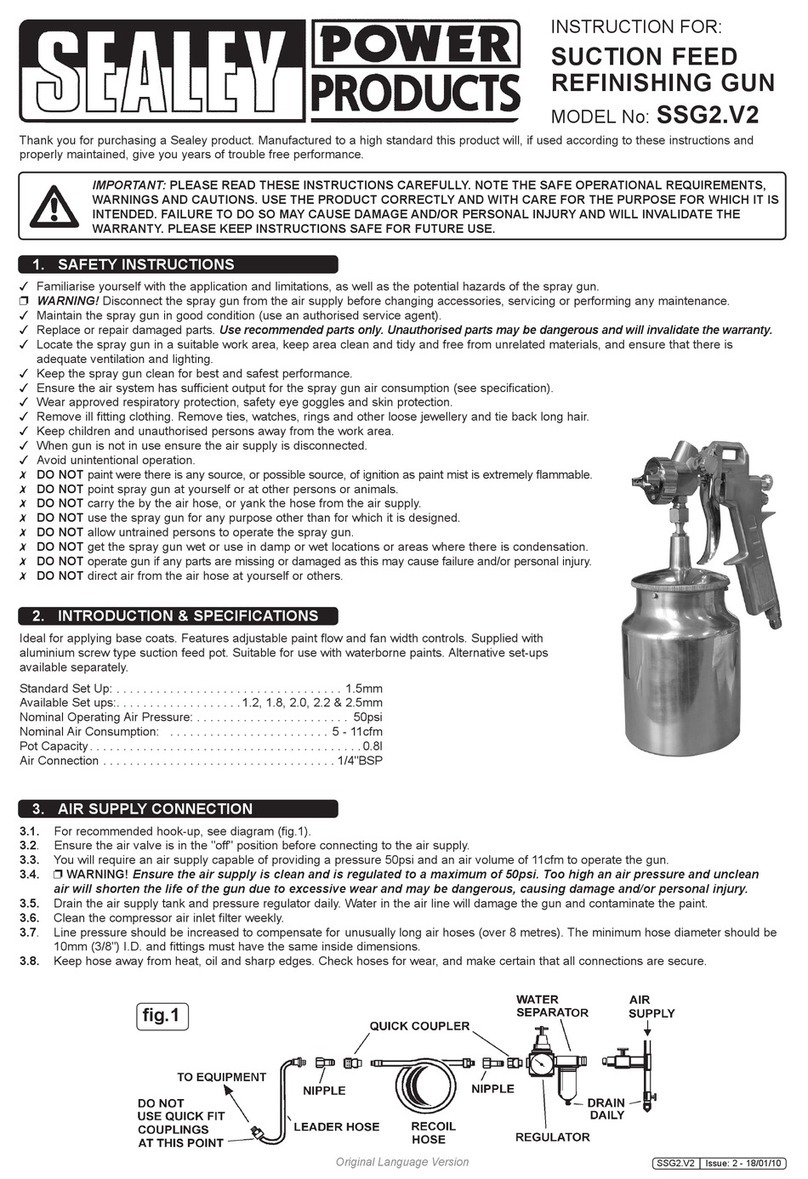

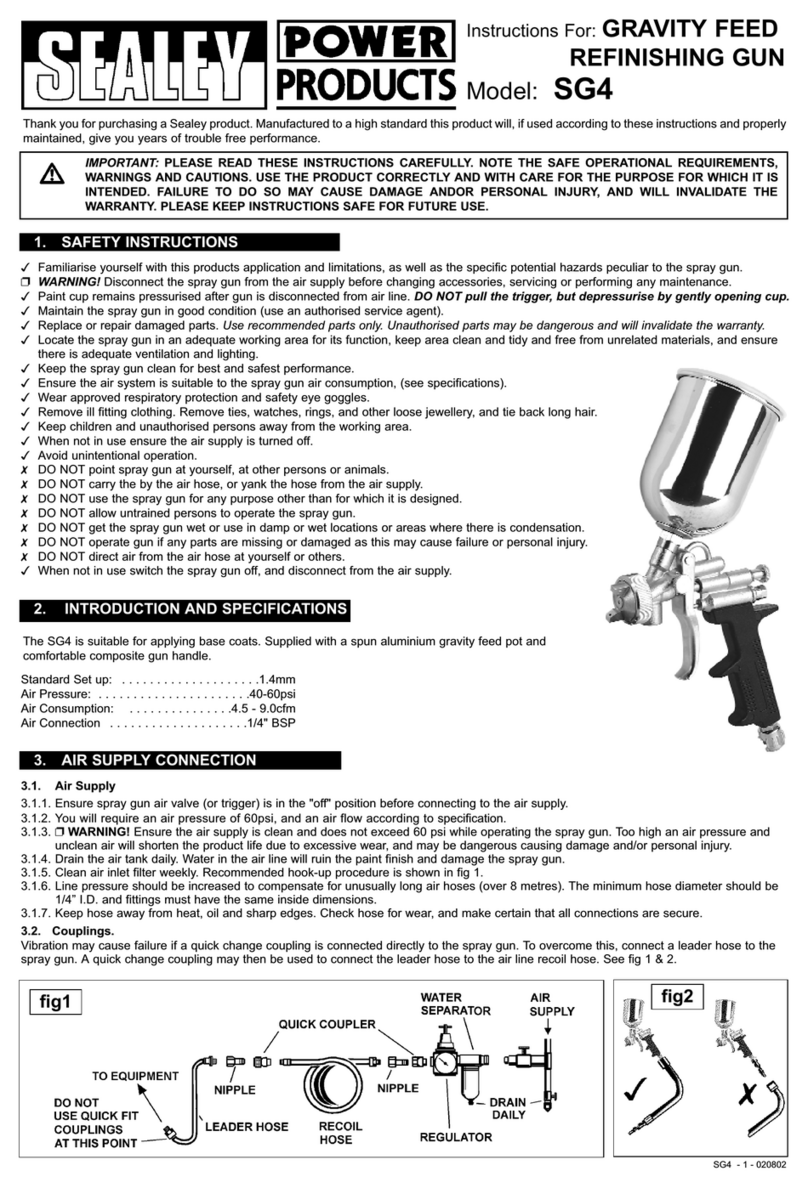

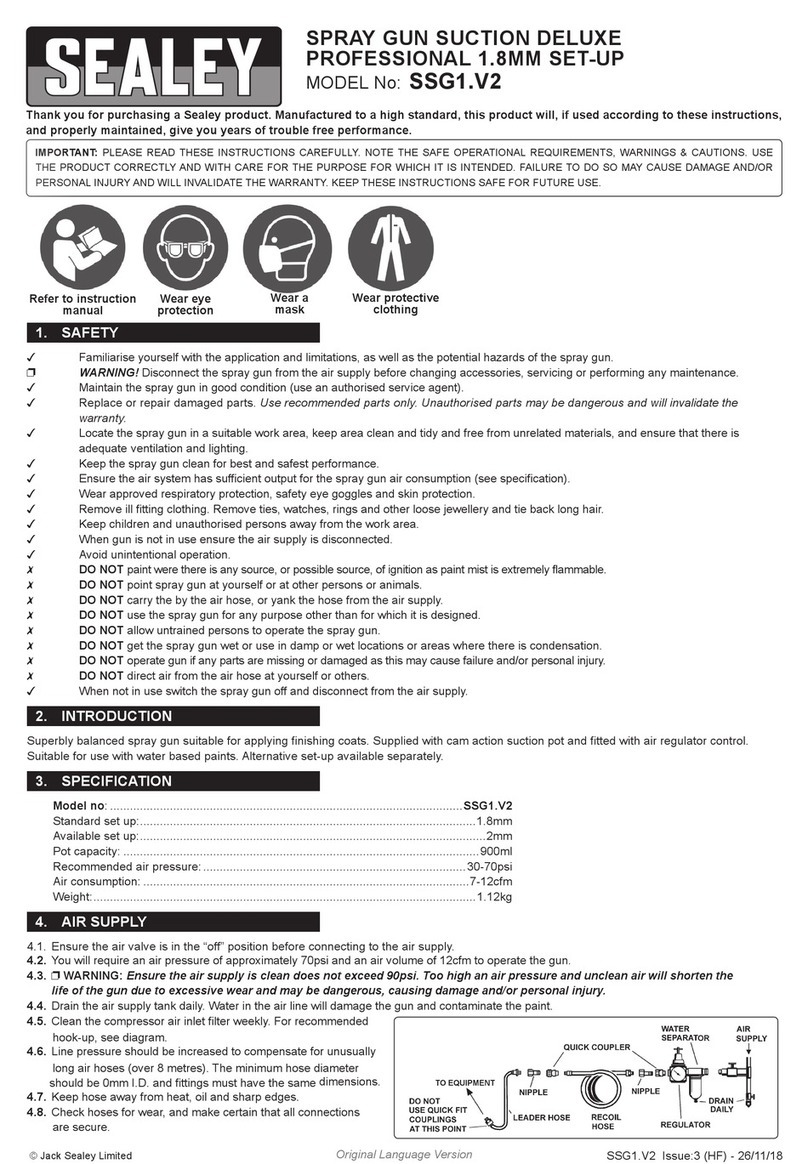

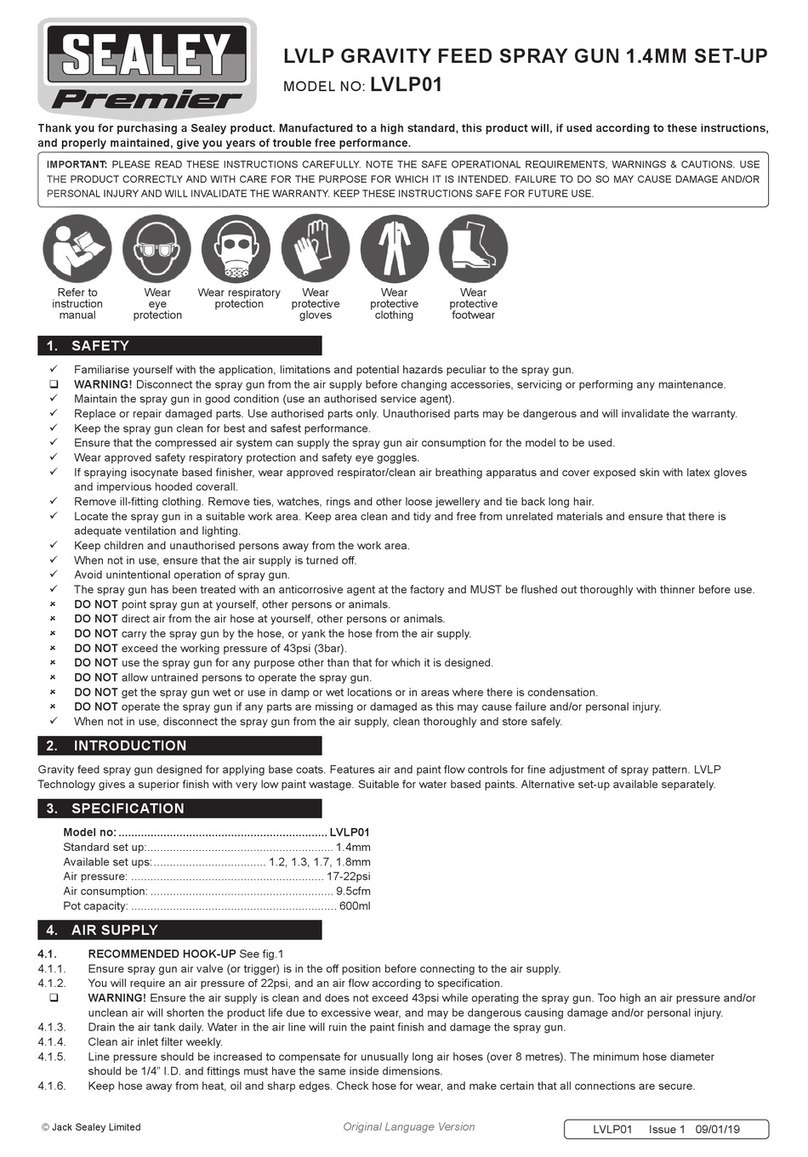

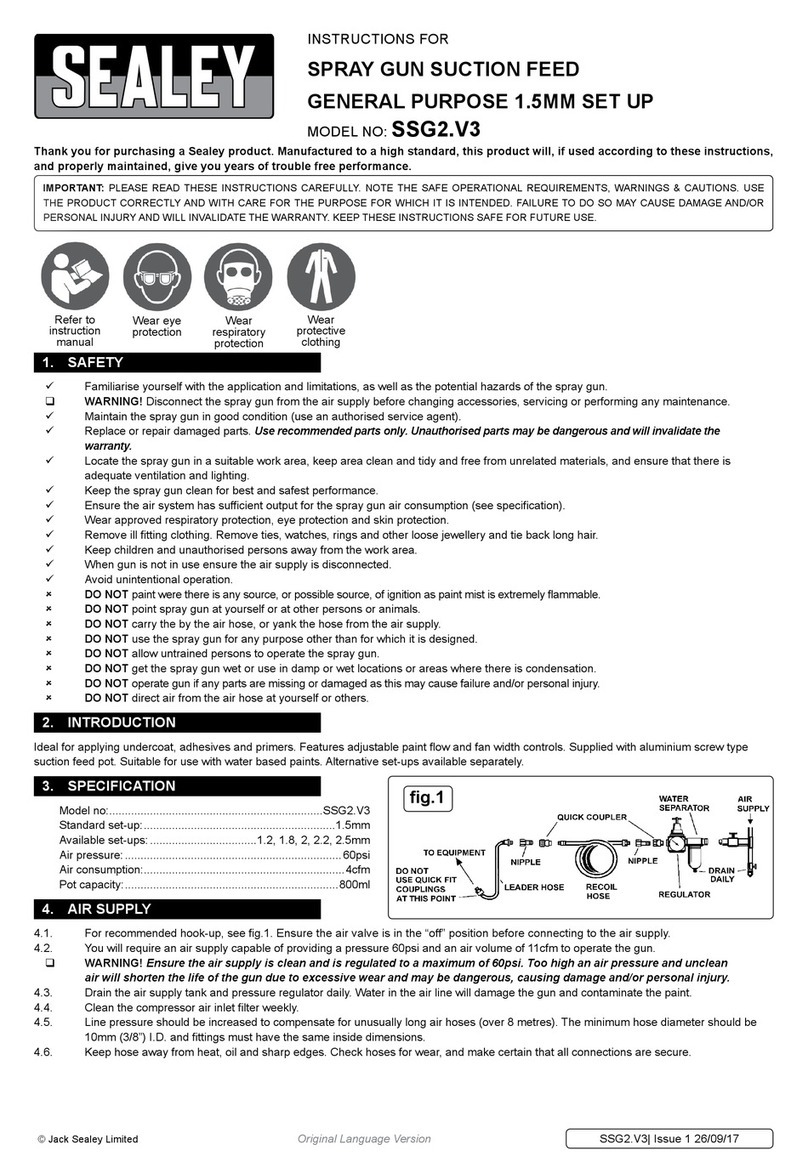

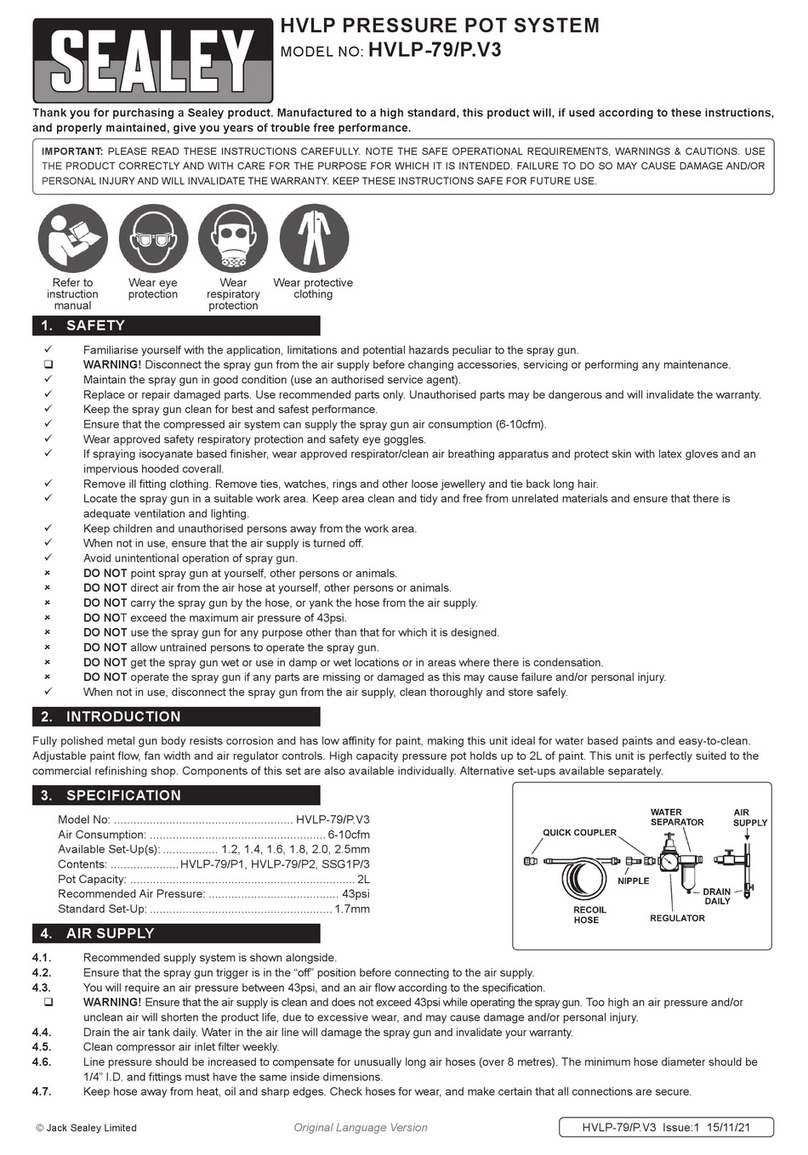

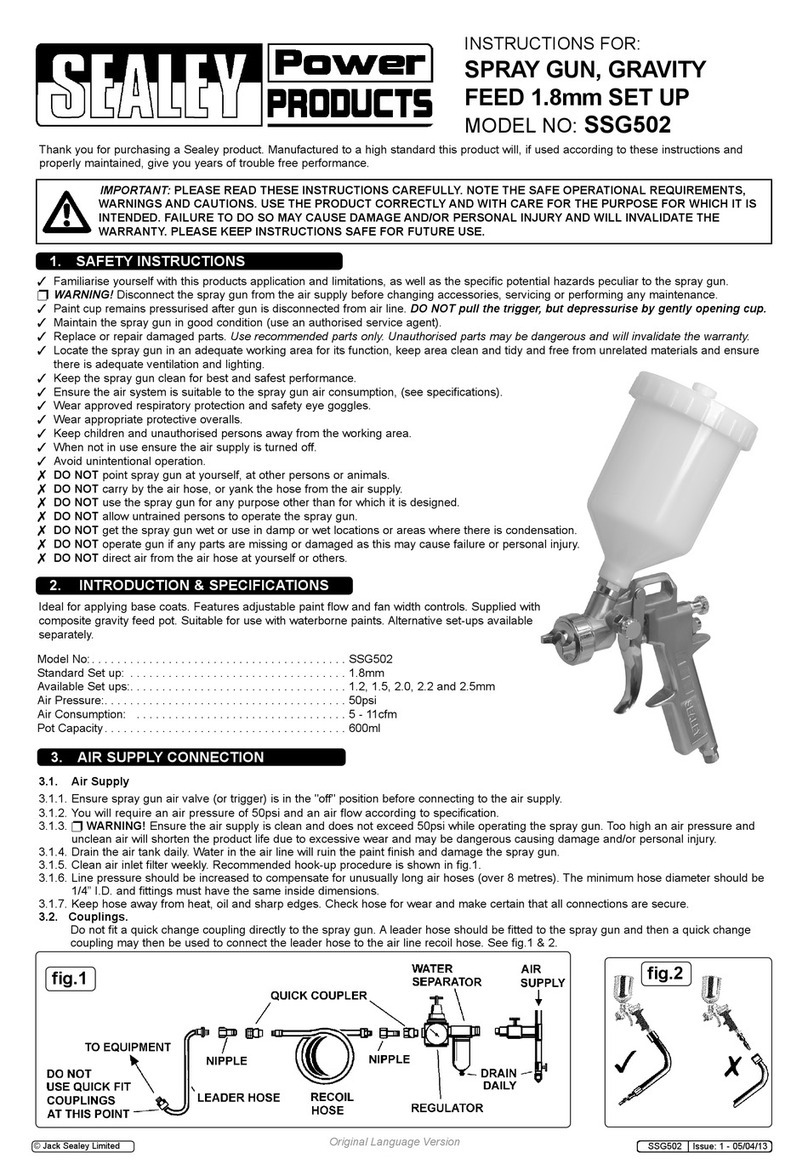

For the recommended hook-up, see fig. 1.

5.1. Ensure that the air valve is in the "off" position before connecting to the air supply.

WARNING! Ensure that the air supply does not exceed 50psi. Too high an air pressure and/or unclean air will shorten the

product life due to excessive wear and may be dangerous causing possible damage and/or personal injury.

5.2. Drain the compressor tank daily. Water in the air line will damage equipment and will invalidate your warranty.

5.3. Clean the compressor air inlet filter screen weekly.

5.4. Line pressure should be increased to compensate for

unusually long air hoses (over 8 metres). The minimum

hose and fittings bore is 10mm I.D.

5.5. Keep hoses away from heat, oil and sharp edges.

Check hoses for wear, and make certain that all connections

are secure.

