C & K Systems DT-6360STC User manual

- 1 -

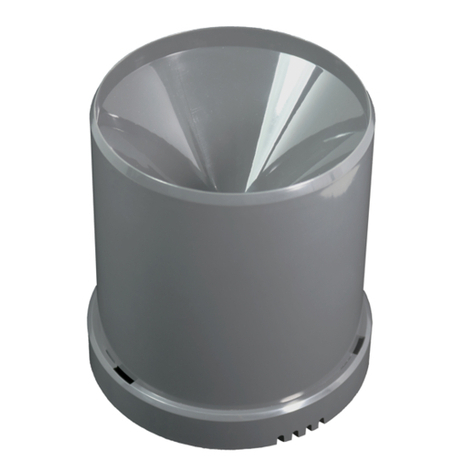

Ceiling Mount Motion Sensor

INSTALLATIONINSTRUCTIONS

Model

DT-6360STC

RECESS

BUCKET

DT-6360STC

RETAINER

RING

If using the retainer ring, place it through, then directly over, the

hole in the ceiling tile. Make sure to orient the retainer ring

and recess bucket as shown in Figure 1.

Next, attach the back housing of the DT-6360STC to the inside

of the recess bucket, using the same screw holes and screws

used for surface mounting [#6 (M3.5) pan head]. Pull several

inches of wiring from the ceiling through the center hole in the

recess bucket and DT-6360STC back housing.

Insert the recess bucket into the hole in the ceiling, securing it to

the ceiling (and retainer bracket) with four mounting screws.

The DT-6360STC is shipped with a special kit for flush mounting.

The kit contains a recess "bucket" and retainer ring. The retainer

ring is only needed when flush mounting the unit in ceiling tile.

Removing the tile from the ceiling (if possible) will make the

installation process easier.

FlushMounting

IMPORTANT: ToensureinsectsdonotgetinsidetheDT-6360STC

housing, make sure to seal all holes. (Recommended sealant:

silicone RTV.)

Note: If surface wiring, use the knockout hole on the side of the

housing.

If mounting the DT-6360STC directly on a ceiling, use the back

cover as a template to mark holes for the mounting screws and

wiring. Drill the holes. Then pull several inches of wiring from

the ceiling through the center hole in the back housing.

Attach the back housing to the ceiling with the mounting screws.

Recommended mounting screws: #6 (M3.5) pan head.

Surface Mounting

To remove the front cover, orient the DT-6360STC so that one of

the sides with the small rectangular slot in the center is visible.

Using a small flathead screwdriver, gently push down on the slot

while separating the housing parts. Set the front cover aside.

Remove the printed circuit board (PCB) by depressing one of

the retaining brackets at its sides. Use the microwave antenna

to carefully pull the PCB out.

MOUNTING PROCEDURE

Note: If you plan to use the DT-6360STC's tamper

switches, read theTamper Installation section on page 1.

CEILING

Figure 1

DT-6360STC

FlushMountingKit

The DUAL TEC®6360STC motion sensor provides maximum

coverage when mounted on ceilings from 8' (2.4 m) to 16' (4.8

m) high. Refer to the System Set-up section to determine which

passive infrared (PIR) mirror assembly to use at different ceiling

heights.

Choose a mounting location in the center of the protected area.

The protected area should be free of objects that might prevent

the PIR sensor from detecting an intruder: large pieces of

furniture, room dividers, etc.

Remember, infrared energy cannot penetrate solid objects. If the

PIR detector is blocked, the DT-6360STC will not trigger an alarm.

MOUNTING LOCATION

To flush mount the unit, cut a 5.5" x 5.5" (14 cm x 14 cm) hole in

the ceiling. Insert the recess bucket into the hole, using it as a

template to mark drill holes for the four mounting screws.

Remove the bucket and drill the screw holes.

The DT-6360STC is equipped with two tamper switches: a cover

tamper and ceiling tamper. When the tamper switches are used,

removing the cover from the sensor will activate the cover tamper;

removing the sensor from the ceiling will activate the ceiling

tamper. Both tamper switches are normally closed (NC) and

internally wired in series.

The cover tamper switch can be used without the ceiling tamper

and requires no modifications to the DT-6360STC housing.

To use the ceiling tamper, remove the square knockout in the rear

housing (directly behind the ceiling tamper switch), then install a

screw* in the ceiling. Leave enough of the screw protruding to

depress the tamper switch. Refer to Figure 2.

