TechnicalSetting

iDigiBook 450 R2: Technical Manual rev.01.00 10-12-2013

Summary

Tools necessary for set up ..................................................................................................................................3

Working principle...............................................................................................................................................3

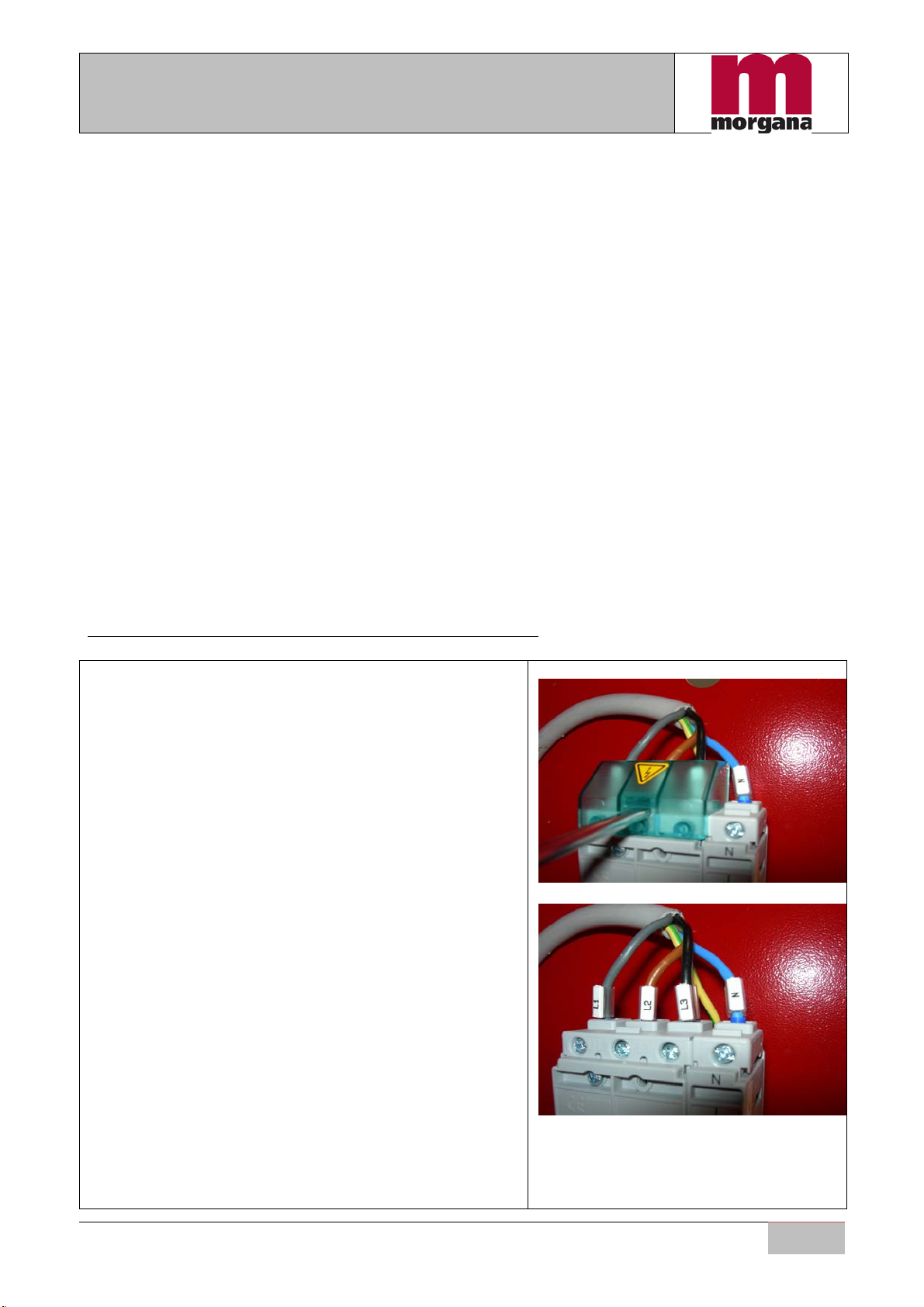

Preliminary Operations.......................................................................................................................................3

