C.P.Bourg Bourg Binder 3001 User manual

EMERGENCY

STOP

NOTSTOP

ARRET

D'URGENCE

NOODSTOP

GLUE TEMPERATURE CONTROL

LEIMTEMPERATURREGULIERUNG

REGULATION

TEMPERATURE

COLLE

LI MTEMPERATUURSTURING

OOPPEERRAATTOORR

MMAANNUUAALL

Initial issue: 12/00

Latest revision : 08/06

9.133.459

Operator Manual

Page 9 - 2 Initial issue: 12/00

Latest revision: 11/01

Content of this documentation has a confidential nature and remains the

exclusive property of C.P. Bourg SA. It is only put at the user (including without

limitation: Renter or Purchaser or their employees) disposal within the

exclusive scope of using and servicing the product. Without C.P. Bourg SA

prior agreement in writing, disclosure to third party and/or reproductions as well

as changes are prohibited.

TABLE OF CO TE TS

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.1 Foreword . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.2 Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.3 Safety labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.4 Instructions for safe use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

1.5 Safety data sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2. System description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.2 eneral . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2.3 Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2.4 Control panel menus and messages . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

2.5 Change of binding parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

2.6 Instructions for timer use (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

2.7 Cover station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

2.8 Milling depth adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

2.9 lue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

2.10 To set up the Binder module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

2.11 Output unit (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

2.12 Binding condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

2.13 Cycle description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

3. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

3.1 Preventive maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

3.2 Paper dust bag replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

4. Mechanical trouble shooting . . . . . . . . . . . . . . . . . . . . . . . . . . .37

5. Some common glueing defects . . . . . . . . . . . . . . . . . . . . . . . . .38

6. Environmental compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Product Recycling and Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

7. Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Operator Manual

Page 9 - 3 Initial issue: 12/00

Latest revision: 08/06

Operator Manual

Page 9 - 4 Initial issue: 12/00

Latest revision: 11/01

Cette page est intentionnellement vide.

This page is intentionally left blank.

Deze blad is opzettelijk in het wit gebleven.

Diese Seite wurde absichtlich leer gelassen.

1. I TRODUCTIO

1.1 Foreword

Thank you for choosing a BOUR product.

The

BOURG BI DER 3001

is a perfect binder destined for the off line production of bound

booklets.

This manual is a guide to operate the BOUR BINDER 3001.

Follow the instructions carefully and you should obtain years of excellent service from your

Finishing on Demand system.

If you have any difficulty using your equipment, please call us and ask for technical assistance

(phone numbers are listed on the last page). We will be delighted to help you.

1.2 Safety information

You are advised to read the "Instructions for a safe use" before you start to actually use the

device.

Technical safety information such as safety data sheet can also be found.

Where applicable, cautions and warnings are used to draw your attention to safety precautions

to be taken.

All information in this publication is based on the latest information available at the time of

approval for printing.

We reserve the right to revise this publication and to make changes in the content without

obligation to notify any person of such revisions or changes.