If the installation is recessed, remove the knockout from the rear

housing, drill a screw hole (behind the knockout) in the recess

bucket, then install the screw* in the recess bucket. Leave

enough of the screw protruding to depress the tamper switch.

Refer to Figure 2.

SURFACE MOUNT FLUSH MOUNT

CEILING

DT-6360STC

Screw

to depress

tamper

Screw

to depress

tamper DT-6360STCinside

recess bucket

CEILING

PINFORPCB

KEYHOLE

REAR HOUSING

KNOCKOUT

LATCH

Figure 2

Cover and Ceiling

TamperSwitches

*Note: #6 (M3.5)

pan head is

recommended.

TamperInstallation

- 2 -

SYSTEMSET-UP

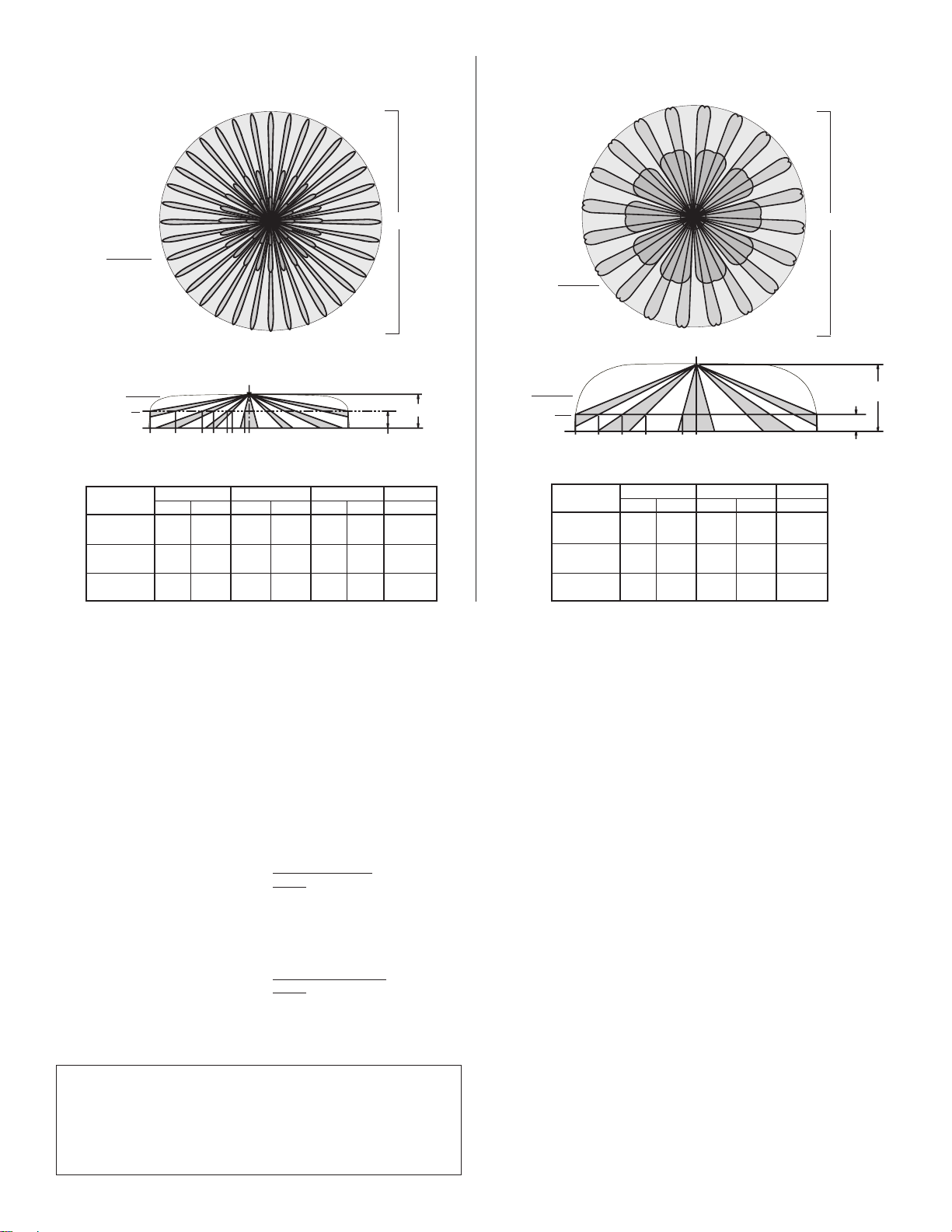

The DT-6360STC package contains two PIR mirror assemblies:

oneforceilingsfrom8'(2.4m)to11'(3.3m)high,anotherforceilings

from 12' (3.65m) to 16' (4.8m) high. The unit is shipped with the

8'-11' (2.4m-3.3m) mirror installed.