Start-up conditions..............................................................................................................................................5

Check height of Zero (MZ).................................................................................................................................5

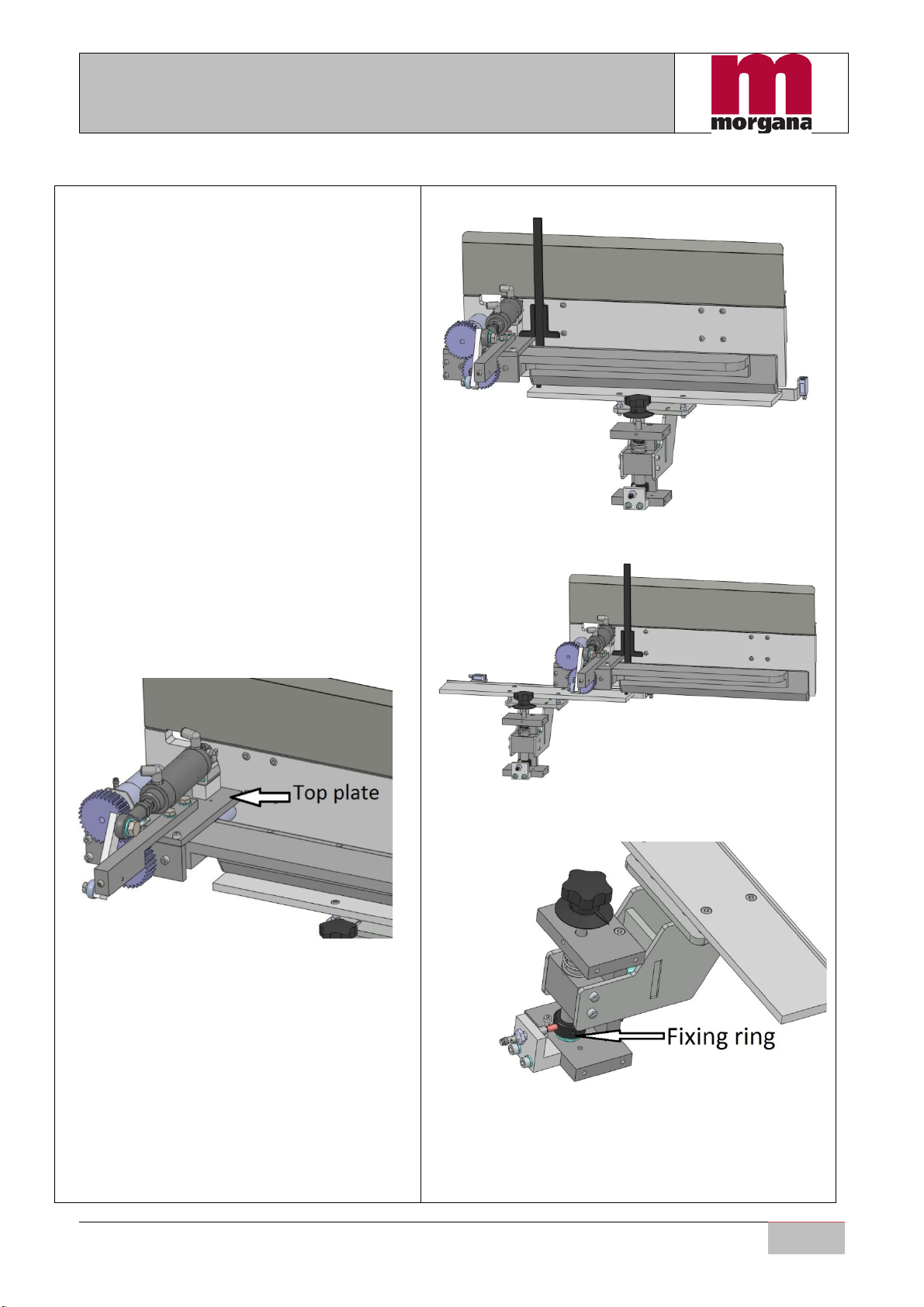

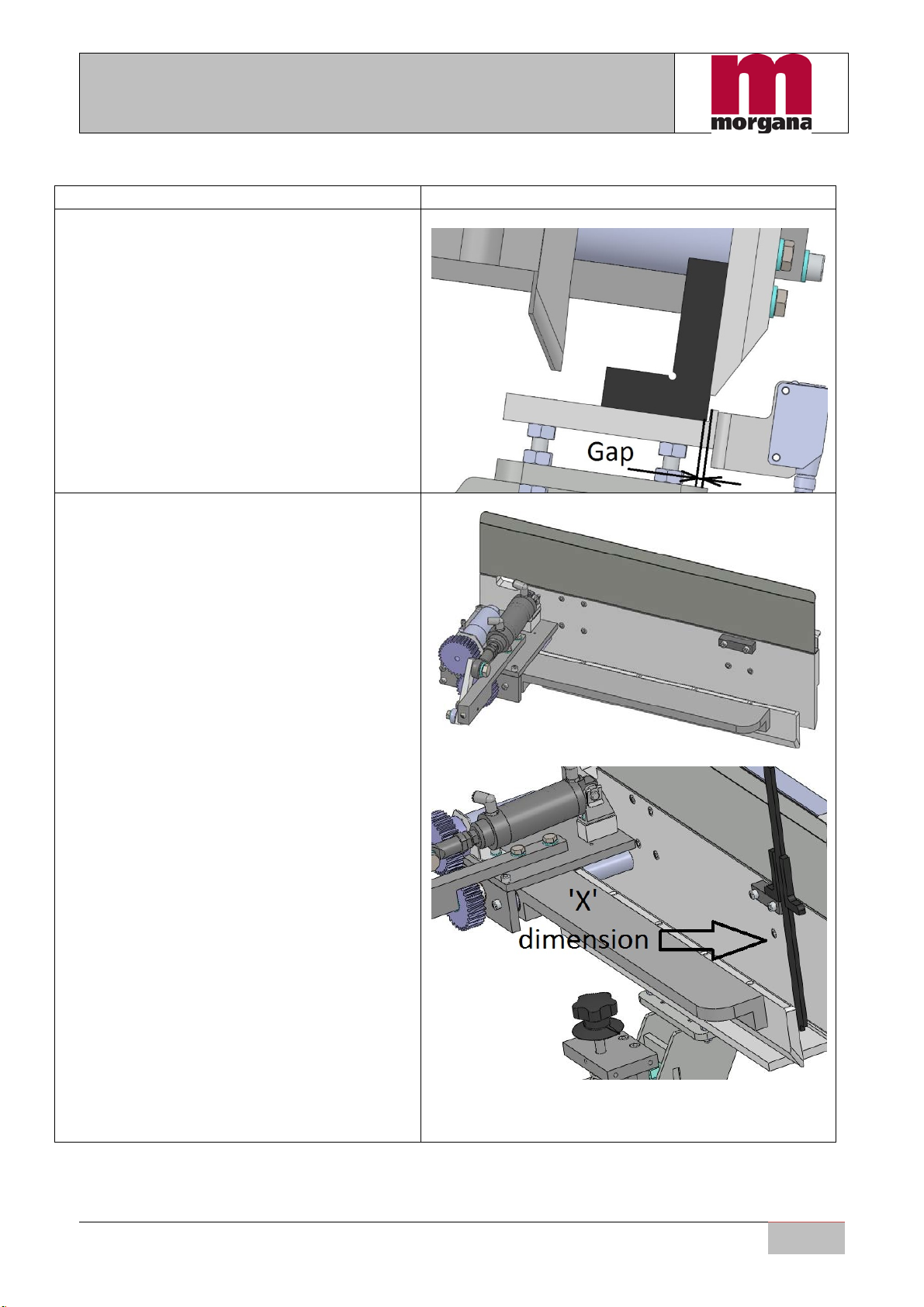

1) Setting the jogger plate...................................................................................................................................6

2) Setting the spine preparation unit...................................................................................................................9

3) Setting the PUR Nozzle................................................................................................................................13

4)Setting the nipping station ........................................................................................................................15

7)To adjust the discharge manipulator.........................................................................................................19

