C&S Electronics WiNmaster 2 User manual

WINMASTER 2 01/01/2015

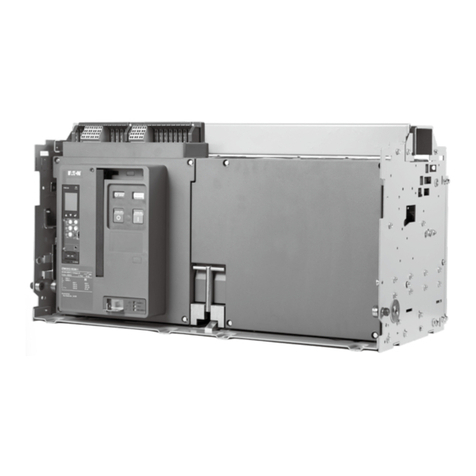

Air Circuit Breaker

C&S Electric Ltd.

222, Okhla Industrial Estate, Phase-III, New Delhi - 110020, INDIA

Tel. : +91-11-3088 7520 - 29

Fax: +91-11-26838291, 2684 8241

Ro SH

Compliant

www.cselectric.co.in

W Nmaster 2i

W Nmaster 2i

630A ~ 3200A

www.cselectric.co.in

W Nmaster 2i

LV Air circuit breaker, 630A to 3200A

Breaker with intelligence

WiNmaster2 Power Circuit Breakers are a new

generation of Air Circuit Breakers having modular

construction to offer a truly global product platform

meeting IEC, ANSI and UL standards.

A line of Three and Four pole devices ranging from 630

to 3200 Amp in two basic frames with fault interruption

ratings of up to 65kA. A design offering a unique

combination of High Fault current withstands ratings,

short fault interruption time and zone selectivity.

The device includes the new state-of-the-art MicroPro2

intelligent trip unit that enables the circuit breaker with

the latest technology for system safety, reliability,

measurement, relaying and communications using the

Modbus, Profibus or devicenet protocol.

CONTENTS

Introduction 7

Constructions Characteristics 8-13

ROHS Compliant 14-15

Technical Characteristics 16-17

Connection Installation 18-19

External Configuration 20-21

Intelligent Trip Units 22-35

Characteristic Curves 36-47

Communication 48

ZSI (micropro2) 49

Accessories 50-53

Electrical Diagram 54-55

Identifying ACB 56-57

Dimensions 58-60

5

C&S Electric Limited

C&S Electric Ltd.

W Nmaster 2i

CONTENTS

Introduction 7

Constructions Characteristics 8-13

ROHS Compliant 14-15

Technical Characteristics 16-17

Connection Installation 18-19

External Configuration 20-21

Intelligent Trip Units 22-35

Characteristic Curves 36-47

Communication 48

ZSI (micropro2) 49

Accessories 50-53

Electrical Diagram 54-55

Identifying ACB 56-57

Dimensions 58-60

5

C&S Electric Limited

C&S Electric Ltd.

W Nmaster 2i

The new WiNmaster2 ACBs are the result of constant commitment to look for new

solutions and the know how C&S has developed over the years.

In this series C&S introduces New WiNmaster2 Air Circuit Breaker which is an

incredibly innovative high quality circuit-breaker supported by state-of-the-art

manufacturing technologies which ensures utmost performance, reliability, complete

safety and uninterruptible service throughout the product life that ultimately reduces

the stress on components.

WiNmaster2 Air Circuit Breaker is available from 630A to 3200 A rating in 3 and 4 pole

execution, with breaking capacity of 50kA / 65kA. It provides total solutions with an

advanced trip relay for measurement, diagnosis, analysis, and communication as well

as protective functions for absolute protective coordination and electric power

monitoring system.

WiNmaster 2 has a modular construction which has been designed according to

customer's

demand and present day complex requirement of electrical systems.

These ACBs are most compact in size with wide range & high breaking capacity.

Compact yet offering Horizontal Type Busbar Termination for ease of installation

enhanced life and intuitive operation makes them a very user friendly range of circuit

breaker for any application. The height and depth are same through out the range. The

accessories are common, front accessible and easy to fit up to 3200 A

WiNmaster2 ACB stands for...Reliability as it confirms to the latest IEC 60947-2/IS

13947-2 standard for Isolation.