To change the mirror assembly, remove the front cover and turn it

over. Next,removetheprotective capandexistingmirrorassembly

by depressing the four retaining latches at their sides. Store (or

discard) the existing mirror and install the new one. Snap the

protective cap back into place, then replace the front cover.

Changing the PIR Mirror Assembly

PIR Masking

To eliminate specific PIR zones from the pattern, mask corre-

sponding segments on the PIR mirror with the adhesive-backed

masking tape provided. Remember, segments to be masked

will be on the side of the mirror OPPOSITE the unwanted zones.

See Figure 4.

Once the tape has been applied, walk-test the sensor to ensure

that the correct mirror segments have been masked.

PIRMASKING

MATERIAL

PLACEDHERE

WILLBLOCKZONES

HITTINGHERE

Figure 4

Masking the PIR Mirrors

1

SYSTEM TESTING

DT-6360STC sensors are equipped with two diagnostic LEDs:

green for PIR and yellow for microwave. The red LED is used to

indicate an alarm condition.

Apply power to the sensor and wait until self-test is completed (90

seconds). Begin walk-testing after all three LEDs have gone out.

Figure 5

DT-6360STC PCB

2

EOL = End-of-Line (spare) terminal.

The Trouble Output is activated when a self-test failure or an INFORMER®condition occurs.

Refer to THE INFORMER CIRCUIT and the TROUBLESHOOTING sections.

Observing the proper polarity, wire the sensor as shown below

(use 22 to 14 AWG). Note: Reverse polarity will not damage the unit.

WIRING

NC COM NO V-

TAMPER SWITCH

Normally Closed

(NC) with cover on

25 mA, 30 VDC.

122

EOL TBL EOLCMD

REMOTE LED ENABLE or

COMMAND INPUT

(Self-TestInitiate)Active

Low 0 to 1.5 V Inactive

High 6 to V+ Input

Impedance 110 Kohms

(minimum).

OPEN COLLECTOR

TROUBLEOUTPUT

Vce .3V max @ 50

mA. 1K series

protection resistor.

1

Figure 3

Wiring

Diagram

ALARMRELAY

125mA, 25VDC. 22ohm

series protection resistor.

POWER

At 12 VDC,

typically

40 mA;

maximum

50 mA

Note: Do not leave excess wire inside the unit. Push as much wire as

possible into the ceiling when returning the PCB to its housing.

Note: For proper wiring methods, refer to National Electrical Code NFPA 70.

Removing Front Cover After Installation (flush mount)

After installing and walk-testing the DT-6360STC flush mount, you

may need to make adjustments. Use a screwdriver to reopen the

front cover.

Insert the screwdriver as far as it will go in the grooves inside the

recess bucket. Gently press outward to release the latches holding

the front cover in place.

DT-6360STC sensors are equipped with a microwave range

thumbwheel (R32) for range adjustment. (Refer to Figure 5.)

Set the range at MINIMUM by turning the thumbwheel all the

way to the left.

As you perform the walk-test, gradually turn the thumbwheel to

the right to increase the microwave sensitivity until the desired

ranged is obtained.

Microwave Range Adjustment

Walk-test

Walk across the protected area at the ranges to be covered.

Two to four normal steps make the diagnostic LEDs light, and

the red LED should indicate an alarm condition. When there is

no motion in the protected area, all three LEDs should be off.

COMMAND INPUT / REMOTE LED ENABLE

Position W4 determines what function the Command Input

(CMD) terminal will provide.

Installing a jumper at position W4 makes the CMD terminal

function as a Remote LED Enable terminal. If the signal to the

Remote LED Enable terminal is low, the LEDs are enabled. If

the signal to the terminal is high, the LEDs are disabled. How-

ever, if a self-test error occurs, the LEDs will light regardless of

the state of the signal.