5.6. Spray gun input connection is 1/4”BSP.

5. AIR SUPPLY

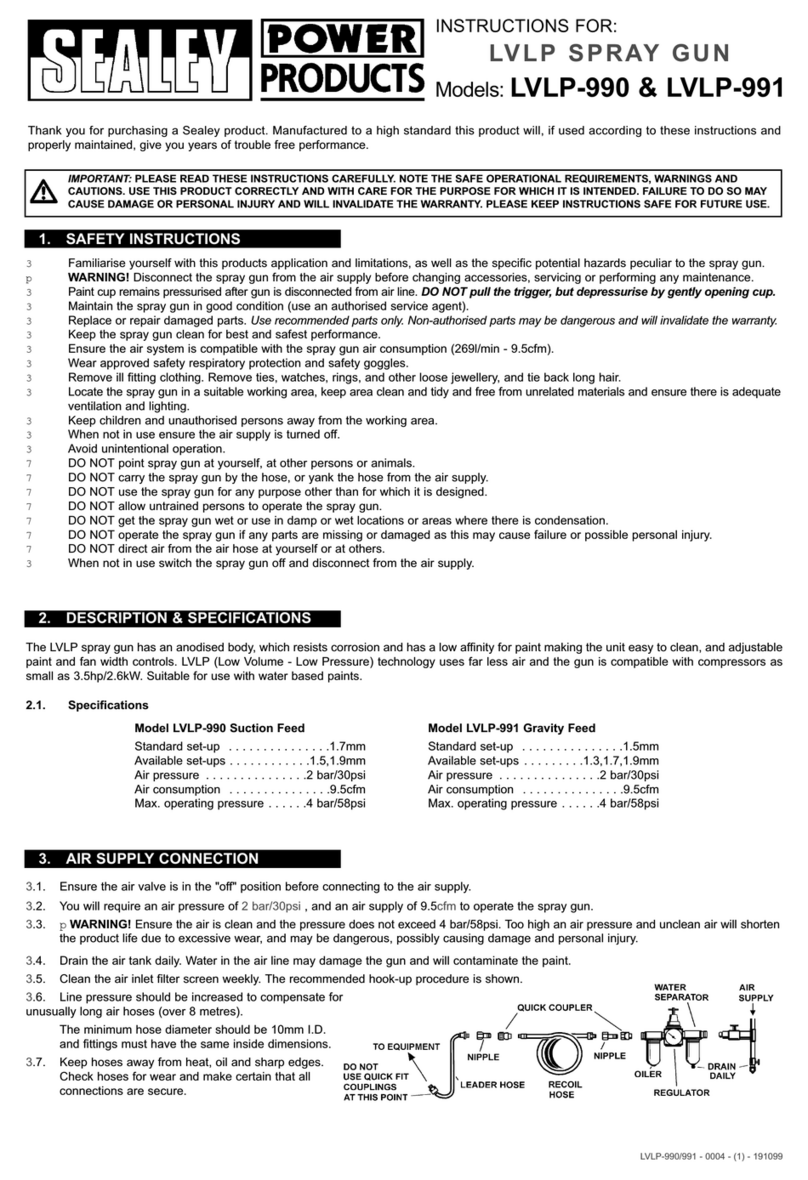

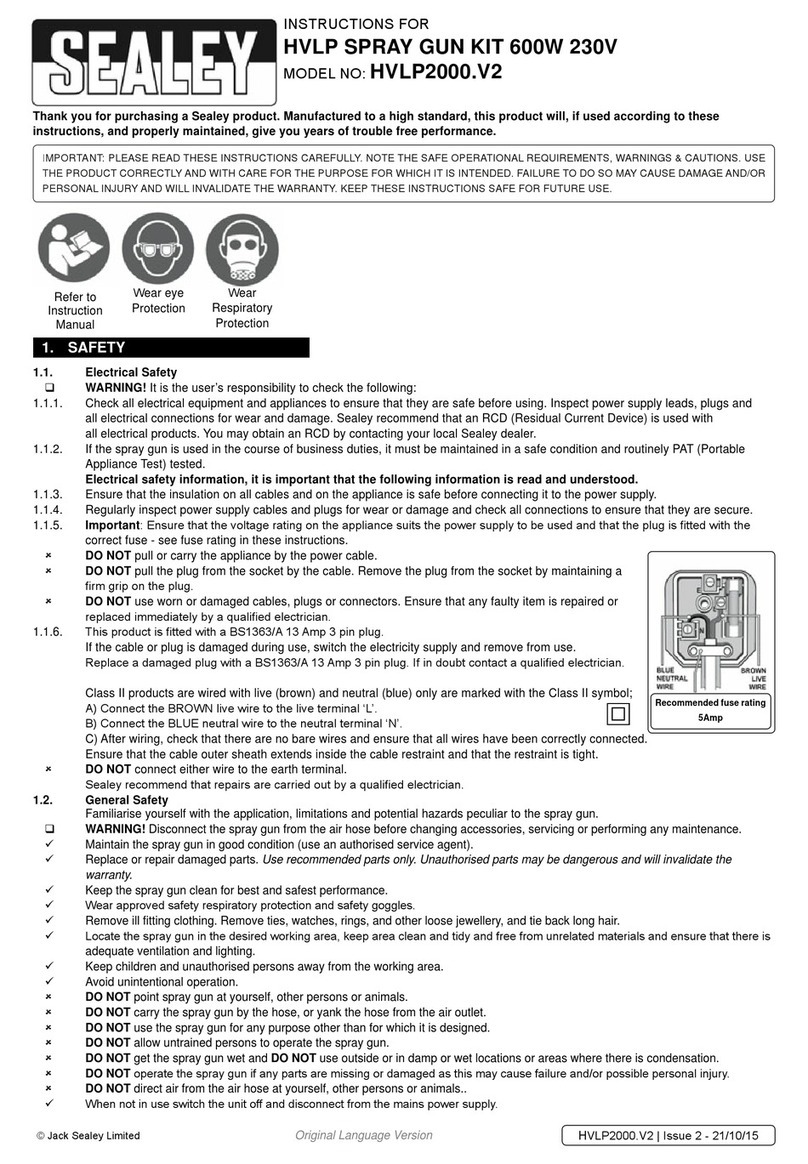

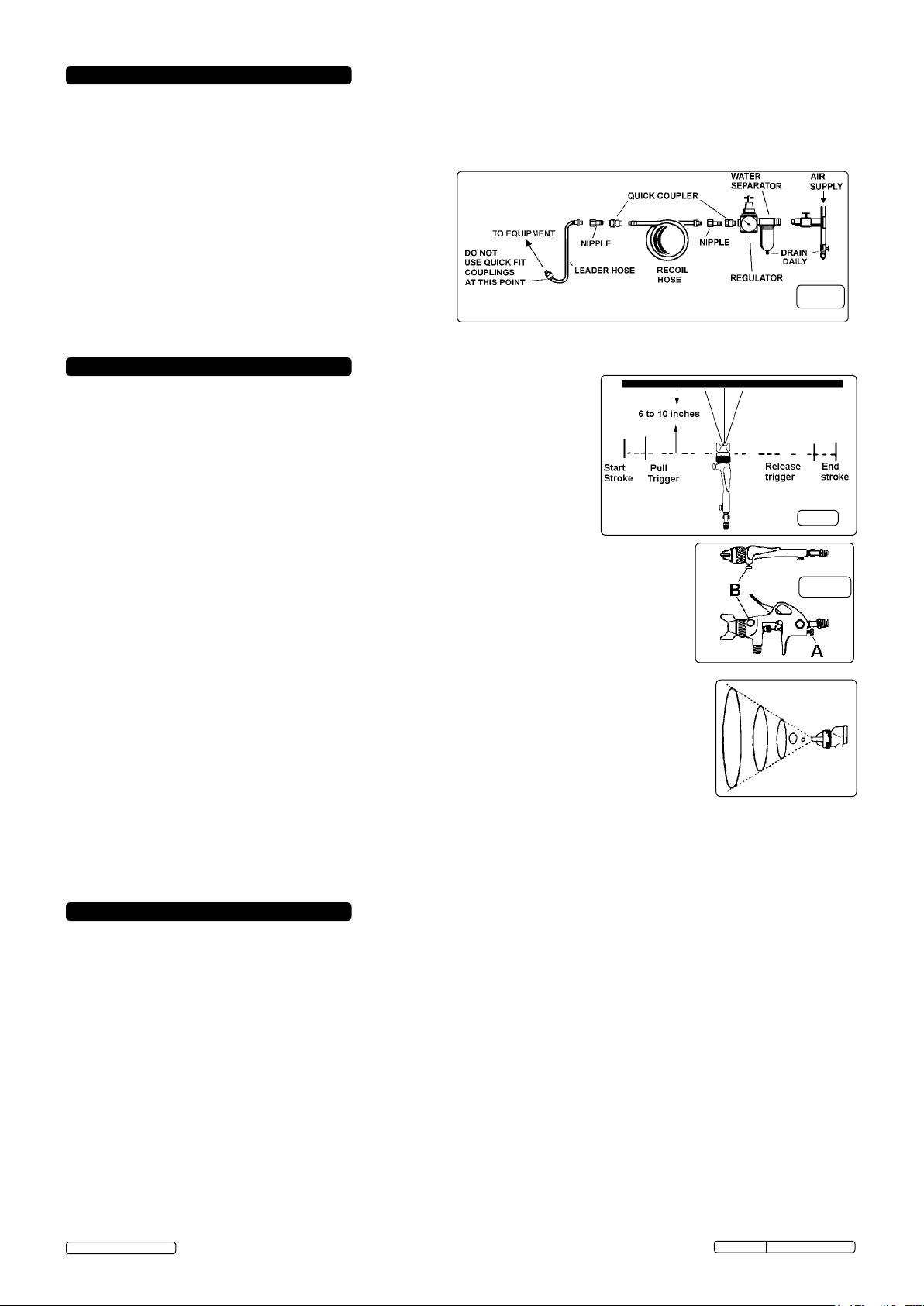

6.1. For best results, handle the gun correctly. It should be held perpendicular to the

surface being sprayed and moved parallel to it. Start the stroke before squeezing

the trigger and release the trigger before finishing the stroke. This will enable you

to accurately control the gun paint (fig.2).

