C.P.Bourg BB3002 PUR User manual

OPERATOR

MANUAL

Initial issue: 05/08

Latest revision: 12/14

9.134.089

For BB3002, BB3102 and BB3202

with PUR VersaPail system and PUR Compact system

Operator Manual

Page 2

Initial issue: 05/08

Latest revision: 11/08

Content of this documentation has a confidential nature and remains the exclusive

property of c.p. bourg s.a. It is only put at the user (including without limitation:

Renter or Purchaser or their employees) disposal within the exclusive scope of using

and servicing the product. Without c.p. bourg s.a. prior agreement in writing,

disclosure to third party and/or reproductions as well as changes are prohibited.

Operator Manual

Page 3

Initial issue: 05/08

Latest revision: 12/14

TABLE OF CONTENTS

Introduction ...............................................

8

BB3002

1.1 Warning pictograms .................................... BB3002 10

1.2 Instructions for safe use ................................. BB3002 13

1.3 Specifications for BB3002 with PUR VersaPail System......... BB3002 14

1.4 Specifications for BB3002 with PUR Compact System ......... BB3002 15

1.5 Space requirements for BB3002 with PUR .................. BB3002 16

1.6 What is PUR? ......................................... BB3002 17

1.7 Working with PUR...................................... BB3002 17

2. General description .............................BB3002 18

2.1 Specifications ......................................... BB3002 18

2.2 General description of the binder .......................... BB3002 19

2.3 Description of the gluing process .......................... BB3002 20

2.4 Description of various parts of the binder.................... BB3002 21

2.4.1 "Vibrating" module (jogger): ............................................................................... BB3002 21

2.4.2 Milling module: ................................................................................................... BB3002 21

2.4.3 Glue gun: ........................................................................................................... BB3002 22

2.4.4 Cover clamp: ...................................................................................................... BB3002 22

2.4.5 Creasing module (optional): ............................................................................... BB3002 23

2.4.6 Cover loading: .................................................................................................... BB3002 23

2.4.7 Binder output:..................................................................................................... BB3002 24

2.4.8 Reception of books in the BBR module (optional):............................................ BB3002 24

2.5 PUR C Glue consumption ............................... BB3002 25

3. Using the binder................................BB3002 26

3.1 Operating procedure.................................... BB3002 26

3.1.1 Powering up the binder: ..................................................................................... BB3002 26

3.1.2 Configuring the binder:....................................................................................... BB3002 26

3.1.3 Preparing the binder:.......................................................................................... BB3002 26

3.1.4 Binding a book:................................................................................................... BB3002 26

3.1.5 Switching the binder off:..................................................................................... BB3002 26

3.1.6 To start the Dust Collator .................................................................................. BB3002 27

3.2 Powering up the binder and heating the glue gun . . . . . . . . . . . . . BB3002 28

3.2.1 Heating the glue/gun: ......................................................................................... BB3002 29

3.2.2 Starting the TIMER - main switch in ON2 position:............................................ BB3002 30

3.3 The binder controls ..................................... BB3002 31

3.3.1 Function of the buttons on the loading console: ................................................ BB3002 31

3.3.2 Function of the pedal:......................................................................................... BB3002 32

3.3.3 Indicator light above the loading area: ............................................................... BB3002 32

3.3.4 Safety barriers:................................................................................................... BB3002 32

3.3.5 Emergency stop button: ..................................................................................... BB3002 33

Operator Manual

Page 4

Initial issue: 05/08

Latest revision: 12/14

3.3.6 Reinitialising the binder:..................................................................................... BB3002 33

4. Graphical Interface (UI) .......................... BB3002 34

4.1 General description of the graphical interface ................ BB3002 34

4.2 "PREFERENCES" menu ................................ BB3002 37

4.3 AUTOMATIC" menu .................................... BB3002 39

4.3.1 Accessing the automatic menu: ......................................................................... BB3002 39

4.3.2 Programming the automatic menu: .................................................................... BB3002 39

4.4 COUNTER menu ...................................... BB3002 44

4.4.1 UNIT mode:........................................................................................................ BB3002 45

4.4.2 SERIES mode: ................................................................................................... BB3002 46

4.4.3 “SEMI-SERIES” mode:....................................................................................... BB3002 48

4.4.4 Additional functions for PUR C .......................................................................... BB3002 49