The CMD terminal functions as a Command Input terminal when

the jumper is removed from position W4. A momentary low

signal to the terminal (at least .5 seconds) will initiate the self-

test.

LED DISABLE (Local)

To disable the diagnostic LEDs and alarm LED, remove the

jumper from position W2 on the PCB. (See Figure 5.)

*If Self-Test fails or an INFORMER condition occurs, LEDs indicates nature of problem (see Tables 1,2 & 3)

ALARM&DIAGNOSTIC LEDs:

Yellow - During normal operation LED flashes ON when a MICROWAVE event is detected.*

Green - During normal operation LED flashes ON when a PIR event is detected.* (PIR Zone Finder)

Red - During normal operation LED illuminates when an ALARM condition is triggered.*

REMOTELEDENABLE

or COMMAND INPUT

Jumper W4 installed:

CMD terminalfunctions

asRemoteLEDEnable.

Jumper W4 removed:

CMD terminalfunctions

as Command Input.

(Set toCommand Input

atfactory)

INSTALLERINITIATED

SELF-TEST

MOMENTARYSHORT

INSTALLJUMPERW3

TO DISABLE TROUBLE

OUTPUTWHENAN

INFORMER CONDITION

OCCURS

(jumper is

factory installed)

W2

REMOVEJUMPER

W2TODISABLE

DIAGNOSTICLEDS

ANDALARM LED

(jumper is factory

installed)

RED

GREEN

YELLOW

PLACEJUMPERW1

TODETERMINEPIR

SENSITIVITY

(jumper set to

normal at factory;

see page 3)

MICROWAVERANGE

THUMBWHEELR32

(setto

maximumatfactory)

