◆Switch any two of the drive motor wires (three-phase motor)

Connecting Lines/Pipes

●Connect the suction line

Installation without suction line:

◆Make sure that the gas inlet (d) is open

●Connect the discharge line

or

●Connect the pressure line

Installation without discharge line:

◆Make sure that the gas discharge (e) is open

●Make sure that all provided covers, guards, hoods etc. are

mounted

●Make sure that cooling air inlets and outlets are not covered or ob-

structed and that the cooling air flow is not affected adversely in

any other way

In case the side channel blower comes with an eyebolt for the attach-

ment of lifting gear:

◆Make sure that the eyebolt is firmly tightened

Recording of Operational Parameters

As soon as the side channel blower is operated under normal operating

conditions:

●Measure the drive motor current and record it as reference for fu-

ture maintenance and troubleshooting work

Operation Notes

Use

CAUTION_a

The side channel blower is designed for operation under the condi-

tions described below.

In case of disregard risk of damage or destruction of the side

channel blower and adjoining plant components!

Risk of injury!

The side channel blower must only be operated under the condi-

tions described below.

The side channel blower is intended for

–the suction

–the compression

of

–air and other dry, non-aggressive, non-toxic and non-explosive

gases

Conveying media with a lower or higher density than air leads to an in-

creased thermal and/or mechanical load on the side channel blower

and is permissible only after prior consultation with Busch.

The gas shall be free from vapours that would condensate under the

temperature and pressure conditions inside the side channel blower.

The side channel blower is intended for the placement in a non-poten-

tially explosive environment.

The side channel blower is suitable for continuous operation, provided

that the housing can transmit heat to the environment without ob-

struction and a certain minimum gas transfer is warranted. If there is a

risk that the side channel blower may be operated against a closed inlet

or outlet for more than a few seconds, a vacuum or pressure relief

valve, respectively, shall be provided. Frequent switching on and off

leads to increased coil temperatures. In case of doubt seek advice from

your Busch representative!

The nominal value (=reference value for performance data) for the

temperature of the process gas is 15 °C. The max. allowed temperature

of the inlet gas is 40 °C.

The nominal value for the ambient temperature is 25 °C. The min. al-

lowed ambient temperature is -15 °C. The max. allowed ambient tem-

perature is 40 °C.

Binding data with regard to the allowed differential pressure are to be

read from the nameplate (value with negative sign (“-”) for vacuum

operation, value without sign for pressure operation). The data is valid

for ambient temperatures up to 25 °C and location altitudes up to

1000 m above sea level. Higher ambient temperatures reduce the al-

lowed differential pressures by up to 10 percent at 40 °C. In case of

placement in altitudes beyond 1000 m above sea level the allowed dif-

ferential pressure shall be agreed upon with Busch.

The maximum allowed pressure on the pressure connection (e) is

2 bar abs. By means of process control and/or pressure relief valves it

must be made sure that the maximum allowed pressure will not be

exceeded.

CAUTION_ac

During operation the surface of the side channel blower may reach

temperatures of more than 70 °C.

Risk of burns!

The side channel blower shall be protected against contact during

operation, it shall cool down prior to a required contact or heat pro-

tection gloves shall be worn.

CAUTION_a4

Depending on the construction size the side channel blower may

emit noise of high intensity.

Depending on the operating state the side channel blower may emit

noise in a narrow band.

Risk of damage to the hearing.

Persons staying in the vicinity of a non noise insulated side channel

blower over extended periods shall wear ear protection.

