Page 6

REPLACEMENT PARTS

03772.0001 .... Base Guide

05920.0000 .... Cable Clamp .25”

00603.0000 .... Cable Clamp .437”

03024.0005 .... Control Thermostat

03409.0000 .... Decal, Caution, Hot Liquid

03408.0000 .... Decal, Caution, Remo e Funnel Slowly

24447.0000 .... Decal, Hood Front

03717.0000 .... Dilution Nozzle

03773.0000 .... Dilution Nozzle Spacer Housing

24613.0001 .... Fitting, .25” Flare x .128” MPT Adapter

22397.0001 .... Fitting, .25” Hose Barb x .125” MPT

00459.0000 .... Fitting, Bulkhead, .25” Male Flare

00400.0001 .... Fitting, Elbow, .25” Male Flare x .125” MPT

00412.0001 .... Fitting, Hex Nipple, .125” MPT

00432.0001 .... Fitting, Street Elbow, .125” NPT

24599.0001 .... Fitting, Tee Union, .125” FPT

24614.0001 .... Fitting, Union, .25” Female Flare

20528.1330 .... Flow Control Assy, .33 gpm

01155.0000 .... Flow Control Gasket

01154.0001 .... Flow Control Outlet

20526.1330 .... Flow Control Washer, .33 gpm

24600.0000 .... Foot Replacement Kit

12485.0003 .... Funnel Handle

24659.0000 .... Funnel Handle Mounting Bracket

12499.0000 .... Funnel Handle Screw

24657.0000 .... Funnel, Assy, Complete

12305.1000 .... Heater Kit, 4000W/208V or 3700W/200V

12322.1000 .... Heater Kit, 4000W/240V

00668.0000 .... Hole Plug, .75” Dia

12422.0000 .... Hose Clamp .5”

23717.0001 .... Limit Thermostat

03170.0000 .... Mounting

00484.0002 .... Needle Val e

12984.0004 .... Ready Indicator Assy, Green

10966.0000 .... Shipping Carton Complete

01592.0000 .... Snap Bushing 1” Dia

01079.0000 .... Solenoid Val e Base

01101.0000 .... Solenoid Val e Coil, (IC3)

21181.0000 .... Solenoid Val e Coil, (IC3B)

01111.0000 .... Solenoid Val e Repair Kit

01085.0002 .... Solenoid Val e, (IC3)

21180.0000 .... Solenoid Val e, (IC3B)

24527.0000 .... Sprayhead Assy

05515.0000 .... Sprayhead Tube Gasket

24697.0000 .... Sprayhead Tube Kit

02753.0000 .... Switch, Lighted On/Off, (IC3)

02754.0000 .... Switch, Lighted On/Off, (IC3B)

02628.0000 .... Switch, Momentary Start

05789.0000 .... Switch, Rocker, Batch Selector

24612.0000 .... Tank

24410.0000 .... Tank Lid

12377.0000 .... Tank Lid Gasket

07038.0000 .... Terminal Block, (IC3)

01106.0001 .... Terminal Block, (IC3B)

32400.0002 .... Timer kit, Digital (120V) (IC3)

32400.0001 .... Timer, kit, Digital (240V) (IC3B)

24435.0000 .... Top Lid

24427.0000 .... Trunk Extension Rear Panel

24698.0000 .... Trunk Rear Panel

00310.0005 .... Tube Assy, Bulkhead Fitting to Solenoid

24569.0000 .... Tube Assy, Flow Control To Tank

24531.0000 .... Tube Assy, Tank Fill

24532.0000 .... Tube Assy, Vent

00310.0000 .... Tube Assy, Water Strainer to Bulkhead Fitting

11707.1001 .... Tube, Silicone-.25” ID x 36"

22249.0000 .... Water Strainer End Cap .25” Flare

23721.0000 .... Water Strainer Replacement Screen

23820.1000 .... Water strainer Assy., Complete

02240.0002 .... Wire Assy, 1/2 Batch Switch to Timer

21014.0055 .... Wire Assy, Limit Thermostat to Tank Heater

24533.0000 .... Wiring Harness, Main (IC3)

24533.0001 .... Wiring Harness, Main (IC3B)

