Table of Contents

2 / 28 0870203784_WZ2400A_-0001_IM_en

Table of Contents

1 Safety .......................................................................................................................................3

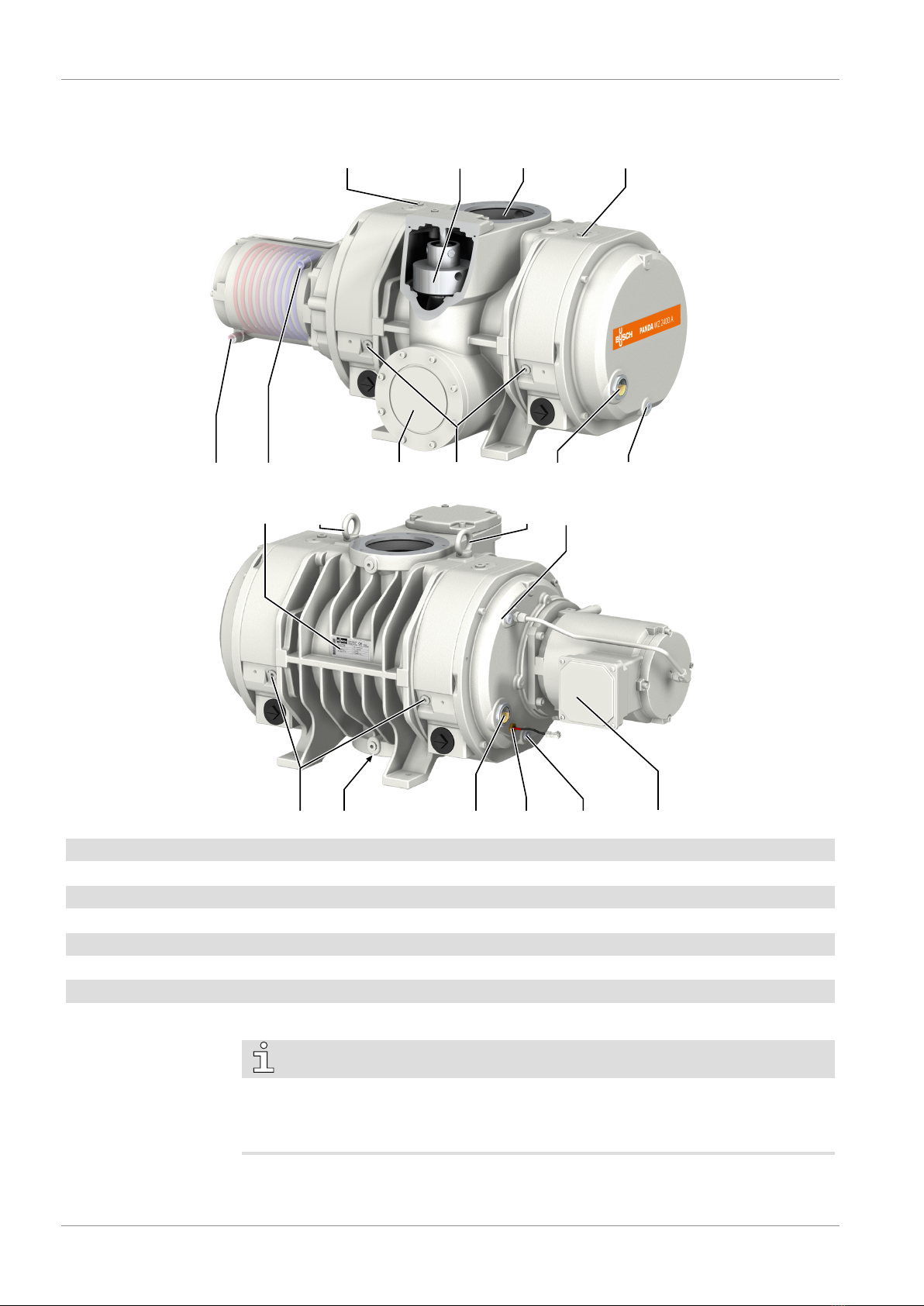

2 Product Description ..................................................................................................................4

