TROUBLE SHOOTING GUIDE CHECKLIST

NEVER MAKEADJUSTMENTS TOANY ELECTRICALAPPLIANCE OR PRODUCTWITH THE POWER CONNECTED.

DON’T JUST UNSCREW THE FUSE OR TRIP THE BREAKER, REMOVE THE POWER FROM THE RECEPTACLE.

Check all connections.

Check battery and replace if low or defective.

Check that float switch tether is long enough to

allow pump to operate.

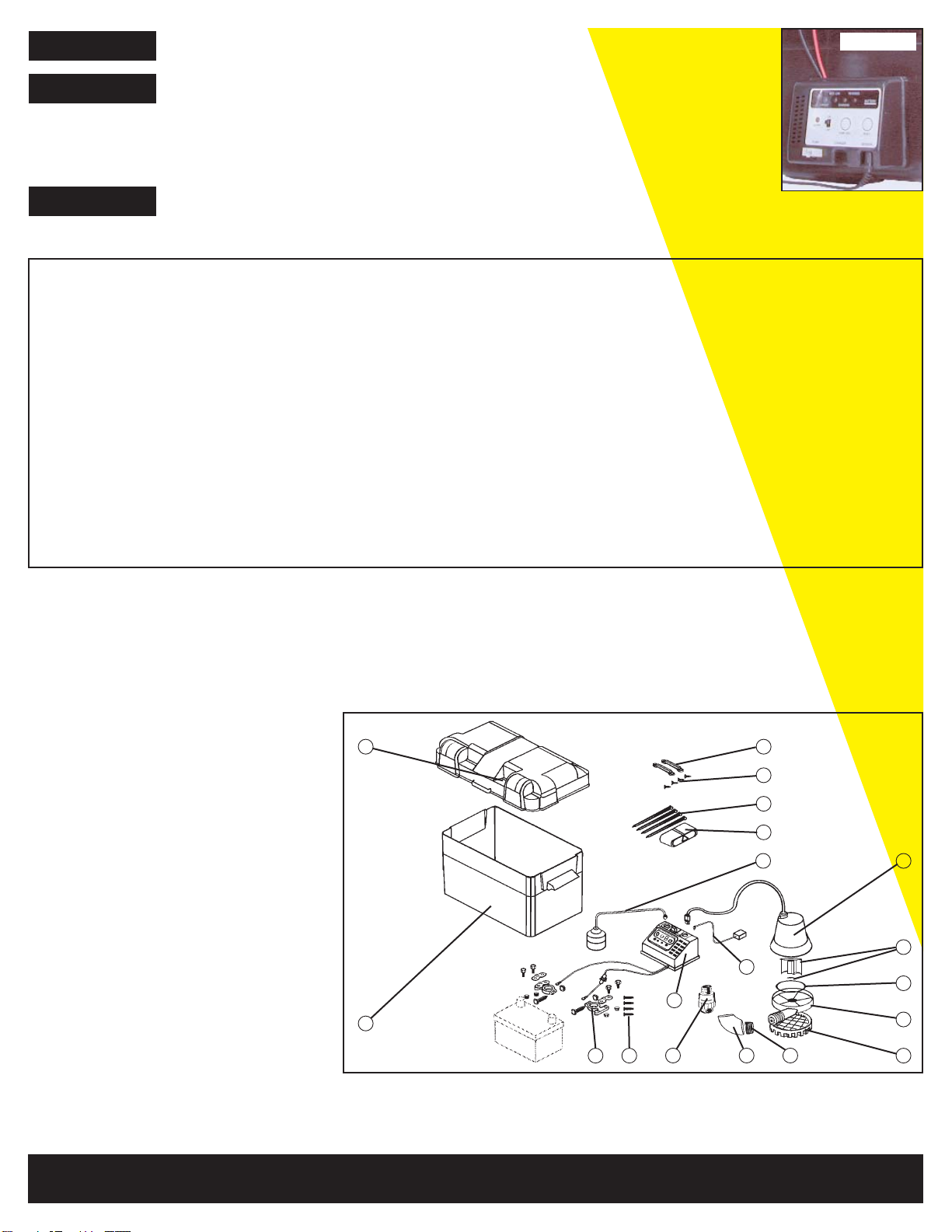

Check the internal fuse located inside the control

box.

Pull the charger from the wall outlet and remove.

If the fuse is blown, replace it with a 15 amp

automotive type fuse.

Check battery and replace if low or defective.

Unplug pump andn check to see if impeller is

free to turn. If impeller is locked, remove the 4

screws on the bottom of the pump to release the

housing around the impeller.

Remove the obstructions

Reassemble pump and reconnect.

Check to make sure a check valve is installed

and functionning between primary pump

discharge and emergency sump pump elbow

fitting.

Check for obstruction and clear if necessary.

Check that pump is rotated 450in elbow fitting as

shown on picture #2.

Pump is not install at 450 angle.

Clean out to hole and replace cover.

If the discharge is too high, a separate line may

be required with a lower discharge height.

Check battery and replace if low or defective.

Tether lenght should be at least 2”. Adjust if

necessary. CAUTION : Ensure tether will swing

freely without obstruction.

Install check valve or repair as required.

TROUBLE PROBABLE CAUSE REMEDIES

Pump won’t run.

Motors hums

but pumps won’t

run.

Pump runs but

pumps very little

or no water.

Pump cycles

too frequently.

TO THE END CONSUMER

If you have any problems with the product, before advising the store, where you’ve

purchased the pump, please contact us at 514 337-4415 , and ask for our sales department,

and they will be pleased to help you with any questions you might have, concerning your

installation.

Connections not secure.

Low or defective battery.

Float switch unable to swing up and down as

needed.

Defective or blown fuse.

Defective battery.

Impeller is locked.

Check valve missing or improperly installed.

Obstruction in discharge pipe.

Pump not rotated 450.

Pump air locked.

Discharge pipe lenght and/or height exceeds

capacity of pump.

Low or defective battery.

Tether lenght too short on float switch.

Main check valve located between the

discharge of the primary pump and the

emergency pump elbow fitting or the

emergency pump check valve not installed or

working properly.

6