Methods for daily and periodic clean of the Ekomilk Spectra analyzer’s ultrasonic

module

1. DAILY CLEANING

Daily cleaning is required when:

The interval between two consecutive measurements is more than half of one hour.

The daily job is finished.

1.1. Cleaning out when the interval between two consecutive measurements is more than

half an hour.

Steps:

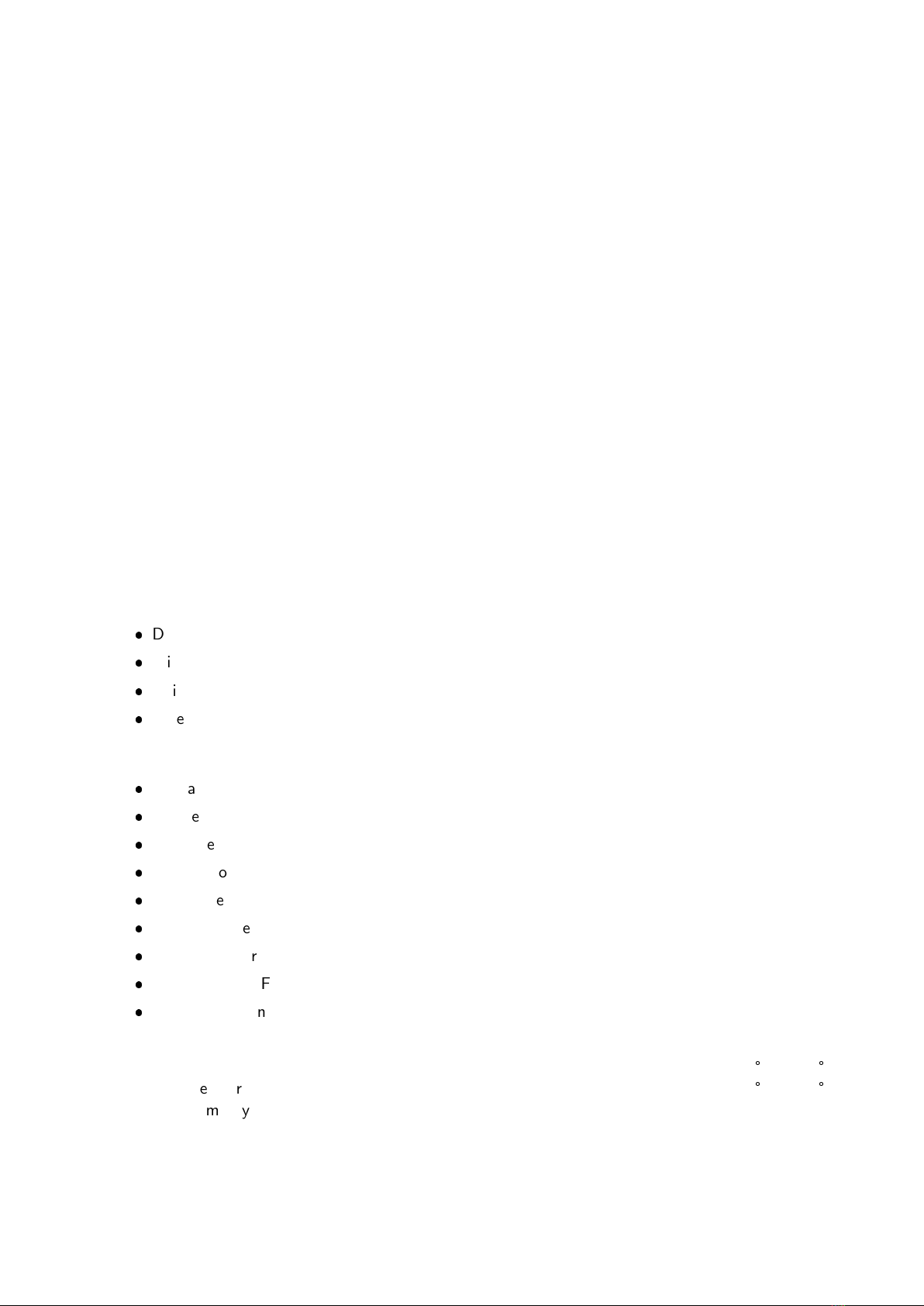

1.1.1. Fill the mug for cleaning solution (below the US peristaltic pump) with clean and warm,

but not hot, water (40

°

C-60

°

C). On the input of the ultrasonic module place the mug

for waste milk, press the button <Cleaning US>, cleaning starts immediately.

1.1.2. Remove the mug and throw away the muddy water. Repeat this procedure several times

until clean water comes out from the Analyzer.

1.2. Cleaning out at the end of a working day.

This procedure prevents formation and collection of fat and ”Milk stone” deposits into the

sensor. Milk stone consists of milk solids, calcium, magnesium, iron, sulfates, etc. Milk and

water mineral deposits become hardened and layered on the sensor and vinyl pipes inner

surfaces, which contact with milk and disturbs the milk analyzer work. Cleaning will be

effective if a reagent which attacks the ”milk stone” is used. We recommend EkoDay to be

used as a daily cleaning solution.

Preparation of EkoDay working solution:

Dissolve 2 g of powder detergent EkoDay in 100 ml distilled or deionized water. The solution

can be used within 7 days after preparation.

