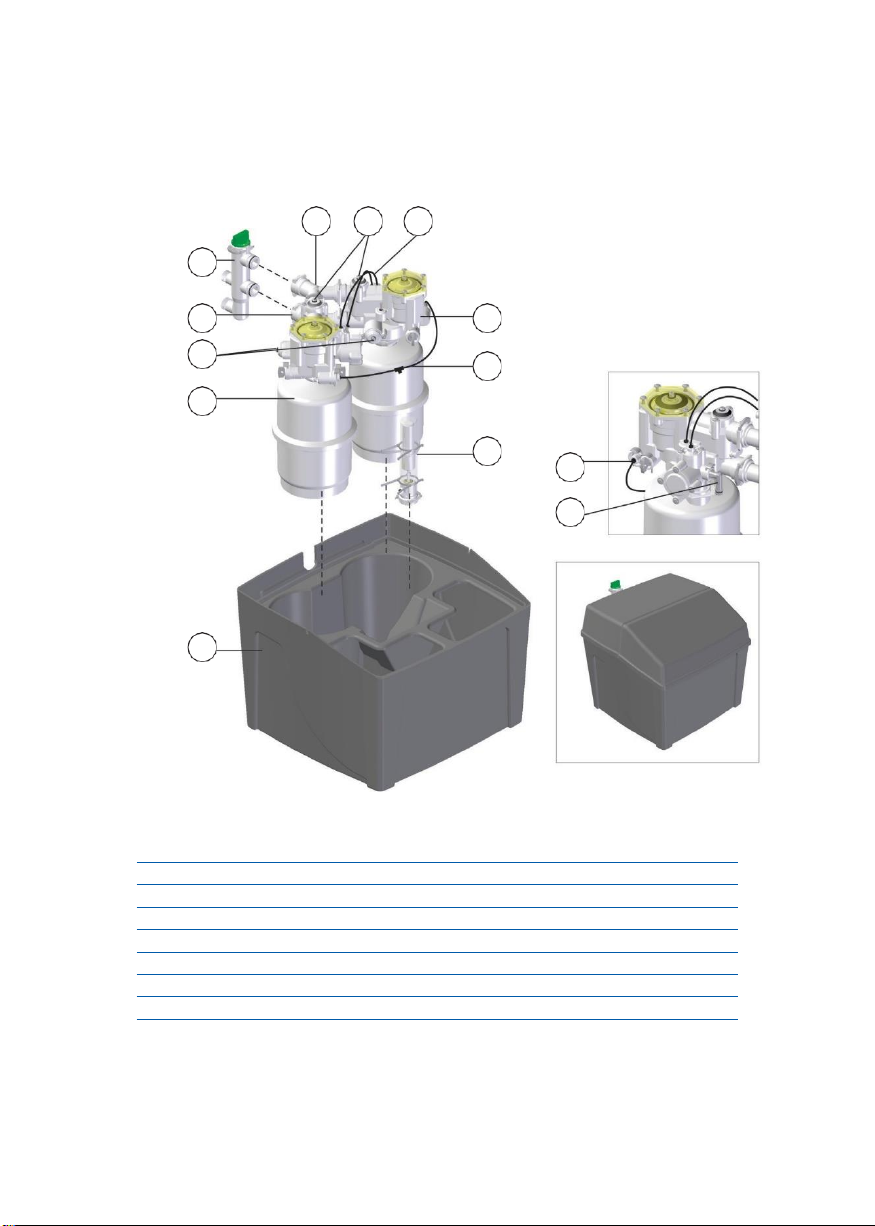

3.4 INSTALL BYPASS

Cut open the main water supply in

order to install direct connections to

the softener or to install the Bypass

(recommended). Follow the arrows

on both, bypass and softener for the

water inlet and outlet.

Please note - the inlet filter

is not required in the UK.

