PARTS BREAKDOWN HAWK 214

PART QUANT. PART

#QUANT.

1. Bottom Blade Holder Assembly FA-46 138. Plastic Blade Holder Clip HA99 1

2. Blade 139. 5/16-18 x 1" Bolt RZ-181 2

3. Blade Holder Arm Insert FA-40 140. 5/16" Lock Washer RZ-178 2

4. 1/8" x 1/2" Roll Pin FA43 141. Rear Table Pivot Bracket HAlO 1

5. 8-32" x 1/2" Allen Head Screw ES-35 142. 1/4-20 x 5/8" Carriage Hd Bolt RB-99 24

6. Blade Holder Side FA-4l 143. Nylon Slide Spacer RB-517 1

7. Top Blade Holder Assembly FA-45 1 44. Table HA04-Z

1

8. 1/8" x 3/4" Roll Pin FA-42 145. 1/4 x 3/4 Sac. Flat Hd Screw RZ-182 2

9. 3/8"16 Hex ut w/ leoprerne Insert RZ-51 346. Table Tilt Thread. Knob 5/16-18 x 1" ES-42 1

10. 3/8" Flat Washer RZ-50 3 47. Table Tilt HA-20-P 1

11. Top Arm HA01 1-i8. Rubber Crornmet HA16 2

12. Bottom Arm HA-06 1 49. Quick Change Hold Rod HA-65 1

13. Bronze Bushings R-369 4-0. Serial Tag HA-28 1

14. Connector Arm Pivot HA-18 2 51. U-Drive Screws FA-12 2

15. Blade Tension Handle HA74 1 52.

r

Handle Allen Wrench 9/64" ES-86 1

16. Round Handle Pivot HA77 153. '18 CA Spacer HA-'14

2

17. Spring FA-36 154. Pittman Arm SA-05 1

18. 10-32 x 1/4" Rd Hd Slotted Screw FA35 255. Bearing PS-07 2

19. Blade Tension Rod SH-Ol 156. Shoulder Bolt 1/2" x 1-1/16" HA13 1

20. Wedge Hold Bracket HA-97 1 57. 3/8-16 Hex Nut RZ-58 8

21. 1/4" Lock Washer RBZ-207 10 58. Clides ES-57 4

22. 1/4-20 x 1-1/4" Hex Hd Bolt PS-80 259. Leg CD-07 4

23. Hold Down Arms HA-l06-Z 1 60. 1/2" Hex Nut HA68 1

24. Threaded Knob w/ 1/4"x 1/2" Stud ES-40 1 61. 5/16" Flat Washer RB-150 3

25. Hold Down Rod SH-12 1 62. Crank Assembly SA-17 1

26. 5/16-18 Hex ut RZ-81 2 63. 1/4" Set Screw RZ-83 1

27. 1/4" Flat Washer RB-l77 16 64. Electrical Cord Set HA60 1

28. Pressor Foot HA-l04 'I 65. Power Switch HA61 'I

29. 1/2" x 1-3/4" Shoulder Bolt HA7l 2 66. Cable Clamp HA76 1

30. Rear Arm Support HA-100 2 67. 10-32 Hex Nut RB-l07 'I

31. 1/4-20 Whiz Nut RB-223 24 68. Machine Screw RB-106 1

32. 1/4-20 Neopreme Lock Nut HA-78 169. Motor ES-44-Z 1

33. 1/4-20 x 1" Hex Hd Bolt PS-52 1 70. Base Braces HA-12 2

34. Base HA02-V 171. Base Tilt HA21-P 1

