Table of Contents

2 / 36 0870231979_WT0100-0730CP_CV_-0001_IM_en

Table of Contents

1 Safety .......................................................................................................................................3

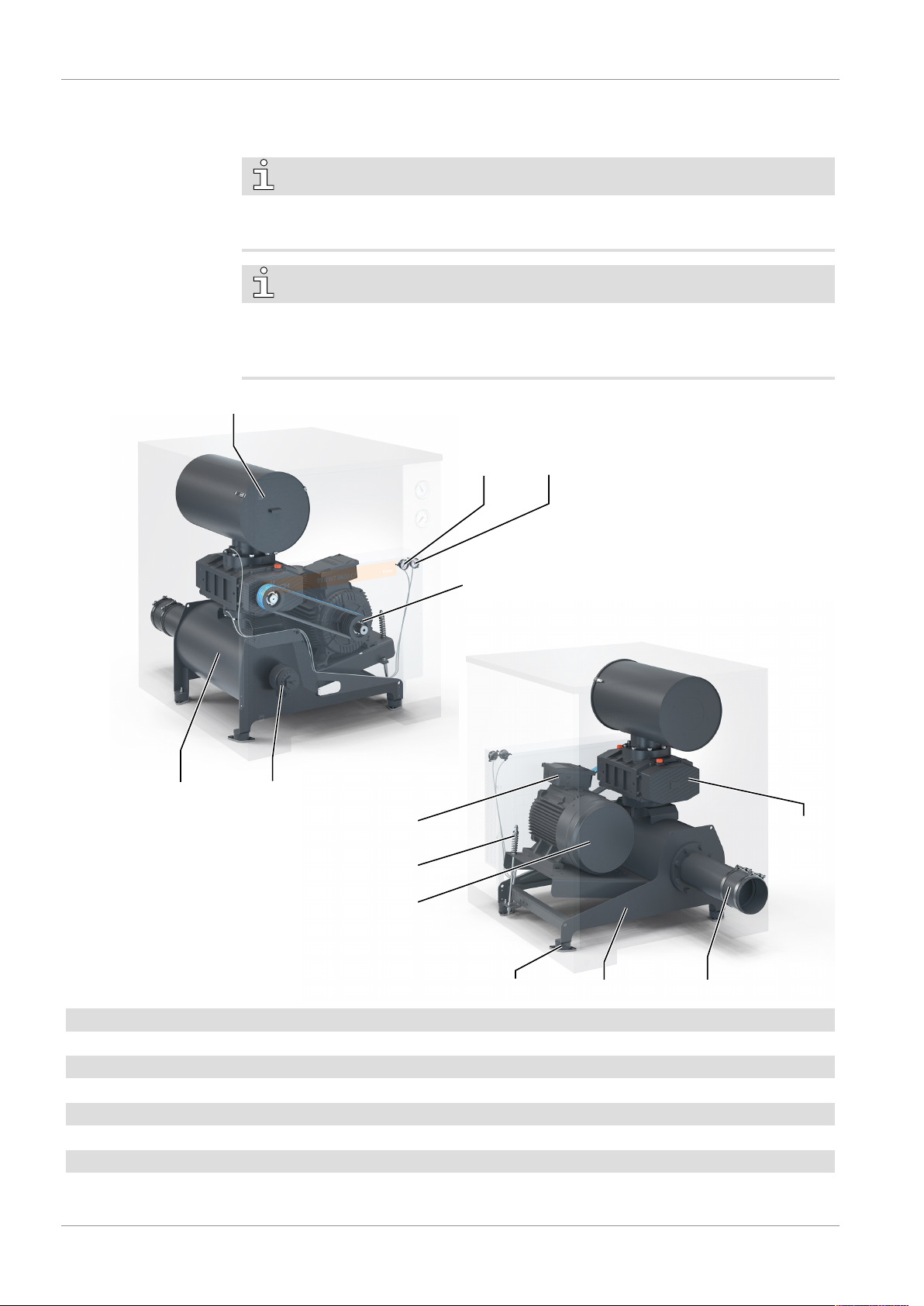

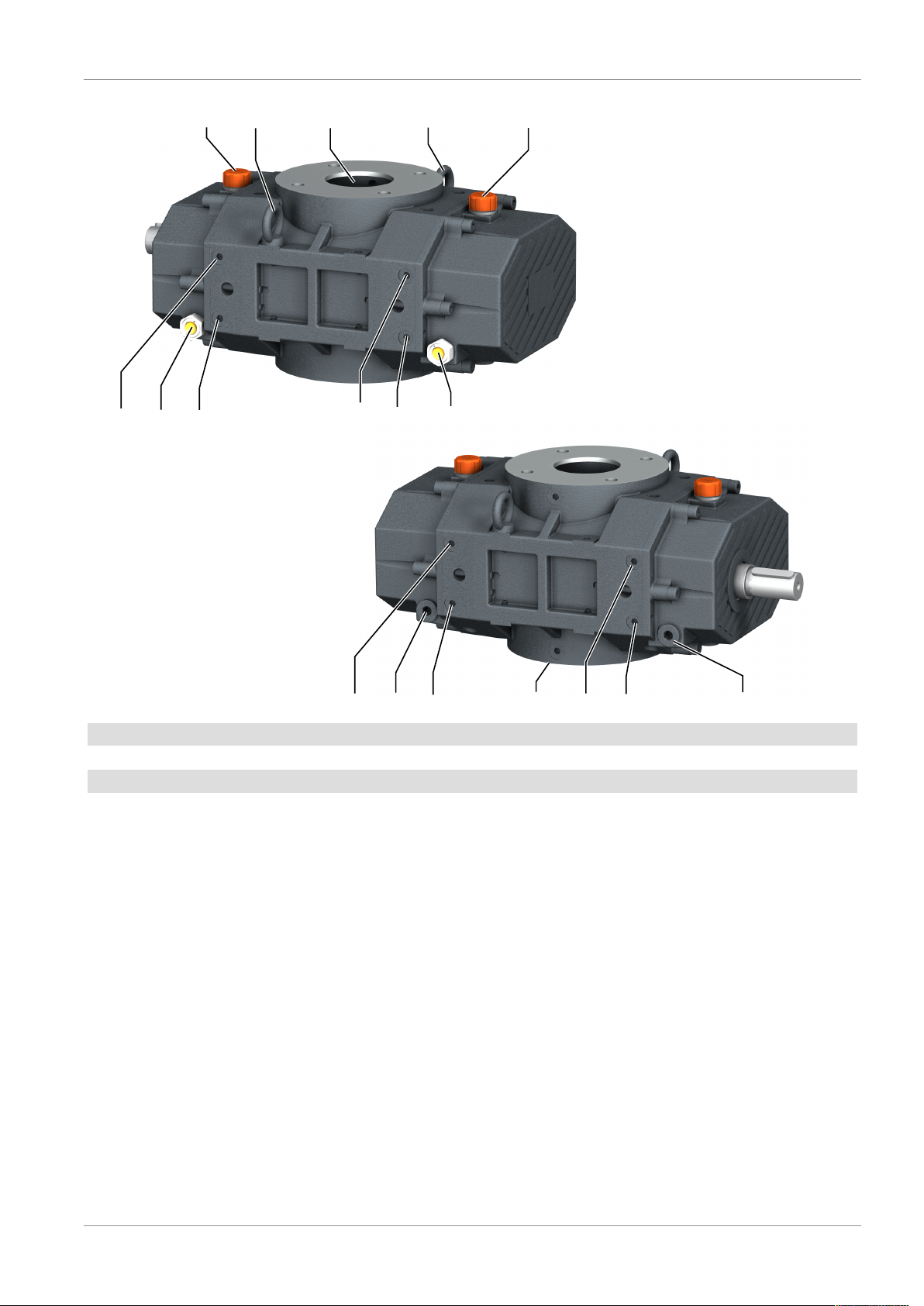

2 Product Description ..................................................................................................................4

2.1 Operating Principle .......................................................................................................... 6

2.2 Application....................................................................................................................... 6