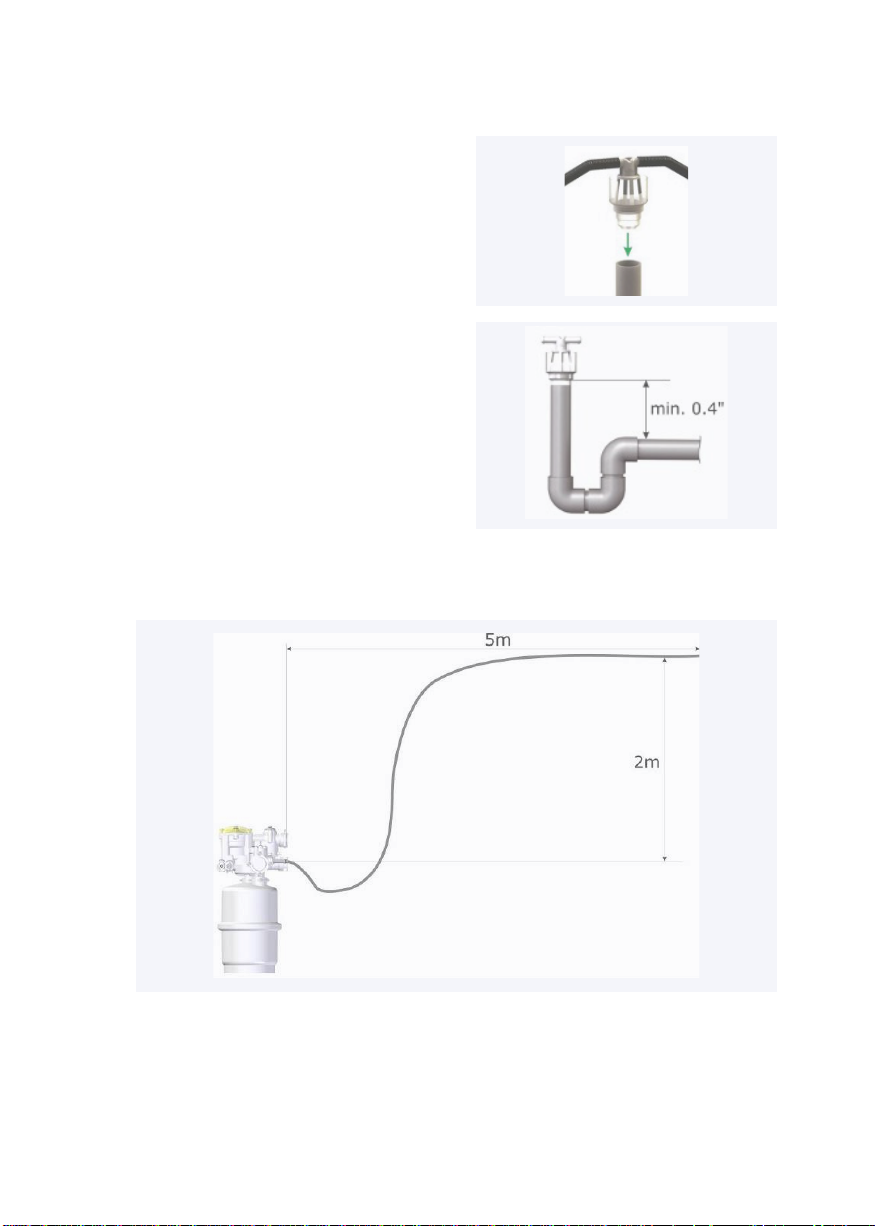

3.5 CONNECT DRAIN

Connect both drain outlets (#12) to a

local drain (with an air gap, using the

provided Open Drain Connector, see

par. 3.7) by means of the provided

13mm flexible drain pipe. In order to

guarantee that the device will keep

on functioning perfectly in the future,

this drain pipe is spirally reinforced

to avoid later blocking and/or kinks.

It is possible that both drains are

connected with each other through

a Y-piece. In this case, connect the

Y-piece to the local drain. Please

protect the drain against frost and

heat (min. temp. 5°C, max. temp.

40°C).

When another drain pipe is

used, the guarantee on the unit

is expired.

CAUTION: before installing the

softener,set the Bypass in “bypass”

mode, not in “service”.