TOP

BOTTOM

TAMPERSWITCH

MAX

R32

W4

W3

W1

V+

- 3 -

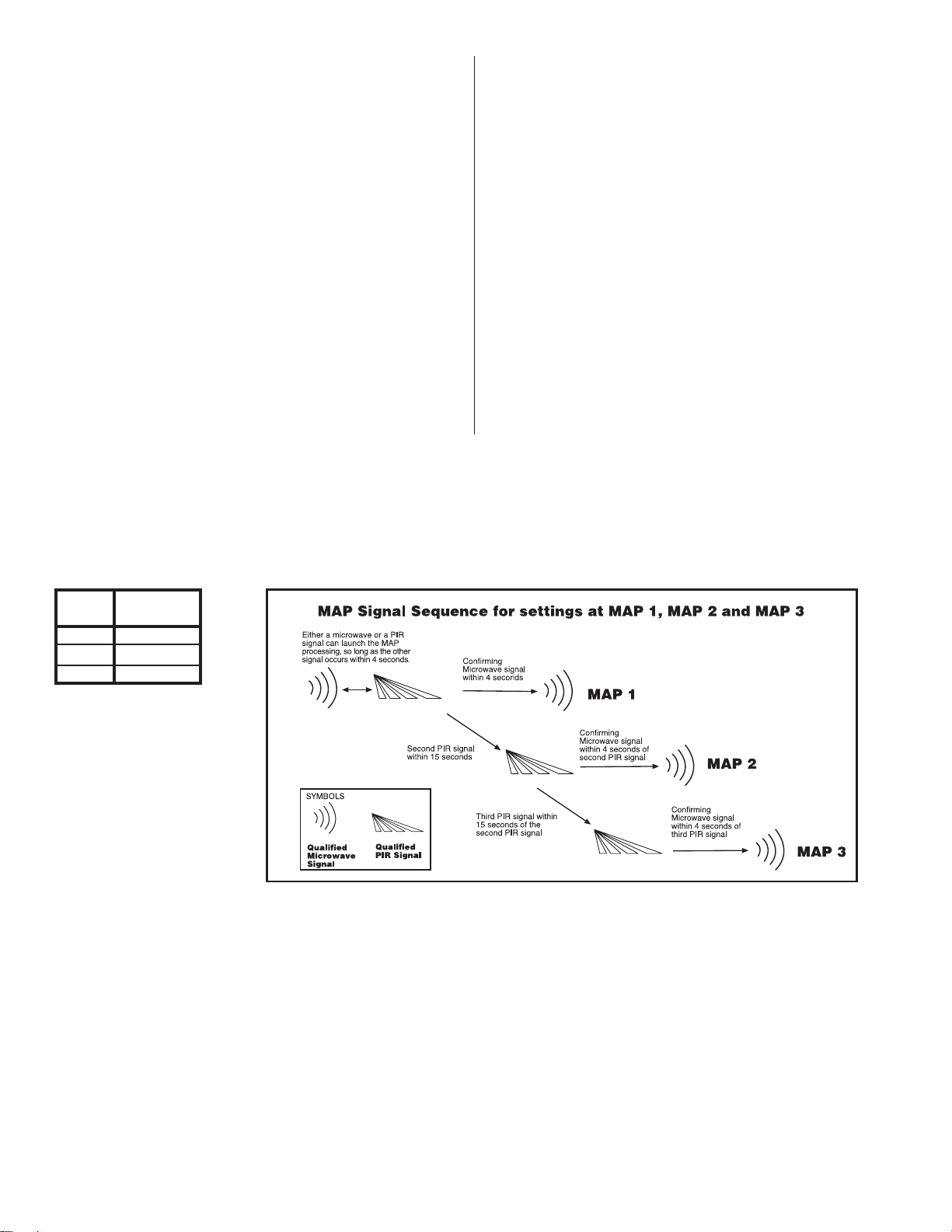

DT-6360STC sensors use the event sequence in Figure 6

(below) to determine an alarm:

If the microwave technology malfunctions (determined by a self-

test), the sensor reverts to a PIR sensor.

DT-6360STC ALARM SEQUENCE (MAP PROCESSING)

Note: An event is the detection of a microwave signal or a single

edge of a PIR signal. (The PIR pulse count is 3.)

•

If a self-test error is detected

, the self-test LED pattern

replaces the INFORMER LED pattern and the Trouble

output becomes active for eight seconds. (Refer to the

Troubleshooting Matrix on page 4.)

THE INFORMER CIRCUIT

The INFORMER circuit counts the number of events registered

by both the microwave and PIR technologies, and uses the

resulting ratio to determine if either technology is misapplied or

working properly.

The informer ratio is preset at 32 to 1. This ratio means that before

one technology registers 32 events, the other must register at

least one event. If it does not, trouble will be signaled.

When an INFORMER condition occurs, the trouble output

becomes active until the INFORMER condition is cleared, and

the LEDs display an INFORMER trouble code. (By installing the

jumper at position W3, the LEDs will display an INFORMER

trouble code, but there will be no trouble output. See Figure 5.)

The DT-6360STC immediately performs a self-test to determine if

the problem is internal.

•

Note: If eight microwave (and no PIR) events occur within one

minute, the INFORMER circuit will disable itself for eight minutes.

This feature allows the INFORMER circuit to compensate for

temporary environmental disturbances. If a PIR event occurs

during the disable period, the microwave is automatically reset.

Figure 6

MAP Signal Sequence

Important: If the LEDs are enabled by Remote LED Enable and an

INFORMER condition occurs, the LEDs will flash the INFORMER

trouble code until the condition is cleared, even if the LEDs are

subsequently remotely disabled.

M.A.P.

Processing W1 Jumper

Position

1

2

3

On pins 1 & 2

On pins 2 & 3

Removed

If no self-test error occurs

, the unit continues to display the

INFORMER LED pattern. The problem is misapplication.

Walk-test the DT-6360STC to pinpoint the cause.

- 4 -

1Return the DT-6360STC to C&K for repair.

Send the unit in for repair.1

Send the unit in for repair.1

Microwave Pulse Self-Test

Temperature Compensation

Self-Test

ALARM MW PIR

TEST DESCRIPTION (Red) (Yellow) (Green) ACTION

Table 3

Trouble Output

Troubleshooting

Matrix

ALARM MW PIR

TEST DESCRIPTION (Red) (Yellow) (Green) ACTION

DT-6360STC sensorsautomaticallyperformaseriesofself-testsin

the following instances: when the unit is powered up, when the

tests are installer initiated, upon command input, and periodically

during normal operation as on-going self-tests. When a self-test

erroroccurs,all three LEDsflash (if enabled)and the troubleoutput

becomes active until the failure is cleared. The following chart

describes how the diagnostic LEDs appear during self-tests, and

what action needs to be taken for each type of display.

Table 2 INFORMER

TroubleshootingMatrix

Note: If you enter the detection

pattern and the LEDs go off, you

canretrievethe LEDpatterntopin-

point the problem. Refer to the

Trouble Memory section below.

