7. Be extremely cautious of the rotating Blades in the Chipper/Shredder.

Never allow your hands, fingers, or any other part of your body to

enter the Chipper or Shredder hopper units.

8. Never place your hands, fingers, feet, or any other part of your body close

to the Discharge Opening while the Chipper/Shredder is in operation.

9. Do not look into the Hoppers or Discharge Opening when the machine is

running.

10. Never allow metal, stone, glass, or other foreign objects to be fed into the

Chipper/Shredder. Use a stick to push the tree limbs, leaves, etc. into the

feed Hopper.

11. Do not attempt to use the machine on a slope or hard, smooth surface.

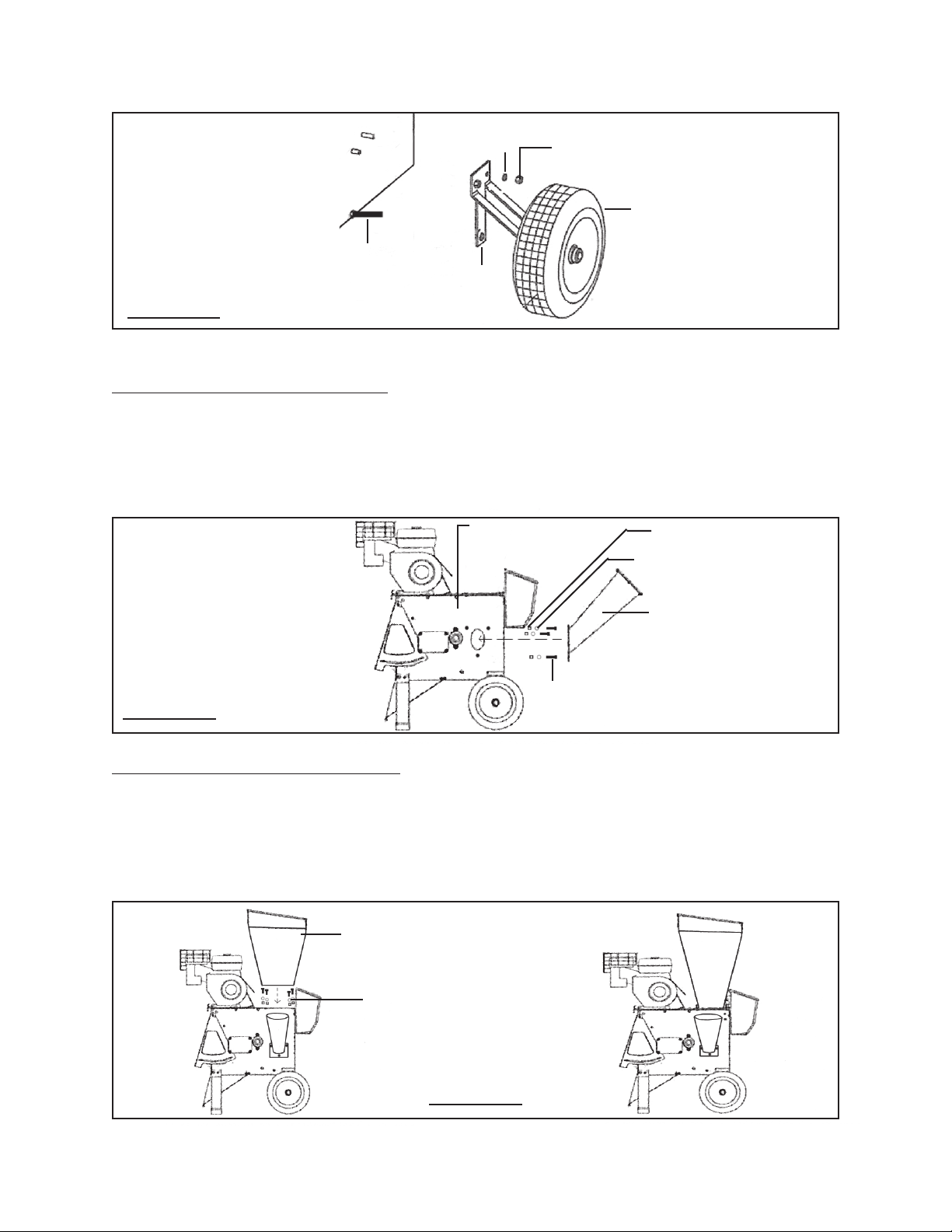

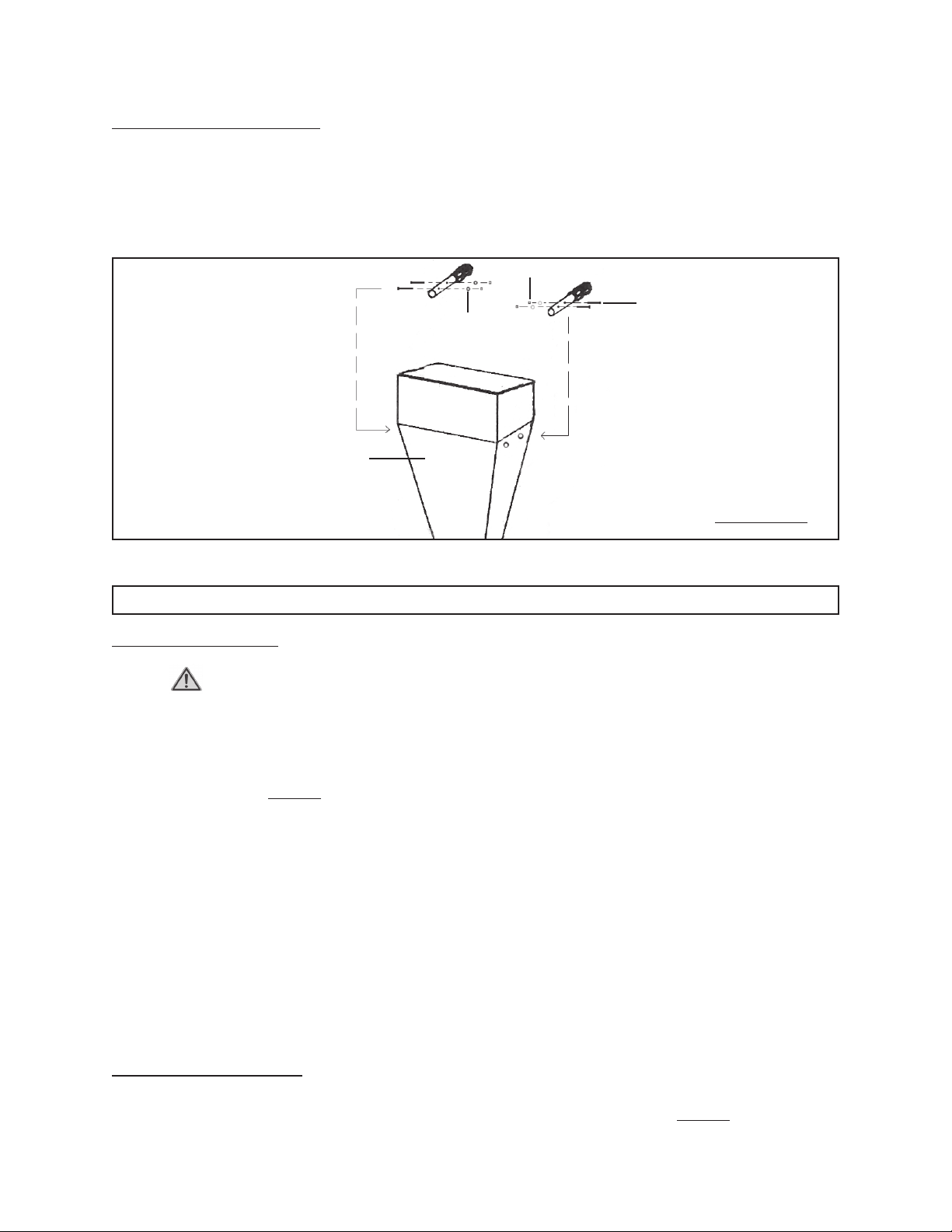

12. Make sure the plastic cover on the upper Hopper is closed when the

machine is running.

