element assembly consists of thermoelectric 'Peltier' elements, temperature feedback sensors

and a cold water fed heat exchanger.

4

7600S Tissue bath with rem

he bath assembly will fit onto any Campden Instruments tissue cutter without modification

urrent from the power supply flows through the thermoelectric elements, which act as heat

. Set-up

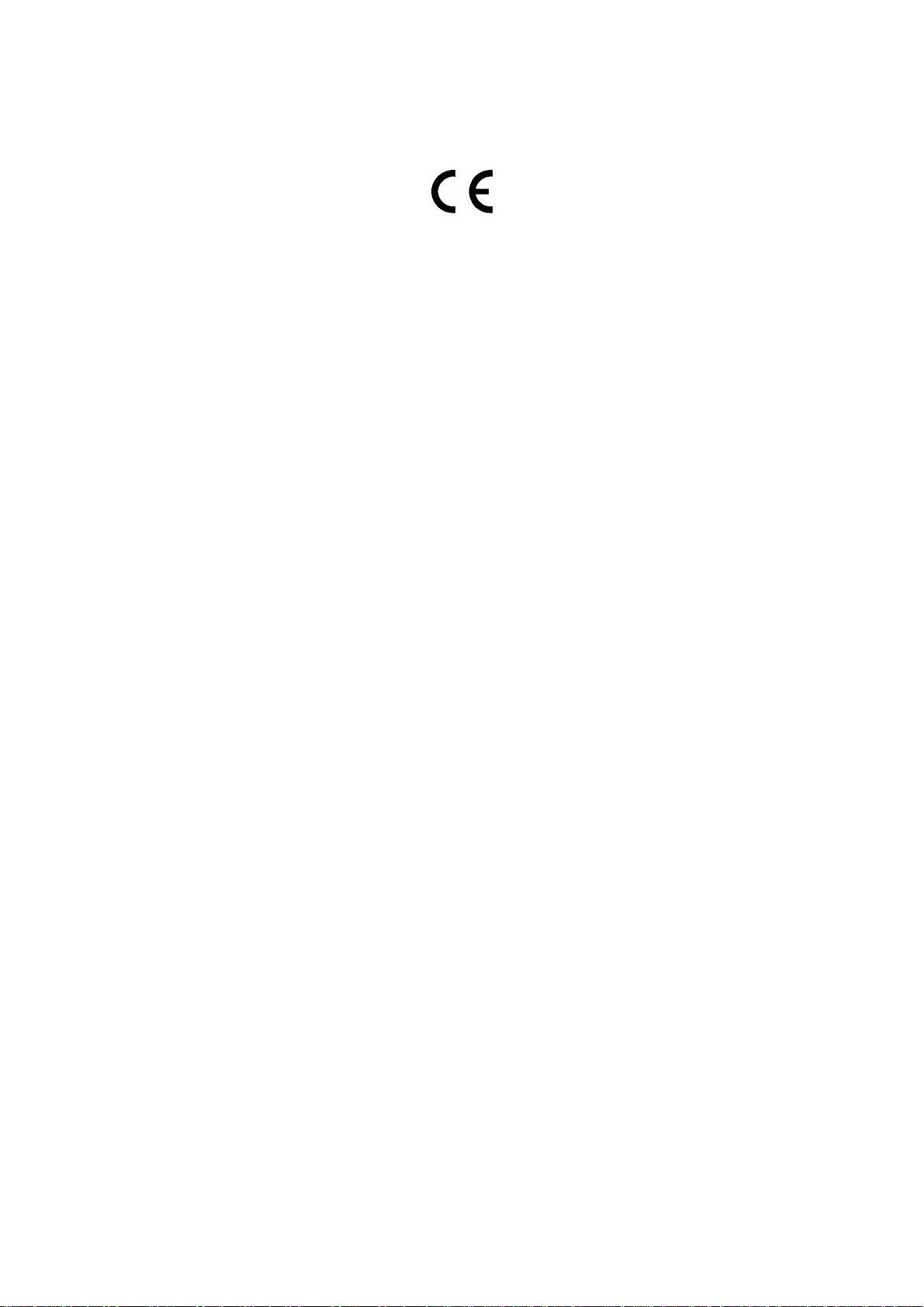

.1 Bath Assembly Set-up sembly be connected to an adequate cold water supply whenever

the temperature

ded

ovable, autoclavable piece,

T

and the bath chamber has the same volume as the standard Campden Instruments tissue bath

(752/2B). The tissue holder is the standard Campden Instruments tissue holder (752/2A).

C

transfer units. Heat is drawn off, cooling the solution in the tissue bath. The heat generated by

this process is removed by the water supply fed through the heat exchanger. The unit uses a

PID (proportional integral derivative) temperature control algorithm to maintain temperature

stability. This will hold the bath temperature to within 0.5ºC of the temperature set point.

