8

Clearances to Combustibles

The distance to be maintained from the surfaces of the

replace to combustibles must be observed. Below is a list of

the most common combustible materials to name a few:

Drywall Wood ooring Plywood

Sub-ooring Wood Framing Particle board

Mill board Plywood paneling

Maintain the following clearances:

Unit front, sides, rear: 2” (50 mm)

Combustible Floor: 8” (150 mm)

Combustible Sheathing above opening top: 8” (200 mm)

Sheathing or trim to opening sides: 8” (200 mm)

Mantel above opening: (refer to Fig.9)

Opening to sidewall: 24” (500 mm)

Hearth extension beyond front: 20” (500 mm)

Hearth extension beyond sides: 12” (300 mm)

Insulation from rebox: 2” (50 mm)

Understanding Clearance to Combustibles

There is a build-up of considerable amount of radiant heat

on the outer surfaces of the BURNTECH Fireplace. It’s

critical that proper clearances to combustibles be maintained

so that this radiant heat is maintained to safe limits.

Combustible Floor Clearances

TFS43-ST Fireplace haSbeen designed with clearance to

combustible floors at a minimum of 8-1/2” (eight and one half

inches) as provided by the 8” metal base and 1/2” concrete

board. Cover any part of the combustible floor system left

exposed with 1” (one inch) thick ceramic fiber insulation rated

up to 2,100°F.

The BURNTECH Steel Platform , the 1/2” concrete board

above, the 1” ceramic fiber blanket or board within the

platform (Fig.15) and the 2” clearance for dome front, and unit

sides provide the temperature safety margin to combustible

materials.

•

•

•

•

•

•

•

•

•

BURNTECH Fireplace & Chimney System

Prior to starting the installation, check with local, regional or

state codes for any restrictions or required permits regarding

your replace installation.

The BURNTECH is designed to be installed with a

listed UL-103-16” I.D. Class A, Metal Chimney System.

This BURNTECH fireplace is intended as a supplemental

heat source only. It is not intended as a primary heat

source.

It is the responsibility of the contractor installer (not the

manufacturer) to ensure that adequate combustion air is

provided for proper function of this replace. Fireplaces

take up a large volume of replacement air from outside the

house and if the house is of airtight construction, smoke

spillage may occur if proper draft is not achieved.

There are many conditions beyond a manufacturer’s

control regarding improper replace operation. The

manufacturer cannot ensure “smoke free” operation,

nor can the manufacturer take on the responsibility for

problems with surrounding construction; chimneys that

have not been built at the right heights; system drafts

caused by faulty mechanical systems; adverse weather

conditions or any other inclement environmental situations

over which the manufacturer has no control.

Inspect all replace & chimney components for evidence

of damage prior to starting installation. Consult your local

distributor for replacement parts if necessary.

Under no circumstances should you make any adjustments

or modications to the chimney system during the

installation procedure. If you do, you are not only liable

for negating the warranty, but you could very well cause a

serious malfunction of the replace. You must follow your

chimney manufacturer’s instructions.

Caution is urged if it is decided to add insulation material

to any part of the BURNTECH Fireplace or Chimney

system, be certain that the insulation material is kept at

least 2” (two inches) away from any part of the system.

When using insulation or vapor barrier materials, cover

with a layer of plywood, particle board or gypsum board

to maintain the specified 2” (two inch) clearance.

Air spaces around rebox must remain open. DO NOT ll

these open spaces with insulation or packing material of

any kind.

Chimney System Heights

When installed, the maximum overall height of the chimney

system from bottom of replace to the top/termination chimney

is 40 feet. The minimum installed height of the completed

Chimney System is 14 feet with a straight ue stack, 17 feet if

the chimney includes one or two offset sections.

1)

2)

3)

4)

5)

6)

7)

8)

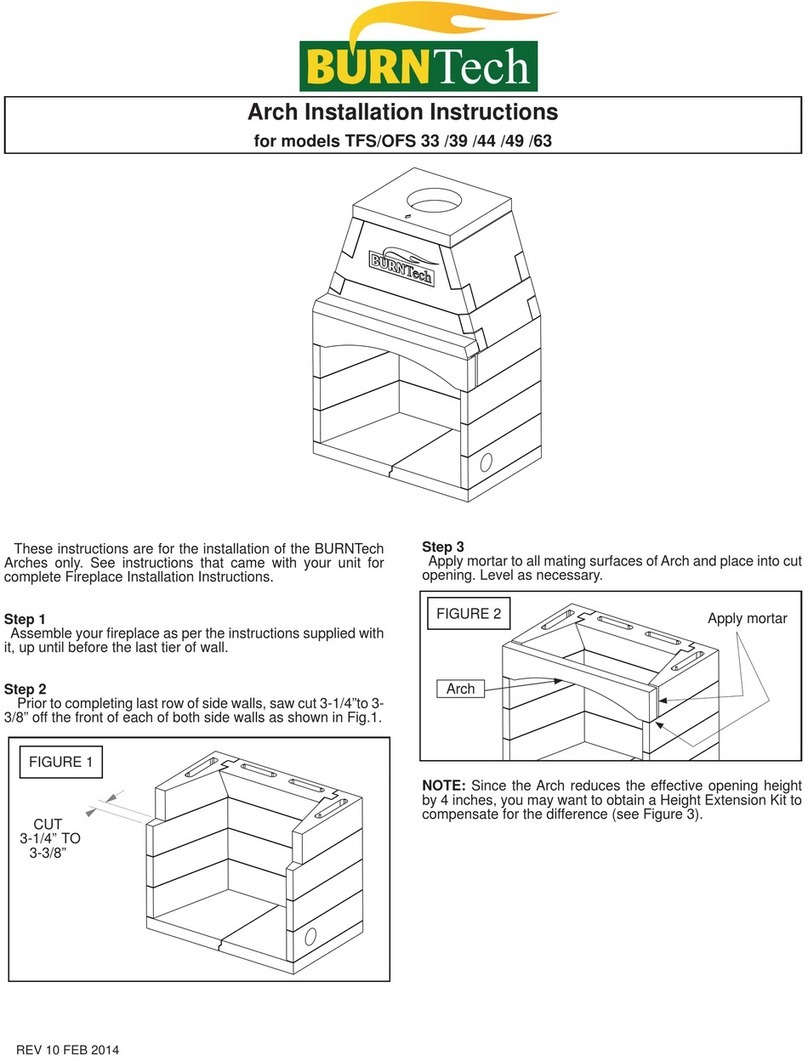

Figure 9