Operator Manual

Page 9 - 5 Initial issue: 12/00

Latest revision: 11/01

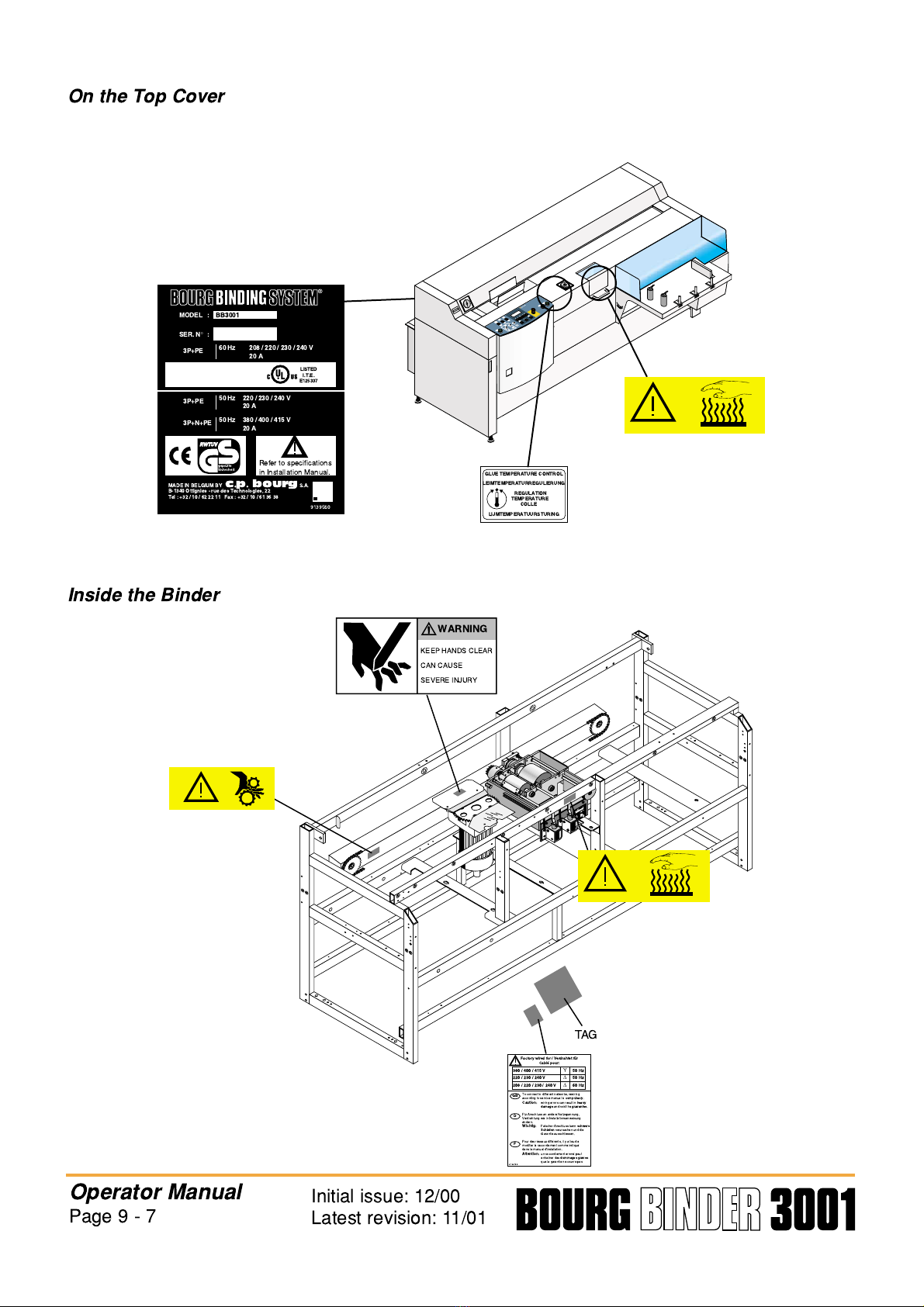

1.3 Safety labels

Please pay particular attention to the description of the following pictograms:

Caution: on a yellow background,

indicates a hazardous situation that can cause small or severe injury.

Warning: on a orange background is used to indicate a hazardous situation which

has some probability of death or severe injury. Warning should not be

considered for property damaged accidents unless personal injury risk is

present.

Danger: on a red background:indicates a hazardous situation with a high risk of

death or severe injury. The ‘danger’ sign does not apply to accidents

causing material damage, unless they can cause personal injury.

An Emergency stop on the control panel can be pressed to disable the binder.

Dangerous area. Keep hands clear !

Hot glue. Burn hazard

Operator Manual

Page 9 - 6 Initial issue: 12/00

Latest revision: 11/01

WARNING

KEEP HANDS CLEAR

CAN CAUSE

SEVERE IN URY

On the Top Cover

Inside the Binder

Operator Manual

Page 9 - 7 Initial issue: 12/00

Latest revision: 11/01

GLUE TEMPERATURE CONTROL

LEIMTEMPERATURREGULIERUNG

REGULATION

TEMPERATURE

COLLE

LI MTEMPERATUURSTURING

MADE IN BELGIUM BY

c p bourg

S.A.

B-1340 Ottignies - rue des Technologies, 22

Tel : +32 / 10 / 62 22 11 Fax : +32 / 10 / 61 36 38

3P+PE 50 Hz 220 / 230 / 240 V

20 A

3P+N+PE 50 Hz 380 / 400 / 415 V

20 A

9139560

gepru¨ fte

Sicherheit

Refer to specifications

in Installation Manual.

®

MODEL

SER. N

°

:

:

BB3001

3P+PE 60 Hz 208 / 220 / 230 / 240 V

20 A

LISTED

I.T.E.

E125337

WARNING

KEEP HANDS CLEAR

CAN CAUSE

SEVERE IN URY

TAG

9.139.158

Factory wired for / Verdrahtet f

u¨

r

Cabl

e´

pour:

To connect to different networks, rewiring

according to service manual is

compulsary

.

Caution:

wiring errors can result in

heavy

damage

and void the

guarantee

.

F

u¨

r Anschluss an andere Netzspannung,

Verdrahtung wie in Installationsanweisung

a¨

ndern.

