EN

77-2625-R13.1 (8/2014) 5 / 12

SPRAY GUN CLEANING INSTRUCTIONS

MAINTENANCE

In certain states it is now against the law

to spray solvents containing Volatile

Organic Compounds (VOC)’s into the

atmosphere when cleaning a spray gun. In

order to comply with these air quality

laws Binks recommends one of the fol-

lowing two methods to clean your spray

finishing equipment:

1. Spray solvent through the gun into a

closed system. An enclosed unit or

spray gun cleaning station condenses

solvent vapors back into liquid form

which prevents escape of VOC’s into

the atmosphere.

2. Place spray gun in a washer type

cleaner. This system must totally

enclose the spray gun, cups, nozzles

and other parts during washing, rins-

ing and draining cycles. This type of

unit must be able to flush solvent

through the gun without releasing any

VOC vapors into the atmosphere.

Additionally, open containers for storage

or disposal of solvent or solvent-contain-

ing cloth or paper used for surface prepa-

ration and clean-up may not be used.

Containers shall be nonabsorbent.

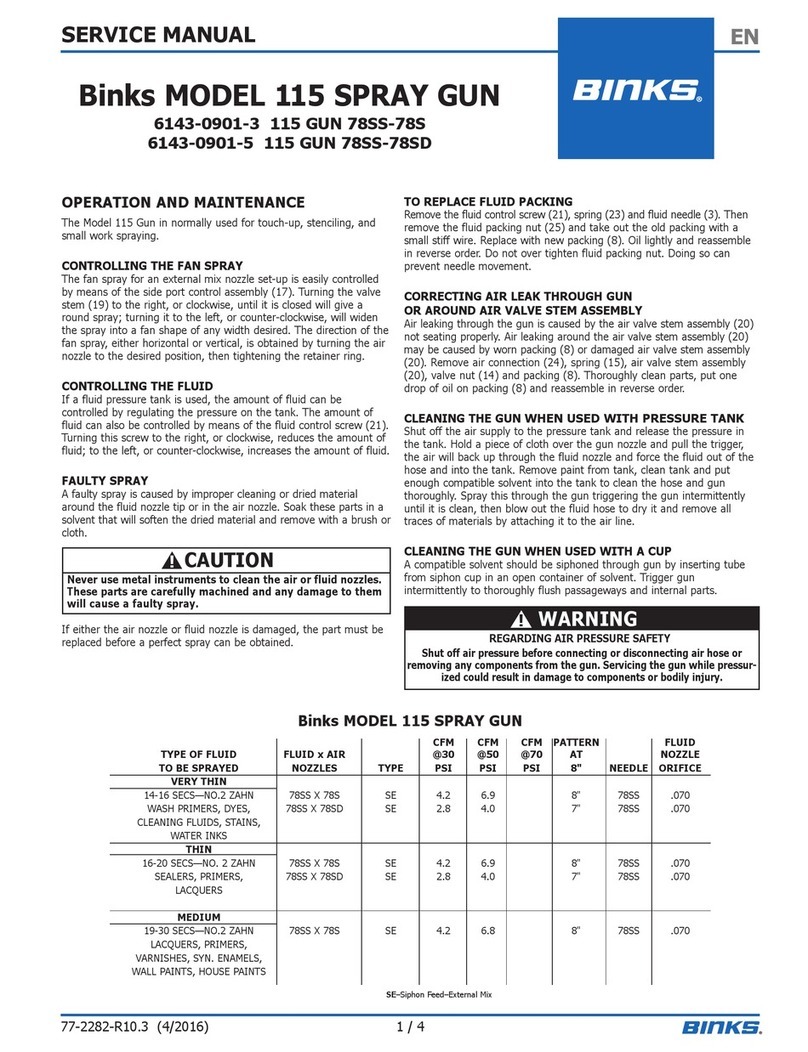

AIR AND FLUID NOZZLE

CLEANING

A faulty spray pattern is often caused by

improper cleaning resulting in dried

materials around the material nozzle tip

or in the air nozzle. Soak these parts in

thinners to soften the dried material and

remove with a brush or cloth.

If either the air nozzle or fluid nozzle are

damaged, these parts must be replaced

before perfect spray can be obtained.

CLEANING GUN USED WITH

1 QUART CUP

Relieve pressure in the cup. Then,

unscrew, empty and carefully rinse cup

out with thinners. Place clean thinners in

the cup and spray this through the gun

until it is clean. Blow air through gun to

dry it.

CLEANING GUN USED WITH

PRESSURE CONTAINER

Hold a piece of cloth wadded in the hand

over the gun nozzle and pull the trigger.

The air will back up through the material

nozzle and force the material out of the

hose into the container. Empty container.

Put enough thinners into the container to

wash the hose and gun thoroughly and

spray this through the gun until it is clean.

Then blow out the material hose to dry it

and remove all traces of material by

attaching it to the air line.

CLEANING GUN USED WITH

PAINT CIRCULATING SYSTEM

Shut off material supply and remove

material hose from gun. Clean gun as

used with siphon cup or pressure contain-

er or connect quick release on paint line

solvent line. To ensure clean air to spray

gun, use Binks oil and water extractor.

See your Binks distributor for the correct

model.

