Page 2

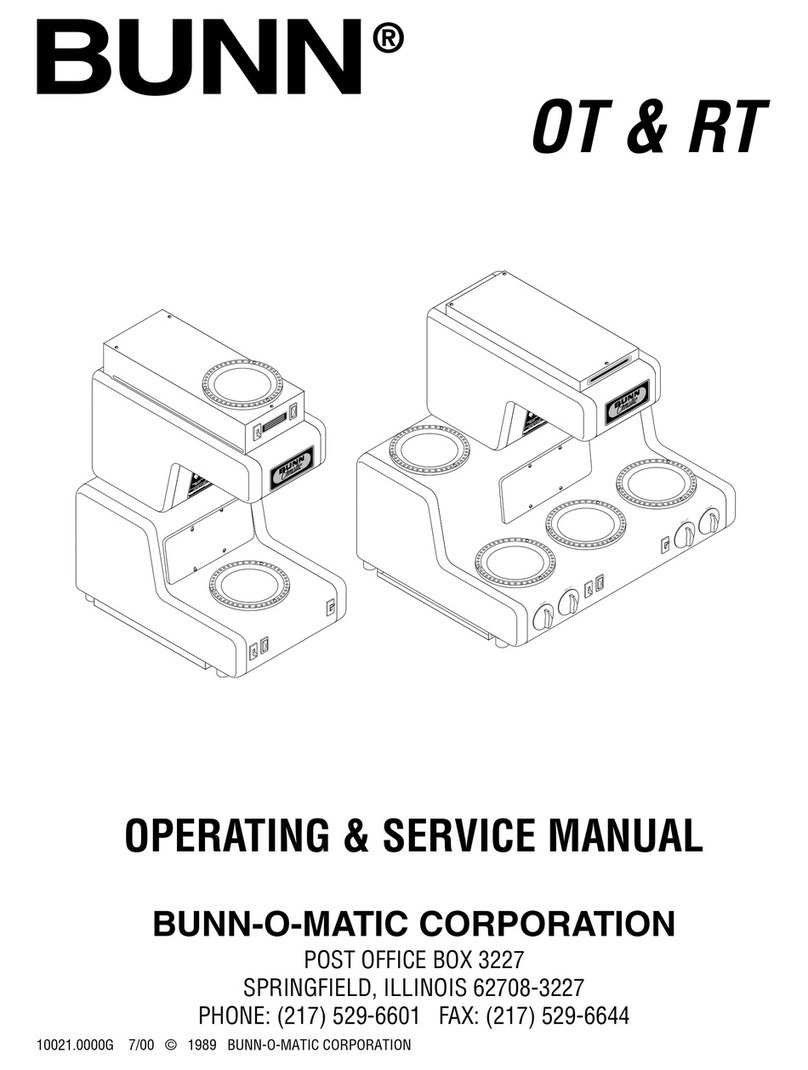

INTRODUCTION

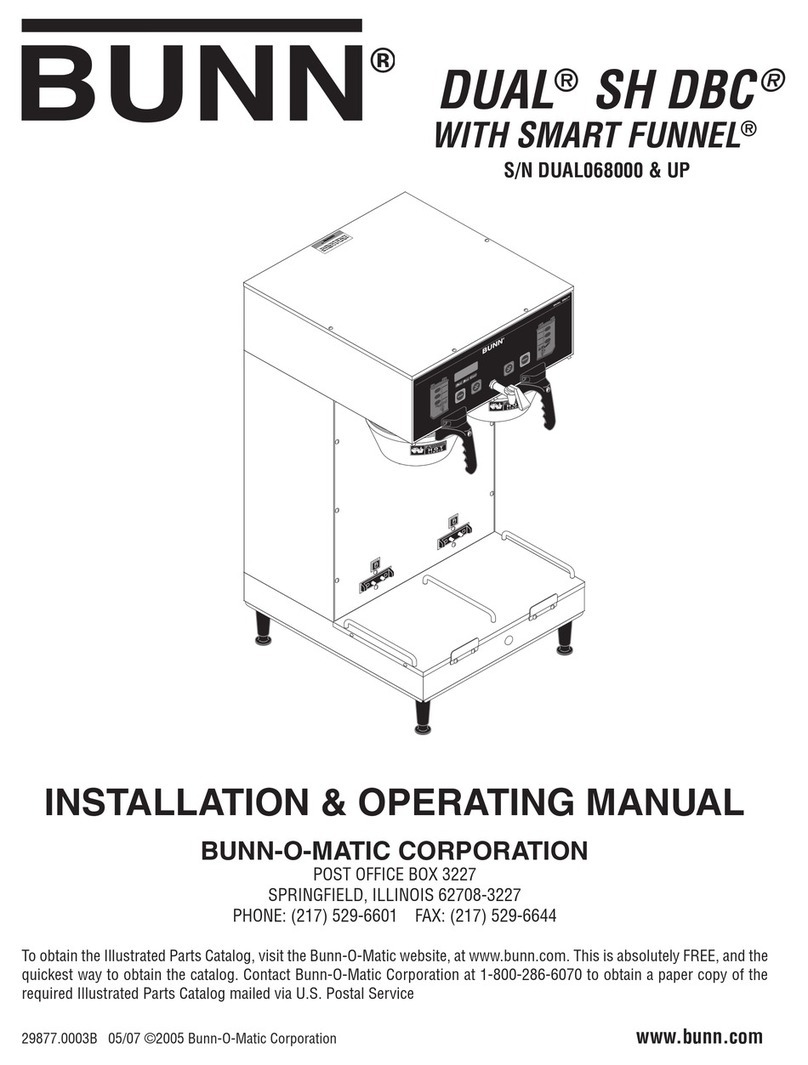

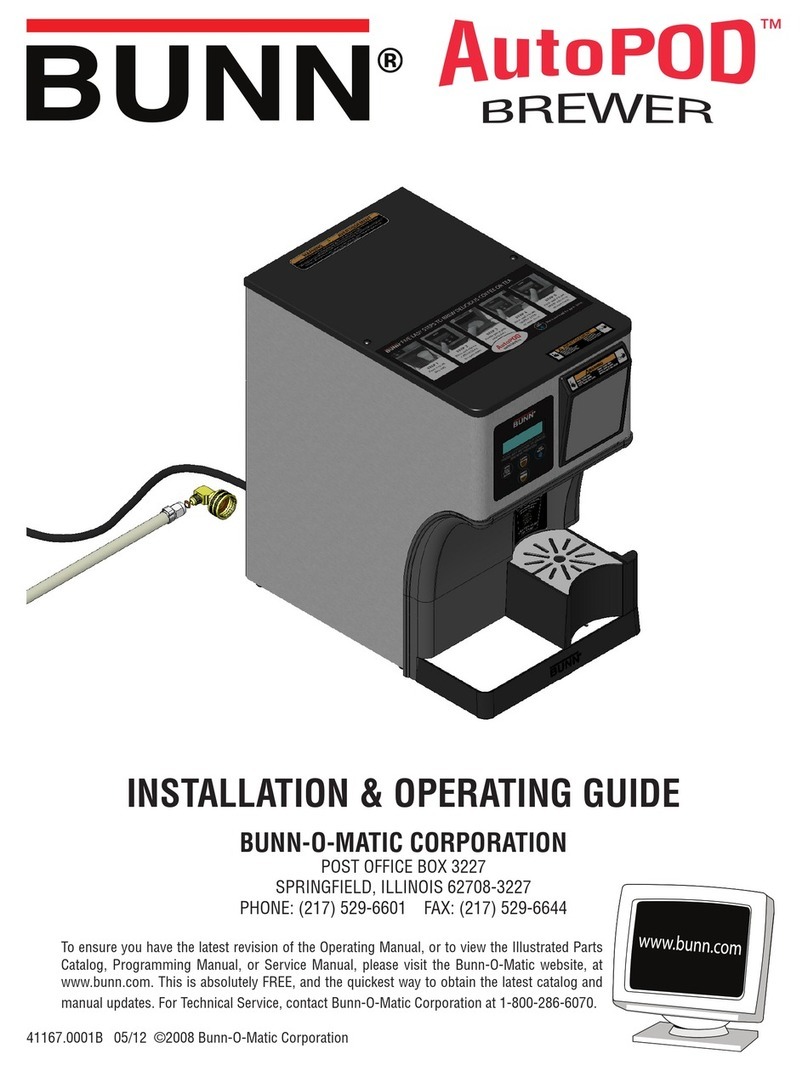

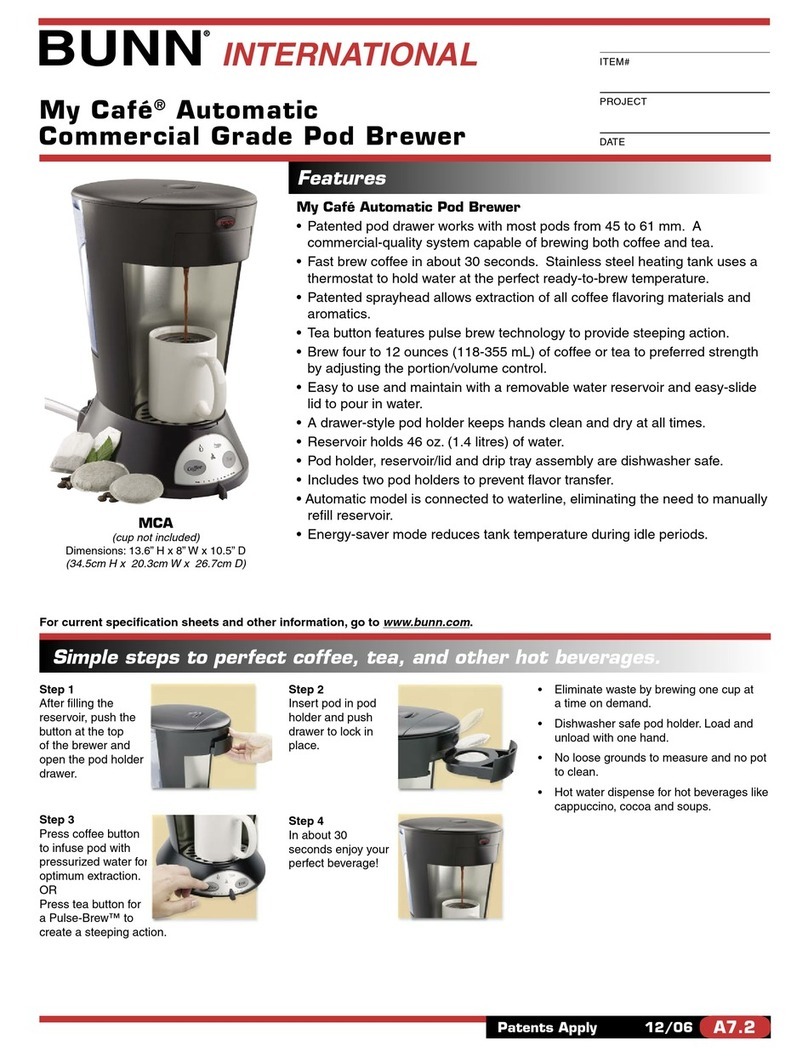

This equip ent will auto atically brew a half-gallon batch of coffee into an awaiting server at the press of a

button. A hot water faucet ay be included for allied beverage use. Most functions of the brewer are digitally

controlled. It is only for indoor use on a sturdy counter or shelf.

CONTENTS

Introduction & Warranty .................................................................................... 2

User Notices ...................................................................................................... 3

Electrical & Plu bing Require ents ................................................................. 4

Operating Controls............................................................................................. 5

Initial Set-Up, Coffee Brewing, & Cleaning......................................................... 6

CEZ-APS/TS/TSR Adjust ents & Optional Settings .......................................... 7

CDBC-APS/TS/TSR Adjust ents & Optional Settings ....................................... 8

Troubleshooting ................................................................................................. 9

Service............................................................................................................. 20

