CALECTRO Uniguard 8 User manual

Calectro AB Phone: +46 31-69 53 00 info@calectro.se www.calectro.se

Installation instruction

Uniguard 8

Hydraulic diameter ( )

Example of installation at

sources of interference:

- fan

- damper

- silencer

- battery

- air handling unit

- duct bend

- duct branching

- duct narrowing or expansion

Where large temperature variations

occur, e.g. on outdoor

locations or in areas subject to

outside temperatures (roof,

attics), the Uniguard should be

insulated, see para 8.

Note the foot’s shape of an arrow, which shall be installed towards the air flow direction.

Example of location after

change of duct direction.

Example of location before

a ventilation grill.

Ventilation grill

Airflow direction

5 dh3 dh

© 2023.10.03 R1.0 Calectro AB

d = D

Ø D

hd =

h2xHxB

H+B H

B

Hydraulic diameter

MIN 3xdhMIN 5xdh

UG8 UG8

FAN

MIN 5xdh

UG8

MIN 3xdh

UG8

DUCT BEND

UG8

MIN 5xdh

UG8

MIN 3xdh

UG8

MIN 3xdh

DUCT BRANCHING

UG8

UG8

MIN 3xdh

MIN 5xdh

AIR HANDLING UNIT

RETURN AIR

INLET AIR

RECTANGULAR DUCT

CIRCULAR DUCT

MIN 3xdhMIN 5xdh

GX GX

MIN 3xdhMIN 5xdh

GX GX

MIN 3xdhMIN 5xdh

GX GX

MIN 3xdhMIN 5xdh

GX GX

MIN 3xdhMIN 5xdh

GX GX

MIN 5xdh

GX

MIN 3xdh

GX

MIN 5xdh

GX

MIN 3xdh

GX

GX MIN 3xdh

GX

GX

MIN 3xdh

MIN 5xdh

d = D

Ø D

h

d =

h

2xHxW

H+W H

W

Hydraulic diameter

Example of location

FRÅNLUFT / RETURN AIR

TILLUFT / INLET AIR

RECTANGULAR DUCT

CIRCULAR DUCT

MIN 3xdhMIN 5xdh

GX GX

MIN 3xdhMIN 5xdh

GX GX

MIN 3xdhMIN 5xdh

GX GX

MIN 3xdhMIN 5xdh

GX GX

MIN 3xdhMIN 5xdh

GX GX

MIN 5xdh

GX

MIN 3xdh

GX

MIN 5xdh

GX

MIN 3xdh

GX

GX MIN 3xdh

GX

GX

MIN 3xdh

MIN 5xdh

d = D

Ø D

h

d =

h

2xHxW

H+W H

W

Hydraulic diameter

Example of location

FRÅNLUFT / RETURN AIR

TILLUFT / INLET AIR

RECTANGULAR DUCT

CIRCULAR DUCT

CIRCULAR DUCT

RECTANGULAR DUCT

h

d

ENGLISH

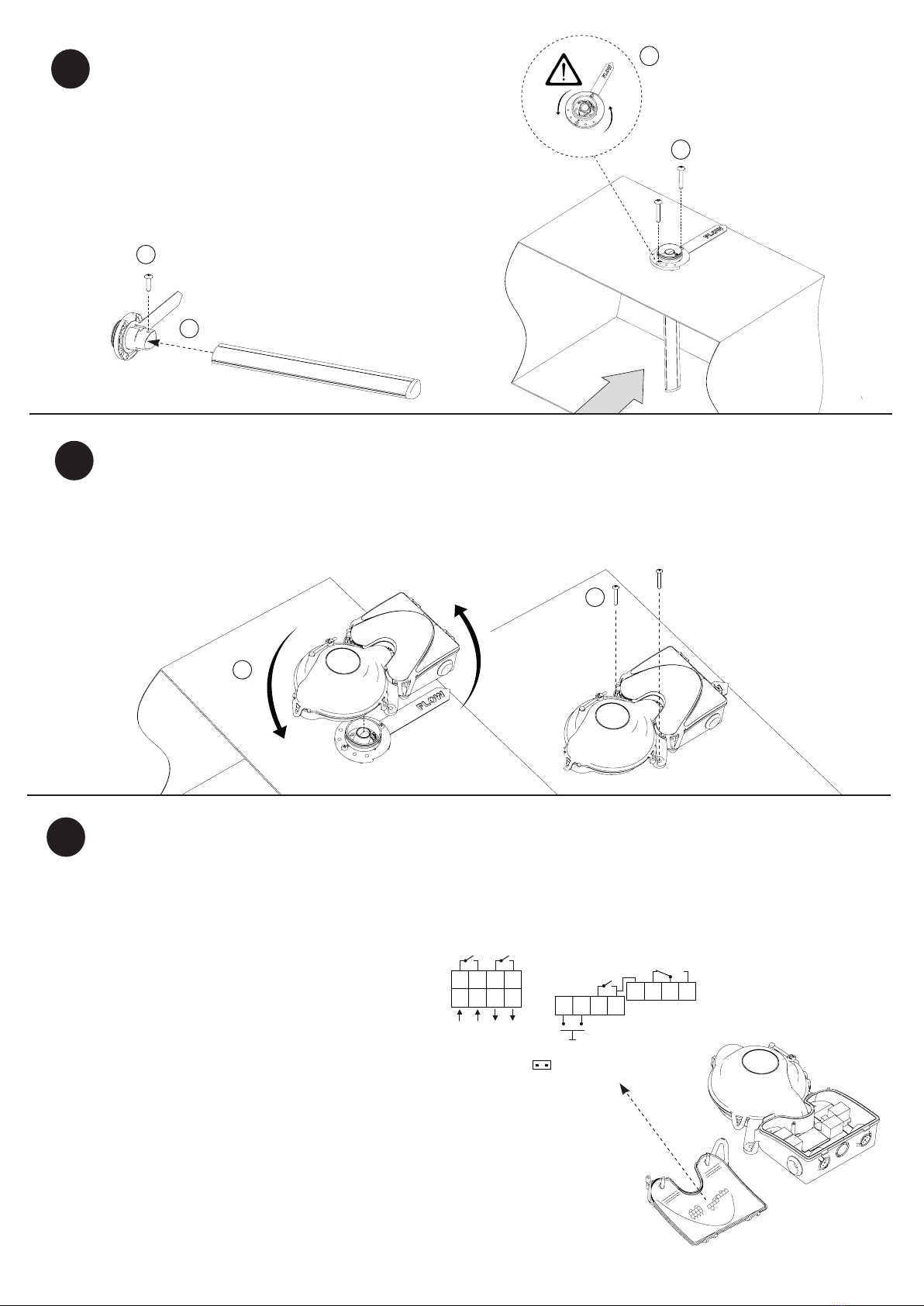

Mounting and positioning

The Uniguard should be installed according to the