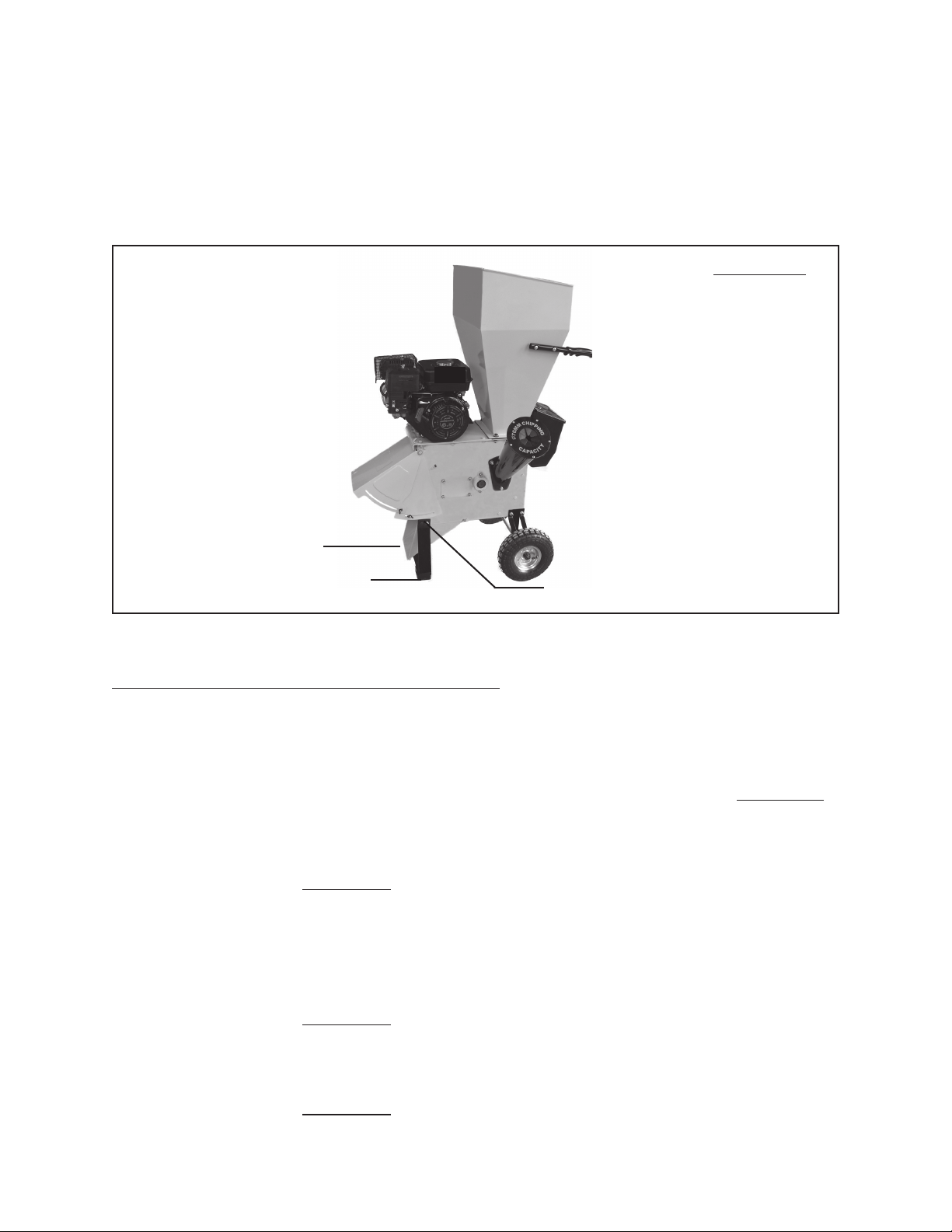

13. Always feed large branches slowly into the machine. Branches larger than

the yellow ring on the Hopper should never be fed into the machine.

14. Do not allow processed material to build up in the discharge area. This may

prevent proper discharge and can result in kickback of material through the feed

Hopper.

15. If the machine becomes clogged, immediately turn off the Ignition Switch of

the Engine. Unplug the Spark Plug Wire from the Spark Plug. Wait until the

Chipper/Shredder comes to a complete stop. Then clear the machine of the

clogged material.

16. Do not allow children and other unauthorized people to handle or play with

the Chipper/Shredder. Never allow people or animals in the work area. When

not in use, store the Chipper/Shredder in an area that is not accessible to chil

dren. Before storing this product, unplug the spark plug wire from the spark plug.

17. This Chipper/Shredder is designed for outdoor use only. Do not operate the

Chipper/Shredder in a closed area or in a poorly ventilated area. When running,

the Engine of this machine produces carbon monoxide, a colorless, odor

less, toxic gas that, when inhaled, can cause serious personal injury or

death. Whenever possible, use a carbon monoxide detector (not included)

to detect excessive carbon monoxide fumes in the work area and in the

surrounding area.

18. Do not force the Chipper/Shredder. This tool will do the work better and safer

at the speed and capacity for which it was designed.

SKU 95435 For technical questions, please call 1-800-444-3353 PAGE 5