4.5 ADVANCED" menu..................................... BB3002 50

4.6 ADVANCED menu: Managing parameters for cover clamping ... BB3002 52

4.6.1 Selecting "with cover" or "without cover" mode ("BLOCK" mode): .................... BB3002 52

4.6.2 In "WITH COVER" mode:................................................................................... BB3002 53

4.6.3 In "WITHOUT COVER" mode: ........................................................................... BB3002 59

4.7 ADVANCED MENU: Managing binding parameters ........... BB3002 60

4.7.1 Setting the carriage movement speed: .............................................................. BB3002 60

4.7.2 Selecting milling and the milling depth:.............................................................. BB3002 61

4.7.3 Setting front and back glue cut-offs:................................................................... BB3002 62

4.7.4 Setting the thickness of the glue film: ................................................................ BB3002 62

4.8 “JOB" menu .......................................... BB3002 63

4.8.1 Correction of the paper pile thickness to be bound ........................................... BB3002 64

4.8.2 Setting the thickness of the glue film: ................................................................ BB3002 65

4.8.3 Setting lateral pressure: ..................................................................................... BB3002 65

4.8.4 Setting the spine pressure: ................................................................................ BB3002 65

4.8.5 Setting the glue drying time before cover nipping:............................................. BB3002 65

4.8.6 Setting the glue drying time during cover nipping:............................................. BB3002 66

4.8.7 Activation/deactivation of the jogger + adjustment of the amplitude of the vibration:BB3002 66

4.8.8 Activation/deactivation of milling + selection of milling depth:............................ BB3002 66

4.8.9 Book output mode: ............................................................................................. BB3002 67

4.8.10 Configuring front and back glue cut-offs: ......................................................... BB3002 67

4.8.11 Adjusting the creasing position: ....................................................................... BB3002 68

4.8.12 Adjusting the cover position: ............................................................................ BB3002 68

4.9 "FILE" menu .......................................... BB3002 69

4.9.1 To create and save a new job:............................................................................ BB3002 69

4.9.2 To open an existing job:...................................................................................... BB3002 70

4.9.3 To delete an existing job:.................................................................................... BB3002 70

4.10 "TIMER" menu ....................................... BB3002 71

4.11 ALARM" menu ....................................... BB3002 72

4.12 "TOOLS" menu ....................................... BB3002 73

4.12.1 Setting the date and time: ................................................................................ BB3002 73

4.12.2 Opening/closing the cover clamps: .................................................................. BB3002 74

4.12.3 Restarting the graphical interface, the PLC and communication between them:BB3002 74

Operator Manual

Page 5

Initial issue: 05/08

Latest revision: 12/14

4.12.4 Thickness value of the last booklet bound: ...................................................... BB3002 74

4.12.5 Accessing the advanced menu: ....................................................................... BB3002 75

4.12.6 Exit roller mode: ............................................................................................... BB3002 75

4.12.7 Checking the opening/closing the BBR or Start/Stop the conveyor:................ BB3002 76

5. Preparing the binder ............................ BB3002 77

5.1 Loading the cover station ............................... BB3002 77

5.2 Adjusting the cover position on the book .................... BB3002 78

5.3 Cover picking and separators............................. BB3002 80

5.3.1 Separators:......................................................................................................... BB3002 80

5.3.2 Cover suction:..................................................................................................... BB3002 81

5.4 Not available .......................................... BB3002 82

5.5 Creasing depth adjustment............................... BB3002 83

6. Special applications.............................BB3002 84

6.1 Binding of sewed book .................................. BB3002 84

6.2 Binding of a top stitched brochures ........................ BB3002 85

6.3 Not available .......................................... BB3002 85

6.4 Multicreasing mode..................................... BB3002 86

6.5 “Doctor” booklet application .............................. BB3002 88

7. Using the PUR C Melter..........................BB3002 89

7.1 Refilling the PUR C Melter ............................... BB3002 89

7.1.1 Opening.............................................................................................................. BB3002 89

7.1.2 Closing ............................................................................................................... BB3002 89

7.1.3 Operation with the lid closed.............................................................................. BB3002 89

7.1.4 Extended production stop .................................................................................. BB3002 89