Wichtig:

Falscher Anschluss kann

schwere

Sch

a¨

den

verursachen und die

Garantie ausschliessen.

Pour des r

e´

seaux diff

e´

rents, il y a lieu de

modifier le raccordement comme indiqu

e´

dans le manuel d'installation.

Attention:

un raccordement erron

e´

peut

entra

ıˆ

ner des

dommages graves

que la garantie ne couvre pas

GB

D

F

380 / 400 / 415 V

Υ

50 Hz

220 / 230 / 240 V

∆

50 Hz

208 / 220 / 230 / 240 V

∆

60 Hz

In the Power Ra k

On the ba k (inside)

Operator Manual

Page 9 - 8 Initial issue: 12/00

Latest revision: 11/01

PE

Power supply

connection

Main Ground

Pictogram

L3

L2

L1

N

9.139.163

High leakage current

earth connection essential

before

connecting supply

Courant de fuite

e´

lev

e´

Raccordement

a`

la terre indispensable

avant

le raccordement au r

e´

seau

WARNING

WHEN WIRING THE BINDER TO A

380v or 415v NETWORK AALLLL

MMUUSSTT BE

OF

THE OMISSION OF THE NEUTRAL

WILL RESULT IN HEAVY DAMMAGE

AND BBRREEAACCHH OOFF WWAARRAANNTTYY

(

B

E

W

AR

E

O

F

EX

T

E

N

S

I

O

N

C

O

RD

S

)

Y

5 WIRES

WARNUNG

BEIM ANSCHLUSS DER MASCHINE ANS

380v oder 415v Y NETZ M

U

¨

SSEN

WENN DIE NEUTRALE ADER NICHT

ANGESCHLOSSEN WIRD, ENTSTEHEN

SCHWERWIEGENDE SCHADEN UND

DDIIEE GGAARRAANNTTIIEE FFAALLLLTT.

(

ACH

T

UN

G

B

E

I

VE

R

L

AN

G

E

RUN

G

SS

CHNUR

)

"

""

ATTENTION

LORS DU RACCORDEMENT A UN

RESEAU 380v ou 415v Y LES 55

CONDUCTEURS DDOOIIVVEENNTT ETRE

RACCORDES.

UN RACCORDEMENT ERRONE

ENTRAINERAIT DES DOMMAGES

IMPORTANTS QUE LA

NNEE CCOOUUVVRREE PPAASS.

(

M

E

F

I

E

Z

-

V

O

U

S

D

ES

C

O

RD

O

N

S

P

R

O

L

O

N

G

A

T

E

UR

S

)

GGAARRAANNTTIIEE

V

O

I

R

I

N

S

T

R U C

T

I

O

N

S

D

E

M

O

N

T

A

G

E

A

V

A N

T

R A C C

O

R D

E

M

E

N

T

A U

R

E S E

A U

GB D F

THE UUNNBBEEDDIINNGGTT AALLLLEE 5 ADERN

CONNECTED. ANGESCHLOSSEN WERDEN.

S E E

I

N

S

T

A

L L

A

T

I

O

N

I

N

S

T

R U C

T

I

O

N

S

B

E

F

O

R

E

C

O

N N

E

C

T

I

N

G

T

O

T

H

E

S

U

P P

L

Y

S

I

E

H

E

I

N

S

T

A

L L

A

T

I

O

N

S

A N

L

E

I

T

U N

G

V

O

R

A N

S

C H

L

U

S S

A N

S

S

T

R

O

M

N

E

T Z

1.4 Instructions for safe use

Bourg products have been tested in accordance with the strictest international safety

standards. To help assure safety it is important that you observe the following rules:

Conne tion:

• Do not move the machine yourself, but contact our Customer Service.

• For equipment connected via a fixed connection to the network. The cable connection to the

interface box should be easily accessible.

• Do not place the machine in rooms which are too small and insufficiently ventilated.

See safety data sheet (in appendix)

for information about space and ventilation

requirements.

Note : • If an other type of glue is used of the recommended one (National Coolbind

1300), please refer to the safety data sheet of the used glue.

• Vapours which may be formed at elevated temperature may be irritating to

eyes and respiratory tract. A local exhaust over glue tank and a good

ventilation of the room are required.

• Different fume regeneration/extraction are available following the type of

binder (see spare parts catalog).

Surroundings:

• Do not block the ventilation openings of the machine.

• Ensure that the machine is placed on a level, horizontal surface of sufficient strenght. See

machine specifications for information about the weight of the equipment.

Maintenan e:

• Do not remove any screws from fixed panels.

