5

Safety Information

Carbon Monoxide Poisoning: Early signs of carbon monoxide

poisoning resemble the flu, with headaches, dizziness, or

nausea. If you have these signs, the fireplace may not be

working properly. Get fresh air at once! Have the fireplace

serviced.

Note: Some people are affected more than others by carbon

monoxide. These may include pregnant women, people with

heart or lung disease, are anemic, anyone under the influence

of alcohol, and those at high altitude.

IMPORTANT: Read this owners manual carefully

and completely before trying to assemble, operate,

or service this fireplace. Improper use of this

fireplace can cause serious injury or death from

burns, fire, explosion, electrical shock, and carbon

monoxide poisoning.

General Safety Concerns

1. If you smell gas

OShut off gas supply.

ODo not try to light any appliance.

ODo not touch any electrical switch; do not use any

phone in your building.

O immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

O If you cannot reach your gas supplier, call the fire

department.

2. This fireplace shall not be installed in a bedroom or

bathroom.

3. Never install the fireplace

O In a recreational vehicle.

O Where curtains, furniture, clothing, or other flammable

objects are less than 36 inches from the front, top, or

sides of the fireplace.

O In high traffic areas.

O In windy or drafty areas.

4. Do not use this fireplace as a wood-burning fireplace.

5. Do not add extra logs or ornaments such as pine cones,

vermiculite, or rock wool. Using these added items can

cause soot build-up.

6. This fireplace is designed to be smokeless. If logs appear

to smoke, turn off fireplace and call a qualified service

person.

7. Avoid any drafts that alter burner flame patterns. Do not

allow fans to blow directly into the fireplace. Do not place

a blower inside burn area of the firebox. Ceiling fans may

create drafts that alter burner flame patterns. Soot build-up

and improper burning will occur. Soot build-up can settle on

household surfaces outside the fireplace.

8. This fireplace needs fresh air ventilation to run properly.

The Vent free decorative gas log set must have an

oxygen depletion sensor (ODS) pilot light safety system.

The ODS shuts down the fireplace if not enough fresh

air is available. See Air for Combustion and Ventilation,

page 8. If the fireplace keeps shutting off, see appliance

manufacturers’ troubleshooting instructions.

9. Do not run fireplace

O Where flammable liquids or vapors are used or stored.

O Under dusty conditions.

10. Do not use this fireplace to cook food or burn paper or

other objects.

11. Never place any objects in the fireplace or on logs.

12. Fireplace screens must be provided and are to be closed

before operating the decorative room heater. If doors are

installed, they must be open during operation. Fireplace

front and screen become very hot when running fireplace.

Keep children and adults away from hot surfaces to avoid

burns or clothing ignition. The fireplace will remain hot

for a time after shut down. Allow surfaces to cool before

touching.

13. Carefully supervise young children when they are in the

room with the fireplace.

14. Do not use fireplace if any part has been exposed to or

under water. Immediately call a qualified service technician

to inspect the fireplace and to replace any part of the control

system and gas control which has been under water.

15. Do not operate the fireplace if any log is broken. Do not

operate the fireplace if a log is chipped (dime-sized or

larger). Verify proper log placement prior to operating

appliance.

16. Turn fireplace off and let cool before servicing. Only a

qualified service person should service and repair the

fireplace.

17. Operating the fireplace above elevations of 4,500 feet

may cause pilot outage.

DO NOT USE OR STORE GASOLINE OR OTHER

FLAMMABLE LIQUIDS OR GASES IN OR NEAR THE

FIREPLACE!

ATTENTION: A fire or an explosion could occur causing property

damage, injury or loss of life if you do not follow the information

in this manual!

NOTE: THIS MANUAL MUST BE REPRODUCED ONLY IN

ITS ENTIRETY.

Carefully review the instructions supplied with the decorative

type unvented room heater for the minimum firebox size

requirement.

DO NOT INSTALL THE APPLIANCE IN THIS

FIREBOX UNLESS THIS FIREBOX MEETS THE

MINIMUM DIMENSIONS REQUIRED FOR THE

INSTALLATION.

When choosing a location for your fireplace, avoid locations

that are subject to too much draft or locations where you may

encounter obstructions that may be in the way of the fireplace

once installed. Always check local codes and familiarize yourself

with the surrounding construction.

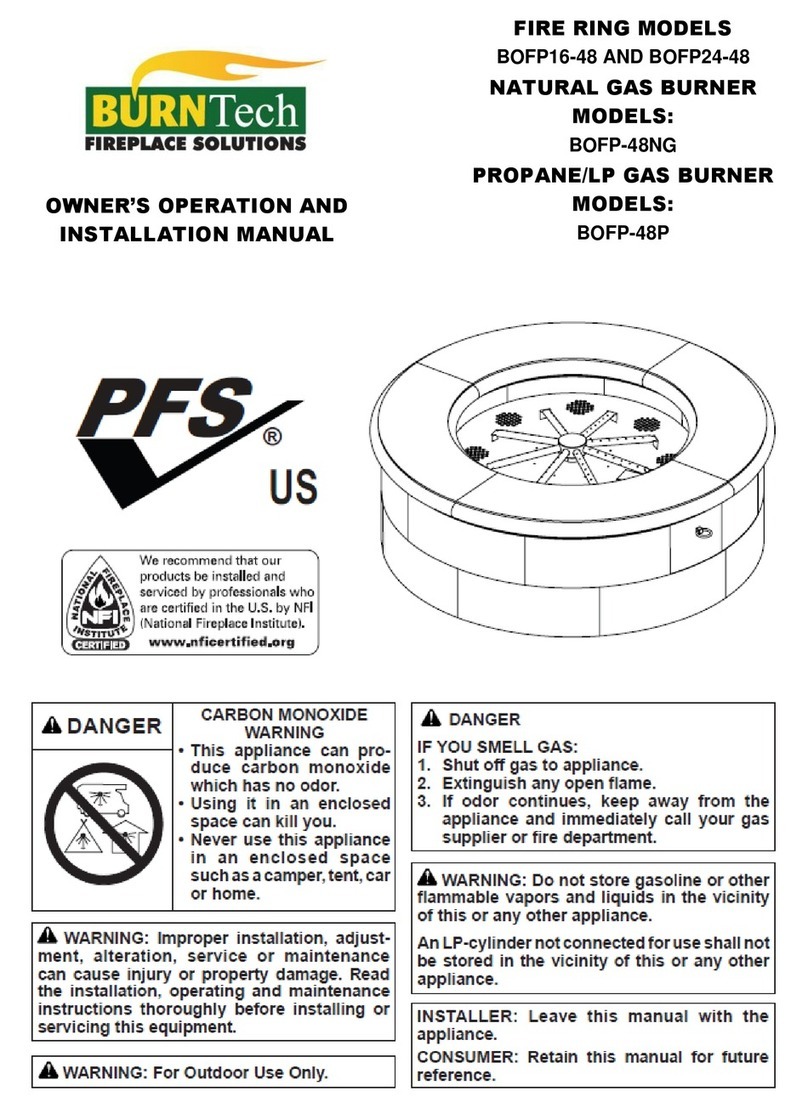

nDANGER:

Carbon monoxide poisoning may lead to

death!