Side 1

Bunn-O-Matic Corporation | Post Office Box 3227 | Springfield, Illinois 62708-3227 | Phone (217) 529-6601 | Fax (217) 529-6644

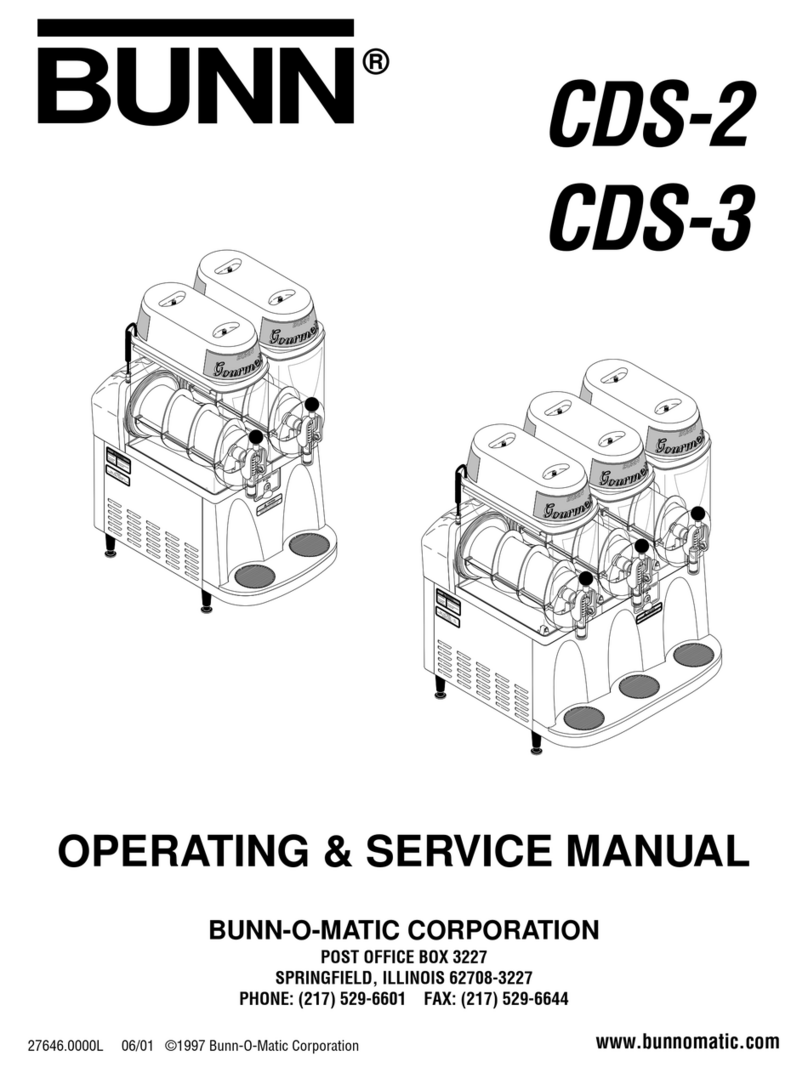

Ultra®NX

Frozen Beverage Dispenser

PROBLEM Possible Cause / Remedy

Blank LCD display screen Power cord may be disconnected. Also, press main power switch to the ON position.

Left (or Right) side auger not turning Press left (or right) uager toggle switch to start. (Power must be ON).

Left (or Right) side not freezing

1) Left (Right) side auger must be turning.

2) Press left (or right) ice control switch until the display reads “ICE”.

3) Adjust product thickness (See “How-to” box below or the manual).

Product is very slow to freeze

1) Check that rear of machine has a 4-inch minimum air clearance.

2) Clean rear screen with soapy water or compressed air.

3) Deflect away any warm air from nearby equipment.

Lamps in top covers are out Check that tops are plugged into base of unit.

HOW TO Steps

Access Cleaning Guide on LCD Display Press and hold the Center Dot switch for 5 seconds. When “Cleaning Guide” is displayed, press the Right Dot

switch to select YES. Then select the Center Dot switch to step through the 9 instructional screen displays.

Adjust Product Thickness

(This feature may be password protected)

Press and hold the Center Dot switch for 5 seconds. When “Cleaning Guide” is displayed, press the Left Dot

switch to select NO. The screen will then display “Set Thickness?” Select YES (the Right Dot switch) to display

thickness scale for the LEFT hopper. Move the scale up or down using the Left Dot and Right Dot switches

(minimum is 1; maximum is 16). Then press the Center Dot switch to display thickness setting for the RIGHT

hopper. Adjust as necessary. Display will time-out and return to home screen after 60 seconds.

Display Temperature & Torque readings

This provides valuable information to a technician and helps to determine whether a problem is in the

refrigeration system or mechanical in nature. Simultaneously press and hold the Left Dot and Right Dot

switches for 5 seconds. The top number displayed is the auger torque reading for each cooling drum.

The bottom number toggles between the cooling drum temperature and the hot gas temperature. Record

all three numbers for each drum before calling for service. Simultaneously press and release the Left Dot

and Right Dot switches to return to the home screen.

• Activate/change night time thaw mode

• Activate/change cleaning schedule

• Change Date and Time

See “Programming the Dispenser” in the equipment Operating and Service Manual.

These features may be password protected.

Clean REAR Filter Screen Pull Left and Right tab out to remove screen.

Clean with soapy water or compressed air and re-install the screen.

If the suggested remedy does not solve the problem, call for help or service.