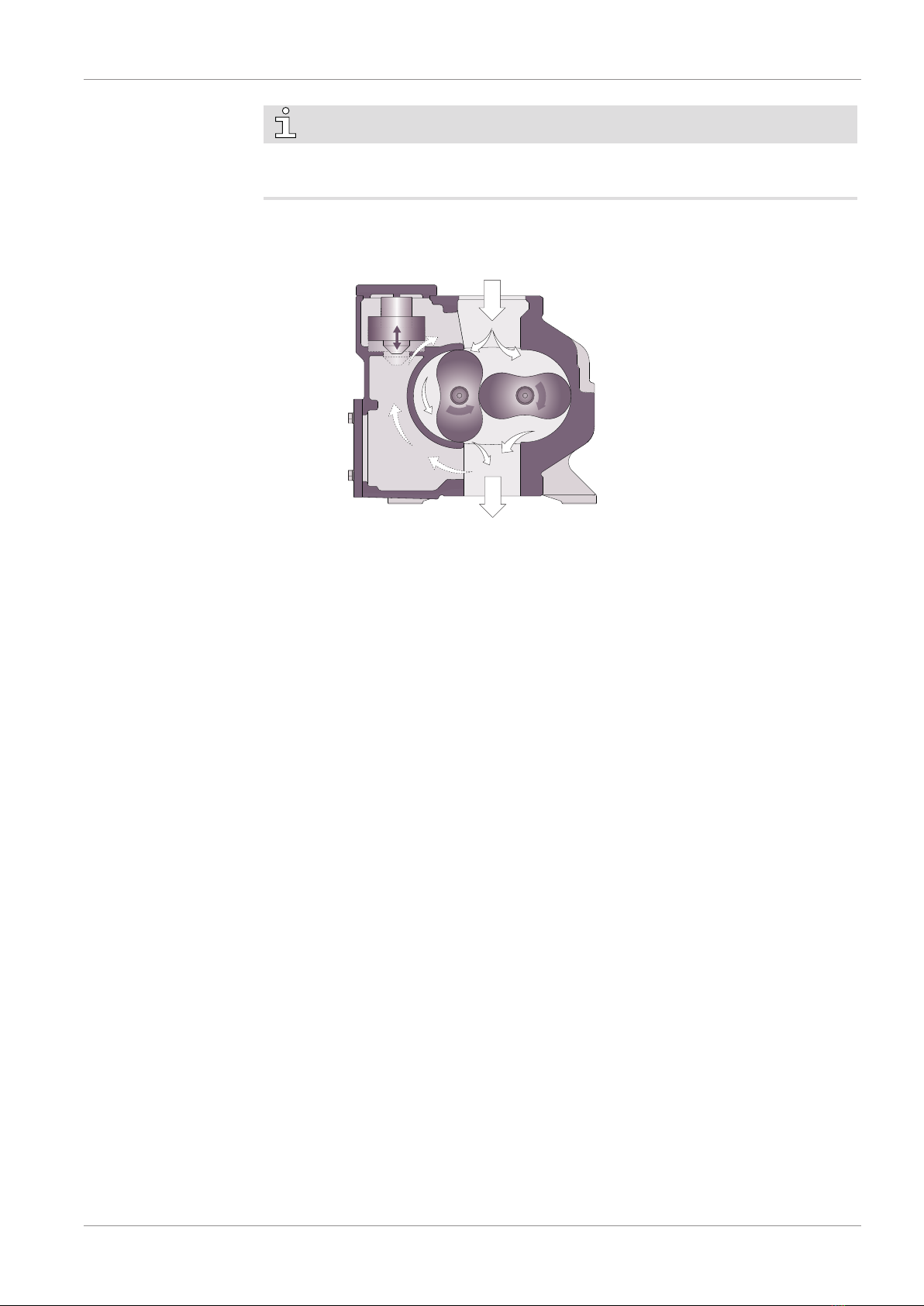

2.1 Operating Principle .......................................................................................................... 5

2.2 Application....................................................................................................................... 5

2.3 Standard Features ............................................................................................................ 6

2.3.1 Water Cooling.......................................................................................................6

2.3.2 Temperature Switch .............................................................................................. 6