●Make sure that all provided covers, guards, hoods etc. remain

mounted

●Make sure that protective devices will not be disabled

●Make sure that cooling air inlets and outlets will not be covered or

obstructed and that the cooling air flow will not be affected ad-

versely in any other way

●Make sure that the installation prerequisites (Úpage 5: Installation

Prerequisites) are complied with and will remain complied with,

particularly that a sufficient cooling will be ensured

Maintenance

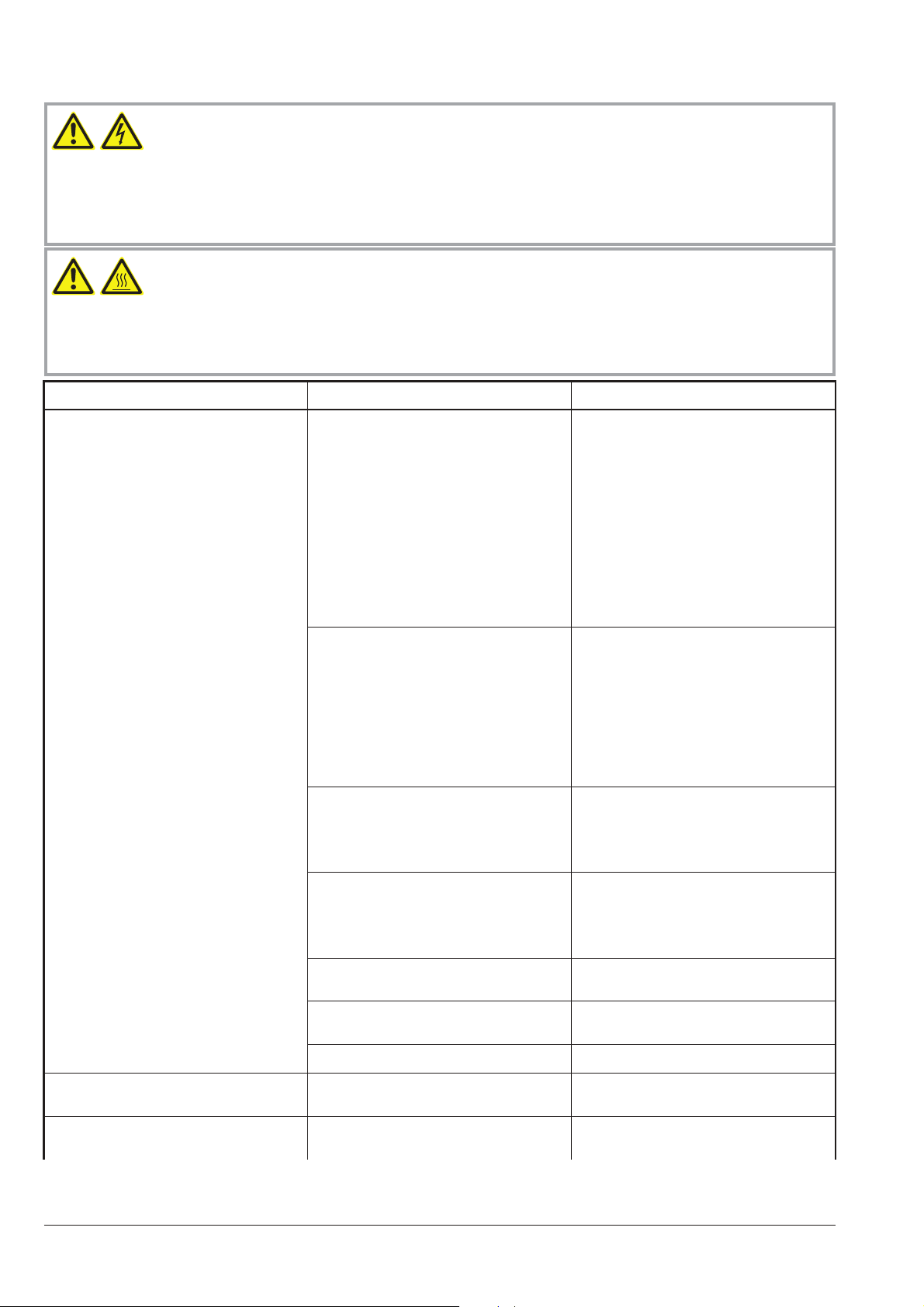

DANGER_age32

In case the side channel blower conveyed gas that was contami-

nated with foreign materials which are dangerous to health, harm-

ful material can reside in filters.

Danger to health during inspection, cleaning or replacement of

filters.

Danger to the environment.

Personal protective equipment must be worn during the handling

of contaminated filters.

Contaminated filters are special waste and must be disposed of

separately in compliance with applicable regulations.

Maintenance

page 7