2

2. Operation Procedure

Cover/Tape Binding Mode

Turn on power switch.

About 13 minutes

later.

Set sheets into

clamper.

Press start button.

Set cover sheet or tape

and press start button

again.

Take out book.

Press reset button.

- Heater begins to warm up.

- "Preparation" lamp illumi-

nates.

- "Cover/Tape Mode" lamp

illuminates.

- Alarm sounds.

- "Preparation" lamp goes out.

- "Insert stock. Depress start

button." lamp illuminates.

- Nipper lowers and clamper

moves to the rear side and

stops above melt tank while

"Operation" lamp is illuminat-

ing.

- "Operation" lamp goes out.

- "Place cover sheet. Depress

start button." lamp illuminates.

- "Operation" lamp illuminates.

- Clamper goes back to home

position and stops on nipper.

- Nipper rises to nip cover

sheet and stock.

- Alarm sounds and nipper

lowers.

- "Operation" lamp goes out.

- "Take out stock. Depress

reset button." lamp illuminates.

- "Operation" lamp illuminates.

- Nipper rises.

- "Operation" lamp goes out.

- "Insert stock. Depress start

button." lamp illuminates.

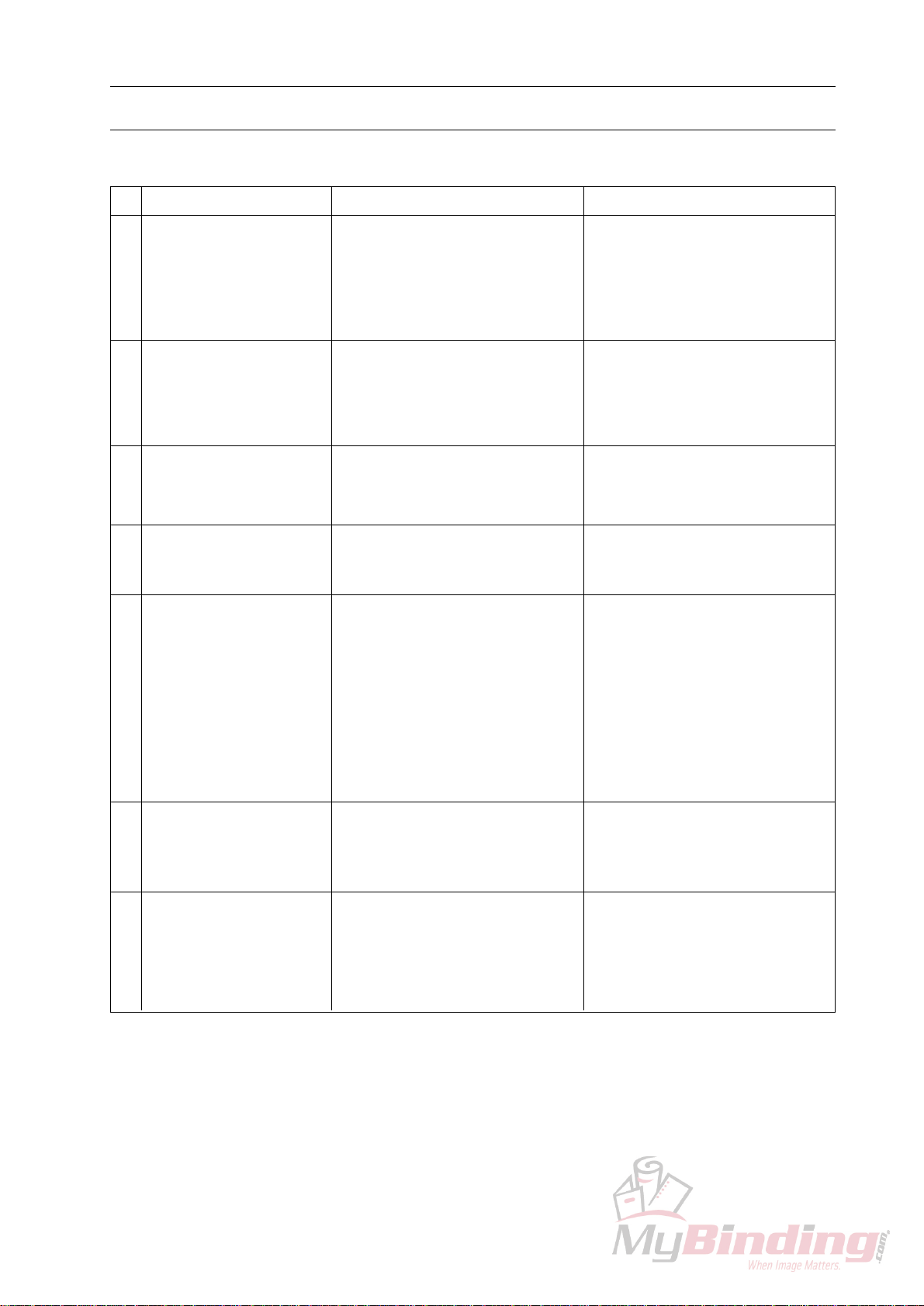

Operation Sensor or SwitchAction (Operation Panel LED)

1

2

3

4

5

6

7

- Clamper home position switch

ON

- Nipper upper limit

microswitch OFF

- Sheet presence microswitch

ON

- Nipper lower limit

microswitch OFF

- Clamper reverse switch ON

- Cover sheet sensor ON

- Clamper home position switch

ON

- Nipper lower limit

microswitch OFF

- Stock presence microswitch

OFF

- Nipper upper limit

microswitch OFF