7.2 Purging System Sequence ............................... BB3002 90

7.3 Adjusting the pressure for PUR C Melter .................... BB3002 94

8. Maintenance ...................................BB3002 95

8.1 Preventive maintenance ................................. BB3002 95

8.2 Replacing the dust bag.................................. BB3002 96

8.3 Supplies and Accessories................................ BB3002 97

8.4 Adjusting Temperature on PUR C Melter.................... BB3002 98

8.5 Tips for successful operation:............................. BB3002 99

9. Guides ....................................... BB3002 100

10. Mechanical troubleshooting .................... BB3002 101

11. Common glueing defects ...................... BB3002 102

BBL

12. Using the Binder with the BBL ..................... BBL 104

12.1 Introduction ............................................ BBL 104

Operator Manual

Page 6

Initial issue: 05/08

Latest revision: 12/14

12.2 Warning pictograms ..................................... BBL 104

12.3 Ergonomics ............................................ BBL 105

12.4 Easy and flexible operation ............................... BBL 105

12.5 Daily productivity........................................ BBL 105

12.6 Electrical specifications................................... BBL 105

12.7 Space requirements ..................................... BBL 106

12.7.1 BB3102 with EVA System .................................................................................... BBL 106

12.7.2 BB3102 with PUR Compact System.................................................................... BBL 106

12.8 Paper size............................................. BBL 107

12.9 BBL performances ...................................... BBL 108

12.10 BBL loading .......................................... BBL 109

13. User Interface MENU FOR BBL .................... BBL 111

13.1 Main screen ........................................... BBL 111

13.2 "TOOLS" menu ......................................... BBL 113

13.3 "PREFERENCES" menu of the BBL ........................ BBL 114

13.4 "ALARM" menu......................................... BBL 115

14. Troubleshooting Guide BBL ....................... BBL 116

BBC

15. Using the Binder with the BBC.....................BBC 121

15.1 Introduction ............................................BBC 121

15.2 General description......................................BBC 122

15.3 Operation modes .......................................BBC 123

15.3.1 Perfect Binding Mode (On - line)......................................................................... BBC 123

15.3.2 Perfect Binding Mode (Near - line)...................................................................... BBC 123

15.3.3 Stacking/Compiling mode.................................................................................... BBC 123

15.3.4 Padding Mode - (Not available in PUR version).................................................. BBC 123

15.4 Electrical specifications (BBC) .............................BBC 124

15.5 Paper size.............................................BBC 124

15.6 Space requirements .....................................BBC 125

15.6.1 BB3202 with EVA System ................................................................................... BBC 125

15.6.2 BB3202 with PUR Compact System................................................................... BBC 125

15.7 BBC performances ......................................BBC 126

16. User Interface menu for BBC ......................BBC 127

16.1 Main screen ...........................................BBC 127

16.2 "TOOLS" menu ......................................... BBL 135

16.3 "PREFERENCES" menu of the BBC ........................ BBL 136

16.4 "ALARM" menu......................................... BBL 137

17. Jam clearance for BBC ...........................BBC 138

BB3002 with PUR Compact System Operator Card ............140

Operator Manual

Page 8

Initial issue: 05/08

Latest revision: 11/08

INTRODUCTION

Foreword

On behalf of everyone at CP Bourg, we would like to thank you for choosing a BOURG product

and congratulate you for your choice.

The Bourg Binder 3002 is a single clamp thermal binder designed in a user-friendly way to

create perfect bound books.

Adjustments can quickly and easily be made via touch screen (GUI).

The machine automatically adapts to book thickness (from 1to 60 mm - 0.04" to 2.36") and

ensures a constant productivity of on demand books. Its cover creasing system is

performed by a “knives/matrix” method which guarantees both quality and flexibility.

The BB3002 binder together with the automatic Bourg Book Loader (BBL) form the complete

BB3102 unit. This ergonomic option enables automatic book block feeding into the binder.

See chapter "12. Using the Binder with the BBL", page 104.

The BB3002 binder together with the Bourg Book Compiler (BBC) form the complete

BB3202 unit. This module allows using the BB3002 in in-line mode behind a printer or

nearline behind a sheet feeder.

See chapter "15. Using the Binder with the BBC", page 121.

This manual is a guide to the use of the BB3002/BB3102/BB3202 binder.

Follow the instructions carefully, and you shall obtain years of excellent service from your book

binding system.

Should you have any difficulty using your equipment, please contact us at the addresses given

at the end of the manual to ask for technical assistance. We will be delighted to help.

Safety Information

Please read the safety instructions carefully before using your equipment.

This manual contains all the information you need to use your thermal binder safely.

Pay particular attention to the warning notices on the machine. They indicate places presenting

particular risks, and advise you to take the appropriate precautions.

All the details contained in this publication are based on the most recently available information

at the time of going to press.

We reserve the right to modify the content of this publication at any time, without notice.