35. 1/4-20 x 3/4" Hex Hd Bolt RBZ-206 672. Plastic Pointer HA10l 1

36. Rear Table Mounting Bracket HA08 2

37. 10-32 x 1/2" Machine Screw RB-l06 1

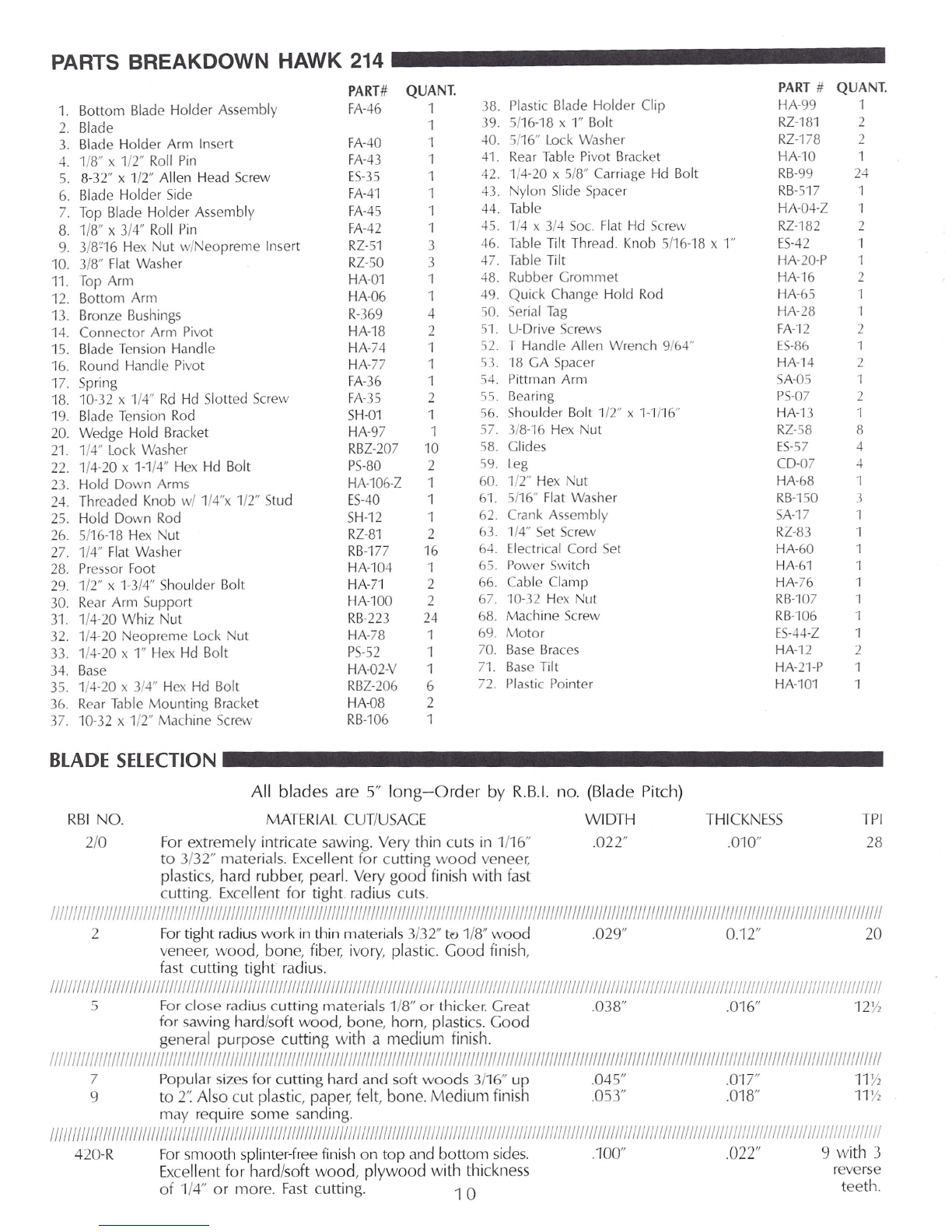

BLADE SElECTION

All blades are 5" long-Order by R.B.I. no. (Blade Pitch)

MATERIAL CUT/USAGE WIDTH

For extremely intricate sawing. Very thin cuts in 1/16" .022"

to 3/32" materials. Excellent for cutting wood veneer,

plastics, hard rubber, pearl. Very good finish with fast

cutting. Excellent for tight radius cuts.

///

/

/

////

///

//

/

/

/

/

/

///

/

///

/

/

////

/

///

/

/

///

///

/

///

/

//

/

/

///

//

/

/

//

//

/

//

/

///

/

/

//

//

//

/

//

//

//

/

/

//

//

//

/

//

////

///

/

/

/

//

/

///

/

/////

/

//

//

//

//

/

/

/

//

//

/

///

//

/

//

/////

/

/

/

//

//

//

////

//

//

/

//

/

/

/

//

/

/

/

/

/

//

//

/

/

/

/

/

/

/

2 For tight radius work in thin materials 3/32" te 1/8" wood .029" 0.12" 20

veneer, wood, bone, fiber, ivory, plastic. Good finish,

fast cutting tight radius.

//////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

5 For close radius cutting materials 1/8" or thicker. Creat .038" .016"

12Y2

for sawing hard/soft wood, bone, horn, plastics. Good

general purpose cutting with a medium finish.

//////////// /// ///I// //// //////////////////////////////////////////////// // /////// //////////////////////////////////////////////////// /////// ///IIIIIIII/IIIIIIIIIIIIIIIIIIIIIIIIIIII/II/III//

7 Popular sizes for cutting hard and soft woods 3/16" up .045" .017"

11}'2

9 to 2': Also cut plastic, paper, felt, bone. Medium finish .053" .018"

llY,

may require some sanding.

1111///1111/////11/11/111111111111/1111/111111/111111111111111111111111111111/111111111111111111111111/111111//1111/1111111111111111111/11111111111111/111111111111111111111111111111111111111

420-R For smooth splinter-free finish on top and bottom sides. .100"

.022" 9

with

3

Excellent for hard/soft wood, plywood with thickness reverse

of

1/4

or more. Fast cutting. 1

0

teeth.

RBI NO.

2/0

THICKNESS

.010"

TPI

28