6.2. Spray from a distance of about 6 to 10 inches depending on the material and the

atomizing pressure. The material deposited should always be even and wet.

Each stroke must overlap the preceding stroke to obtain a uniform finish.

To reduce overspray and obtain maximum efficiency, spray with the lowest possible

atomizing air pressure.

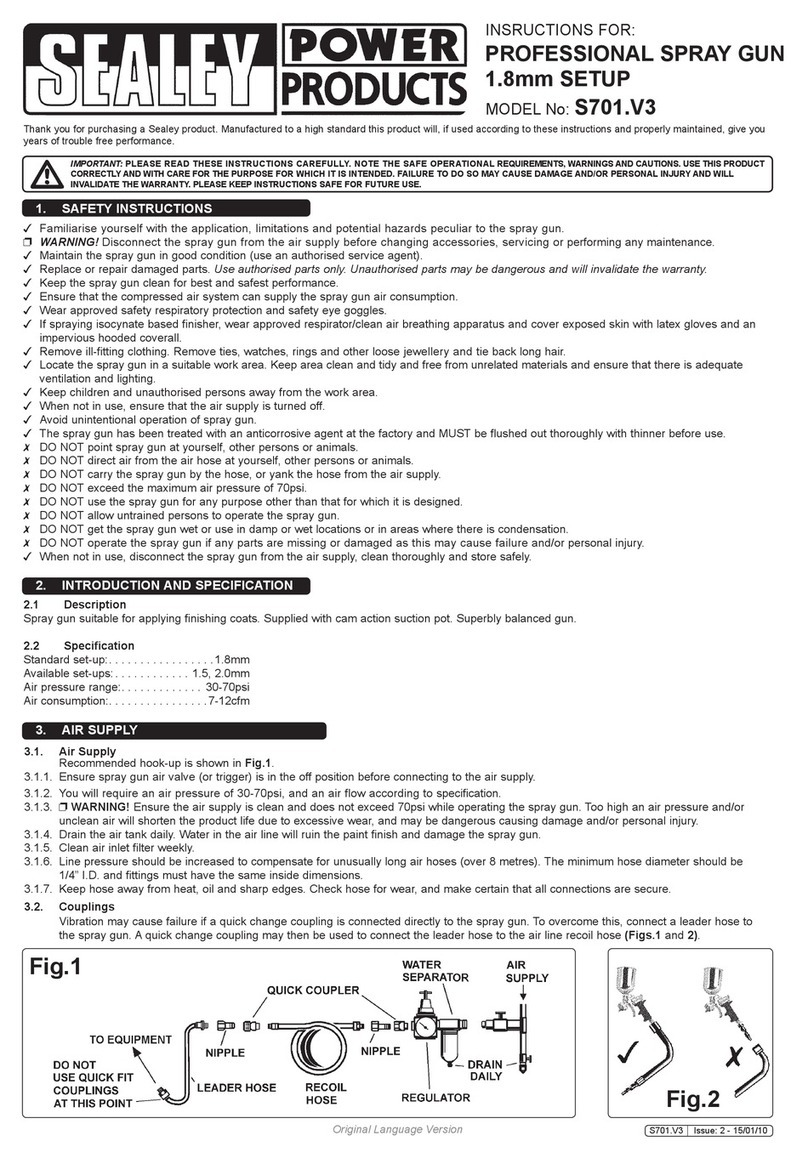

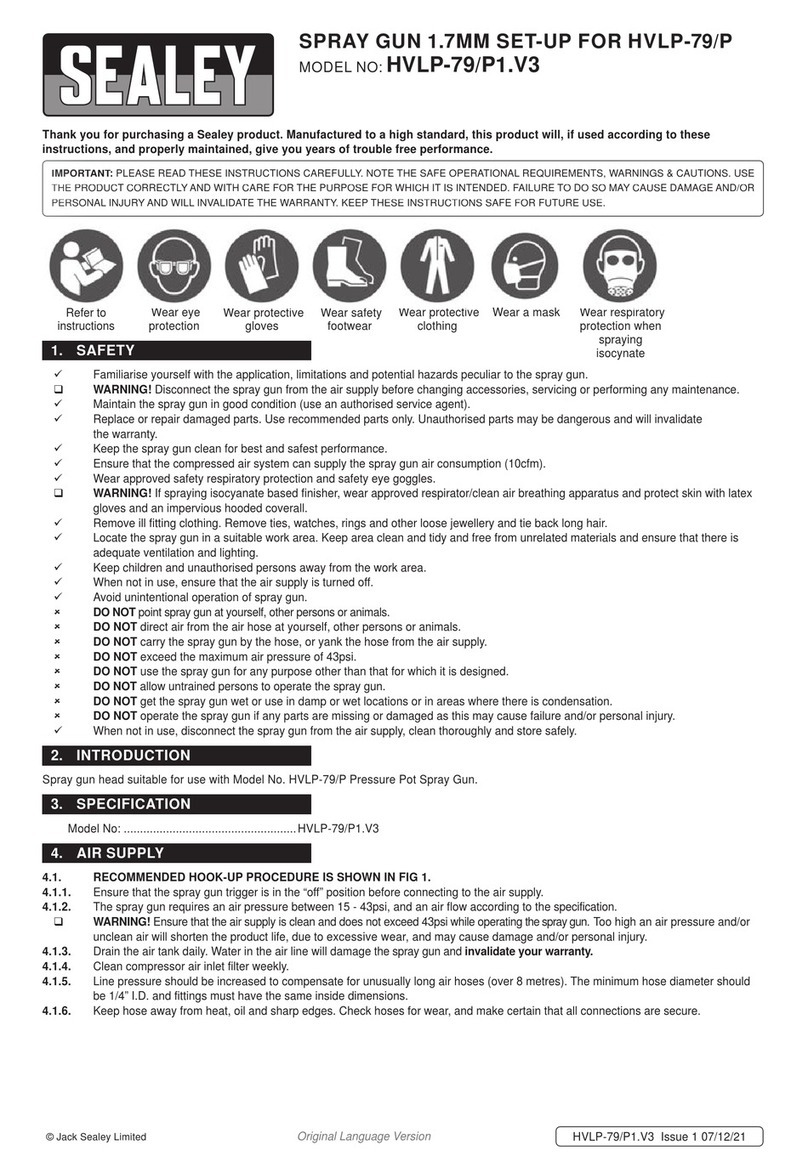

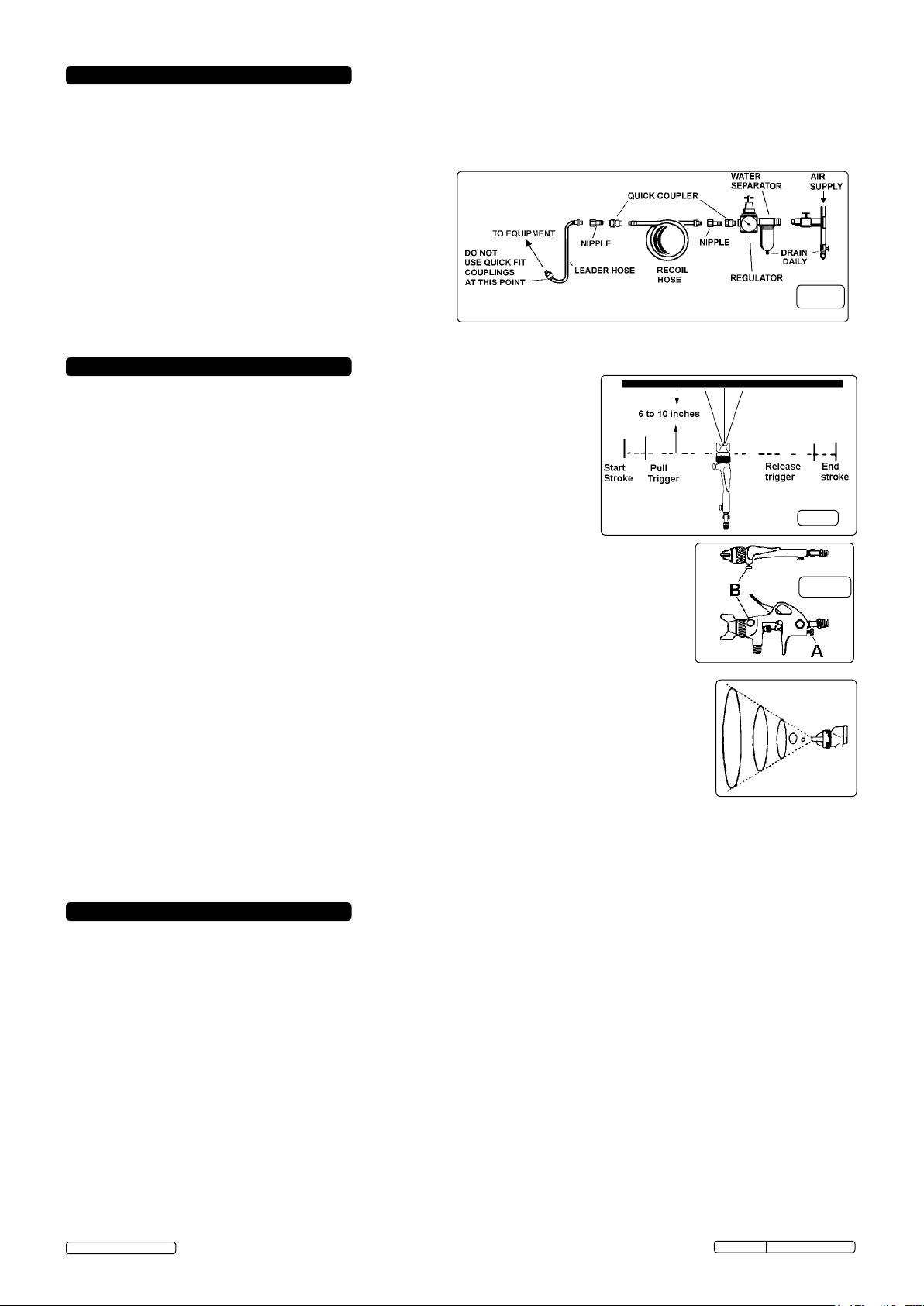

6.3. Controlling the fan spray and the fluid;

6.3.1. If a fluid pressure tank is used, the amount of fluid can be controlled by regulating the

pressure on the tank. Otherwise, use the fluid control screw on the gun (fig.3.A). Turn right to decrease

the flow, left to increase.

6.3.2. As the width of the spray is increased (with knob fig.3.B), more material must be allowed to pass

through the gun to obtain the same coverage on the increased area.