Operator Manual

BB3002 Page 9

Initial issue: 05/08

Latest revision: 11/08

BB3002

Operator Manual

BB3002 Page 10

Initial issue: 05/08

Latest revision: 11/08

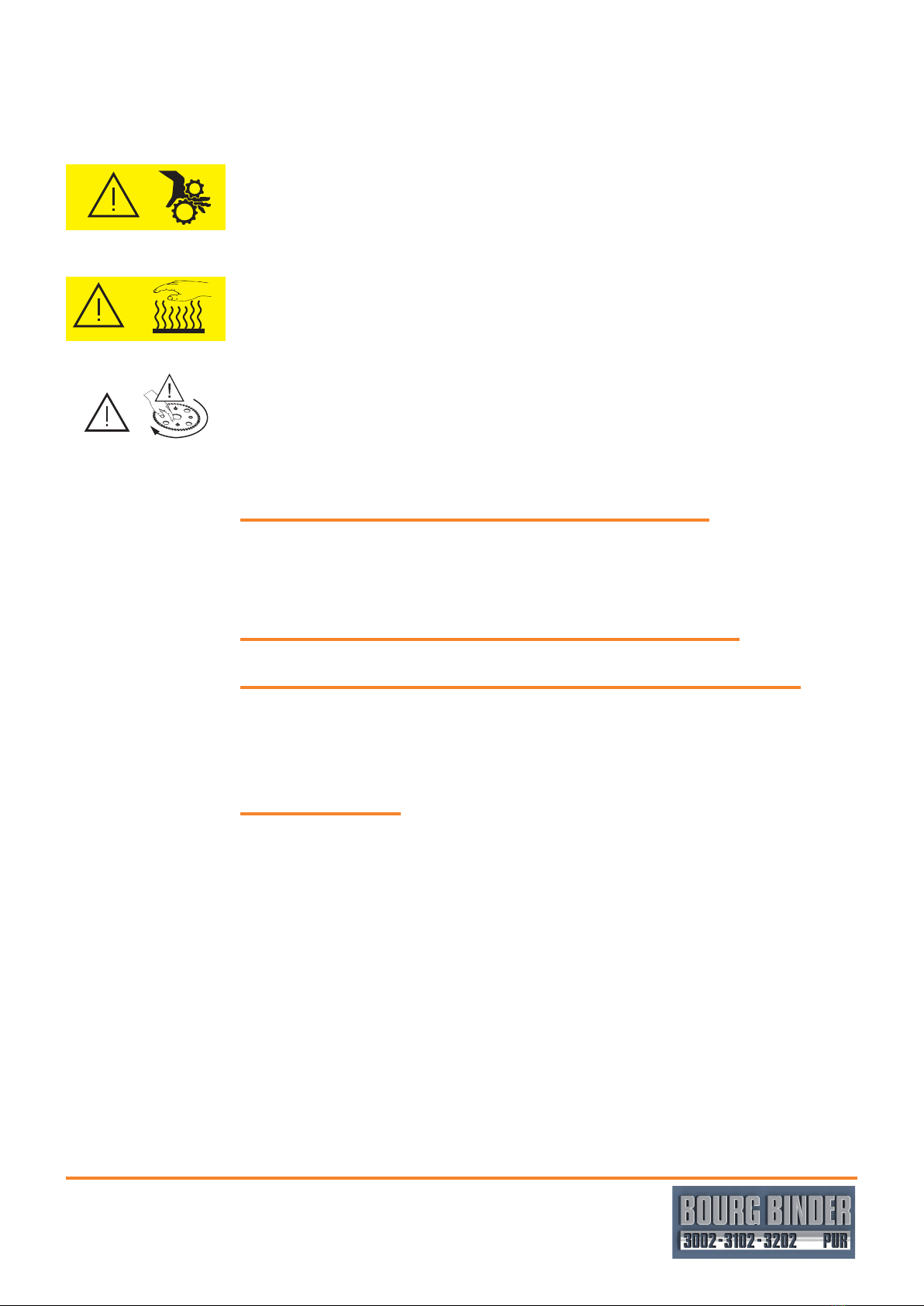

1.1 Warning pictograms

Please pay special attention to the description of the following pictograms :

This label is located near the wheel-work, the chain and belt. It indicates a

high risk of injury to your fingers if they get stuck between the wheel-work,

the chain and belt.

This label is located near the glue gun and near the valve for the draining

of the glue gun.

It indicates a high burning risk if you touch the hot glue.

This label is located near the milling blade. It a high risk of injury to your

hands if you touch indicates the rotating tools.

ATTENTION: These safety alert symbols are for your personnal safety.

