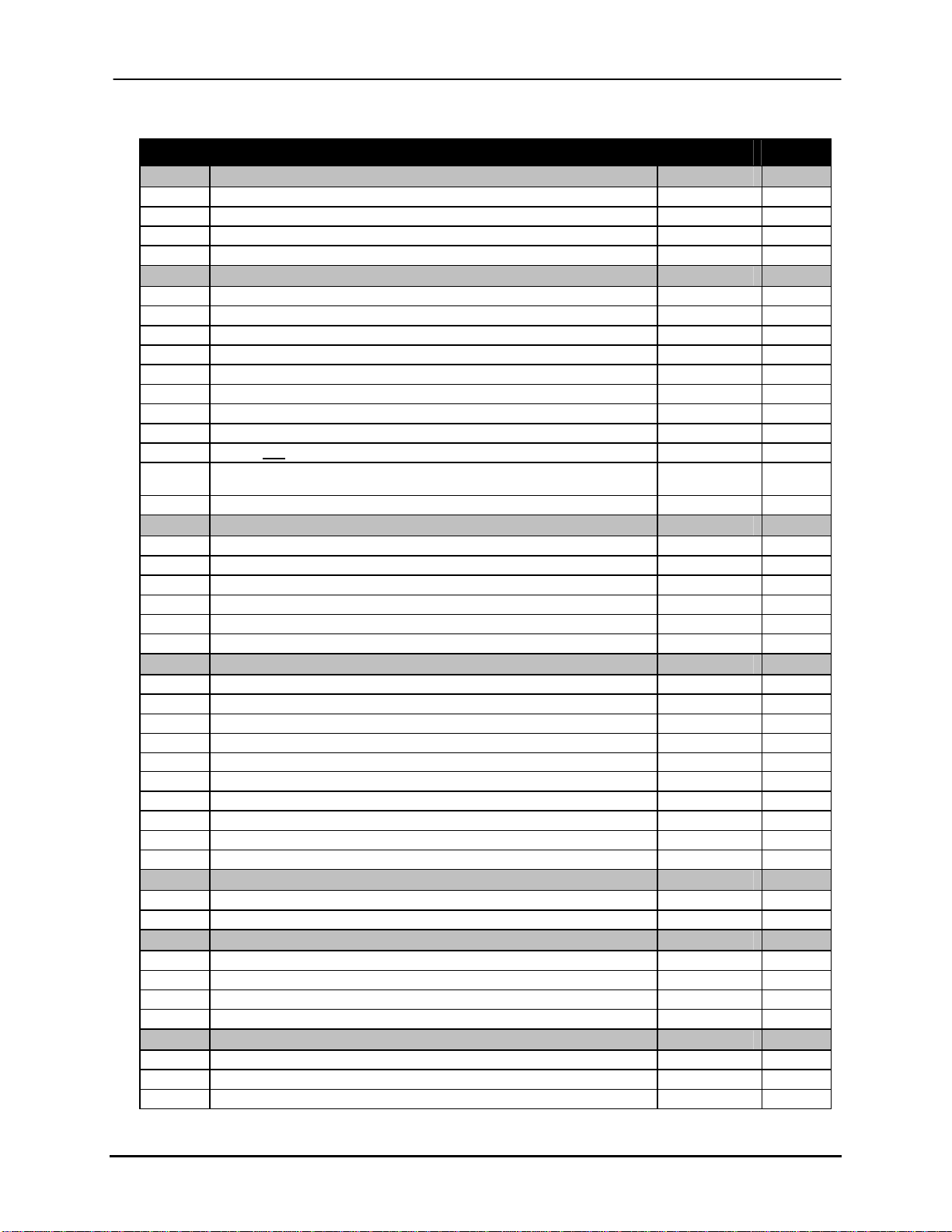

Chapter 1 General Information Page 1-4

Table 1-1:Feature Comparison (Compose IQ and SI)

No. Feature description Si IQ

1 Job Handling

1.1 Multiple List Types: text, MS Access, Dbase, Foxpro, Excel √√

1.2 Multiple Code Pages; Foreign character sets √√

1.3 Multiple Copy Printing √

1.4 Job Preparation and Recall √√

2 Setup

2.1 Stacker/Diverter Control √√

2.2 Printhead Supported: Apollo, Atlas, Atlas UVC, Elite √√

2.3 Printhead Micro-Alignment √√

2.4 Master/Slave Communication √

2.5 Product Tracking; up to 8 zones √

2.6 (Optional) OCR for camera/database lookup applications √

2.7 (Optional) Selective for control of feeder and other devices √

2.8 Print Verification √

2.9 English only Language Interface √

2.10 English, French, Spanish, German, Japanese, Korean, Chinese (simplified,

traditional), Thai Language Interface √

2.11 Password Protection √√

3 Operator Display

3.1 Record Navigation Tools √√

3.2 Record Search, Re-printing, and Cueing √√

3.3 Record Status Color Coding √√

3.4 Single Record Display - Static √

3.5 Multiple Record Display – Real-time refresh √

3.6 Operator View: Multiple record or product tracking √

4 Layout

4.1 Text: Fixed and Variable up to 99 components @ 255 characters/field √√

4.2 128 frames per printhead √√

4.3 Graphics: Fixed and Variable, Bitmap √√

4.4 Barcode; Linear: Code 128, Codabar, EAN, UPC, 2 of 5, 3 of 9 √√

4.5 Barcode, postal: Postnet, Planet ALL

4.6 Barcode, 2D: Datamatrix ECC200, PDF417, QR √

4.7 Alignment Tools : 0, 90, 180, 270 orientation √√

4.8 Text Manipulation Tools: typeface, alignment, True Type √√

4.9 Serial Numbering √√

4.10 Time and Date Stamping √√

5 Reports (Crystal)

5.1 Production: Job, Machine √

5.2 Audit: completed, not completed, duplicate, lost/wasted records √

6 Diagnostics

6.1 Printhead test label and test firing √√

6.2 Input Sensors and Output Device testing √√

6.3 Encoder Scope √√

6.4 Printhead Parameter Viewing √√

7 General

7.1 Windows-based, XP compatible (Compose V6.0) √√

7.2 Multiple Print Resolutions: 110, 150, 220, 330, 440, 660 √√

7.3 Core Charge Rebate applicable √

Buskro Ltd. BK760 / BK76IB Inkjet