User’s guide MBE-300 User’s guide MBE-300

1. After binding process the jaw automatically moves back and leaves the space to take

documents from the machine in easy way. Keep the START button till the signal of the

end of the process –the jaw stops.

2. Take out bound documents.

After binding process the jaw does not go back to the starting position. It shorter the time to

move the jaw to the document. If you want to bind wider channel you have to move forward

the jaw to the right position.

At every moment you can stop the binding process by releasing START buttons. Another

buttons pressing continues the process. If while binding process the jaws are moved back –

the process starts again (from the moment of locking the channel).

Document width measurement:

1. Place the document with covers to the document width measurement slot (as

it is shown on a figure).

2. At the same time press and keep it pressed START button.

3. Document width measurement always starts from the borderline position to

guarantee precise result –at first the jaw is placed forward.

4. The jaw goes to the document and when left hook touches the document is shown on

the display the information on what size of channel should be used.

5. The jaw moves back.

At every moment you can stop the process by pressing START button.

5

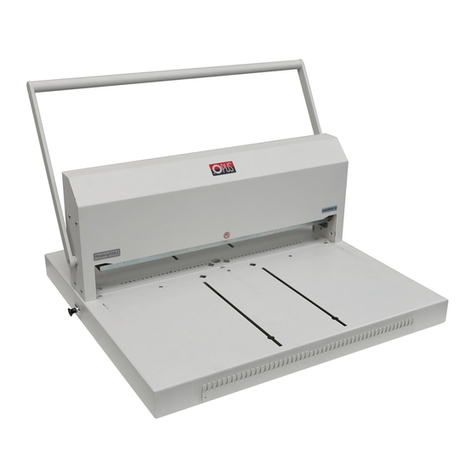

MBE-300 is based on popular binding machine. It is equiped with one binding jaw powered

by two screws linked together by special cogged belt with motor. Mechanism assures the

parallelism of the moving jaws what guarantee regular channel tightness. Motor operation

is controlled by microprocessor control with LCD display. While binding the channel is

pressed to the permanent debinding plate. The channel while debinding by debinding

wedge (placed in debinding hooks) is pressed to the same permanent plate. Left hook

measures the width of the document.

Preparation to work:

1. Connect the plug to the electric socket.

2. Turn the machine on by the button placed on the right side of the cover (display turns

on and shows the information about machine version and the total number of binder

documents).

3. Machine always starts its work with binding mode.

4. Press proper button to choose other mode.

Binding in MB mode:

5. On the display it is shown daily number of bound documents or the pressure level. This

information can be changed by pressing proper counter or pressure button.

6. In accordance with the information on a display place the channel to the slot (straight

side of the channel should be placed on the moving side of the jaw, the curved side

should be placed on a debinding plate side).

7. Press and keep both START buttons (the time between pressing those buttons can

not be longer than 0,2 seconds).

8. The jaw moves to the channel and stops –the channel is locked to place the

document inside in easier way. Place the document into the channel.

9. Press and keep both START buttons once again. The machines starts to bind

documents together.

There are available four different binding pressure moods. The most universal is the level

number 3 that can be used to the wide range of documents. This mood is set after every

start of the machine. If there is a necessity to change the binding pressure press proper

button on a control panel. (because of using shorter channel than 300mm, channel in soft

veneer or binding together very taught materials)

4