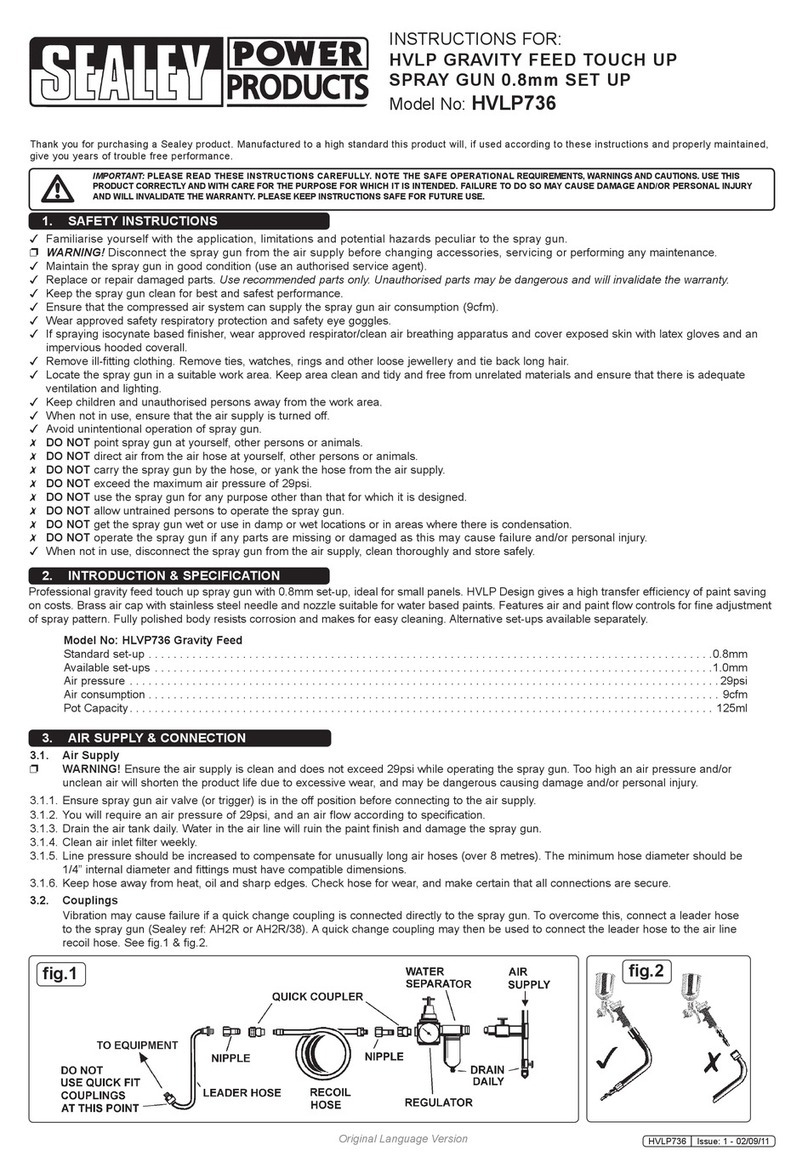

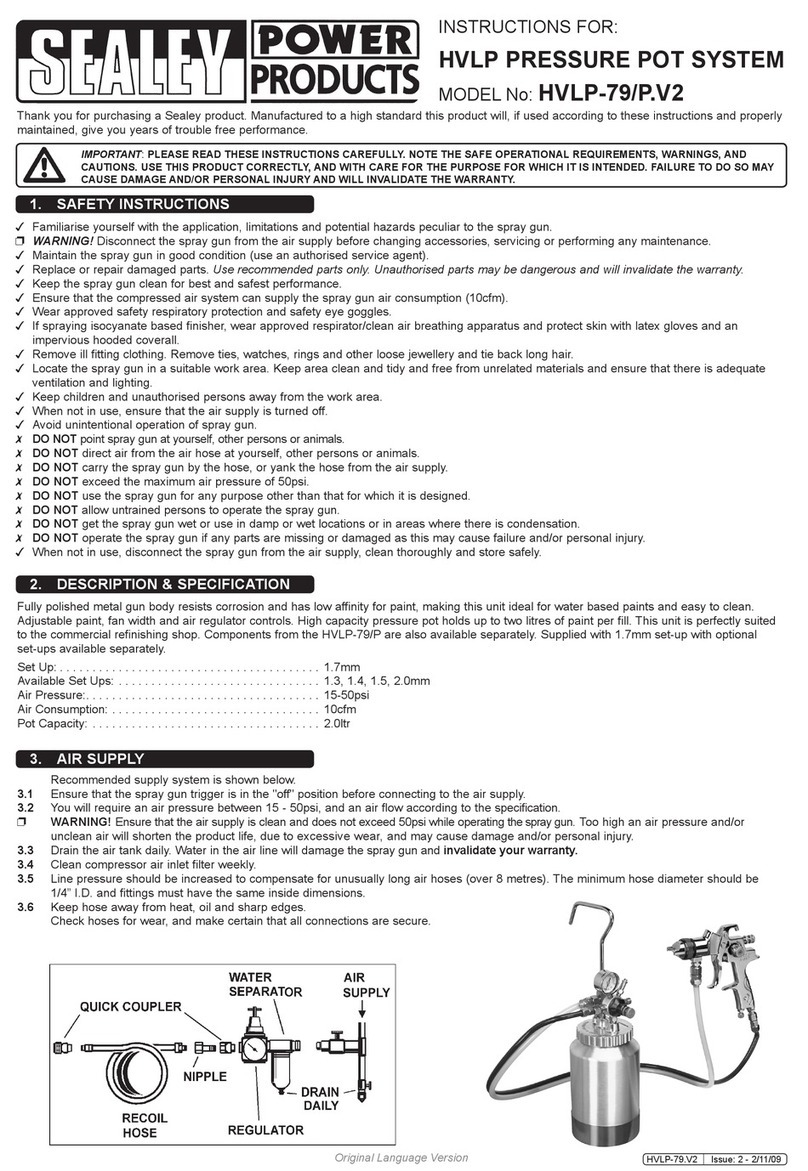

6.3.3. The direction of the fan spray, either horizontal or vertical, is obtained by turning the air nozzle

to the desired position then tightening the retaining ring. The spray pattern of the gun is variable from

round to flat with all patterns in between. In normal operation, the wings on the nozzle are

horizontal. This provides a vertical fan-shaped pattern which gives maximum uniform and even coverage

when moving the gun back and forth, parallel to the work surface, see fig.4.

6.4. Syphon spraying

Set the atomization pressure at approximately 45psi for lacquer and 50psi for enamel then test spray.

If the spray is too fine, reduce the air pressure or open the fluid control screw. If the spray is too coarse,

close the fluid control screw. Adjust the pattern width and repeat the adjustment of the spray if necessary.

6.5. Pressure spraying

Set the fluid pressure for the desired flow. Open the atomization air and test spray. If the spray is too fine,

reduce the air pressure. If it is too coarse, raise the air pressure.

Adjust the pattern width and repeat the adjustment of the spray. Keeping the fluid control screw in the

open position will reduce fluid needle wear.

Note: To reduce overspray and obtain maximum efficiency, always spray with the lowest possible atomization air pressure.

6. OPERATION

fig. 1

fig.2

When reassembling after maintenance or cleaning, take care when screwing parts together. First screw parts hand tight to avoid

cross-threading. If a part cannot easily be turned by hand, check that you have the correct part, or unscrew, realign and try again.

DO NOT use excessive force when reassembling.

7.1. Spray gun

1. Immerse the front end of the gun only in solvent until the solvent just covers the fluid connection. DO NOT immerse the entire gun in

solvent. This will cause lubricants to dissolve and other packings to dry out. Dirty solvent may also clog the small narrow passages

in the gun.

2. Use a bristle brush and solvent to wash off accumulated paint and wipe the outside of the gun with a dampened solvent rag.

3. Lubricate the gun daily with a light machine oil. Be sure to lubricate the fluid needle packing, air valve packing, side port control

packing and trigger pivot point. DO NOT use lubricants containing silicone.

4. When finished spraying, flush the gun through with clean thinners.

7.2. Air nozzle, fluid nozzle and needle assembly

1. To clean the nozzles, soak them in solvent to dissolve any dried material then blow them clean with air. Handle all nozzles carefully

and do not make any alterations in the gun.

2. If you need to probe the holes in the nozzles, be sure to use a tool that is softer than brass; do not use metal instruments.

3. Adjust the fluid needle valve so that when the gun is triggered, air flow occurs before fluid flow.

7. MAINTENANCE & CLEANING

fig.4

fig.3

Original Language Version SG6T.V4 Issue: 1 - 06/11/13

© Jack Sealey Limited