Introduction

W Nmaster 2 - WX Series ACB

Range: 630A~3200A

Two frame sizes for complete range

Intelligent release

- Micropro 2-3.1

- Micropro 2-4.1

- Micropro 2-7.1

Communication

- RS-485/232

- Modbus

- Profibus

- Devicenet

i

n

n

n

n

6C&S Electric Limited 7

C&S Electric Limited

Complete Modular construction

W Nmaster 2i

The new WiNmaster2 ACBs are the result of constant commitment to look for new

solutions and the know how C&S has developed over the years.

In this series C&S introduces New WiNmaster2 Air Circuit Breaker which is an

incredibly innovative high quality circuit-breaker supported by state-of-the-art

manufacturing technologies which ensures utmost performance, reliability, complete

safety and uninterruptible service throughout the product life that ultimately reduces

the stress on components.

WiNmaster2 Air Circuit Breaker is available from 630A to 3200 A rating in 3 and 4 pole

execution, with breaking capacity of 50kA / 65kA. It provides total solutions with an

advanced trip relay for measurement, diagnosis, analysis, and communication as well

as protective functions for absolute protective coordination and electric power

monitoring system.

WiNmaster 2 has a modular construction which has been designed according to

customer's

demand and present day complex requirement of electrical systems.

These ACBs are most compact in size with wide range & high breaking capacity.

Compact yet offering Horizontal Type Busbar Termination for ease of installation

enhanced life and intuitive operation makes them a very user friendly range of circuit

breaker for any application. The height and depth are same through out the range. The

accessories are common, front accessible and easy to fit up to 3200 A

WiNmaster2 ACB stands for...Reliability as it confirms to the latest IEC 60947-2/IS

13947-2 standard for Isolation.

Introduction

W Nmaster 2 - WX Series ACB

Range: 630A~3200A

Two frame sizes for complete range

Intelligent release

- Micropro 2-3.1

- Micropro 2-4.1

- Micropro 2-7.1

Communication

- RS-485/232

- Modbus

- Profibus

- Devicenet

i

n

n

n

n

6C&S Electric Limited 7

C&S Electric Limited

Complete Modular construction

W Nmaster 2i

Constructions Characteristics

Performance levels: 50kA (N) 65kA (H)

WX-A WX06A n

WX08A n

WX10A n

WX12A n

WX16A n

WX20A n

WX25A n

U cniform onstruction

… … … . Offering ease for installation and possibility for optimized panel size.

The height and width are showing below for frame WX-A up to 2500A. The panel cutout

size is same for all types of W Nmaster2, which makes it easy to arrange them in

switchboards. Panel cutout for front remains same.

i

The sheet steel structure of WiNmaster 2 is extremely compact, considerably reducing

overall dimensions.

W Nmaster 2 circuit breakers comes in two frame sizes.

WX-A: 630A to 2500A

WX-B: 2000A to 3200A

i

Fixed Type Drawout Type

8C&S Electric Limited

9

C&S Electric Limited

Structure of the Circuit Breaker

WX-B WX20B n

WX25B n

WX32B n

Available in both Fixed & Drawout version

W Nmaster 2i

Constructions Characteristics

Performance levels: 50kA (N) 65kA (H)

WX-A WX06A n

WX08A n

WX10A n

WX12A n

WX16A n

WX20A n

WX25A n

U cniform onstruction

… … … . Offering ease for installation and possibility for optimized panel size.

The height and width are showing below for frame WX-A up to 2500A. The panel cutout

size is same for all types of W Nmaster2, which makes it easy to arrange them in

switchboards. Panel cutout for front remains same.

i

The sheet steel structure of WiNmaster 2 is extremely compact, considerably reducing

overall dimensions.

W Nmaster 2 circuit breakers comes in two frame sizes.

