Ref. “Slimfold O&M Manual 11-02-09” Page 6/7

SECTION 3 – MAINTENANCE & REPAIR

3.1 General

3.1.1 All Burgess products are designed to give a long, trouble free working life with the

minimum of maintenance and as such there are no user- serviceable parts. However,

there is still a requirement for the operator to carrying out simple periodic inspection and

maintenance as detailed below.

3.1.2 The maintenance procedures given should be carried out with the table unfolded and

ready for use. (See Section 2 – Handling, Storage & Operation.)

3.1.3 Light damage as outlined below may be repaired by (or by agents of) the operator. More

severe damage should be referred to Burgess Furniture Ltd.

3.2 Maintenance Schedule

3.2.1 The following maintenance procedures should be carried out at least every 3 months

under normal operating conditions, or every 1 month under severe contract conditions.

3.3 Cleaning

3.3.1 Table underframes should be cleaned using a damp cloth and, where necessary, a mild

soap cleaning agent.

•Abrasive scourers should not be used.

3.3.2 Flock coated tops should be cleaned using a damp cloth and a mild detergent. Heavy

staining may be difficult to remove.

•DO NOT use bleach or any other caustic / solvent based cleaner as permanent

damage to the top will result.

3.3.3 High Pressure Laminate tops should be cleaned using a damp cloth and a mild

detergent, then dried with a soft lint-free cloth. Do not use any form of furniture polish on

laminate table tops as this will result in smearing.

3.4 Inspection & Repair

•Inspections must be carried out by a competent person. All defective tables

must be immediately removed from service. Repairs must only be carried out

by competent personnel.

•Referring to Section 2 – Handling, Storage & Operation:

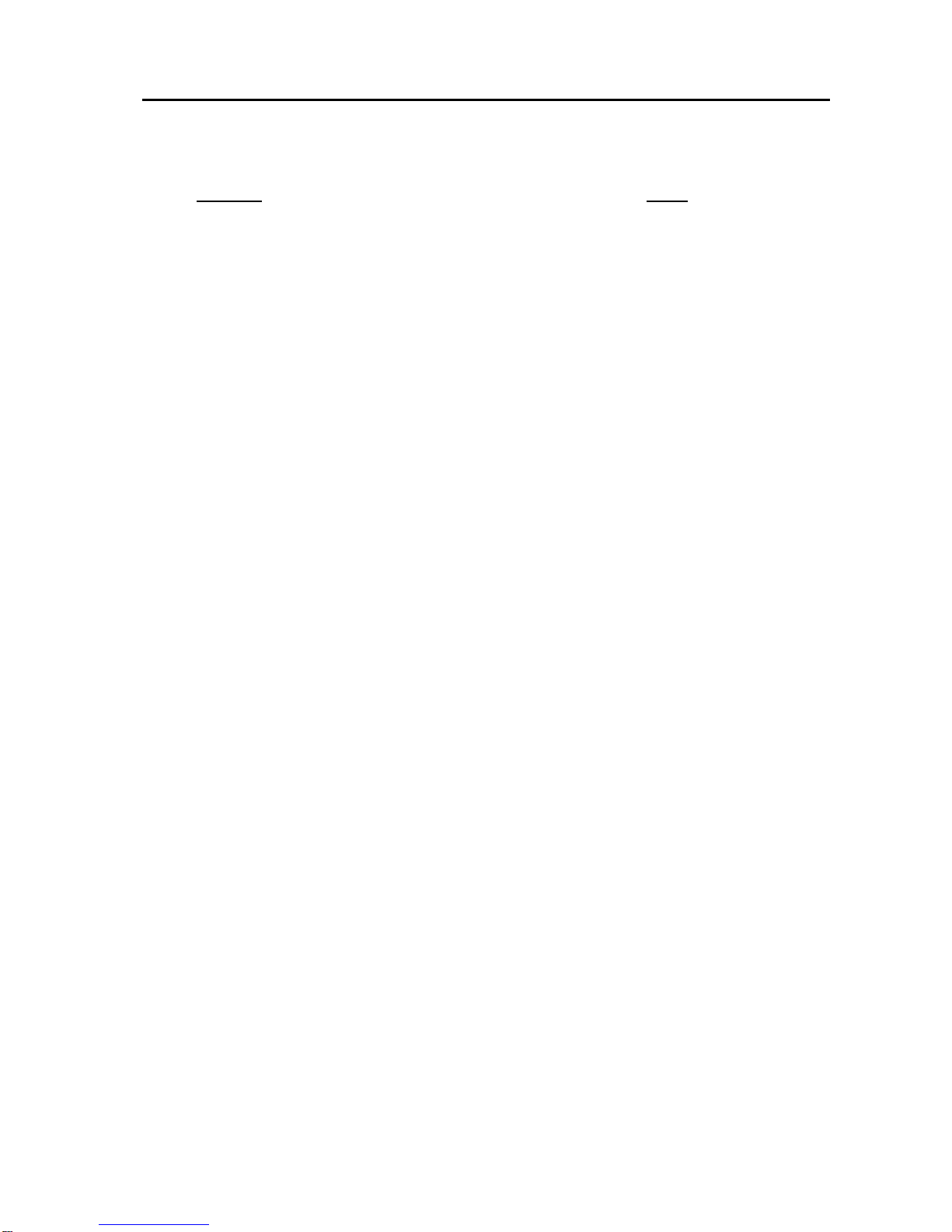

3.4.1 Operate the leg folding mechanisms and check that all moving parts are free from

damage and function smoothly.

