1. Do NOT leave this appliance unattended

while in use. The user must remain in the

immediate area of the product and have

a clear view of the product at all times

during operation.

2. Keep children and pets away from burner

at all times.

3. The use of alcohol, prescription or non-

prescription drugs may impair your ability

to properly assemble or safely operate

this appliance.

4. For OUTDOOR use only. Do NOT use in

a building, garage or any other enclosed

area. Do NOT use in or on recreational

vehicles or boats. NEVER use this

appliance as a heater.

5. Do not operate appliance under ANY

overhead construction. Keep a minimum

clearance of 3 m / 10 ft from the sides,

front and back of appliance to ANY

construction. Keep the area clear of all

combustible material and flammable

liquids, including wood, dry plants and

grass, brush, paper, and canvas.

6. Use ONLY on a level, stable non-

combustible surface like bricks, concrete

or dirt. Do NOT use this appliance on any

surface that will burn or melt like wood,

asphalt, vinyl, or plastic.

7. Keep the fuel supply hose away from any

heated surfaces.

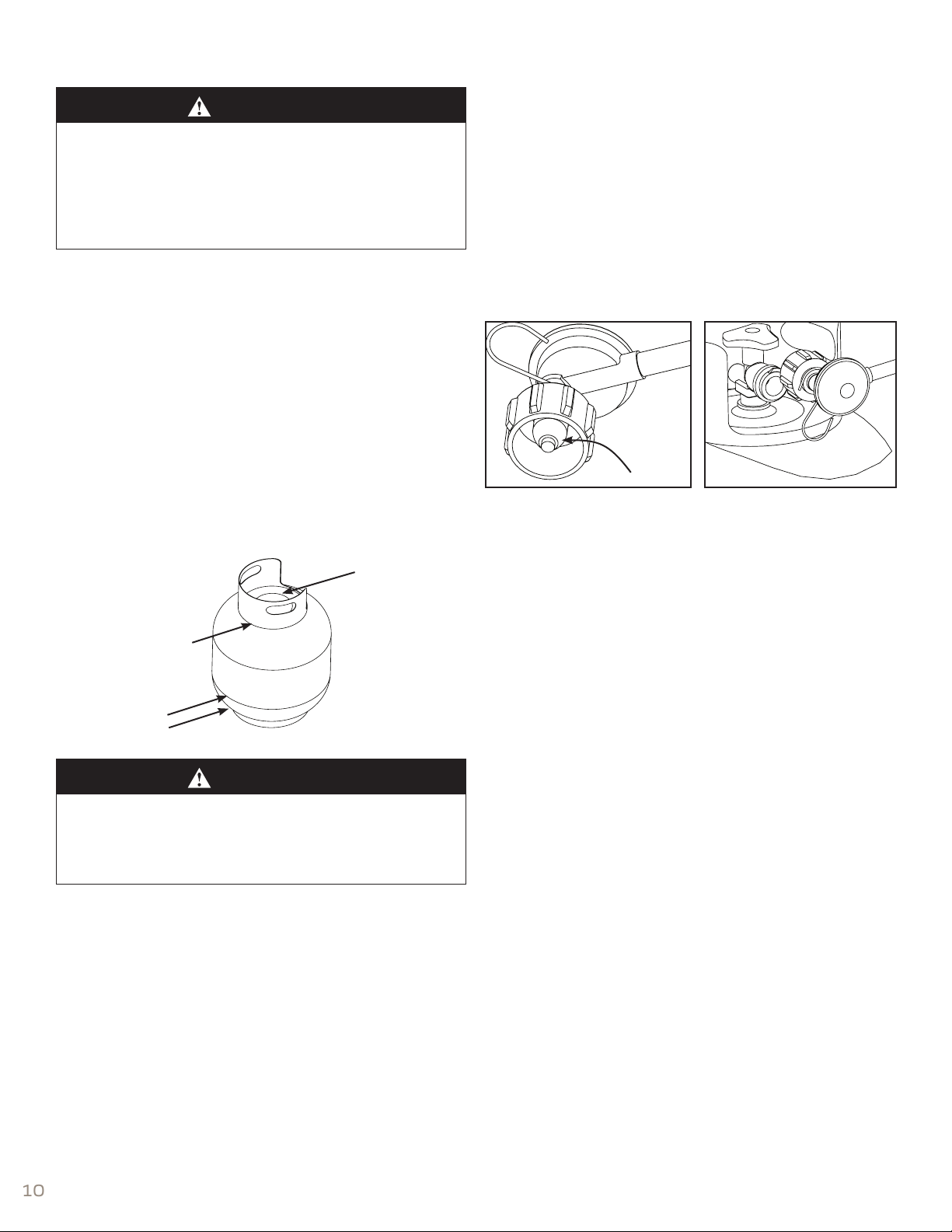

8. To prevent accidental fires, before using

the appliance ensure that the hose is not

damaged and all joints and connections

are not leaking by turning on the cylinder

valve, leave the burner valve closed, and

apply a soapy solution to the joints and

connections. If a continuous hissing sound

is heard, or if the soapy solution bubbles,

there is a leak. Do not use the appliance if

there is a leak. Replace the faulty parts.

9. Extinguish all open flames before

connecting the gas supply to the

appliance and before checking for leaks.

10. In the event of fire do NOT attempt to

extinguish with water. Use a Type BC dry

chemical fire extinguisher or smother fire

with dirt, sand or baking soda.

11. NEVER overfill the cooking pot water.

Follow instructions in this manual for

establishing proper water levels.

12. Never drop food or accessories into

hot cooking liquid. Lower food and

accessories slowly into the cooking liquid

in order to prevent splashing or overflow.

When removing food from the appliance,

care shall be taken to avoid burns from

hot cooking liquids. Once food is removed

from pot, do not allow pot to boil dry.

13. DO NOT place an empty cooking vessel

on burner while in operation. Do not allow

a filled pot to boil dry while appliance is

in operation. Use caution when placing

anything in the cooking vessel while

burner is in operation.

14. In the event of rain, hail, sleet or other

forms of precipitation, IMMEDIATELY turn

off burner(s) and gas supply, then cover

cooking vessel. Do NOT attempt to move

the appliance or the cooking vessel.

15. Avoid bumping or impact with the

appliance to prevent spillage or splashing

of hot cooking liquid.

16. Do NOT move the appliance when in use.

Allow unit to cool to 45°C / 115°F before

moving or storing.

17. This appliance will be hot during and after

use. Use insulated oven mitts or gloves for

protection from hot surfaces or splatter

from cooking liquids. Wear close-toed

shoes when operating appliance.

18. In case there is a fire, call the local fire

department. Stay clear from flames. Do

not attempt to extinguish an oil or grease

fire with water.

IMPORTANT SAFETY WARNINGS