Characteristics

11ANAC

1. The oscillating weight arbor is

soldered

to the combined bridge.

In the rare case that it might be

necessary to replace it, a new com-

bined bridge is required.

2. The minute wheel spring has been

riveted

to the pillar plate in order to

make sure that the watchmaker will

not lose it or forget to replace it after

servicing. It is, therefore, part of the

pillar plate and not available sepa-

rately.

3. Beryllium-made bushing for the top

pivot of the sweep second wheel is

fitted inside the bottom part of the

oscillating weight arbor and for that

reason oiling is done through the

oscillating weight arbor with an

appropriate oiler. Bulova recommend

oiling this bushing from under the

bridge,

before

setting the latter.

Disassembling the

watch

Uncasing

Excluding the one-piece, «rnonocoque»

cases, the movement is normally held

in the case by two casing clamps (191)

and two casing screws (45C).

Removing the dial

After removing the hands and releasing

the two lateral dial screws (47), the

dial may be removed. The day star with

dial disk (591) can be lifted up and after

removing the three date indicator

guard screws (577), the day and date

mechanisms can be removed.

A dial rest (148) is used for day date

watches (caliber

11

ANACB) having a

flat dial.

Checking the automatic gear

By moving the oscillating weight (344)

in both directions, the transmission of

the power from the oscillating weight

(344) to the ratchet wheel (13) can be

checked.

Removing the oscillating weight

The oscillating weight is held in place

by a gib (343). To remove it, unscrew

the gib screw (336) and remove the gib.

.~

,

.