drawing below. The Uniguard can be installed on any

side of the duct.

We recommend that the Uniguard is mounted at an

equal distance from sources of interferance, and similar

to the siting of flow monitors.

A distance of 3 times the duct hydraulic diameter should

be left before a source of interferance, and 5 times the

hydraulic diameter after.

UG8-E models

2

1

2

3

Drill a hole in the duct

Cut the venturi sampling tube

1. Measure the diameter of the duct.

2. The tube should penetrate at least 90% of

the width of the duct. NOTE! See para 3.

3. Shorten the sampling tube, if necessary.

4. Insert the end plug.

Fitting of tubes in ducts with different diameters

Shorten the tube to correct length.

Insert the end plug.

Put on the end plastic

gasket.

Put on the rubber

gasket, HFU204.

NOTE!

Drill a hole

Ø 51 mm (2").

ST-EXTEND

Drill a hole

Ø 38 mm (1,5")

Drill a hole

Ø 38 mm (1,5")

Max diameter of the duct 600 mm (2 ft).

Use the venturi tube 280 or

580 mm (1 or 2 ft).

Shorten the tube, if necessary.

For ducts with a ø of less than 0,6 m use the 0,6 m pipe.

For ducts with a ø of between 0,6 m and 1,4 m use the 1,5 m pipe.

For ducts which are larger than 1,4 m use the 2,8 m pipe.

The venturi tube shall not

protrude more than 30 mm (1")

through the duct wall.

Diameter of the duct larger

than 600 mm (2 ft).

The venturi tube should penetrate

the whole duct. Extend with

one or more extention tubes.

For ducts up to 300 mm (1 ft), use ST280.

For ducts between 300-600 mm (1-2 ft), use ST580.

For ducts over 600 mm (2 ft), extend the tube with

ST-EXTEND.

When using ST-EXTEND, the tube must always be attached

to the opposite duct wall, together with rubber gasket HFU204.

If strong vibrations occur in the venturi tube, we recommend

stabilizing the tube further, e.g. with mounting strap.

2

1

3

4

≥ 90%

100%

9

ø 38 mm (1,5") ø 51 mm (2")

Ø > 200 mm (2/3 ft)

1. For all ducts larger than 200 mm (2/3 ) hydralic diameter,

the UG8 can be mounted directly on the duct.