Wiring Diagra s .............................................................................................. 31

W RR NTY

Bunn-O-Matic Corp. (“Bunn”) warrants the equip ent anufactured by it to be co ercially free fro defects

in aterial and work anship existing at the ti e of anufacture and appearing within one year fro the date of

installation. In addition:

1.) Bunn warrants electronic circuit and/or control boards to be co ercially free fro defects in aterial and

work anship for two years fro the date of installation.

2.) Bunn warrants the co pressor on refrigeration equip ent to be co ercially free fro defects in aterial

and work anship for two years fro the date of installation.

3.) Bunn warrants that the grinding burrs on coffee grinding equip ent will grind coffee to eet original factory

screen sieve analysis for three years fro date of installation or for 30,000 pounds of coffee, whichever co es first.

This warranty does not apply to any equip ent, co ponent or part that was not anufactured by Bunn or that,

in Bunn’s judge ent, has been affected by isuse, neglect, alteration, i proper installation or operation, i proper

aintenance or repair, da age or casualty.

THE FOREGOING W RR NTY IS EXCLUSIVE ND IS IN LIEU OF NY OTHER W RR NTY, WRITTEN OR

OR L, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, NY IMPLIED W RR NTY OF EITHER

MERCH NT BILITY OR FITNESS FOR P RTICUL R PURPOSE. The agents, dealers or e ployees of Bunn are

not authorized to ake odifications to this warranty or to ake additional warranties that are binding on Bunn.