Never operate without all safety covers in place.

An emergency stop switch (red) located on the top cover allows

the operator to stop the machine at any time or any incident.

ATTENTION: - The room must be equipped with a chimney to evacuate the fume/

vapors outside of the room.

- Compressed air of 6bar (0.6MPa/87psi) is necessary.

- For more information about the glue, see Henkel Purmelt QR3317

Safety Data Sheet.

Operator Manual

BB3002 Page 11

Initial issue: 05/08

Latest revision: 11/08

On the cover:

Inside the Binder:

®

MODEL

SER. N°

:

:

BB3002

3P+PE 60 Hz 208 / 220 / 230 / 240 V

12 A

MADE IN BELGIUM BY c.p. bourg S.A.

B-1340 Ottignies - rue des Technologies, 22

Tel : +32 / 10 / 62 22 11 Fax : +32 / 10 / 61 36 38

3P+PE 50 Hz 230 / 240 / 380 / 400 / 415 V

12 A

9139727A

geprüfte

Sicherheit

Refer to specifications

in Installation Manual.

LISTED

I.T.E.

E125337

B

Operator Manual

BB3002 Page 12

Initial issue: 05/08

Latest revision: 11/08

Operator Manual

Page 12

Initial issue: 05/08

Latest revision: 12/08

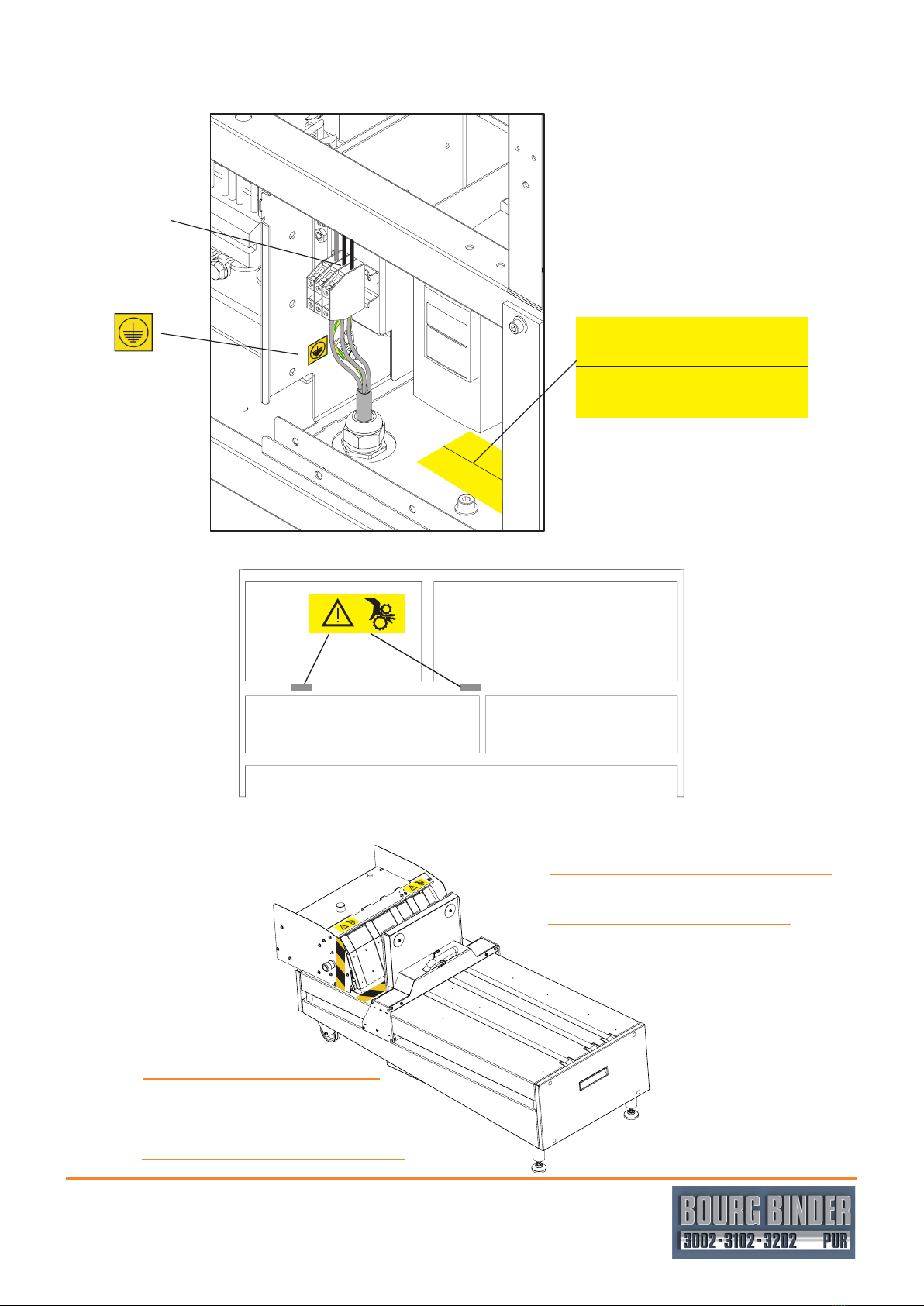

Inside the power rack :

On the back (inside) :

BBR :

L3

L2

L1

Power supply

connection

WARNING

High leakage current

earth connection essential before

connecting supply

ATTENTION

Courant de fuite élevé

Raccordement à la terre indispensable

avant le raccordement au réseau

9.139.163A

WARNING

High leakage

earth connection

connecting supply

ATTENTION

Courant de fuite élevé

Raccordement à la terre in

avant le raccordement au rés

Note: Risk of injury to your fingers if you

take the booklets in this area.

Note: The book can be manipulate

approximately after 1min.30.The

gluing is optimal after 24 hours.

Operator Manual

BB3002 Page 13

Initial issue: 05/08

Latest revision: 11/08

1.2 Instructions for safe use

All Bourg products are tested according to the strictest safety standards in compliance with

international law. To ensure that your work is carried out under the safest possible conditions,

please observe the following instructions:

Installation and movement:

• Do not move the machine yourself - contact our technical team.

• The machine should only be connected to the electricity supply by qualified personnel in

accordance with the installation manual.

• Do not locate the machine in a room which is too small or insufficiently ventilated.

See the technical specifications for full information about the space and ventilation

