TLC Sprayer

Instruction manual, May-18 6

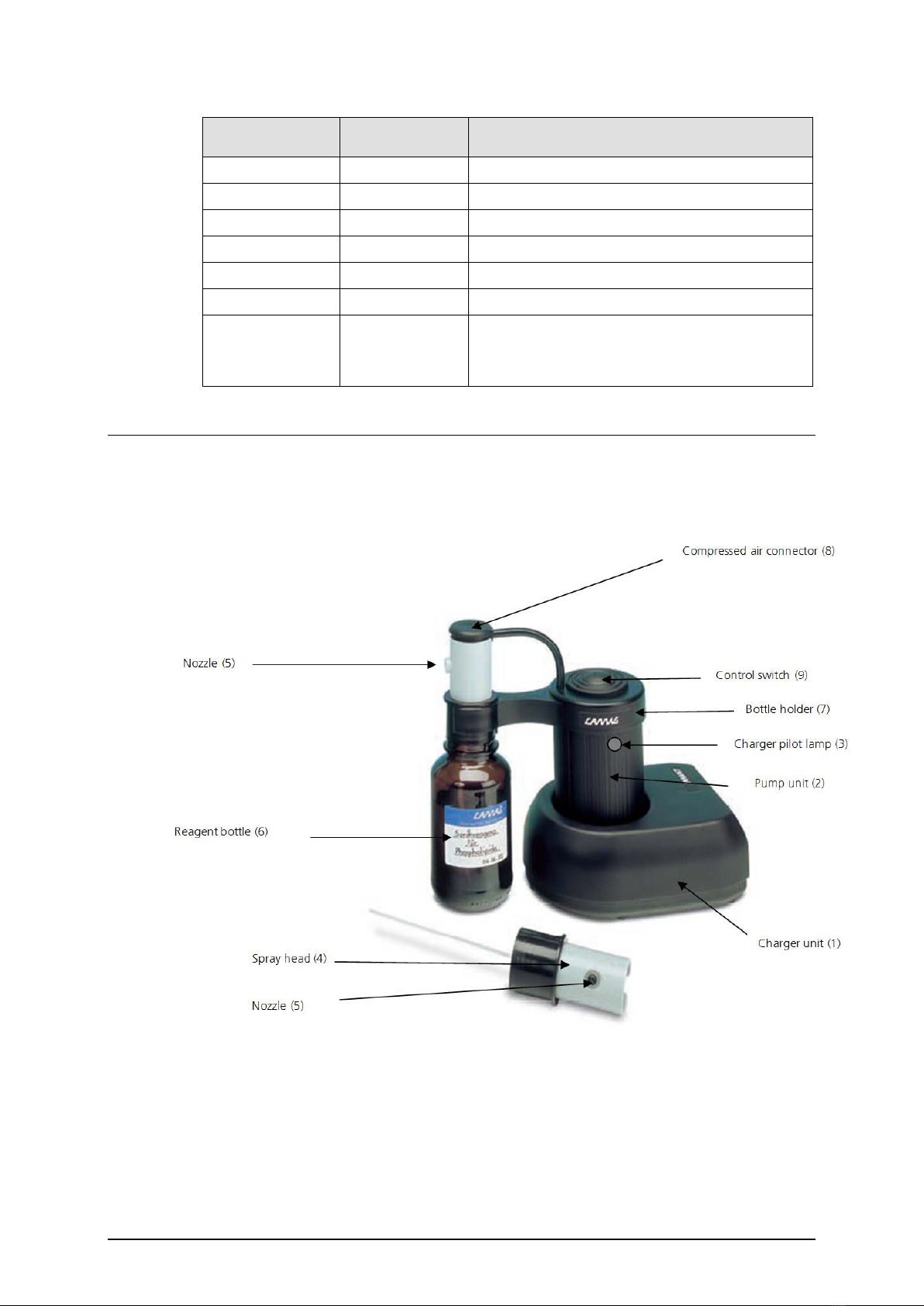

2.2 Connect the spray unit

For solutions of regular viscosity, spray head type A is suitable.

For solutions of higher viscosity (such as sulphuric acid up to 30%), CAMAG recommends

to use spray head B (black cover).

•Remove the cover and the cover disc, screw the spray head (4) with bottle adapter

(7) on the filled reagent bottle (6).

•Insert the reagent bottle with spray head into the clamp, so that the cam of the

spray head is positioned within the groove of the clamp.

•Press the end of the connecting tube (8) onto the spray head until it snaps into

position.

By following this procedure, the pump unit is tightly connected with the spray unit.

2.3 Hints

•Make sure reagent solutions are free from solid particles; filter if necessary.

•Do not fill the reagent bottle higher than to its shoulder.

•When using a 50 mL bottle, shorten the capillary tube of the spray head, cutting it

at 45°angle.

•Do not store the instrument in the charger.

•Use the sprayer until the battery is almost down, and then fully re-charge it.

•If the instrument is not used for a longer time, disconnect the mains connection.

3Getting started

Remove the charged and prepared TLC Sprayer unit from the charger unit and start

spraying by pressing the control switch (9).

CAMAG recommends to start spraying at a distance of 20cm from the plate. Move the

sprayer in a steady motion over the plate until the surface is sufficiently wet (to get best

results, stop before the plate is totally wet).

Spray distance, time and after-spraying treatment depend strongly on the method used.

4Maintenance/Troubleshooting

4.1 Maintenance

A regular maintenance is mandatory to keep the instrument in perfect working condition.

Therefore follow the steps below:

•Discharge the sprayer once a month (by spraying until the battery is almost empty)

and charge it fully (also if the TLC sprayer is not used)

•Replace the spray head on a regular base