III

TABLE OF CONTENTS

1

General information....................................................................................................................................1

2

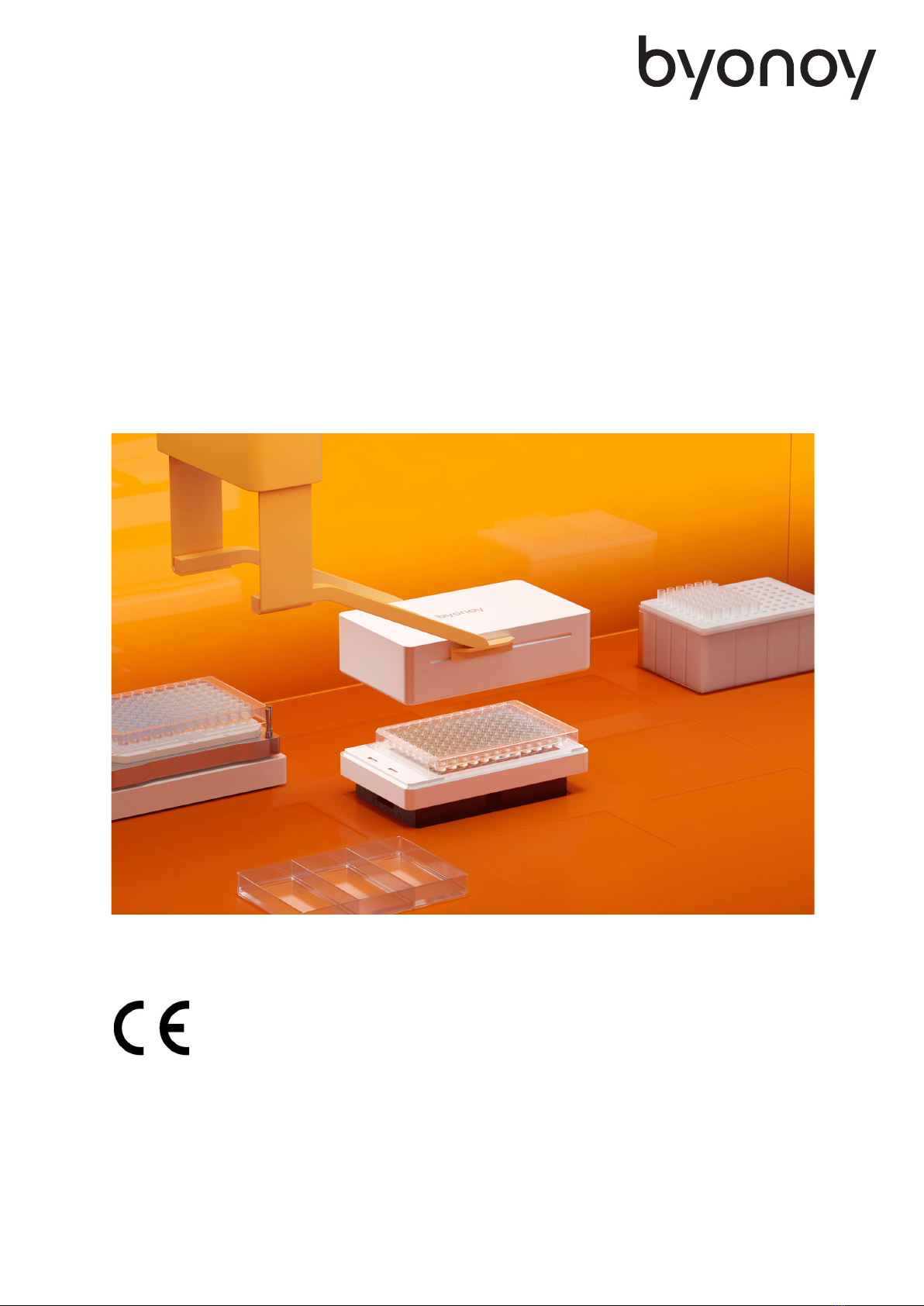

Overview of Absorbance 96 Automate ......................................................................................3

2.1 Scope of application .................................................................................................... 3

2.2 Measurement method ................................................................................................. 3

2.3 Absorbance 96 Automate System ............................................................................ 4

2.4 Consumables .................................................................................................................. 5

3

Preparing the product for use.......................................................................................................... 6

3.1 Unpacking, storage, and transport ........................................................................... 6

3.2 Supplied materials ........................................................................................................ 6

3.3 Working environment .................................................................................................. 7

3.4 Installation ...................................................................................................................... 7

4

Operation ......................................................................................................................................................... 9

4.1 App installation procedure and updates .............................................................. 10

4.2 Computer connection ................................................................................................ 10

4.3 Workflow ....................................................................................................................... 10

5

Signals and troubleshooting.............................................................................................................12

5.1 Signal lights .................................................................................................................. 12

5.2 Troubleshooting ......................................................................................................... 12

6

Maintenance and cleaning.................................................................................................................14

6.1 Maintenance ................................................................................................................ 14

6.2 Cleaning ........................................................................................................................ 15

6.3 Technical support ....................................................................................................... 16

6.4 Repairs .......................................................................................................................... 16

7

Technical specifications.......................................................................................................................17

8

Guarantee .......................................................................................................................................................19

9

Declaration of Conformity................................................................................................................. 20