Take care this solution does not contact your eyes or skin!

Attention! Use only EkoDay working solution as a cleaning agent. The EkoDay

concentrate can damage your analyzer!

Steps:

1.2.1. First clean the analyzer with pure water as it is described in procedure 1.1. (see above).

Attention! Always clean analyzer with pure water before using the cleaning

agent. Using cleaner EkoDay without first cleaning analyzer for removing the

fats and proteins will result in fixing the ”milk stone” to the surface.

1.2.2. Fill the cleaning solution mug with cleaner EkoDay (25

°

C-40

°

C), place the mug for waste

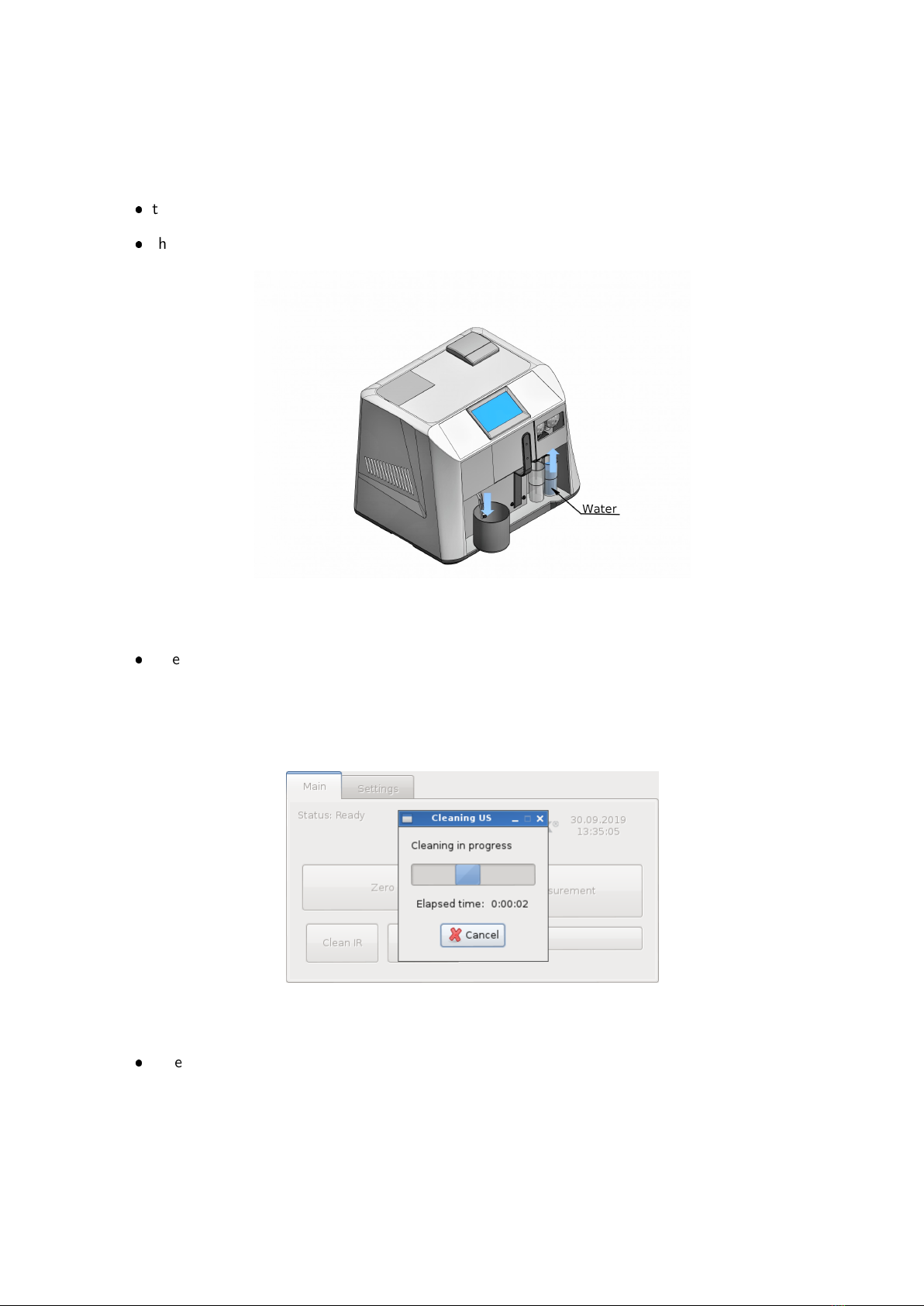

milk on the input of the US module. Press the button <Cleaning US>, cleaning starts

immediately. Make 5 cycles.

1.2.3. Fill the cleaning solution mug with alkaline clean water, press the button <Cleaning

US>. Make 5 cycles. It’s important to remove all the residues from the cleaning

solution EkoDay!

2. PERIODICAL CLEANING PROCEDURE

To ensure a good work of the Milk Analyzer it is advisory to clean the device at least once a

week strictly performing underwritten procedure. This procedure uses acid cleaner EkoWeek as a

periodical cleaning solution.

Preparation of EkoWeek working solution:

Dissolve 1.8 g of powder detergent EkoWeek in 100 ml distilled or deionized water. The solution

can be used within 30 days after preparation.

8