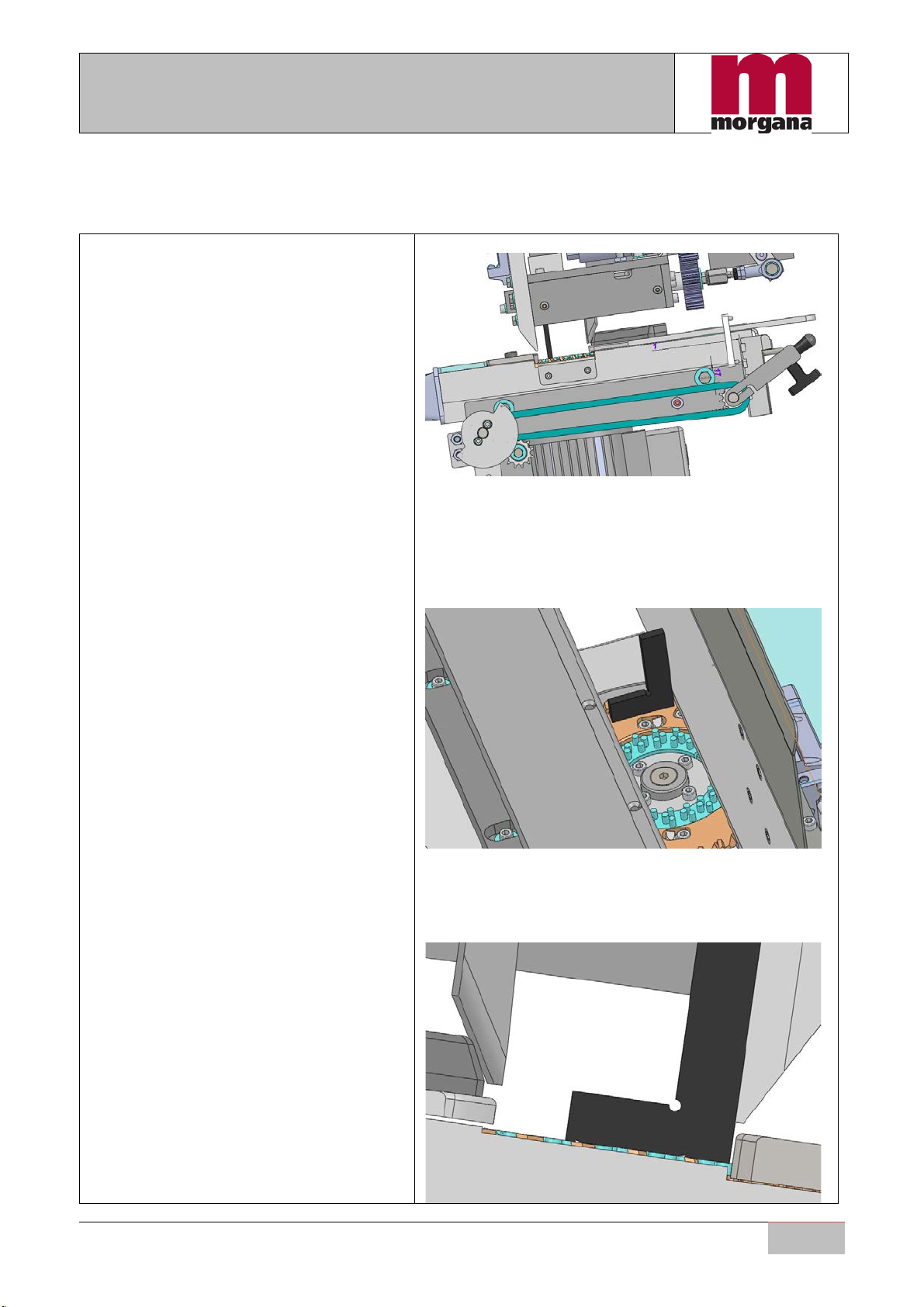

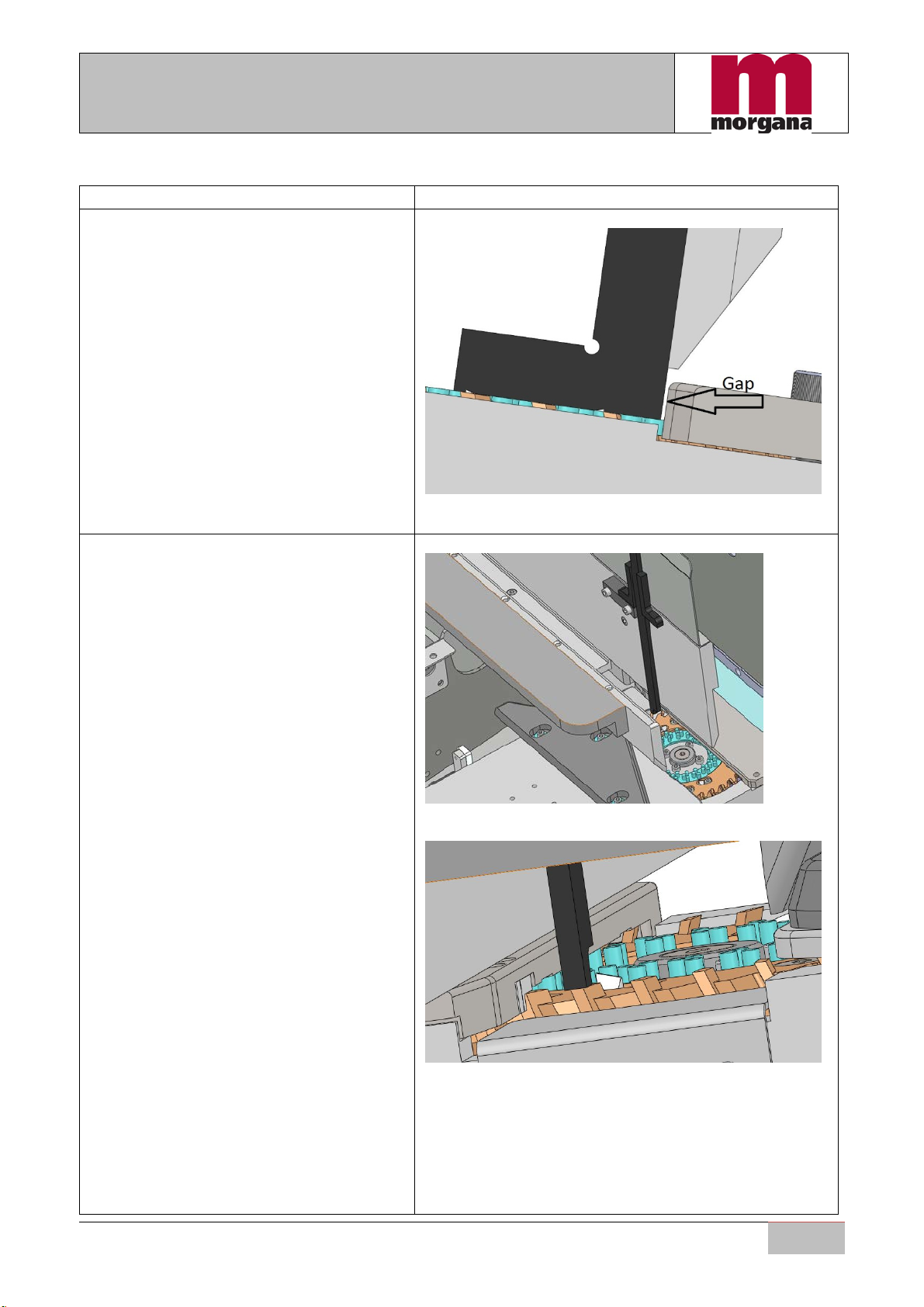

7)Adjust the cover feeder.............................................................................................................................23

8)Adjustment of discharge belt. ...................................................................................................................24

9)Pressure adjustment ..................................................................................................................................27

10)Setting of operating distance for sensors..............................................................................................27

11)Photosensors adjustment.......................................................................................................................27

12)Cylinders speed.....................................................................................................................................27

13)Axes positioning. ..................................................................................................................................27

14)Machine parameters..............................................................................................................................28