required.

• Do not obstruct the machine's air vents.

• Ensure that the machine is placed on a level horizontal surface of sufficient strength.

See the machine's specifications for full details of its weight.

Precautions:

• Do not remove any screws from the fixed panels.

• Do not attempt any maintenance activities yourself except for those described in this

manual, and use only the appropriate materials.

• Do not place any liquids on the machine.

• To avoid any risk of creating potential hazards, no Bourg equipment should be modified

except by qualified technical personnel.

• Always use materials recommended by C.P.Bourg and developed for Bourg machines.

Unsuitable materials may damage the equipment.

• Do not use the machine if it makes unusual noises. Disconnect the machine from the

electricity supply and contact the Maintenance Service.

WARNING: This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to part 15 of the FCC* Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference

in which case the user will be required to correct the interference at his own expense.

*F.C.C. = Federal Communications Commission.

Canadian Department of Communications Compliance Statement

This equipment does not exceed Class A limits for radio noise emissions for digital

apparatus, set out in Radio Interference Regulation of the Canadian Department of

Communications.

Operator Manual

BB3002 Page 14

Initial issue: 05/08

Latest revision: 06/13

1.3 Specifications for BB3002 with PUR VersaPail System

Model BB3002 PUR VersaPail

Description Glue binder Bulk Melter

Dimensions

Length - Width - Height in m(ft) 2,02 - 2,4 - 1,5 m (6.62 - 7.9 -4.92 ft) 1,92 m (6.3 ft.)

Weight 650 Kg (1430 Lbs) 275 kg (606 lbs)

Power required

208/220 V, 60 Hz, 3 phase delta12 A

One of the following, see ID plate: 200 V (+/-

10%), 50/60 HZ, 3 phase delta, 25 A

220/230 or 240 V, 50 Hz, 3 phase delta 12 A 230 V (+/- 10%), 50/60 HZ, 3 phase delta, 25 A

400 V (+/- 10%), 50/60 HZ, 3 Y, 12 A

380/400 or 415 V, 50 Hz, 3 phase star, no neutral12 A 400 V (+/- 10%), 50/60 HZ, 3 delta, 12 A

480 V (+/- 10%), 50/60 HZ, 3 delta, 10 A

Power consumption, stand by 1000 W TBD

Power consumption, operation 2500 W 7500 W (25 500 Btu/h)

Power consumption,

maximum

3500 W 8500 W

Safety class I (IEC 536) Protective earth connection CE IEC 60950-1 for class A

Protection class IP 20 (IEC 529) IP 54

Noise level (Lpa) 76 dB (A) (at operator position) 62 db at 1 meter (3.3 ft)