10792 091701

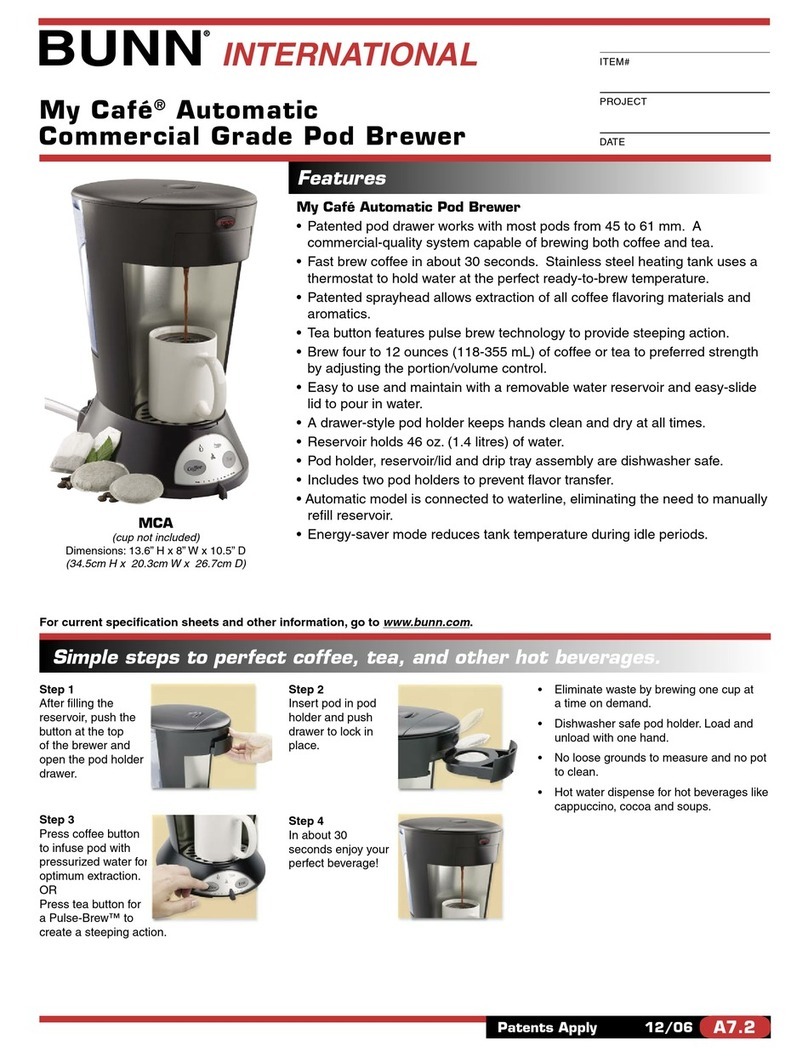

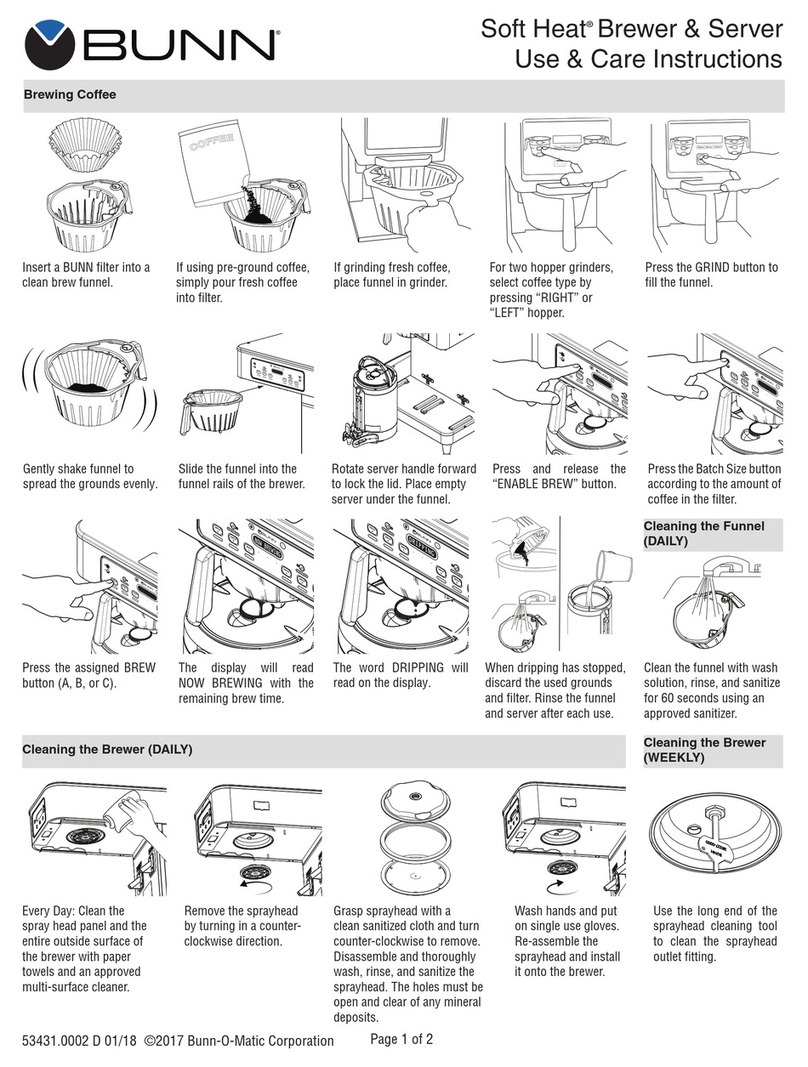

COFFEE BREWING

1. Begin each brew cycle with a clean empty brew funnel and dispenser. (Be sure the dispenser lid doesn’t

interfere with the flow of dilution water.)

2. Insert a BUNN® 3-gallon urn filter into the funnel.

3. Pour the recommended amount of fresh coffee into the filter.

4. Le el the bed of coffee grounds by gently shaking.

5. Slide the funnel into the funnel rails until it stops.

6. Place the On/Off switch in the lighted “ON” position.

7. Place the batch selector switch in the desired position.

8. Momentarily press the start switch.

CAUTION - The funnel contains hot liquids. Remo e funnel slowly.

9. Carefully remo e the funnel and discard the used filter when coffee no longer drips from the funnel.

10. Place the lighted On/Off switch in the “OFF” position to pre ent a false start.

11. Room temperature fresh coffee is a ailable at the faucet.