• Do not carry out maintenance activities except for the parts and maintenance materials

mentioned in this manual.

• Do not place any liquids on the machine.

• To avoid the risk of introducing hazards, all modifications to Bourg equipment are

strictly reserved to properly qualified and trained service technicians.

Operator Manual

Page 9 - 9 Initial issue: 12/00

Latest revision: 08/06

General:

• Always use materials recommended by Bourg and developed for the Binder.

Materials not approved by Bourg may result in machine failures.

• Do not use the machine when it is emitting unusual sounds. Remove the plug from the power

socket or switch off the fixed connection to the network, and contact your Service provider.

Dangerous area

keep hands clear

Hot glue

burn hazard

Note: These safety alert symbols are for your personal safety. Never operate without

all safety covers in place.

WARNIN : This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to part 15 of the FCC* Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at

his own expense.

*F.C.C. = Federal Communications Commission.

Canadian Department of Communications Compliance Statement:

This equipment does not exceed Class A limits per radio noise emissions for digital

apparatus set out in the Radio Interference Regulation of the Canadian

Departement Communications.

Operator Manual

Page 9 - 10 Initial issue: 12/00

Latest revision: 11/01

1.5 Safety data sheet

Model

BB 3001

Description

lue binder

Max. process speed

Maximum 500 cycles/hour

Dimensions & Weight

Lenght: 1,88 m 6.17 ft

Width: 1,16 m (3.8 ft) (with the possibility to split machine to have 695 mm

(2.28 ft) width for narrow way)

Height: 1,06 m 3.48 ft

Weight: 400kg 882 lbs

Voltage

208V/220V/230V/240V/3 220V/230V/240V/3 380V/400V/415V/3 N

Frequency

60 Hz 50 Hz 50 Hz

Current, rated

20 A 20 A 20 A

Power consumption, stand by

1500 W

Power consumption, operation

3000 W

Power consumption, maximum

5500 W

Mains connection

Cable with fixed connection and separation switch

Safety class

I (IEC 536) Protective earth connection

Protection class

IP 20 (IEC 529)

Sound pressure level

Standby In operation

Operator position

55 db(A) 76 db(A)

Radio interference

Complies with Directive 89/336/EEC

Radiation

Not applicable

Radiant heat

10224 Btu/hour

Ozone emission

Not applicable

Room volume

Recommendation: 95 m3(7 x 4,5 x 3 m) 3336 ft3 (23x14.8x9.8 ft)

Room ventilation

Recommendation: min. 47,5 m3/h (natural ventilation)

For heat evacuation at continuous binding extra ventilation may be necessary

Dust concentration

0,04 mg/m3at continous operation

(TLV for nuisance dust = 10 mg/m3)

Additionnal safety information

To avoid higher sound pressure levels than given above, the machine

should be installed in a room with at least minimum room volume (see

above) and favourable acoustical properties.

Operator Manual

Page 9 - 11 Initial issue: 12/00

Latest revision: 11/01

®

MODEL

SER. N

°

:

:

BB3001

3P+PE 60 Hz 208 / 220 / 230 / 240 V

20 A

LISTED

I.T.E.

E125337 MADE IN BELGIUM BY

c p bourg

S.A.

B-1340 Ottignies - rue des Technologies, 22

Tel : +32 / 10 / 62 22 11 Fax : +32 / 10 / 61 36 38

3P+PE 50 Hz 220 / 230 / 240 V

20 A

3P+N+PE 50 Hz 380 / 400 / 415 V

20 A

9139560

gepr

u¨

fte

Sicherheit

Refer to specifications

in Installation Manual.

2. SYSTEM DESCRIPTIO

2.1 Specifications

Book

Dimensions (max - min) See the illustration above

Cover types lossy paper, with cutouts, with transparent front, “kromekote”, etc.

Cover weight 80-250 gsm (may require creasing) 30-90 lb cover

Paper weight 60-160 gsm 15-40 lb bond

Features

Cover pile height 60 mm 2.4 in.

Miss detector Yes

Speed max. up to 500 cycles/hour.

lue temperature From 140° C to 165° C (284°F to 392°F)

Milling + notching Yes

Paper waste collection Yes

Book counter Yes

Start up timer optional

Fume extractor

with active charcoal filter optional

Outdoor fume exhaust optional

Ma hine

Dimensions: (l x w x h) 1,88 m x 1,16 m x 1,06 m (6.17 ft x 3.8 ft x 3.48ft)

Weight

Binder 400 kg (882 lbs)

Output Unit (optional) 55 kg (121 lbs)

Electrical supply 208V/220V/230V/240V (60Hz)

∆

-20A

220V/230V/240V (50Hz)

∆

-20A

380V/400V/415V (50Hz) Y -20A

Radiant heat 10224 Btu/hour

Noise level (Lpa) 76 dB (A) (at operator position)

Operator Manual

Page 9 - 12 Initial issue: 12/00

Latest revision: 11/01

320mm

(12.6in.)