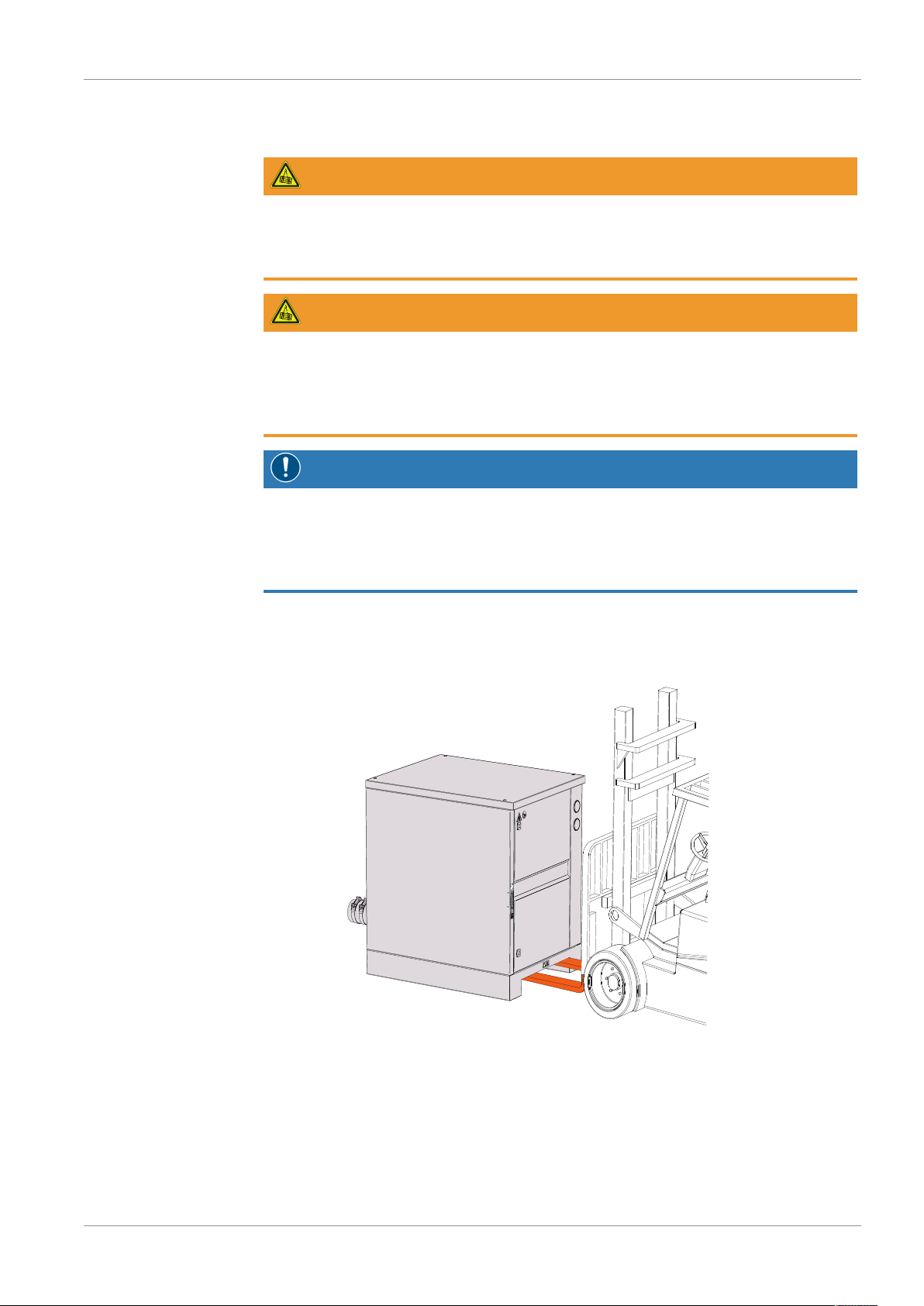

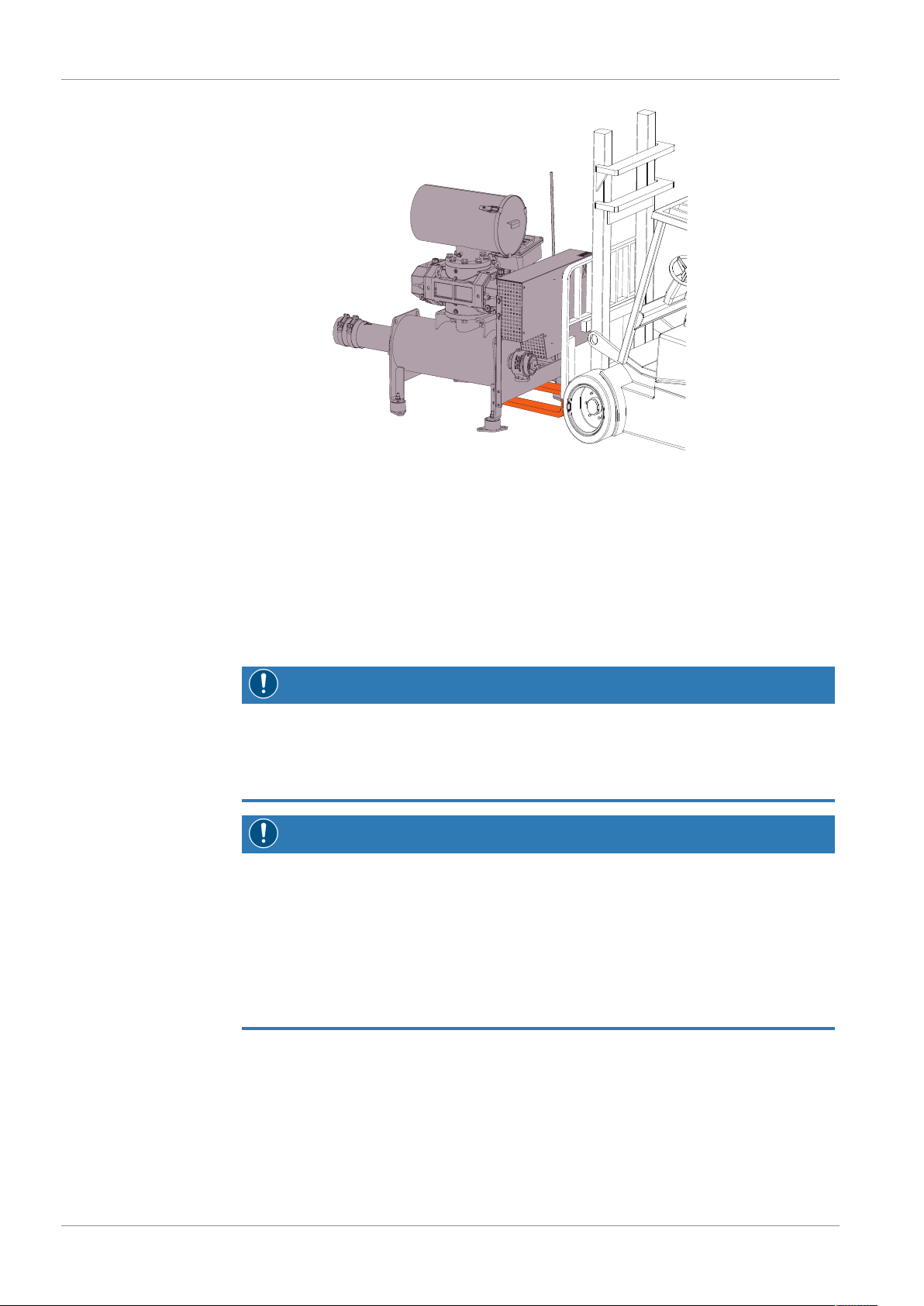

3 Transport ..................................................................................................................................7

4 Storage .....................................................................................................................................8

5 Installation................................................................................................................................9

5.1 Installation Conditions...................................................................................................... 9

5.2 Blower Unit Installation .................................................................................................... 9

