Capital Automotive Equipment Model:4PG8000

IMPORTANT SAFETY INSTRUCTIONS SAVE THESE INSTRUCTIONS

PLEASE READ THE ENTIRE CONTENTS OF THIS MANUAL PRIOR TOINSTALLATION AND OPERATION. BY

PROCEEDING WITH LIFT INSTALLATION AND OPERATION YOU AGREE THAT YOU FULLY UNDERSTAND AND

COMPREHEND THE FULL CONTENTS OF THIS MANUAL. FORWARD THIS MANUAL TO ALL OPERATORS.

FAILURE TO OPERATE THIS EQUIPMENT AS DIRECTED MAY CAUSE INJURY OR DEATH

BE SAFE

Your new lift was designed and built with safety in mind. However, your overall safety can be increased with

proper training and thoughtful operation on the part of the operator. DO NOT operate or repair this

equipment without reading this manual and the important safety instructions shown inside. Keep this

operation manual near the lift at all times. Make sure that ALL USERS read and understand this manual.

PRODUCT WARRANTY

Four post lift is covered under warranty for 5 years on equipment structure, to be free of defects in material and

workmanship. Power units, hydraulic cylinders, and all other assembly components (such as cables, chains, valves,

switches etc.) are warrantied for one year against defects in material or workmanship under normal use. We shall repair or

replace at its discretion, within the warranty period, those parts returned to the factory freight, prepaid, which prove upon

inspection to be defective.

The warranty does not extend to:

Defects caused by ordinary wear, abuse, misuse, negligence, shipping damage, improper installation, voltage or lack

of required maintenance;

Damages resulting from purchaser’s neglect or failure to operate products in accordance with instructions provided in

the owner’s manual(s) and/or other accompanying instructions supplied;

Normal wear items or service normally required to maintain the product in a safe operating condition;

Any component damaged in shipment;

Other items not listed but may be considered general wear parts;

Damage caused by rain, excessive humidity, corrosive environments or other contaminants.

THESE WARRANTIES DO NOT EXTEND TO ANY COSMETIC DEFECT NOT INTERFERING WITH EQUIPMENT FUNCTIONALITY OR

ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM ANY DEFECT,

FAILURE, OR MALFUNCTION OF OUR PRODUCT OR THE BREACH OR DELAY IN PERFORMANCE OF THE WARRANTY.

IMPORTANT NOTICE

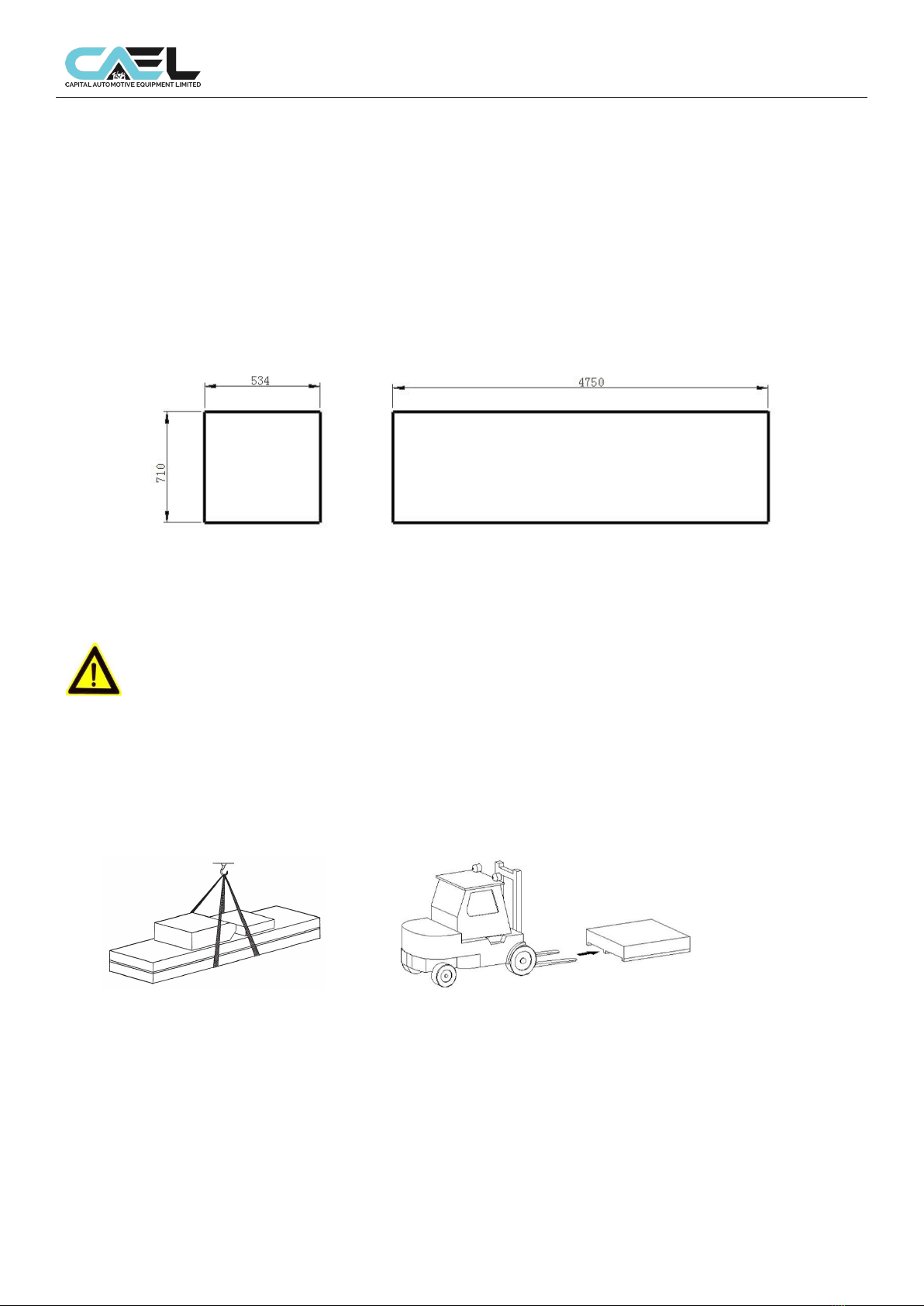

Do not attempt to install this lift if you have never been trained on basic automotive lift installation procedures. Never

attempt to lift components without proper lifting tools such as a forklift or cranes. Stay clear of any moving parts that can

fall and cause injury. These instructions must be followed to insure proper installation and operation of your lift. Failure to

comply with these instructions can result in serious bodily harm and void product warranty. Manufacturer will assume no

liability for loss or damage of any kind, expressed or implied resulting from improper installation or use of this product.