385mm

(15.2in.)

100mm

(3.9in.)

100mm

(3.9in.)

140mm

(5.5in.)

210mm

(8.3in.)

Max.thickness

45mm

(1.8in.)

MAX. BOOK DIMENSIONS MIN. BOOK DIMENSIONS

•

With manual reception

•

With automatic reception

90mm

(3.5in.)

75mm

(2.95in.)

•

Padding mode

(without BBR - with manual

reception and only by the low exit)

Min. thickness:

2 sheets (theorecal,

with very thin cover)

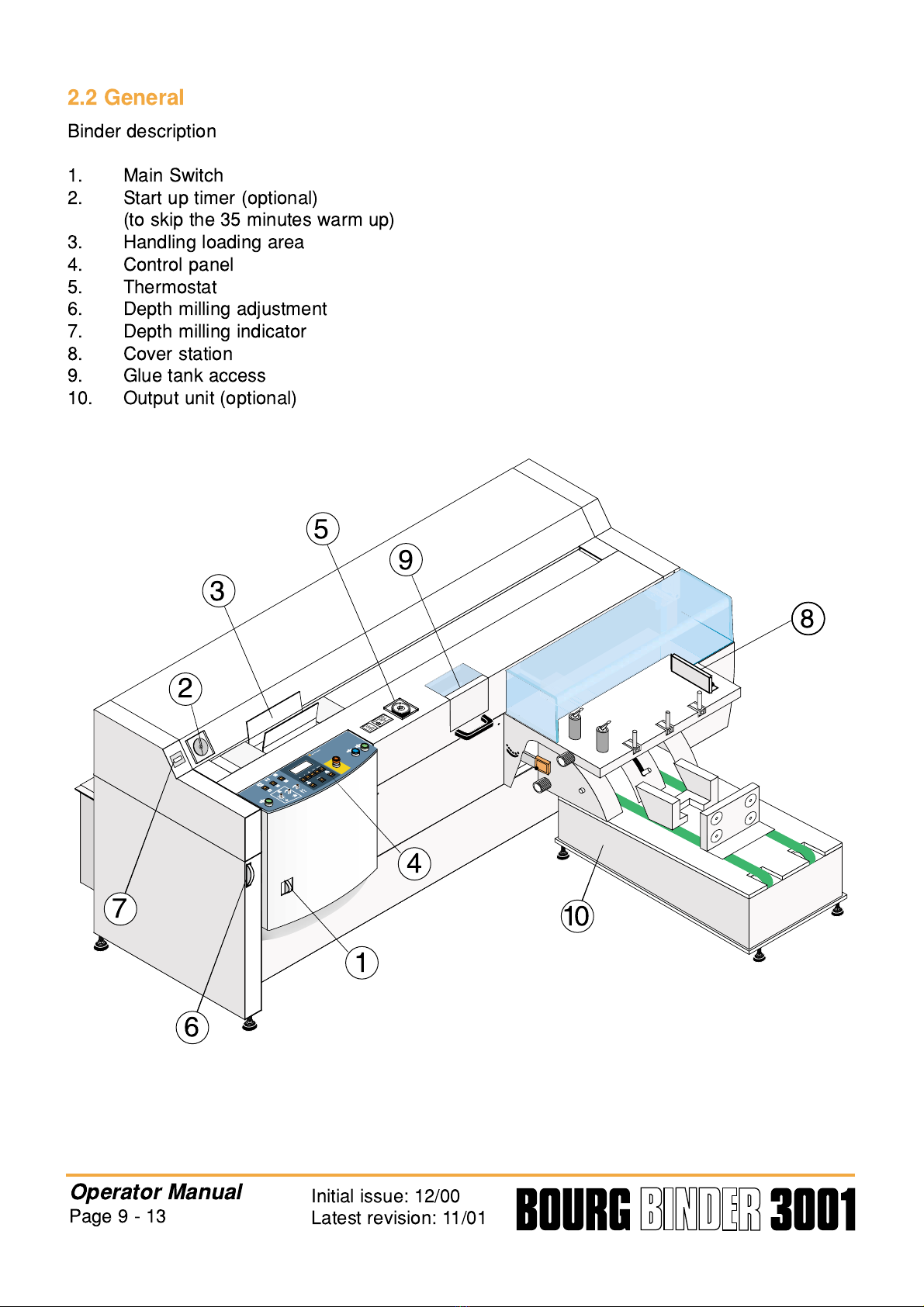

2.2 General

Binder description

1. Main Switch

2. Start up timer (optional)

(to skip the 35 minutes warm up)

