Operators Manual Model : LT

Manual No. :132.2008.01.03

Release Date : Pending

Butterworth®, Inc. – 16737 West Hardy Street – Houston, TX 77060 - USA Page 2 of 36

Phone : 281.821.7300

Fax : 281.821.5550

Web Site : www.butterworth.com

TABLE OF CONTENTS

TABLE OF CONTENTS ...............................................................................................................................................................................................................2

INTRODUCTION ..........................................................................................................................................................................................................................3

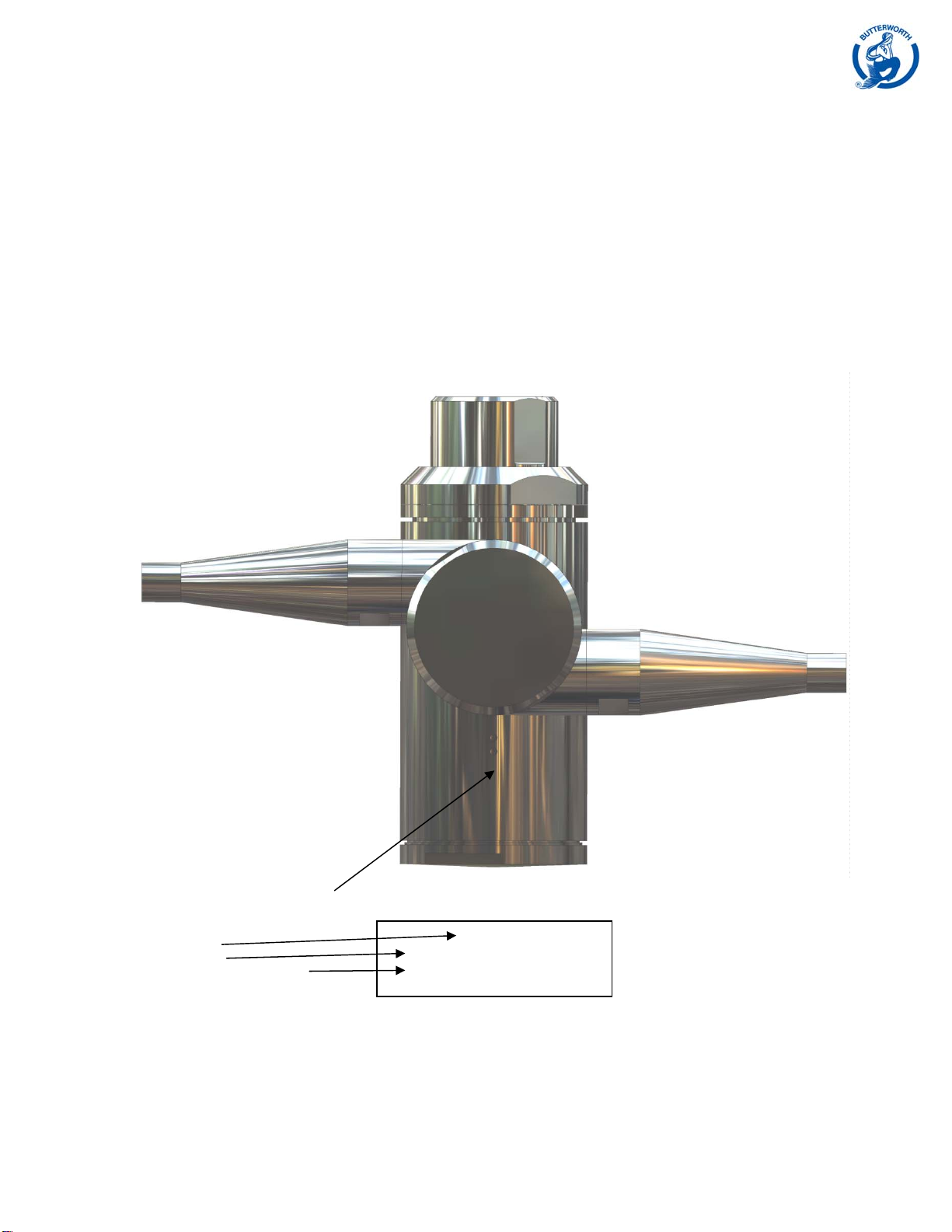

GENERAL DESCRIPTION...........................................................................................................................................................................................................4

How It Works...........................................................................................................................................................................................................................................4

Standard configurations: .........................................................................................................................................................................................................................5

INSTALLATION INSTRUCTIONS................................................................................................................................................................................................6

TECHNICAL DATA ......................................................................................................................................................................................................................7

Dimensions and Weight ..........................................................................................................................................................................................................................7

Performance Curves – PRESSURE & FLOW ......................................................................................................................................................................................... 8

Performance Curves – Pattern Time.......................................................................................................................................................................................................9

Performance Curves – Jet Length......................................................................................................................................................................................................... 10

INSTALLATION AND NORMAL OPERATION..........................................................................................................................................................................11

General Installation Instructions............................................................................................................................................................................................................ 11

MAINTENANCE AND REPAIR..................................................................................................................................................................................................12

PREVENTIVE MAINTENANCE............................................................................................................................................................................................................. 12

TOP ASSEMBLY .................................................................................................................................................................................................................................. 13

Disassembly.............................................................................................................................................................................................................................................................. 13

Reassembly............................................................................................................................................................................................................................................................... 13

Top Assembly - Exploded View Drawing.............................................................................................................................................................................................. 14

Impeller housing sub-assembly............................................................................................................................................................................................................. 15

Disassembly.............................................................................................................................................................................................................................................................. 15

Reassembly............................................................................................................................................................................................................................................................... 15

Impeller housing sub-assembly - Drawing............................................................................................................................................................................................. 16

Bottom Assembly.................................................................................................................................................................................................................................. 17

Disassembly.............................................................................................................................................................................................................................................................. 17

Reassembly............................................................................................................................................................................................................................................................... 17

Bottom Assembly - Exploded View Drawing.......................................................................................................................................................................................... 18

Hub SubAssembly................................................................................................................................................................................................................................. 19

Hub SubAssembly - Drawing................................................................................................................................................................................................................. 20

Gearbox SubAssembly.......................................................................................................................................................................................................................... 21

Gearbox SubAssembly - Drawing ......................................................................................................................................................................................................... 22

Tool Listing............................................................................................................................................................................................................................................ 23

TOOLS .......................................................................................................................................................................................................................................24

TROUBLE SHOOTING GUIDE..................................................................................................................................................................................................26

REFERENCE LIST OF PARTS..................................................................................................................................................................................................27

EXPLODED VIEW DRAWING....................................................................................................................................................................................................32

CROSSECTIONAL DRAWING ..................................................................................................................................................................................................33

STANDARD SPARE PART KIT.................................................................................................................................................................................................34

LUBRICANT SPECIFICATION ..................................................................................................................................................................................................35

HOW TO ORDER SPARE PARTS AND WARRANTY CLAIM PROCEDURE..........................................................................................................................36

Ordering Spare Parts............................................................................................................................................................................................................................ 36

Warranty Claim Procedure.................................................................................................................................................................................................................... 36