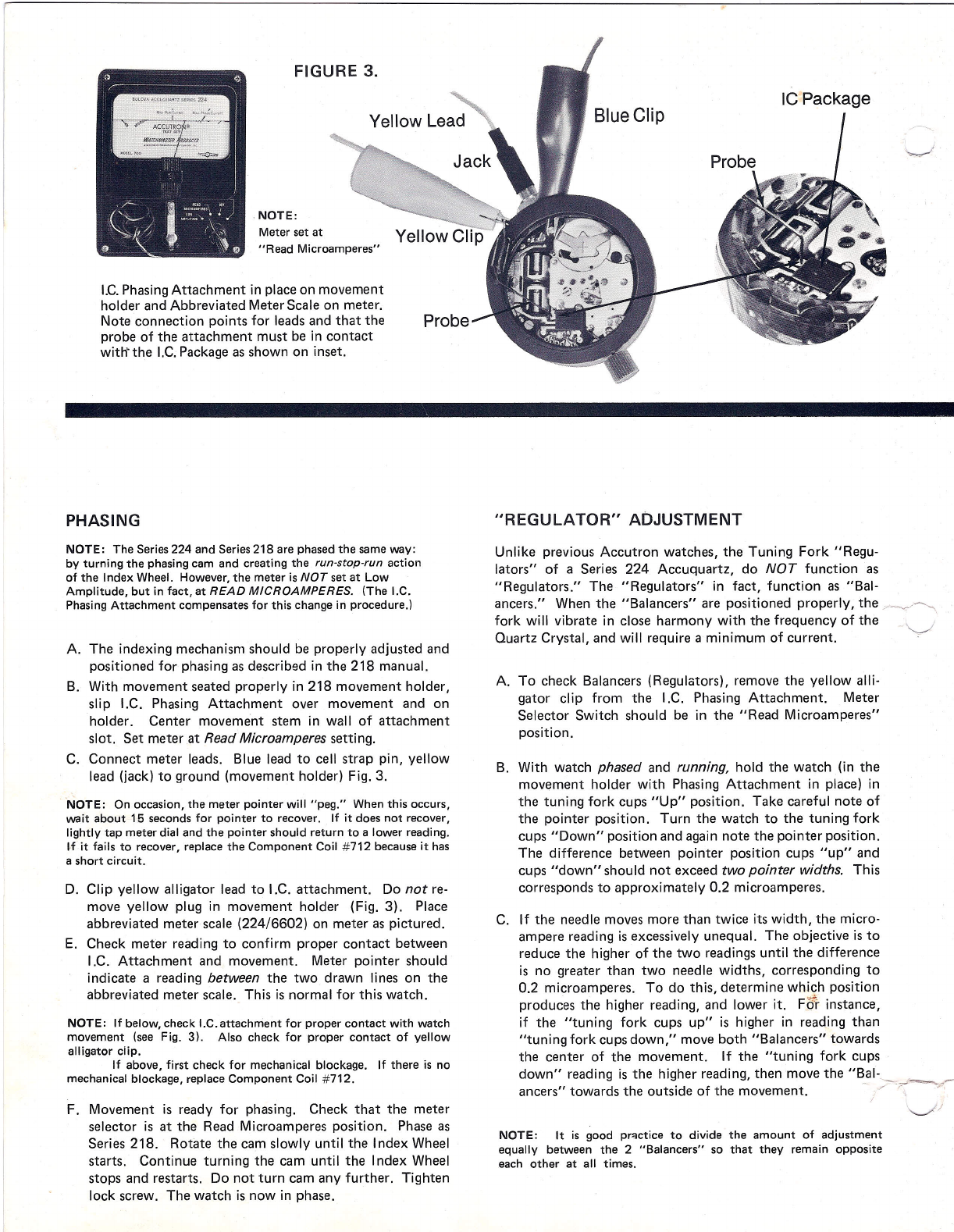

FIGURE 3.

NOTE:

Meter setat

Read Microamperes

I.C.PhasingAttachment in place on movement

holder and Abbreviated Meter Scale on meter.

Note connection points for leads and that the

probe of the attachment must be in contact

withthe I.C.Packageasshown on inset.

PHASING

NOTE: The Series224 and Series218 are phasedthe sameway:

by turning the phasingcam and creating the

run-stop-run

action

of the Index Wheel. However,the meter is

NOT

set at Low

Amplitude, but in fact, at

READ MICROAMPERES.

(The I.C.

PhasingAttachment compensatesfor this changein procedure.l

A. The indexing mechanism should be properly adjusted and

positioned for phasing asdescribed in the 218 manual.

B. With movement seated properly in 218 movement holder,

slip I.C. Phasing Attachment over movement and on

holder. Center movement stem in wall of attachment

slot. Set meter at

Read Microamperes

setting.

C. Connect meter leads. Blue lead to cell strap pin, yellow

lead (jack) to ground (movement holder) Fig. 3.

NOTE: On occasion, the meter pointer will peg. When this occurs,

wait about 15 secondsfor pointer to recover. If it does not recover,

lightly tap meter dial and the pointer should return to a lower reading.

tf it fails to recover, replace the Component Coil #712 becauseit has

a short circuit.

D. Clip yellow alligator lead to I.C. attachment. Do

not

re-

move yellow plug in movement holder (Fig. 3). Place

abbreviated meter scale (224/6602) on meter aspictured.

E. Check meter reading to confirm proper contact between

I.C. Attachment and movement. Meter pointer should

indicate a reading

between

the two drawn lines on the

abbreviated meter scale. This is normal for this watch.

NOTE: If below, check I.C.attachment for proper contact with watch

movement (see Fig. 3). Also check for proper contact of yellow

alligator clip.

If above, first check for mechanical blockage. If there is no

mechanical blockage, replaceComponent Coil #712.

F. Movement is ready for phasing. Check that the meter

selector is at the Read Microamperes position. Phaseas

Series 218. Rotate the cam slowly until the Index Wheel

starts. Continue turning the cam until the Index Wheel

stops and restarts. Do not turn cam any further. Tighten

lock screw. The watch is now in phase.

REGULATOR ADJUSTMENT

Unlike previous Accutron watches, the Tuning Fork Regu-

lators of a Series 224 Accuquartz, do

NOT

function as

Regulators. The Regulators in fact, function as Bal-

ancers. When the Balancers are positioned properly, the /_,/~

fork will vibrate in close harmony with the frequency of the

Quartz Crystal, and will require a minimum of current.

A. To check Balancers (Regulators), remove the yellow alli-

gator clip from the I.C. Phasing Attachment. Meter

Selector Switch should be in the Read Microamperes

position.

B. With watch

phased

and

running

hold the watch (in the

movement holder with Phasing Attachment in place) in

the tuning fork cups Up position. Take careful note of

the pointer position. Turn the watch to the tuning fork

cups Down position and again note the pointer position.

The difference between pointer position cups up and

cups down should not exceed

two pointer widths.

This

corresponds to approximately 0.2 microamperes.

C. If the needle moves more than twice its width, the micro-

ampere reading is excessively unequal. The objective is to

reduce the higher of the two readings until the difference

is no greater than two needle widths, corresponding to

0.2 microamperes. To do this, determine which position

produces the higher reading, and lower it. Fo'r instance,

if the tuning fork cups up is higher in reading than

tuning fork cupsdown, move both Balancers towards

the center of the movement. If the tuning fork cups

down reading is the higher reading, then move the Bal-. . .-

ancers towards the outside of the movement. - /'

-r-=-/

\....,//

NOTE: It is good practice to divide the amount of adjustment

equally between the 2 Balancers so that they remain opposite

each other at all times.