2. If the duct is insulated or smaller than 200 mm (2/3 ),

use mounting bracket UG-MB-8.

1

2

3

1. Mount the Uniguard on the rotation part and

rotate it to the desired direction.

2. Secure the Uniguard with the two screws.

Installation on the duct

5

4Mount the sampling tube and the rotation part

1. Insert the sampling tube into the bottom

of the rotation part.

2. Secure the tube with the locking screw.

3. Turn the rotation part in the correct air-flow direction,

so that the white FLOW-arrow and the air-flow

direction of the duct correlate.

4. Fix the rotation part to the ventilation duct

according to the illustration.

3

4

2

1

2

1

360°

6

1. Gently remove the cover over the connection

housing by releasing the snap locks. Uniguard 8

has two pre-mounted IP67 approved glands for

cable diameter 4-11 mm, type Klikseal.

NOTE! The cable must only be pulled through

the Klikseal in one direction: into the Uniguard.

To exchange a mounted cable, cut the cable

outside of the Uniguard and pull out the rest

from the inside.

2. Connect the cable wires according to the

wiring diagram on the inside of the cover of the

connection chamber.

UG8-E-24: 24V AC/DC

UG8-E-230: 230V AC

The relay outputs are shown in power off/alarm

condition. For complete technical product

information, see the product data sheet.

Electrical installation

12

11

10

9

16

15

14

13

12 3 4

8

7

6

5

Smoke alarm relay 2

Reset

Jumper

12

11

10

9

16

15

14

13

12 3 4

8

7

6

5

C NC C NC

NO NCC

Relay System failure

G0 -

G0 -

Power supply +

Power supply +

Relay Service alarm*

1

Contamination/Low flow

Smoke alarm relay 1

NC C C

*2

*1 Service alarm can indicate either low airflow or contimination.

*2 Jumper ON disables air flow monitoring.

A

i

r

f

l

o

w

D

i

r

e

c

t

i

o

n

4

Mounting in places where possible condensation problems could arise, e.g. cold attics.

Use protection cover e.g. Calectro´s

UG-COVER-75.

Use insulation cover of 100-200 mm (4-8")

to protect the entire Uniguard.

8

Do not drill any holes in the cover for signs etc.

Holes will cause air leakage and seriously disturb

the function of the detector.

Test of detector

7

T

E

ST

SP

R

AY

1. Check the detector with smoke detector

aerosol test spray (e.g. SOLO A5).

2. Move the "test hole plug" to the side

and briefly release a spray of aerosol.

When alarming, the LED lits red on the

detector and when service alarming

(contamination) it lits green.

IMPORTANT!

Reassemble the "test hole plug".

A sign should be used to show location of the detector.

A remote LED alarm indication is recommended when the Uniguard is hidden.

5

9Mounting bracket for insulated ducts and ducts smaller than 200 mm (2/3 ft).

Shape the mounting bracket in position A or B. The mounting bracket can then

easily be bent to t circular or rectangular ducts.

The position of the legs of the mounting bracket will be locked with the mounting

screws from the rotation part.

The mounting bracket is supplied at.

Fix the bracket

on to the duct.

A B

Turn the mounting bracket in the correct aiflow direction.

Calectro AB Phone: +46 31-69 53 00 info@calectro.se www.calectro.se

1. Remove the cover by gently bending

the snap locks outwards.

4. Insert the new detector and

rotate it clockwise.

2. Detach the cover.

5. Reattach the cover. (1) Start by

placing the “lip” of the cover in

the cavity next to the air inlet.

(2) Then press down the cover.

3. Remove the smoke detector

by rotating it contraclockwise

approximately 1/5 turn.

6. Check that all three snap

locks are properly pressed

in place.

2

1

According to WEEE (Waste of Electrical and Electronic Equipment) directive, you must at the end of life of the product dispose of it separately at an

appropriate collection point and not place it with unsorted waste. Alternatively return it to Calectro for recycling.

FINAL CHECKS

• Check that the rotation part of the Uniguard is correctly

installed according to the air flow in the duct.

• Check that the plastic plug of the test hole is properly

installed.

• It is recommended that smoke from a smoke generator is

introduced into the duct to check the detector’s function.

Trouble shooting

The smoke detector indicates alarm without smoke.

• Smoke detector is faulty or contaminated. The detector needs to be

replaced.

In case you need to replace the smoke detector

10

This manual suits for next models

3

Table of contents