3. Handling loading area

4. Control panel

5. Thermostat

6. Depth milling adjustment

7. Depth milling indicator

8. Cover station

9. lue tank access

10. Output unit (optional)

Operator Manual

Page 9 - 13 Initial issue: 12/00

Latest revision: 11/01

EMERGENCY

STOP

NOTSTOP

ARRET

D'URGENCE

NOODSTOP

GLUE TEMPERATURE CONTROL

LEIMTEMPERATURREGULIERUNG

REGULATION

TEMPERATURE

COLLE

LI MTEMPERATUURSTURING

9

2

1

4

6

10

7

3

5

8

2.3 Control Panel

1. Closes the carriage and starts the Binding Process

(press the two start buttons simultaneously)

2. Adjusts the clamping duration

3. Adjusts the lateral clamping pressure

4. Adjusts the suction level

5. Allows you to select menus and perform operation from these menus

6. Toggles the blade rotation ON/OFF

7. Selects the programs*

8. Toggles the glue tank heating (the drum rotation starts when the glue is warm enough)

9. Confirms the selection

10. Stop all operations in an emergency

11. Opens the carriage

12. Toggles jogger ON/OFF

13. Carriage normal or large pre-opening

14. Fixed speed ON/OFF

15. Liquid Crystal Display for menus and messages

*

With cover

or Without cover evacuation:top (for padding)

or Without cover evacuation:bottom (for padding)

Stop the drum rotation to select the program.

Confirm the choice by starting the drum rotation.

Note: In N 1 mode with pre-feed : yes. If the message “Cover sheet misfeed” is

displayed, it is not possible to change the program.

ou have to press on the emergency button and then change the program.

Operator Manual

Page 9 - 14 Initial issue: 12/00

Latest revision: 11/01

1

2

3

4

56

7

8

9

10

S.A .

N.V .

c p bourg

ENTER

MENU

PROGR.

1 2 3 4 6 7 8 10 11 1

1312 14 15

5 9

2.4 Control panel menus and messages

Operator Manual

Page 9 - 15 Initial issue: 12/00

Latest revision: 11/01

1

2

3

4

56

7

8

9

10

S.A .

N.V.

c p bourg

ENTER

MENU

PROGR.

MENU

MENU

MENU

MENU

MENU

MENU

Display of the values

previously selected in

next two menu steps.

At switch on:

CHANGE TOTAL NUMBER

O

N

F B I ND I NGS

R . OF B I ND I NGS :

COUNTER RESET

GLUE F I LM LENGTH

±

7

±

16

EX TRA CORRECT I ON

COVER POS I

T I ON

OVERLAP (

mm

) : XXX

1

–

>N

L

: CORR :

NR .

.

OF B I ND I NGS : X

XXX

:

BOOK S I ZE :

S I ZE CO ER T I ON :

OM DE 1

–

>N

E

RP E - F ED :

C

LANGU : (

FGB D

NL I E P

)

R

XXX

List of messages and instructions:

• Emergency pressed or hood not

closed

• Reset

• Drum is heating but is still too cold.

• Problem with book in delivery area

• Lift perpex guard remove cover if any

• Press key drum to start heating

• Remove paper from binder if any

• Cover feeder did not move

• Binder is in test mode

• Spine is drying

• Depress both green push buttons

• Cover sheet misfeed

• Milling motor is overheated

• Switch off and open hood

• Binding in progress

• Problems with carriage position

• Remove cover sheet

• Heating is disabled.

Push key to restore

• Delivery conveyer

Not ready / connected

• Replace MCU battery

• lue temperature too high

• Replace dust bag

• Binder is ready

• Open carriage and remove book

ERROR MESSAGES

1 Carriage open/close

Motor problem M7 F35

2 Shutter motor

Problem M15 F5

4

Cover nipping motor

Problem - M14 (F12)

8

Suction bar problem

Up/down motor M13 (F4)

9 Clutch or brake problem

K12 (F2)

10 T21 Time out/process longer

than one min

17 Notching tools index

probl.

18 Error check S45

S49 and Tacho

19 Book too thick or

carr switch probl

messages # on (earlier) eprom

#

2.5 Change of binding parameters

Operator Manual

Page 9 - 16 Initial issue: 12/00

Latest revision: 11/01

no

yes

CYCLE RUN

yes

no

Mode and parameters

are correct

MENU

MENU

Mode is

correct

+ENTER

yes

no

Book size

is correct

yes

+ENTER

no

yes

+ENTER

yes

no

Is cover leading edge

flush with book ?

