CBP-436(2017) Operation and Maintenance Manual-CTS Tractors Camso | 12-17 | 3

Table of Contents

1.0 INTRODUCTION ...................................................................................................................5

1.1 LAW REFERENCES .........................................................................................................5

1.2 MANUFACTURER IDENTIFICATION................................................................................5

1.3 "EC" CERTIFICATE...........................................................................................................6

2.0 SAFETY ................................................................................................................................7

2.1 Important Safety Information..............................................................................................7

2.2 Safety Signs ......................................................................................................................8

2.3 Safety Sign Locations ........................................................................................................9

3.0 GENERAL INFORMATION.................................................................................................. 10

3.1 Technical Description ......................................................................................................10

3.2 Track System Components..............................................................................................11

Suspended Frame (30/36D23MC & 30/36D22MC)............................................................. 11

Fixed Frame (24D17C and 24D18C) ..................................................................................11

Sprocket/Drive Wheel.........................................................................................................11

Axles ..................................................................................................................................11

Idlers and Midrollers ...........................................................................................................11

Tensioning system .............................................................................................................12

Rubber track.......................................................................................................................12

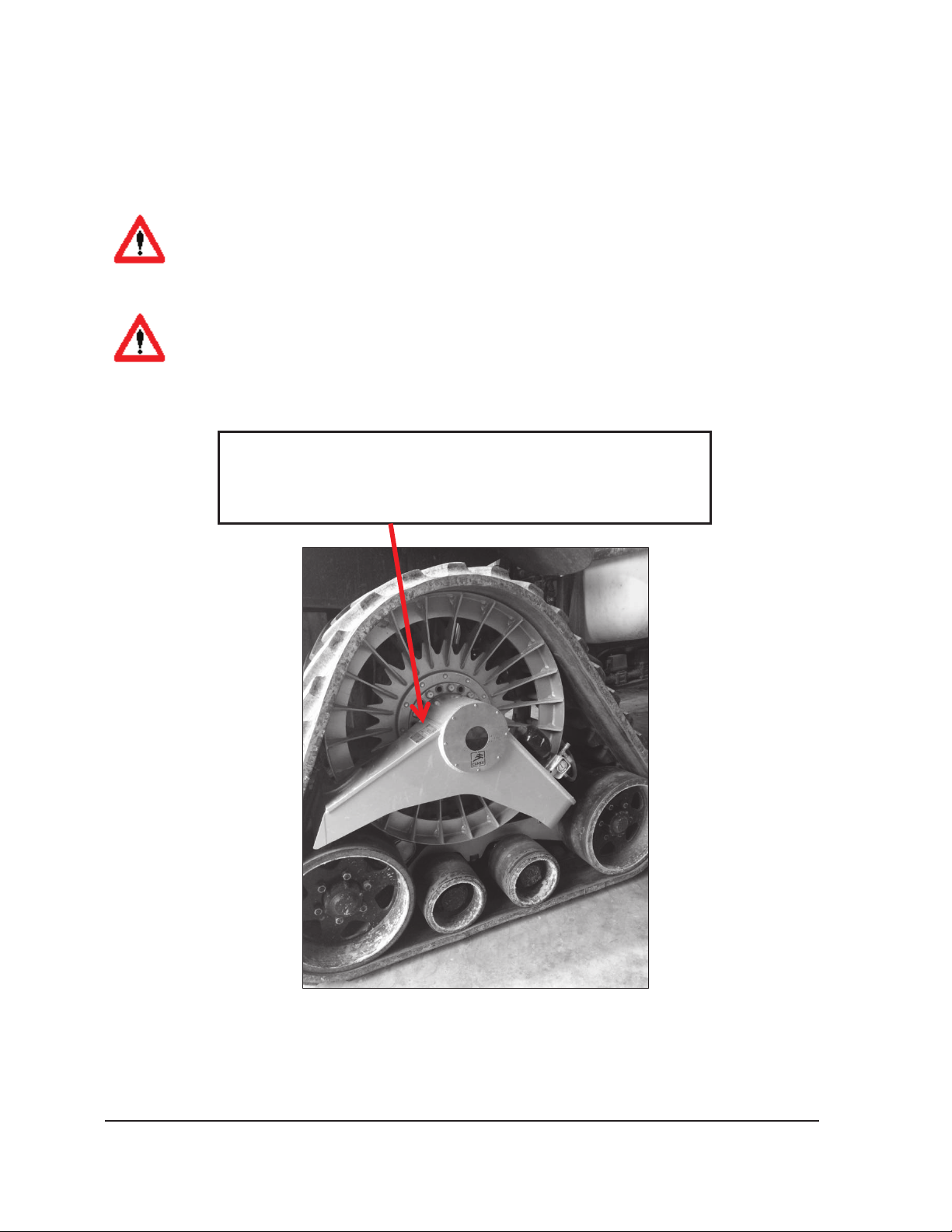

Oscillation Limiter Brackets ................................................................................................12

3.3 30/36D23MC and 30/36D22MC Specifications and Dimensions...................................... 12

3.4 24D17C and 24D18C Specification and Dimensions ....................................................... 13

3.5 Approved Applications .....................................................................................................13

3.6 Weight Limitations ...........................................................................................................14

3.7 Maximum Speeds ............................................................................................................14

3.8 Transport Limitations .......................................................................................................14

3.9 Operational Guidelines .................................................................................................... 15

3.10 Track Break-in Procedures ............................................................................................16

4.0 TRACK SYSTEM INSTALLATION.......................................................................................17

4.1 Handling of the Track System..........................................................................................17

4.2 Tractor Preparation..........................................................................................................17

4.3 Track System Installation onto the Machine..................................................................... 17

5.0 SCHEDULED MAINTENANCE............................................................................................ 19

5.1 General information .........................................................................................................19