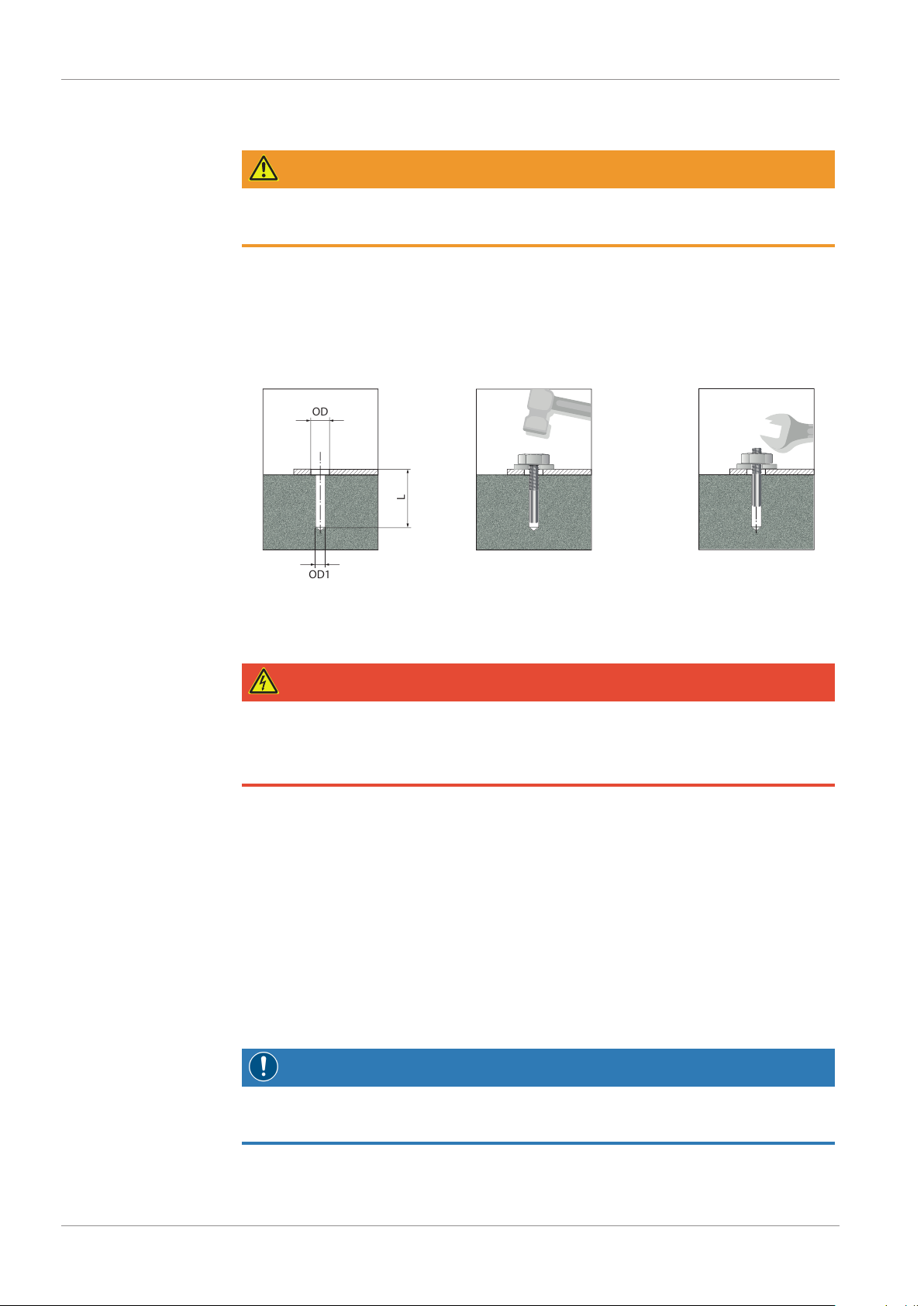

5.2.1 Possible fixing........................................................................................................ 10

5.3 Electrical Connection ........................................................................................................ 10

5.3.1 Wiring Diagram Three-Phase Motor...................................................................... 11

5.4 Connecting Lines / Pipes .................................................................................................. 12

5.4.1 Suction Connection ...............................................................................................12

5.4.2 Discharge Connection ........................................................................................... 13

5.5 Filling Oil.......................................................................................................................... 13

6 Commissioning.........................................................................................................................15

7 Maintenance.............................................................................................................................16

7.1 Maintenance Schedule ..................................................................................................... 17

7.2 Maintenance Inlet Filter.................................................................................................... 17

7.3 Maintenance V-Belt and Pulley Alignment ....................................................................... 19

7.4 Maintenance Oil .............................................................................................................. 20

7.5 Oil Level Inspection.......................................................................................................... 20

7.6 Oil Change....................................................................................................................... 21

8 Overhaul...................................................................................................................................24

9 Decommissioning.....................................................................................................................24

9.1 Dismantling and Disposal ................................................................................................. 24

10 Spare Parts................................................................................................................................25

11 Troubleshooting .......................................................................................................................26

12 Technical Data..........................................................................................................................31

13 Specific Technical Data.............................................................................................................32

14 Oil ............................................................................................................................................33

15 EU Declaration of Conformity...................................................................................................34

16 UK Declaration of Conformity ..................................................................................................35