Radiant heat (BTU/h) 8500 (in operation) 3410 (in stand by) 25500 (in operation)

Room volume

Recommendation

95 m3(7 x 4,5 x 3 m) 3336 ft3(23x14.8x9.8 ft) TBD

Exhaust Requirement 510 m3/h (300 cfm) build-in extractor 510 m3/h (300 cfm) Need for external extractor

Dust concentration 0,04 mg/m3at continous operation (TLV for nuisance dust = 10

mg/m3)

NOT SPECIFIED

Additionnal safety information To avoid higher sound pressure levels than given above, the

machine should be installed in a room with at least minimum

room volume (see above) and favourable acoustical properties.

NOT SPECIFIED

Compressed Air Flow NOT APPLICABLE 5 to 6 bar (72.5 to 87 psi)

Operator Manual

BB3002 Page 15

Initial issue: 05/08

Latest revision: 09/14

1.4 Specifications for BB3002 with PUR Compact System

Model BB3002 PUR Mini PUR Plus

Description Glue binder Adhesive PUR Melter

Dimensions

Length - Width - Height in m(ft) 2,02 - 2,4 - 1,5 m (6.62 - 7.9 -4.92 ft) Height with support 1,10 m (3.60 ft)

Weight 650 Kg (1430 Lbs) 42 kg ( 92 lbs)

Power required

208/220 V, 60Hz, 3 phase delta12 A

200/240 VAC Nominal (180/264 V AC Allowable

range) 50/60 Hz

220/230 or 240 V, 50 Hz, 3 phase delta 12A US: 208 VAC (Between two phases of a US,

3-phase power service 3x208 V)

60 Hz

Europe: 230 VAC

50/60 Hz

380/400 or 415 V, 50 Hz, 3 phase star, no neutral12 A

Power consumption, stand by 1000 W TBD

Power consumption, operation 2500 W TBD

Power consumption,

maximum

3500 W 450 W GUN

124 W HOSE

1650 W MELTER

Safety class I (IEC 536) Protective earth connection TBD

Protection class IP 20 (IEC 529) TBD

Noise level (Lpa) 76 dB (A) (at operator position) 62 db at 1 meter (3.3 ft)

Radiant heat (BTU/h) 8500 (in operation) 3410 (in stand by) 7560 maximum

Room volume

Recommendation

95 m3(7 x 4,5 x 3 m) 3336 ft3(23x14.8x9.8 ft) Use extrator above Mini PUR lid to evacuate the

glue vapors.

Exhaust Requirement 510 m3/h (300 cfm) built-in extractor 510 m3/h (300 cfm) Need for external extractor

Dust concentration 0,04 mg/m3at continous operation (TLV for nuisance dust = 10

mg/m3)

NOT SPECIFIED

Additionnal safety information To avoid higher sound pressure levels than given above, the

machine should be installed in a room with at least minimum room

volume (see above) and favourable acoustical properties.

NOT SPECIFIED

See Glue safety Data Sheet

Compressed Air Flow NOT APPLICABLE 6 to 8 bar (87 to 116 psi)

Total power comsumption

2200 W

Operator Manual

BB3002 Page 16

Initial issue: 05/08

Latest revision: 06/13

1.5 Space requirements for BB3002 with PUR

Dimensions in meter (& foot).

Caster load for BB3002:

Front LH 110 kg (242.5 lbs)

Rear LH 110 kg (242.5 lbs)

Front RH 220 kg (485 lbs)

Rear RH 200 kg (441 lbs)

Top view

2.02m (6.62ft)

0.75m

(2.46ft)

0.8m (2.6ft)

0.8m

(2.6ft)

0.8m

(2.6ft)

0.8m (2.6ft)

2.41m (7.9ft)

1.35m (4.43ft)

0.60m

(1.96ft)

External paper dust collector

PUR

VERSAPAIL

BB 3002

0.54m

(1.7ft)

1.19m

(3.9ft)

0.38m

(1.2ft)

2.02m (6.62ft)

0.75m

(2.46ft)

0.80m (2.6ft)

0.80m

(2.6ft)

0.80m

(2.6ft)

0.80m (2.6ft)

2.41m (7.9ft)

1.35m (4.43ft)

0.60m

(1.96ft)

BB 3002 PUR

C

0.30m

(1ft)

0.55m (1.8ft)

PUR COMPACT SYSTEM

PUR VERSAPAIL SYSTEM

External paper dust collector

Operator and Service clearance

Operator and Service clearance

Operator Manual

BB3002 Page 17

Initial issue: 05/08

Latest revision: 11/08

1.6 What is PUR?

PUR (polyurethane) is a reactive hot melt material that is melted and processed like

conventional hot melt adhesive. It binds in a hot–cold process and cross-links under the

influence of moisture, thus achieving its final solidity.