Power Up Self-Test

On Line - All Self-Tests Passed,

Ready for Walk-Test

1Return the DT-6360STC to C&K for repair.

Table 1

Self-Test

Troubleshooting

Matrix

The troubleshooting matrix below describes two trouble alerts

which are reported by the INFORMER circuit. To use this trouble-

shooting matrix:

1) Find the trouble alert that describes the condition of the

walk-test LEDs (with no motion in the area).

2) Walk-test the sensor, carefully watching the reaction of the

diagnostic LEDs.

3) Refer to the Possible Causes column of the matrix for an

explanationof the way in which the diagnosticLEDs reacted

to the walk-test.

Condition of LEDs

with No Motion

ALARM

(Red) MW

(Yellow) PIR

(Green) ALARM

(Red) MW

(Yellow) PIR

(Green)

Reaction of LEDs

to Walk-Test

RATIO

IMBALANCE

MW environmental problem

MW unstable

MW range too long

PIR was blocked

PIR environmental problem

PIR unstable

MW range too short

RATIO

IMBALANCE

Type of

Problem Possible

Causes

PIR range too short

PIR aimed wrong

PIR not reporting

MW range too short

MW not reporting

RATIO

IMBALANCE

RATIO

IMBALANCE

(Pattern disappears)

(Pattern disappears)

No action required.

Unit is working properly.

TROUBLESHOOTING THE DT-6360STC

Send the unit in for repair.1

On-going Self-Test

When the DT-6360STC signals a trouble output, the LEDs display

a failure pattern — all three LEDs flash at the same rate.

You can recover the individual pattern to determine what trouble

occurred. To recover the LED pattern, remove the front housing

from the unit. Use a screwdriver to connect the two (self-test) pins

at the left-hand side of the PCB (see Figure 5) and cause a

momentary short. The trouble LED pattern will reappear.

TROUBLEMEMORY Connect the pins with the screwdriver again to clear the LED

pattern.

Notes: The Trouble Memory only stores a single event (the last

event to occur) in memory. Once the LED pattern is cleared, the

memory is erased, and the self-test restarts.

The matrix below shows the individual patterns and the appro-

priate action.

LED Legend: = LED is Flashing Fast = LED is OFF

= LED is Flashing Slow = LED is ON

- 5 -

SIDEVIEW

TOPVIEW

TOPVIEW

50' (15 m)

50' (15 m)

microwave

microwave

Floor

SIDEVIEW

DETECTION PATTERN DETECTION PATTERN

8'-11' (2.4m-3.3m)

mirror assembly 12'-16' (3.65m-4.8m)

mirror assembly

microwave

microwave

PRODUCT SPECIFICATIONS

Alarm relay:

Energized Form C (NC)

22 ohm series protection resistor

125 mA, 25 VDC

Range:

50' (15m) diameter

[25' (7.6m) radius]

Tamperswitch:

Form A (NC)

25 mA, 30 VDC

Dimensions:

5" high x 5" wide x 2.3" deep

(12.7 cm x 12.7 cm x 5.8 cm)

Sensitivity:

2-4 normal steps

within field of view

PIR fields of view:

8'-11'(2.4m-3.3m)

mirror

Three 360ofields

36 long range zones

24 intermediate

16 short range

1 look-down

12'-16'(3.65m-4.8m)

mirror

Two 360ofields

40 long range zones

20 intermediate

1 look-down

Troubleoutput:

Open collector

voltage between

collector and

emitter (Vce) is

.3V max at 50 mA

(For future use)

PIR white light

immunity:

900LUX

Power requirements:

10 - 12.9 VDC ,

typically 40 mA

50 mA maximum,

AC Ripple: 3 V peak-

to-peak at nominal

12VDC

Operating

temperature:

32oto 120o F

(0oto 49oC)

Weight:

14 oz (397 g)

Relative

humidity

5% to 95%

(non-condensing)

Approvals/listings:

CE (EMC Directive)

FCC certified

UL listed

*ULC listed

IC certified

Standardaccessories

included:

DT-6360STCrecesskit;

PIR masking material

Command input:

Self-test initiate

Active low 0 to 1.5V

Inactive high 6 to V+

Input impedance

110K (minimum).