+ENTER

MENU

MENU

MENU

MENU

ENTER

+

Pre-feed

is correct no

Press on both green buttons

ENTER

MENU

START

Press on button

Changes the

screen

Selects the

desired line

Changes the

parameters

Confirms the

selected

parameters

MENU

+

ENTER

B I NDER READY

1

–

>N

W

: X XX

XX XXX CORR :

NR . OF B I ND I NGS :

:

BOOK

PRE - FEED

S I ZE :

S I Z E CORRECT I ON :

OM DE N

–

>1

:

BOOK S I Z E :

S I Z E CORRECT I ON :

OM DE

-:

N

–

> 1

:

BOOK S I Z E :

S I Z E CORRECT I ON :

OM DE N

–

>1

Book length

is correct

:

BOOK S I Z E :

S I Z E CORRECT I ON :

OM DE N

–

>1

EXTRA CORRECT I ON

COVER POS I T I ON

OVERL

A

P (

mm

) : XXX

Realign

(each push = 0.2 mm)

E

RP E F E D

-:

E

RP E F E D

-:

E

RP E F E D

Operator Manual

Page 9 - 17 Initial issue: 12/00

Latest revision: 11/01

MENU

MENU

MENU

MENU

no

The right end of

glue film is correct

yes

+ENTER

no

Inhibition cylinder

state is correct

yes

+ENTER

yes

no

+ENTER

yes

no

The language

is correct

ENTER

+ENTER

The left end of

glue film is correct

yes

no

±

I N H I B I T I O N C Y L . 1 :

yes

no

ENTER

MENU

MENU

MENU

MENU

MENU

MENU

MENU

GLUE FILM LENGTH.

±

7

±

16

XXX

:

GLUE F ILM LENGTH.

± ±

16

7

XXX

:

:

GLUE F ILM LENGTH

Number of bindings

is correct

CHANGE TOTAL NUMBER

O

N

FBI NDI NGSxxx

R.OF B I ND I NGS

COUNT ERRESE T:x x x

Reset of

the counter

CHANGE TOTAL NUMBER

O

N

FB I NDI NGSxxx

R.OF B I ND INGS :

COUNT ERRESET

LANGU : (

FGBD

NL I E P

)