The original plastic film thus becomes elastic and very flexible, and it can no longer be

melted or dissolved. It is temperature resistant from -30 °C (-22°F) to +150 °C (302 °F)

and is resistant to chemicals.

1.7 Working with PUR

• The durability of a product bound with PUR can not be evaluated when it first leaves

the binding machine. But when the cover and the edges of the pages show sufficient

adhesive (film strength 0.4 to 0.5 mm), it can safely be assumed that the pull value

after cross-linking is very good.

• The bound products should be handled very carefully within the first 24 hours, even

after stacking. Avoid mechanical force.

• Pull value measurements after 6 hours show approx. 1/3 of the final value to be

achieved. This value depends strongly on the paper and the ambient humidity.

• The maximum pull value is achieved after 24 hours.

• Books that are opened all the way to the inside margin within 24 hours of binding are

no longer suitable for sale.

• Material in opened drums can no longer be used when it has come into contact with

ambient humidity for even a few hours. Thus drums should be emptied completely

(light tower: yellow light on). Lubricate heating punch sealing ring every time the drum

is changed.

• Slugs (for PUR C) must be put in the Melter tank immediately after the opening of the

pack.

• If the system is not used for 5 days, it must be purged with a cleaning agent.

• Observe instructions of adhesive/cleaning agent supplier!

Operator Manual

BB3002 Page 18

Initial issue: 05/08

Latest revision: 06/13

2. GENERAL DESCRIPTION

2.1 Specifications

Cover types: Glossy paper, with cutouts,

with transparent front etc.

Cover weight: 80-300 gsm 20-110 lb

Lamination, grain and thickness of covers may

disturb the clamping/nipping of books.

Paper weight: 60-160 gsm 15-40 lb bond

Features:

Max. operating speed: Up to 300 cycles/hour (operator dependent

and based on A4 format)

Cover pile height: 80 mm / 3.15"

Missing cover detection: Standard

Glue temperature range: See safety Data Sheet

Binding maximum thickness: 60 mm

Milling and notching Standard

Milling depth:

from 0 to 3mm (depending on paper type and format)

External waste paper collection: Standard

Book counter: Standard

Creasing and lateral gluing: Standard

Electrical adjustment of milling depth: Standard

Adjustable jogger vibration: Standard

Detection of minimum glue levels: Standard

Start-up timer: Standard

Fume extractor with condensation filter: Standard

Book reception module (BBR): Optional

Double cover detection: Optional

System to evacuate the fume outside : Standard

Glue Purmelt QR 3317 - 20 Kg - 9195048

Glue Purmelt QR 3317 - 2 Kg - 9196037

ATTENTION : - The room

must be equipped with a

chimney to evacuate the fume/

vapors outside of the room.

- Compressed air of 6 bar (0.6

MPa/87psi) is necessary.

For more information about the

glue, see Henkel Purmelt

Safety Data Sheet.

Perfect Binding mode

Padding mode

(without cover)

60 to 385mm

(2.36" to 15.15")

MAX 60mm (2.36")

MIN 1mm (0.04")

90 to 320mm

(3.54" to 12.60")

Operator Manual

BB3002 Page 19

Initial issue: 05/08

Latest revision: 06/13

7

6

5

4

21

13

12

11

10

9

8

14

15

2.2 General description of the binder 1. Main power switch.

2. Manual loading area.

3. .NA.

4. Pedal.

5. Safety barriers.

6. Indicator lights.

7. Emergency stop button.

8. Front panel.

9. Cover station.

10. Intermediate conveyor.

11. Output conveyor - BBR (optional).

12. UI - graphical interface.

13. Push buttons.

14. Bulk Melter VersaPail.

15. PUR C

Operator Manual

BB3002 Page 20

Initial issue: 05/08

Latest revision: 11/08

2.3 Description of the gluing process

• Place a set of pages in the carriage jaws.

• Start a gluing cycle, withdrawing your hands outside the loading area.

Automatic process

with cover

Jogging

Milling

Roughing

Glueing

Cover

clamping

Automatic process

without cover

Jogging

Glueing

NORDSON

NORDSON

This manual suits for next models

2

Table of contents

Other C.P.Bourg Binding Machine manuals