There will, however, be a small variation in temperature vertically through the bath.

Experience will show the best temperature to be set for any given requirement and ambient

temperature.

2

2

It is essential that the bath as

the unit is in operation. Typically the unit may be connected to a cold-water tap and fed to

waste. Alternatively the water may be pumped through the unit from a suitable reservoir.

The flow of water through the heat exchanger should not be less than 400ml/minute and the

water temperature should be below 25ºC. See figure 1 for connection ports.

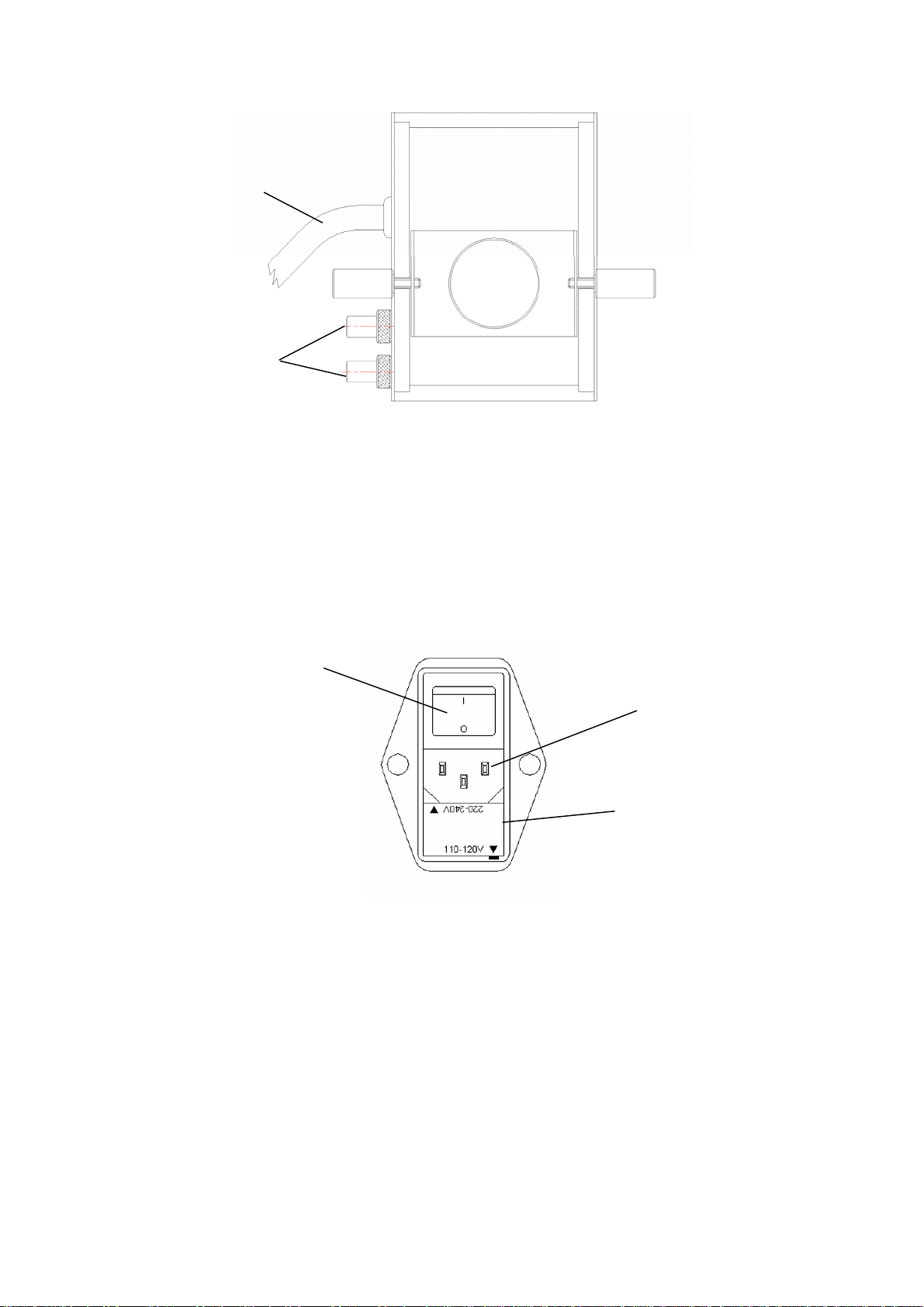

A temperature feedback sensor is built into the bath assembly and monitors

of the heat exchanger. The power supply to the thermoelectric elements will shut down if the

water supply is either inadequate or not present. The unit will give an audible ‘beep’ and the

display read ‘Err’ to indicate that the thermoelectric elements have been shut down due to

inadequate flow of cooling water. Switching the unit on and off will reset this condition.

The tissue bath should be filled with physiological buffer solution prepared at the inten

slicing temperature.