(For future use)

RFimmunity:

30 V/m,

10 MHz-1000MHz

Frequencies:

Center band -

10.525 GHz (USA),

may vary in other

countries

For UL certificated installation, the DT-6360STC must be con-

nected to a UL listed power supply or UL listed control unit

capable of providing a minimum of four hours of standby power.

Important Notices *The ULC label or listed marking on a product is the only evidence

provided by Underwriters Laboratories of Canada to identify products

that have been produced under the Listing and Follow-up Service.

4' (1.2m)

Above Floor

GFEDCBA

Mounting Height

4' (1.2m) Floor

4' (1.2m)

Above Floor

EDCBA

4' (1.2m)

Mounting Height

CENTER

MOUNTING

HEIGHT

12' (3.65m)

14' (4.2m)

16' (4.8m)

OUTER TIER INNER TIER E

2.3'

(0.7m)

3.4'

(1.04m)

2.9'

(0.9m)

AB C D

19.8'

(6m)

24.8'

(8m)

29.7'

(9m)

16.0'

(4.8m)

24.0'

(7.3m)

12.1'

(3.68m)

15.2'

(4.6m)

18.2'

(5.5m)

8.3'

(2.5m)

10.3'

(3.1m)

12.4'

(3.78m)

20.0'

(6m)

CENTER

MOUNTING

HEIGHT

8' (2.4m)

9' (2.7m)

11' (3.3m)

OUTER TIER MIDDLE TIER INNER TIER

AB CDEF

25.3'

(8m)

31.6'

(9.6m)

44.3'

(13.5m)

18.8'

(5.7m)

23.5'

(7m)

33.0'

(10.1m)

11.8'

(3.6m)

14.8'

(4.5m)

20.7'

(6.3m)

9.0'

(2.7m)

15.8'

(4.8m)

5.6'

(1.7m)

7.0'

(2.1m)

9.8'

(3m)

4.3'

(1.3m)

5.4'

(1.7m)

7.5'

(2.3m)

G

1.7'

(0.5m)

2.1'

(0.6m)

2.9'

(0.9m)

11.3'

(3.4m)

The DT-6360STC should be tested at least once each year to

ensure proper operation.

- 6 -

NOTICES

FCC

This equipment has been tested and found to comply with the limits for a

field disturbance sensor, pursuant to Part 15 of the FCC Rules. The user is

cautioned that changes or modifications not expressly approved by C&K

Systems could void the user's authority to operate this equipment.

This equipment has been tested and found to comply with the limits for a

classBdigitaldevice,pursuanttoPart15oftheFCCRules. Theselimitsare

designed to provide reasonable protection against harmful interference in

a residential installation. This equipment generates, uses and can radiate

radiofrequency energy and,ifnot installedandused inaccordancewith the

instructions, may cause harmful interference to radio communications.

However,thereisnoguaranteethatinterferencewillnotoccurinaparticular

installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the interference by one or

more of the following methods:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from

that to which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for

help.

Industry Canada

This device complies with RSS-210 of Industry and Science Canada.

Operation is subject to the following two conditions: (1) this device may not

cause interference, and (2) this device must accept any interference,

including interference that may cause undesired operation of the device.

This Class B digital apparatus meets all requirements of the Canadian

Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe B respecte toutes les exigences du

Règlement sur le matériel brouilleur du Canada.

C&K is a registered trademark of C&K Components, Inc.

DUALTECandINFORMERare registeredtrademarksofC&K

Systems,Inc.

Copyright 1996 C&K Systems, Inc.

5-051-312-00 Rev D http://www.cksys.com

Table of contents

Popular Accessories manuals by other brands

Roland

Roland TM-6 PRO manual

Leuze electronic

Leuze electronic MC3x Series Original operating instructions

Endress+Hauser

Endress+Hauser Cleanfit P CPA472D operating instructions

Panasonic

Panasonic WX-LA20 manual

Balluff

Balluff IO-Link BOS R080K-XM-RS10 S4 Series user guide

Somogyi Elektronic

Somogyi Elektronic home NV MS 2+6 instruction manual

Aqua-Scope

Aqua-Scope RANLWE01 quick start guide

Orbita

Orbita AVANTI 24 Instruction guide

Invacare

Invacare T1358 Assembly, installation and operating instructions

Cognex

Cognex In-Sight 2000 Mini PoE Series reference guide

Ecolink

Ecolink Tilt Installation & operation manual

HORL

HORL ROLLING SHARPENER manual