Accordingly, state ents by such individuals, whether oral or written, do not constitute warranties and should not

be relied upon.

The Buyer shall give Bunn pro pt notice of any clai to be ade under this warranty by telephone at (217)

529-6601 or by writing to Post Office Box 3227, Springfield, Illinois, 62708-3227. If requested by Bunn, the Buyer

shall ship the defective equip ent prepaid to an authorized Bunn service location. If Bunn deter ines, in its sole

discretion, that the equip ent does not confor to the warranty, Bunn shall repair the equip ent with no charge

for parts during the warranty period and no charge for labor by a Bunn Authorized Service Representative during

the warranty period. If Bunn deter ines that repair is not feasible, Bunn shall, at its sole option, replace the

equip ent or refund the purchase price for the equip ent.

THE BUYER’S REMEDY G INST BUNN FOR THE BRE CH OF NY OBLIG TION RISING OUT OF THE S LE

OF THIS EQUIPMENT, WHETHER DERIVED FROM W RR NTY OR OTHERWISE, SH LL BE LIMITED, S

SPECIFIED HEREIN, TO REP IR OR, T BUNN’S SOLE OPTION, REPL CEMENT OR REFUND.

In no event shall Bunn be liable for any other da age or loss, including, but not li ited to, lost profits, lost sales,

loss of use of equip ent, clai s of Buyer’s custo ers, cost of capital, cost of down ti e, cost of substitute

equip ent, facilities or services, or any other special, incidental or consequential da ages.

29253 030101