TO REPLACE AIR VALVE AND

SPINDLE ASSEMBLY

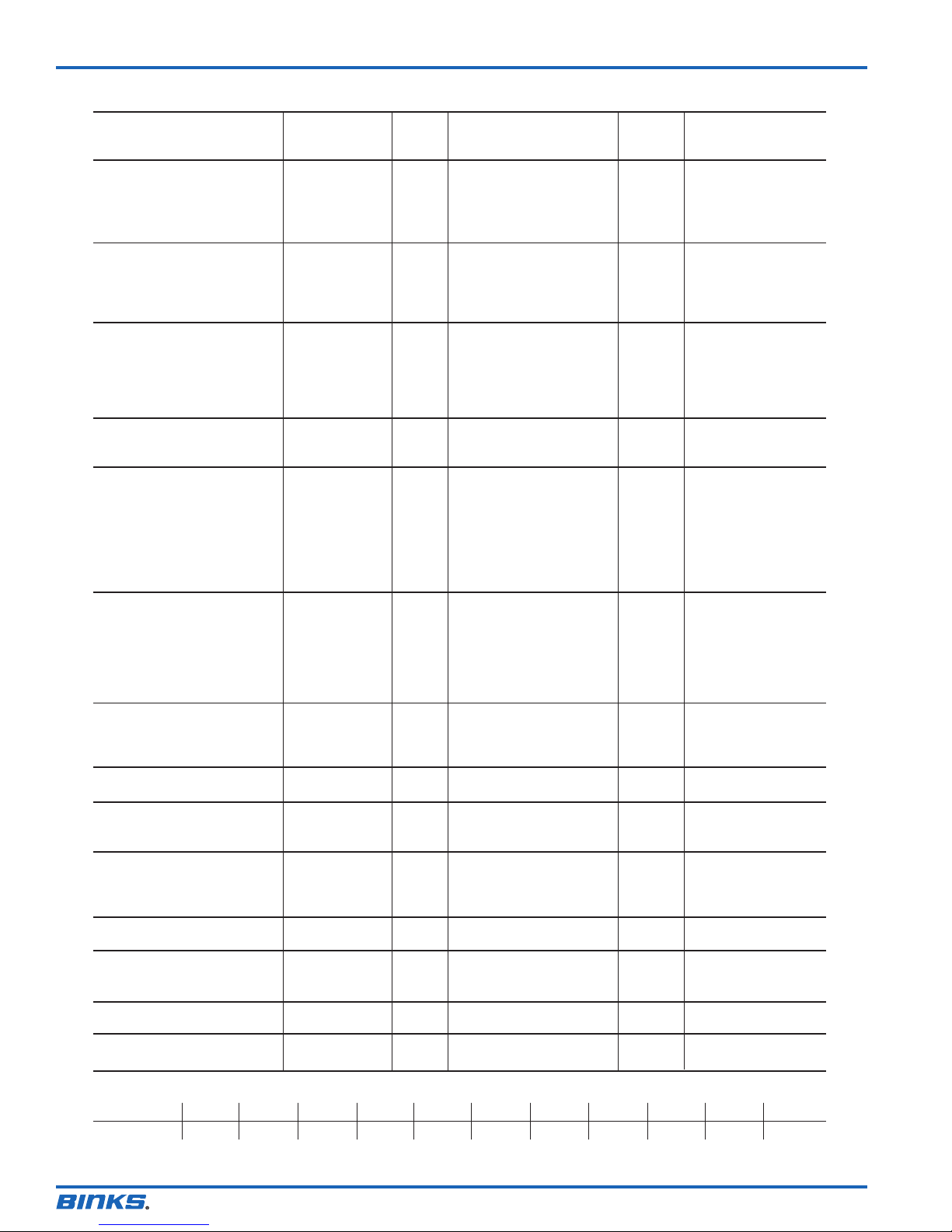

Remove material valve control knob (21),

spring (18), and needle assembly (20).

Unscrew housing (19), and remove spin-

dle assembly (17) with springs (16 & 18),

housings (15), and o-rings (14). Lubricate

new o-rings with Gunners Mate.

Assemble components using material

needle. Place this assembly along with

housing (19) into gun body and screw

into position. Remove material needle

(20) and tighten housing (19).

TO REPLACE NEEDLE SEAL

AND GLAND ADAPTER IN

FLUID INLET

Remove material valve control knob (21)

and spring (18) and pull out fluid

needle (20). Unscrew packing nut (30)

and remove spring (29) and seal backup

(28). Using a no. 10 x 1-1/4" coarse-

thread wood screw (Binks Part No. 20-

6536) or small sheet metal screw, remove

the needle seal (27) and gland adapter

(26). Replace gland adapter (26) and nee-

dle seal (27). Re-insert seal backup (28)

spring (29) and screw on packing nut (30)

a couple of turns so it fits loosely by

hand. Reassemble fluid needle (20),

spring (18) and material valve control

knob (21). Finally, tighten packing

nut (30) until it bottoms out on fluid

inlet (25).

LUBRICATION

Lubricate daily, all moving parts includ-

ing trigger pivot point and air valve spin-

dle and with Binks Gunners Mate (44).

WARNING

Injection of material from the gun

into the skin may result in serious

personal injury. Shut off the air

supply to the container and release

the pressure on the container before

attempting to clean the gun.

!

CAUTION

Never use metal instruments to

clean the air or material nozzles.

These parts are carefully machined

and any damage to them will cause

faulty spray.

!