7

HOW TO ANALYZE THE MILK

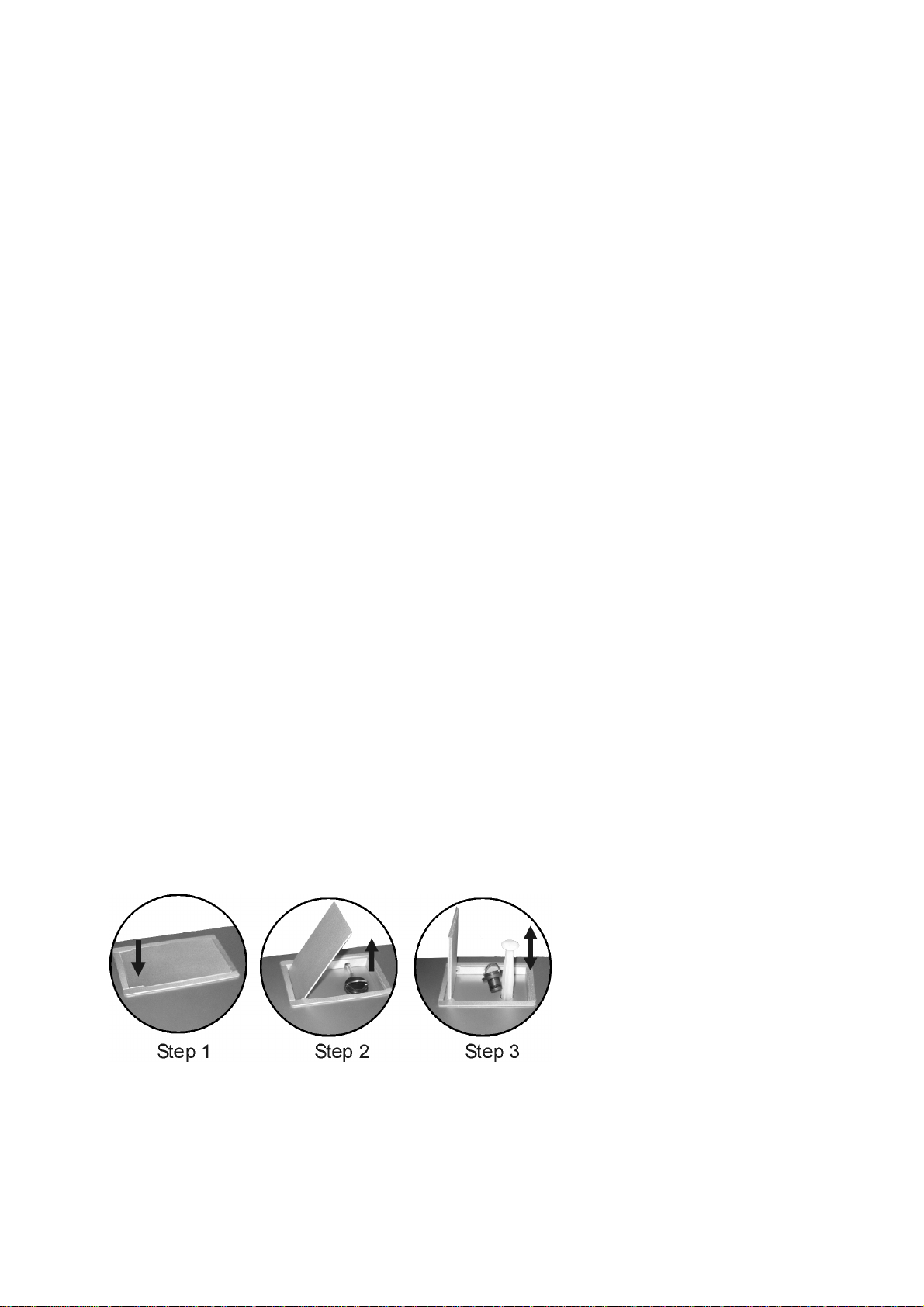

Step 1:

Fill the measuring mug with milksampleto be measured. Dipthe tube (sucker) into the milksample

and place the measuring mug on the Ekomilk working surface.

Step 2:

pH and temperature measurement:

Gentlyremove the protective plasticcap from the pH electrode beforeproceeding with measurement.

Use de-ionized ordistilled waterto rinse the electrodebeforeuse. Thiswill remove impurities that

have adhered on the electrode body. Rinsingwill also serve to activate the electrode, especiallyifit

has been dehydrated(inwhich case you may have to soak the electrodeinwaterfrom 10 minutes

onwards (See Section“pH Measurement -Additionalinformation”).Fill anothermeasuring mugwith

the same milksample. Dipthe electrode and temperaturesensor(fig.1 –pos. 6,7)intothesample. Be

surethatthe electrode iscompletelyimmersed intothe sample. Stirthe mug gentlytocreate a

homogeneous sample. Place it on the Ekomilkworking surface. Formoreinformation, see “pH

MEASUREMENT -ADDITIONAL INFORMATION”.

Remark: EKOMILK BOND uses3sensorsformilkparametersmeasuring –ultrasound, conductivity

and pH. Load on both measuring mugs the same milk and to get correct results atonce.

Step 3:

Press MODE and by means of the search buttons , ▼select the desired mode:

rCOW MILK -analysis of cow milk

rSHEEP/BUFFALO/ GOAT/HOMOG.MILK -analysis of sheep/buffalo/goat milk

When the propertype of milk is displayed, press OK to startthe measurement.

Supplier ID selection:

The message NUMBER:001 appearson the display whilemeasurement isstarted (itdoes no matter

which measuring mode is activated - COW MILK or SHEEP/BUFFALO/ GOAT MILK).

NUMBER defines the ID ofsupplier.In thiscase itisnecessarytowrite inadvance alist byID’sand

names of suppliers.

rbutton ▼changes the cursorposition;

rbutton changes the overcursorvalue;

rbutton MODE cancelsthe changes and returns COW MILK on the display;

rbutton OK confirms the ID NUMBER and QUANTITY:0000.0 appears.

QUANTITYselection:

rbutton ▼changes the cursorposition;

rbutton changes the overcursorvalue;

rbutton MODE cancelsthe changes and returns COW MILK on the display;

rbutton OK startmeasurement.

The message WORKING appears on the display whilemeasurement is goingon.

Remarks:

1. How todiscardthe currentmeasurement? Whilethemeasuring resultsareonthe display, press

button ▼and then press button not releasingbutton ▼and then release both of them. The

message RECORD DISCARDED appears on the display.

2. The maximum numberof records is120. Ifyou tryto write overthen 120 records, NOMEMORY

SPACE errormessage appears on the display. There are 2 possibilities:

a. To send the datatoacomputer and clear(empty)the analyzermemory (See procedure

described in "Data transferring").

b. Deactivating ofdata storage