Mounting Position and Space

●Make sure that the environment of the side channel blower is not

potentially explosive

●Make sure that the following ambient conditions will be complied

with:

–ambient temperature: –5 ... +40 °C

–ambient pressure: atmospheric

●Make sure that the environmental conditions comply with the pro-

tection class of the drive motor (according to the nameplate)

The side channel blower can be operated with horizontal or vertical gas

flow (with vertical gas flow the drive motor shall be in the uppermost

position)

●Make sure that the mounting base is even

●Make sure that in order to warrant a sufficient cooling there will be

a clearance of minimum 0.1 m between the side channel blower

and nearby walls

●Make sure thate there will a clearance of minimum 3.5 cm (up to

construction size 140) or 5.5 cm (as of constructions size 200) be-

tween the fan hood and nearby walls/ceiling

●Make sure that there will be a clearance of minimum 2 cm (up to

construction size 200), 3 cm (for construction size 310) or 4 cm (as

of constructions size 530), respectively, between the cover (70)

and nearby walls/floor

In case of mounting with the drive motor in the uppermost position:

◆Provide vibration insulating rubber feet to fasten the side

channel blower to the floor

●Make sure that no heat sensitive parts (plastics, wood, cardboard,

paper, electronics) will touch the surface of the side channel

blower

●Make sure that the installation space or location is vented such

that a sufficient cooling of the side channel blower is warranted

CAUTION_ac

During operation the surface of the side channel blower may reach

temperatures of more than 70 °C.

Risk of burns!

●Make sure that the side channel blower will not be touched inad-

vertently during operation, provide a guard if appropriate

Suction Connection/Gas Inlet

CAUTION_a

Intruding foreign objects or liquids can destroy the side channel

blower.

In case the inlet gas can contain dust or other foreign solid particles:

◆Make sure that a suitable filter (5 micron or less) is installed

upstream the side channel blower

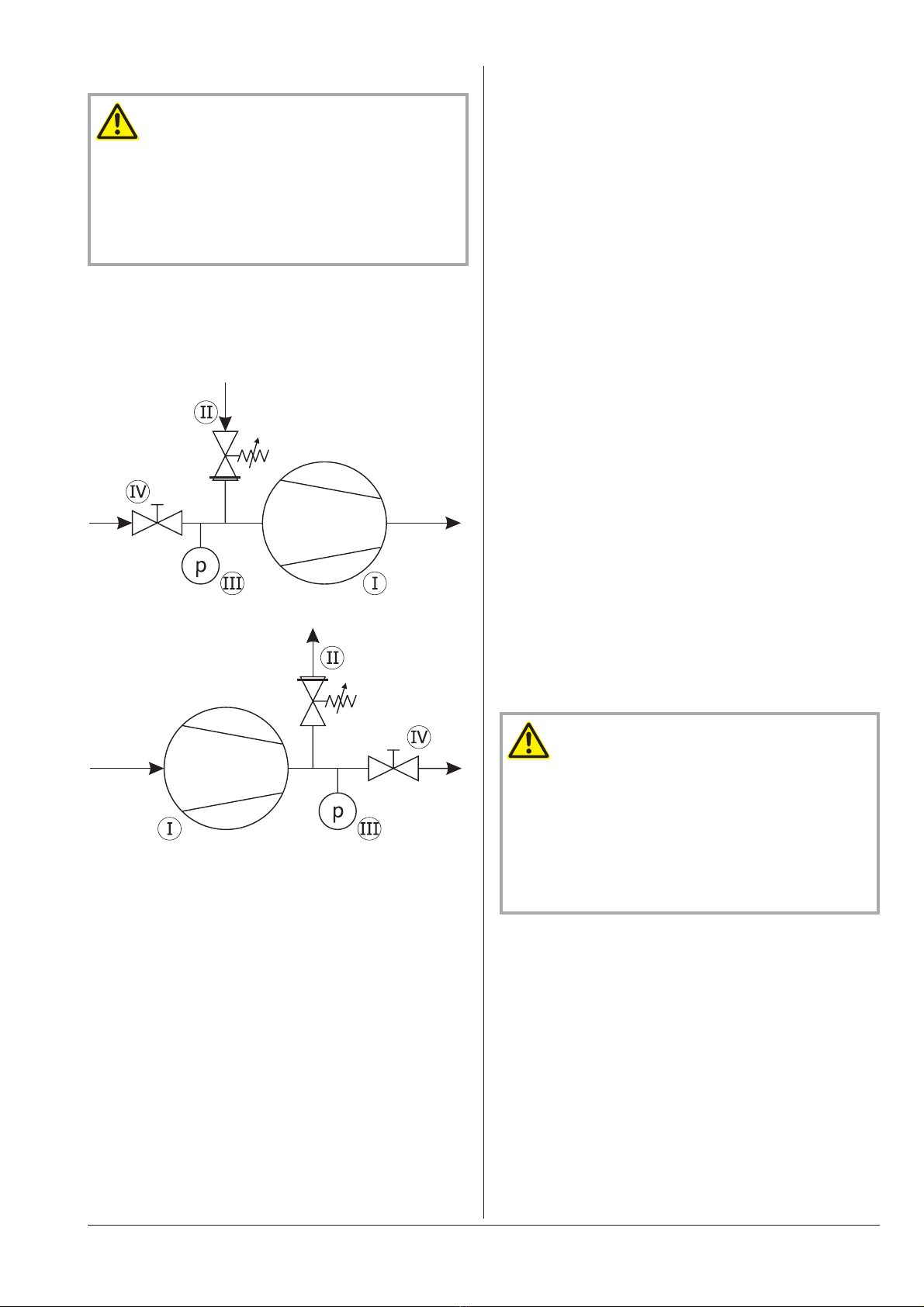

In case of compressor operation:

The following guidelines for the suction line do not apply, if the air

to be compressed is taken in right at the side channel blower.

●Make sure that the suction line fits to the suction connection/gas

inlet (c) of the side channel blower

●Make sure that the gas will be sucked through a vacuum-tight

flexible hose or a pipe

In case of using a pipe:

◆Make sure that the pipe will cause no stress on the side

channel blower’s connection, if necessary use an expansion

joint

●Make sure that the line size of the suction line over the entire

length is at least as large as the suction connection/gas inlet (c) of

the side channel blower

In case the length of the suction line exceeds 2 m it is prudent to use

larger line sizes in order to avoid a loss of efficiency and an overload of

the side channel blower. Seek advice from your Busch representative!

In case the vacuum shall be maintained after shutdown of the side

channel blower:

◆Provide a manual or automatic operated valve (= non-return

valve) in the suction line

●Make sure that the suction line does not contain foreign objects,

e.g. welding scales

In case the side channel blower will be used for vacuum application

and is likely to run against a closed inlet for more than a few seconds:

◆Provide a vacuum relief valve and set it to approx. 75 percent

of the max. differential pressure

In case of doubt seek advice from your Busch representative!

Gas Discharge

In case of vacuum operation:

The discharged gas must flow without obstruction. It is not per-

mitted to shut off or throttle the discharge line or to use it at as a

pressurised air source.

In case of vacuum operation:

The following guidelines for the discharge line do not apply, if the

aspirated air is discharged to the environment right at the side

channel blower.

●Make sure that the discharge line fits to the gas discharge (d) of

the side channel blower

In case of using a pipe:

◆Make sure that the pipe will cause no stress on the side

channel blower’s connection, if necessary use an expansion

joint

●Make sure that the line size of the discharge line over the entire

length is at least as large as the gas discharge (d) of the side

channel blower

In case the length of the discharge line exceeds 2 m it is prudent to use

larger line sizes in order to avoid a loss of efficiency and an overload of

the side channel blower. Seek advice from your Busch representative!

●Make sure that the discharge line either slopes away from the side

channel blower or provide a liquid separator or a drip leg with a

drain cock, so that no liquids can back up into the side channel

blower

Pressure Connection

●Make sure that the pressure line fits to the pressure connection (d)

of the side channel blower

●Make sure that the pressure connection is connected to a pres-

sure-tight flexible hose or a pipe

In case of using a pipe:

◆Make sure that the pipe will cause no stress on the side

channel blower’s connection, if necessary use an expansion

joint

●Make sure that the line size of the pressure line over the entire

length is at least as large as the pressure connection (d) of the side

channel blower

SE 0045 - 1105 D/D2 Installation and Commissioning

0870133372 / 100512 page 5