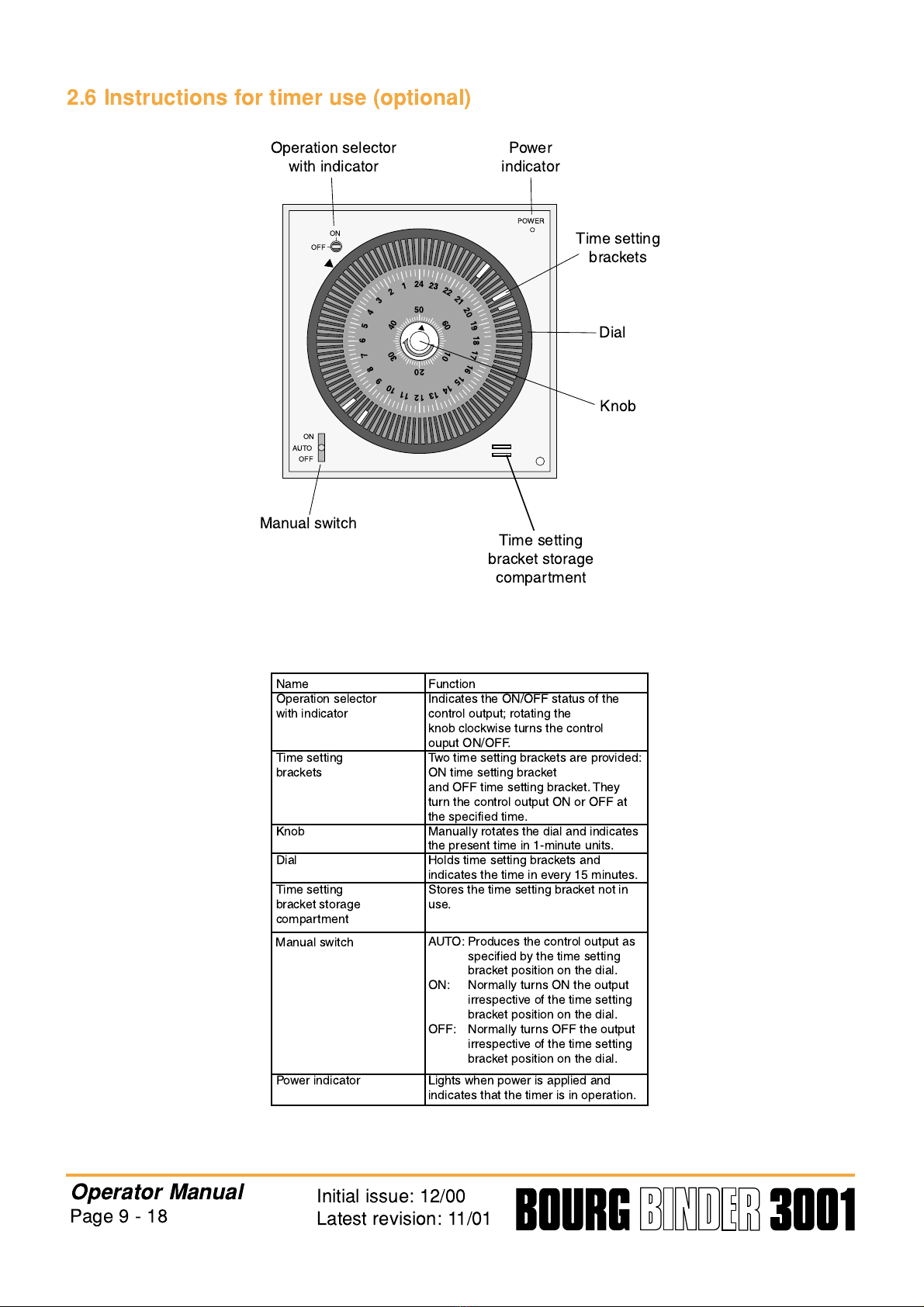

2.6 Instructions for timer use (optional)

Operator Manual

Page 9 - 18 Initial issue: 12/00

Latest revision: 11/01

24

50

40

30

20

10

60

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

ON

POWER

ON

AUTO

OFF

OFF

Operation selector

with indicator Power

indicator

Time setting

brackets

Dial

Knob

Time setting

bracket storage

compartment

Manual switch

Name

Operation selector

with indicator

Time setting

brackets

Knob

Dial

Time setting

bracket storage

compartment

Power indicator

Function

Indicates the ON/OFF status of the

control output; rotating the

knob clockwise turns the control

ouput ON/OFF.

Two time setting brackets are provided:

ON time setting bracket

and OFF time setting bracket. They

turn the control output ON or OFF at

the specified time.

Manually rotates the dial and indicates

the present time in 1-minute units.

Holds time setting brackets and

indicates the time in every 15 minutes.

Stores the time setting bracket not in

use.

Lights when power is applied and

indicates that the timer is in operation.

Manual switch AUTO: Produces the control output as

specified by the time setting

bracket position on the dial.

ON: Normally turns ON the output

irrespective of the time setting

bracket position on the dial.

OFF: Normally turns OFF the output

irrespective of the time setting

bracket position on the dial.

Settings

1. Remove the transparent cover from the front panel.

2. Rotate the center knob in the arrow direction (i.e., clockwise) to set the time. The present

time can be set in 1-minute units. For example 3:50 as shown in the figure. Do not rotate

the knob counterclockwise.

3. Two time setting brackets are provided: ON (gold) and OFF (silver). Be sure to use the

correct bracket and securely insert it in the groove of the dial.

4. Alternately set the ON and OFF time setting brackets.

5. After setting the time, reattach the transparent cover to the front panel.

Operation

6. Firmly insert the ON/OFF time setting bracket to the desired time setting groove. However,

do not insert it in a groove within ± 15 minutes distance from the dial groove that indicates

the present time.

7. After the time setting bracket is fixed and with the power and load connected to the timer,

rotate the knob in the arrow direction. Turn the dial one complete rotation to check if the

control output is turned ON/OFF in accordance wit the setting of the time setting bracket on

the dial.

8. Rotate the knob in the arrow direction and set the desired time according to step 2.

Operator Manual

Page 9 - 19 Initial issue: 12/00

Latest revision: 11/01

24

50

40

30

20

10

60

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

ON

PO ER

ON

AUTO

OFF

OFF

3 o'clock

50 minutes

9. Now start the operation of the timer.

Example:

With the above setting the timing chart will be as follows:

Operator Manual

Page 9 - 20 Initial issue: 12/00

Latest revision: 11/01

24

50

40

30

20

10

60

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

ON

OFF

OFF

ON

ON

ON

OFF

OFF

24 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23

This manual suits for next models

1

Table of contents

Other C.P.Bourg Binding Machine manuals