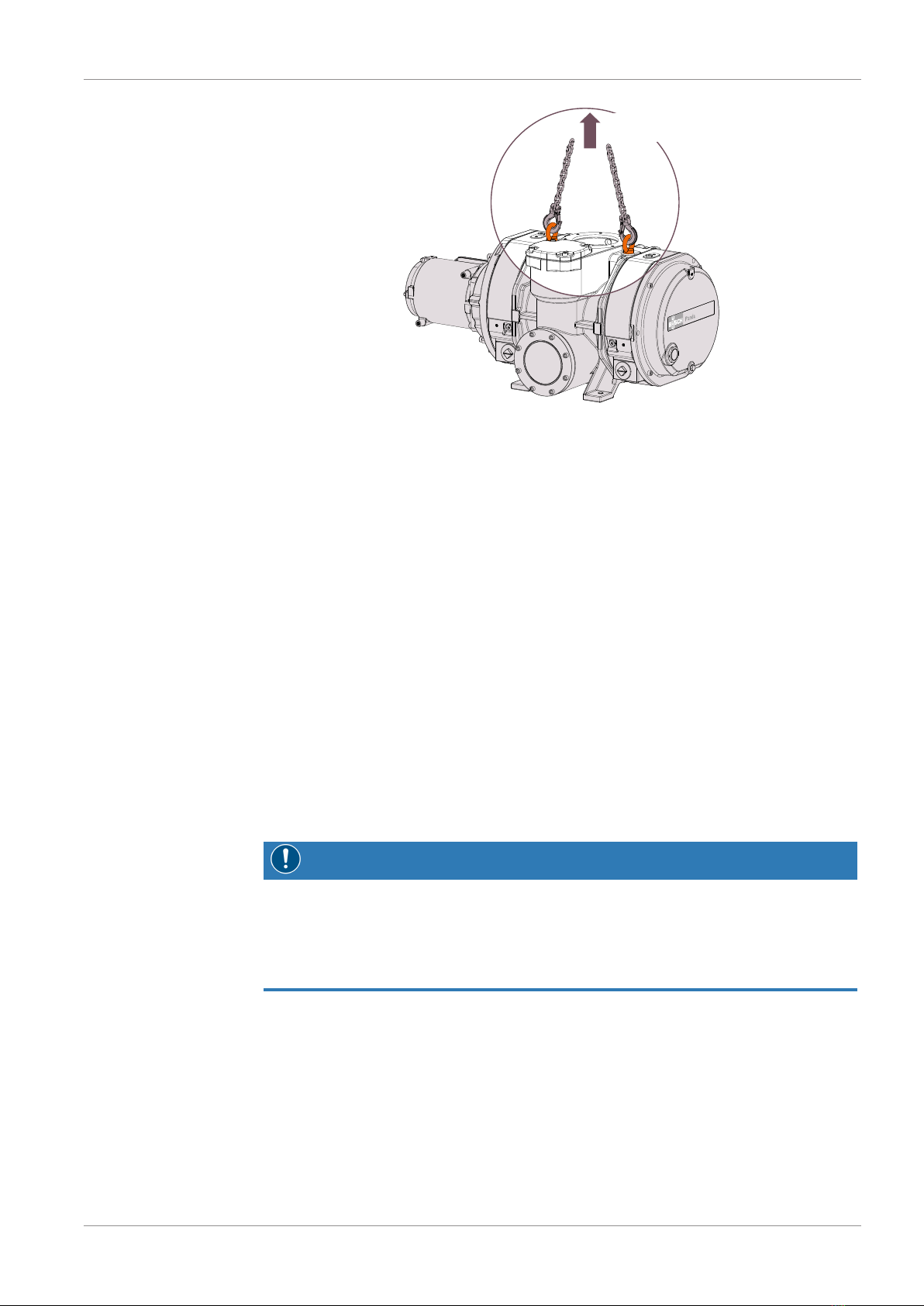

3 Transport ..................................................................................................................................6

4 Storage .....................................................................................................................................7

5 Installation................................................................................................................................7

5.1 Installation Conditions...................................................................................................... 7

5.2 Connecting Lines / Pipes .................................................................................................. 8

5.2.1 Gas Flow Variants.................................................................................................. 8

5.2.2 Suction Connection ............................................................................................... 9

5.2.3 Discharge Connection ........................................................................................... 9

5.2.4 Cooling Water Connection ....................................................................................9

5.3 Filling Oil.......................................................................................................................... 10

5.4 Electrical Connection ........................................................................................................ 12

5.4.1 Wiring Diagram Three-Phase Motor...................................................................... 13

5.5 Electrical Connection of the Monitoring Devices............................................................... 14

5.5.1 Wiring Diagram Temperature Switch..................................................................... 14

6 Commissioning.........................................................................................................................14

6.1 Compression Chamber Flushing ....................................................................................... 15

7 Maintenance.............................................................................................................................16

7.1 Maintenance Schedule ..................................................................................................... 17

7.1.1 With "YLC 250 B" Oil...........................................................................................17

7.2 Oil Level Inspection.......................................................................................................... 17

7.3 Oil Colour Inspection ....................................................................................................... 18

7.4 Oil Change....................................................................................................................... 18

8 Overhaul...................................................................................................................................21

9 Decommissioning.....................................................................................................................21

9.1 Dismantling and Disposal ................................................................................................. 22

10 Spare Parts................................................................................................................................22

11 Troubleshooting .......................................................................................................................22

12 Technical Data..........................................................................................................................25

13 Maximum Permissible Differential Pressures............................................................................26

14 Oil ............................................................................................................................................26

15 EU Declaration of Conformity...................................................................................................27