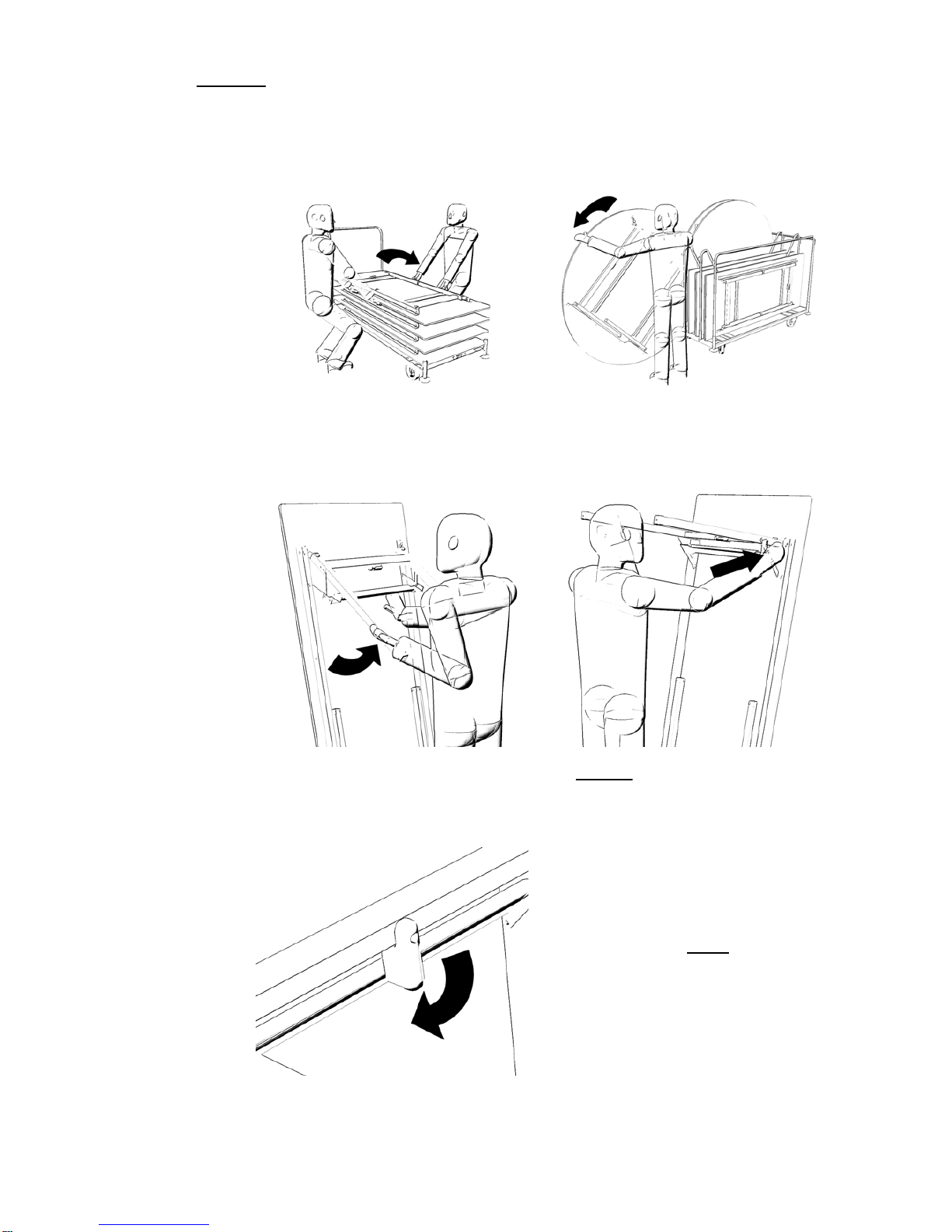

3.4.2 Ensure the green plastic locking tab is in place and turns smoothly without being

excessively loose. If necessary the tab’s mounting screw can be tightened, but be sure

not to over tighten as this will affect the smooth operation of the tab.

3.4.3 Inspect where the underframe is fitted to the top, ensuring that all rivets are intact and the

top is secure.

3.4.4 Flock coated tops: Inspect the aluminium edging for damage such as gouges and nicks

which could be transferred to smooth flooring and table cloths. Any such damage to the

edging can be carefully removed using a fine file or emery cloth.