, f

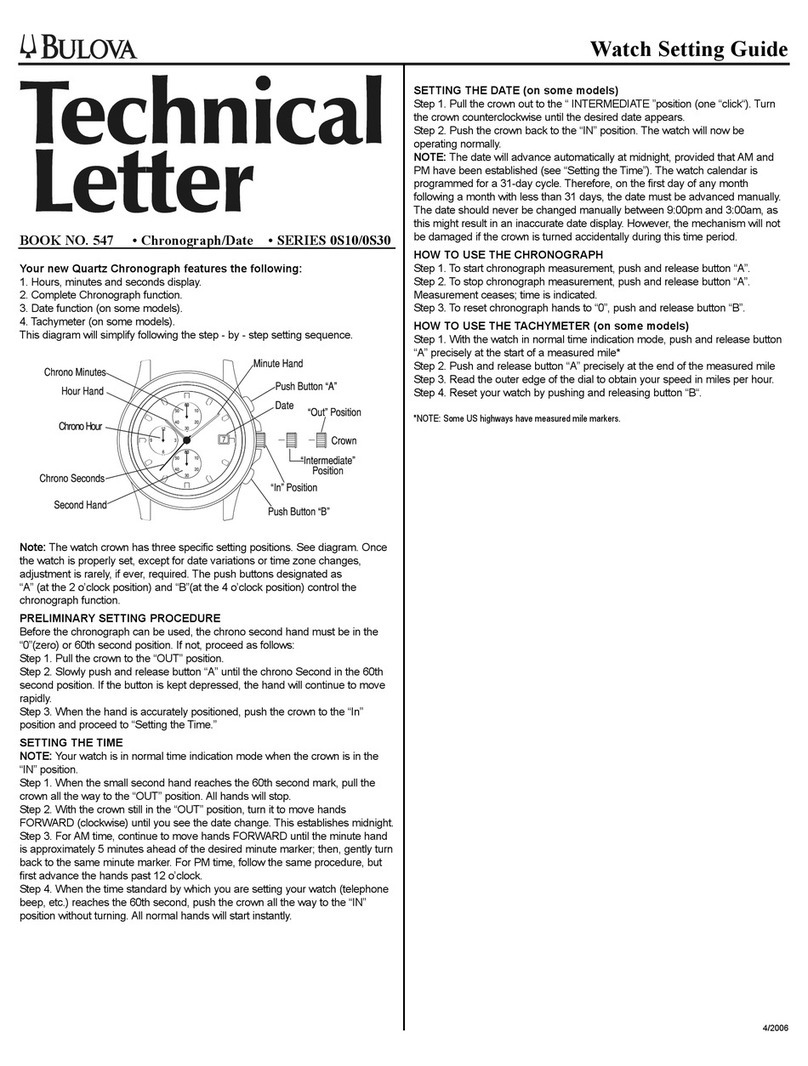

Figure 1

Removal of the balance wheel and

pallet

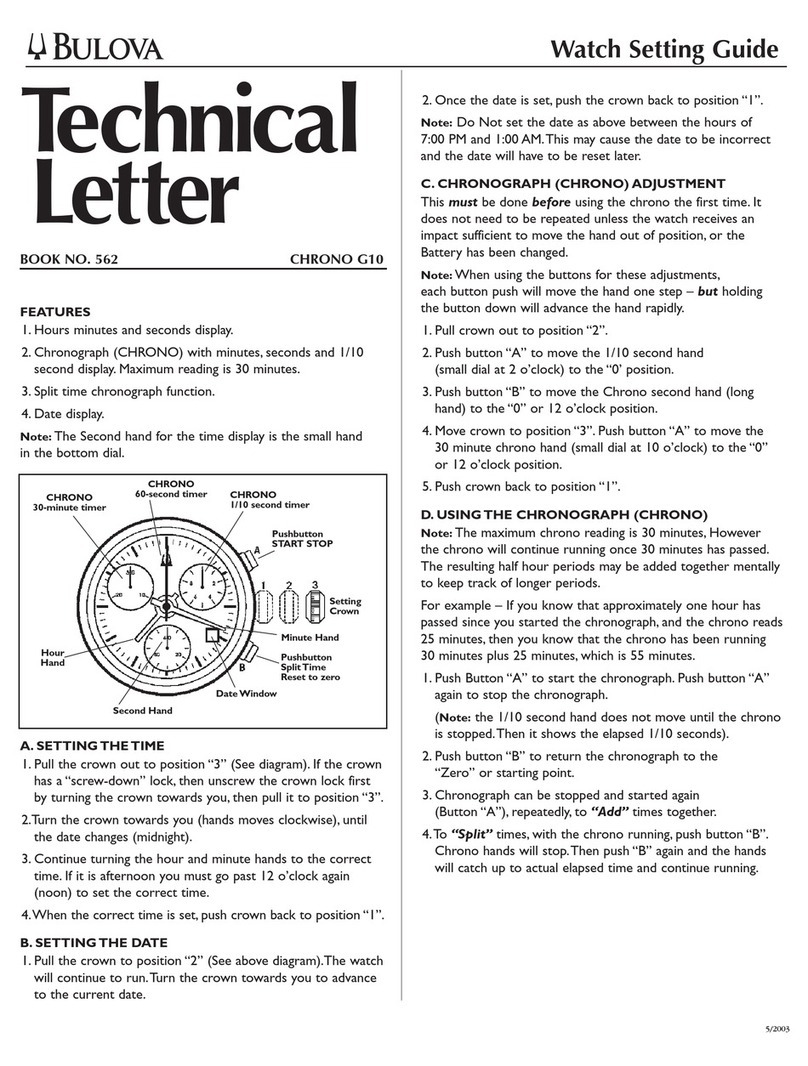

Figure 2

Removal of the barrel

--- •.••0

Releasing the mainspring

With the oscillating weight (344)

removed, the mainspring can be re-

leased by simultaneously disengaging

the ratchet click (32) from the ratchet

wheel (13) and pressing with a pointed

tool on one arm of the breguet spring

(326) through the hole made in the

upper bridge for automatic device (341).

Turn the winding crown one quarter of a

turn forward and then let the automatic

train «run down" by turning the winding

crown

slowly

backwards.

NOTE: Simultaneous disengaging of the

ratchet click (32) from the ratchet

wheel (13) and pressing on the breguet

spring (326) can be done easily with

one hand, using a tweezer sufficiently

open to hold the ratchet click with

one point and pressing on the breguet

spring with the other.

2

Cleaning the escapement

As shown in figure 1, the balance and

pallet are readily removed without

disassembling any other parts of the

movement.

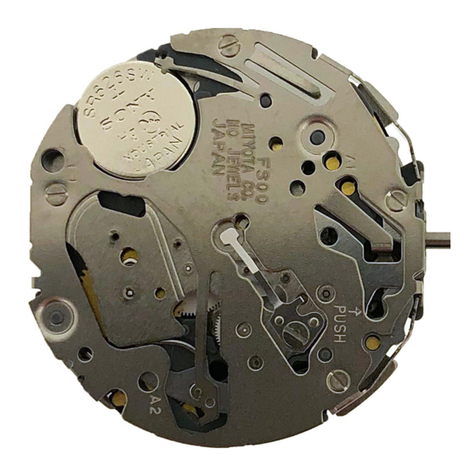

The mainspring barrel

Figure 2 shows how easily the main-

spring barrel (1S) is removed without

disassembly of the self-winding

mechanism. The mainspring arbor must

make six full turns before the brake

spring slips, which represents a total

running time of over 40 hours.

An unbreakable and life-time lubricated

mainspring -is used. Therefore, periodic

cleaning of the barrel and mainspring

is unnecessary.

RECOMMENDATION:

Do not dismantle the mainspring barrel.

In case of difficulty, replace the barrel

(1S) complete.