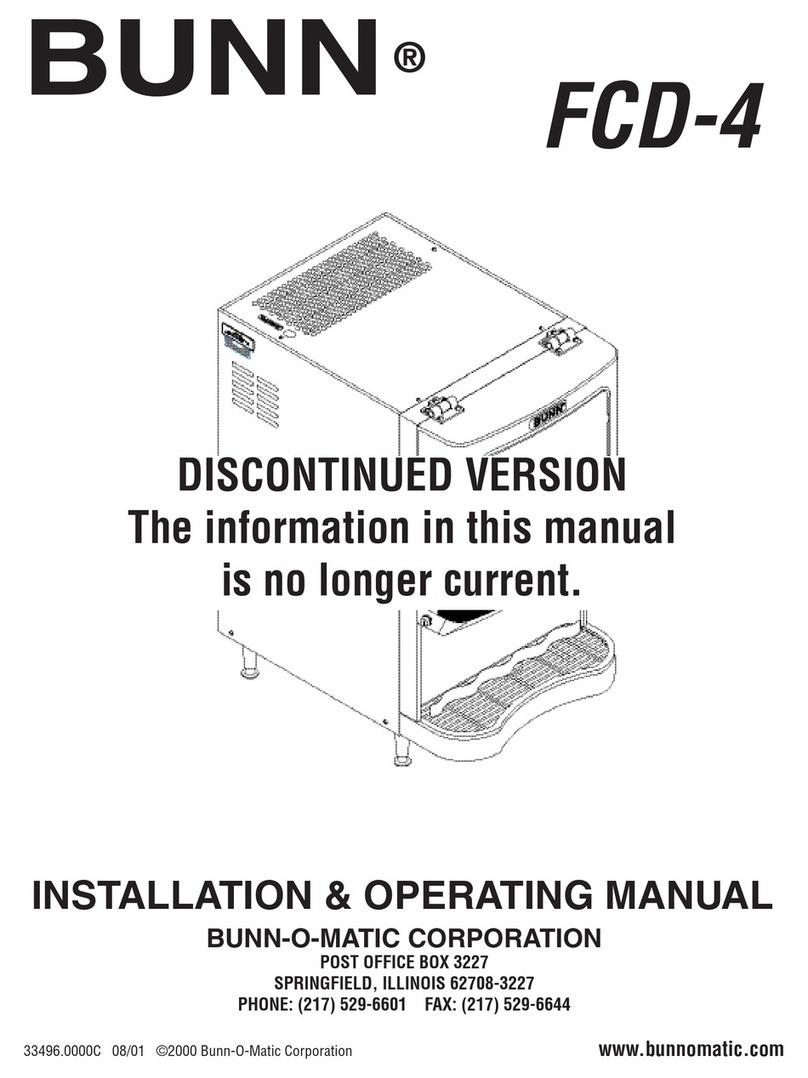

RIGHT DOT SWITCH

LCD DISPLAY SCREEN

ICE CONTROL SWITCH

(Toggles to OFF, ICE, CHILL)

AUGER ON SWITCH

AUGER OFF SWITCH

AUGER REFILL ON

I

O

Right Side

CENTER DOT

SWITCH

LEFT DOT SWITCH

ICE CONTROL SWITCH

(Toggles to OFF, ICE, CHILL)

AUGER ON SWITCH

AUGER OFF SWITCH

AUGER REFILL ON

Left Side

MAIN POWER

ON/OFF SWITCH

WARNINGS & ERROR MESSAGES Interpretation / Action To Take

NIGHT MODE

It is recommended that the product in the dispenser be thawed each day, usually overnight. The ice granules get too

large and a consistent product is difficult to maintain if left frozen too long. The machine will automatically return to

normal freeze mode at the programmed time. To change this setting, check the Operating & Service Manual.

CLEAN DUE TODAY Follow cleaning procedure on the Cleaning Card or access the one on the display window.

(See Access Cleaning Guide on LCD Screen in “How to” section above)

CLEAN DUE NOW See above. You must clean for the LCD display to clear.

MONTHLY FILTER CLEAN REQUIRED Clean rear screen with soapy water or compressed air. Press Left Dot button and hold for 3 seconds to clear screen.

FILTER NEEDS CLEANING Compressor is overheating and will shut down. Clean rear screen and be sure rear of machine has a minimum

4-inch air clearance.

!! FILTER NEEDS CLEANING !! Compressor is running too hot. Service is required.

SHAFT SEAL MAINTENANCE DUE A reminder that a 12-month Preventive Maintenance is recommended. See Operating manual for further instructions.

LEFT/RIGHT TEMPERATURE SENSOR

SHORTED/OPEN Add product to minimum fill line. If warning continues, follow instructions below.

• Left/Right Torque Sensor Shorted/Open

• Hot Gas Thermistor Shorted/Open

Record Temperature & Torque numbers (see “How to” section above).

Call for service and provide these numbers to the technician.

LEFT/RIGHT REFILL ERROR

(Hopper Lights Flashing) Press Left Dot button for 3 seconds to clear.

CHECK RIGHT/LEFT SIDE PRODUCT MIX

OR DRIVE SYSTEM Product thickness not correct. Check product ratio/brix. And/or refill hopper if low.

DEFROST - LEFT/RIGHT BARREL(S) IN

PROCESS OF DEFROSTING This will go back to normal operation after defrost is complete.

HOPPER LIGHTS FLASHING Hopper is low on product. Refill hopper to clear error.

If unit has Autofill; product BIB may be empty. Replace if needed.

Maintenance &

Troubleshooting Guide

www.bunn.com

58028.0000 A 10/21 © 2021 Bunn-O-Matic Corporation

58028.0000 A Ultra NX Use and Care Instructions.indd 158028.0000 A Ultra NX Use and Care Instructions.indd 1 10/19/21 11:06 AM10/19/21 11:06 AM