WX-A: 630A to 2500A

WX-B: 2000A to 3200A

i

Fixed Type Drawout Type

8C&S Electric Limited

9

C&S Electric Limited

Structure of the Circuit Breaker

WX-B WX20B n

WX25B n

WX32B n

Available in both Fixed & Drawout version

W Nmaster 2i

The operation of circuit breaker has two modes: manual operation and electric operation. Operating mechanism of circuit breaker makes use of cam

to compress a group of energy-storage spring to reach the aim of energy storing, makes use of the energy of energy-storage spring during releasing

to close the circuit breaker, the closing speed has no relation to electric or manual operating speed. Circuit breaker will carry out energy pre-storage

under closing state for the next closing. The operating mechanism has function of free tripping. The circuit breaker has three types of working

position, whose operating process as follows:

Energy storage

External force of electric operation or manual operation drives the cam to rotate, the energy-storage lever on the cam rotates along with it. During the

rotation of cam, energy-storage spring is compressed continuously until the cam rotates to a certain angle (finish position of energy storage); the

reaction force of energy-storage lever will push the cam to go on rotating (turn to energy releasing position), in the meantime, the fixed shaft on the

cam is just pressed against the lever 1, and the other end of lever 1 is locked by the energy-releasing tripping half-shaft, so the “go on rotating” of

cam also is locked (in energy-storage position). On the other hand, when the external force of electric operation or manual operation helps the

energy storing of energy-storage spring, cam drives the connecting rod 1 to rotate, the lever 2 on connecting rod 1 rotates towards the re-trip

position, when reaching the re-trip position, the tripping half-shaft is rotated to the re-trip position under the action of spring force on the re-trip half-

shaft, so as to finish the re-trip process. Now the energy storage is finished, it is ready for closing of circuit breaker.

Closing

Press the closing button or closing electromagnet, let the half-shaft of energy-releasing release rotate counterclockwise, then the lever 1 pressing

against the energy-releasing tripping half-shaft trips, cam rotates clockwise under the action of energy-storage spring force until reaching the cam

gap, energy-storage lever rotates counterclockwise under the action of energy-storage spring force, axle pin on the energy-storage lever just hits

the connecting rod 2 fiercely, which enables the connecting rod 2 to rotate, and drives the connecting rod 1 and connecting rod 3 to run, as the

running direction (by means of force transmission of lever 2) of connecting rod 1

is locked by the tripping half-shaft, then the connecting rod 3

pushes the main shaft 8 to rotate clockwise, to close the circuit breaker.

Breaking

Let the shunt tripping half-shaft (10) rotate clockwise by pressing the opening button or through the tripping operation from under-voltage release,

shunt release and intelligent release, lever 2 trips, force pressing against the connecting rod 1 is disappeared, and now the connecting rod 1 is in free

state, the four-rod link mechanism composed of connecting rod 1, 2 and 3 now becomes five-rod linkage mechanism, under the action of contact

reaction force and backspring force, the circuit breaker opens quickly.

Electric energy-storage mechanism

The electric energy-storage mechanism is composed of motor, position limited inching switch and a group of gear reduction system that has

planetary gear, used for energy storing and energy pre-storing of operating mechanism.

10 C&S Electric Limited

11

C&S Electric Limited

Constructions Characteristics

Operating Mechanism

Contact System

Constructions Characteristics

Contact system of each phase is installed in a small chamber that is made up of insulating

materials, with arc-extinguish chamber above it. Contact system is connected with the

main shaft outside the insulating base through connecting rod, so as to finish the closing

and opening operations.

In order to reduce the electric repulsion and improve the reliability, contact system of

each phase adopts parallel connection of 10~14 moving contacts that are installed on a

contact support.

One end of contacting piece of the contact is connected with the busbar through flexible

connection.

When the circuit breaker closes, the main shaft drives the connecting rod to make the

contact support revolve around the point “A” counterclockwise, after the moving contact

touches the static contact, the contact support will continue to rotate around the point

“A” counterclockwise, while the moving contact will rotate around the point “B”

clockwise to compress the spring, so as to produce a certain contact force that

guarantees reliable closing of circuit breaker.

Static Contact

Main Saft

Connecting rod

Contact support

Busbar

Flexible connection

Moving contact

A

B

Energy releasing tripping half-shaft

Lever

Connecting rod 2

Energy storage lever

Energy storage spring

Cam

Connecting rod 1

Main shaft

Connecting rod 3

Breaking tripping -shaft

Lever 2

2

3

1

4

5

6

7

8

9

10

11

11

1

2

3

4

5

6

7

8

9

10

W Nmaster 2i

W Nmaster 2i

The operation of circuit breaker has two modes: manual operation and electric operation. Operating mechanism of circuit breaker makes use of cam

to compress a group of energy-storage spring to reach the aim of energy storing, makes use of the energy of energy-storage spring during releasing

to close the circuit breaker, the closing speed has no relation to electric or manual operating speed. Circuit breaker will carry out energy pre-storage

under closing state for the next closing. The operating mechanism has function of free tripping. The circuit breaker has three types of working

position, whose operating process as follows:

Energy storage

External force of electric operation or manual operation drives the cam to rotate, the energy-storage lever on the cam rotates along with it. During the

rotation of cam, energy-storage spring is compressed continuously until the cam rotates to a certain angle (finish position of energy storage); the

reaction force of energy-storage lever will push the cam to go on rotating (turn to energy releasing position), in the meantime, the fixed shaft on the

cam is just pressed against the lever 1, and the other end of lever 1 is locked by the energy-releasing tripping half-shaft, so the “go on rotating” of

cam also is locked (in energy-storage position). On the other hand, when the external force of electric operation or manual operation helps the

energy storing of energy-storage spring, cam drives the connecting rod 1 to rotate, the lever 2 on connecting rod 1 rotates towards the re-trip

position, when reaching the re-trip position, the tripping half-shaft is rotated to the re-trip position under the action of spring force on the re-trip half-

shaft, so as to finish the re-trip process. Now the energy storage is finished, it is ready for closing of circuit breaker.

Closing

Press the closing button or closing electromagnet, let the half-shaft of energy-releasing release rotate counterclockwise, then the lever 1 pressing

against the energy-releasing tripping half-shaft trips, cam rotates clockwise under the action of energy-storage spring force until reaching the cam

gap, energy-storage lever rotates counterclockwise under the action of energy-storage spring force, axle pin on the energy-storage lever just hits

the connecting rod 2 fiercely, which enables the connecting rod 2 to rotate, and drives the connecting rod 1 and connecting rod 3 to run, as the

running direction (by means of force transmission of lever 2) of connecting rod 1

is locked by the tripping half-shaft, then the connecting rod 3

pushes the main shaft 8 to rotate clockwise, to close the circuit breaker.

Breaking

Let the shunt tripping half-shaft (10) rotate clockwise by pressing the opening button or through the tripping operation from under-voltage release,

shunt release and intelligent release, lever 2 trips, force pressing against the connecting rod 1 is disappeared, and now the connecting rod 1 is in free

state, the four-rod link mechanism composed of connecting rod 1, 2 and 3 now becomes five-rod linkage mechanism, under the action of contact

reaction force and backspring force, the circuit breaker opens quickly.

Electric energy-storage mechanism

The electric energy-storage mechanism is composed of motor, position limited inching switch and a group of gear reduction system that has

planetary gear, used for energy storing and energy pre-storing of operating mechanism.

10 C&S Electric Limited

11

C&S Electric Limited

Constructions Characteristics

Operating Mechanism

Contact System

Constructions Characteristics

Contact system of each phase is installed in a small chamber that is made up of insulating

materials, with arc-extinguish chamber above it. Contact system is connected with the

main shaft outside the insulating base through connecting rod, so as to finish the closing

and opening operations.

In order to reduce the electric repulsion and improve the reliability, contact system of

each phase adopts parallel connection of 10~14 moving contacts that are installed on a

contact support.

One end of contacting piece of the contact is connected with the busbar through flexible

connection.

When the circuit breaker closes, the main shaft drives the connecting rod to make the

contact support revolve around the point “A” counterclockwise, after the moving contact

touches the static contact, the contact support will continue to rotate around the point

“A” counterclockwise, while the moving contact will rotate around the point “B”

clockwise to compress the spring, so as to produce a certain contact force that

guarantees reliable closing of circuit breaker.

Static Contact

Main Saft

Connecting rod

Contact support

Busbar

Flexible connection

Moving contact

A

B

Energy releasing tripping half-shaft

Lever

Connecting rod 2

Energy storage lever

Energy storage spring

Cam

Connecting rod 1

Main shaft

Connecting rod 3

Breaking tripping -shaft

Lever 2

2

3

1

4

5

6

7

8

9

10

11

11

1

2

3

4

5

6

7

8

9

10

W Nmaster 2i

W Nmaster 2i

Basic Structure

W Nmaster2 WX series circuit breakers are available in Drawout & fixed versions. The

drawout version is mounted on a chassis & the fixed version is installed using fixing

brackets.

i

Drawout version

Fixed version

Chassis

Circuit breaker

Front cover

12 C&S Electric Limited

13

C&S Electric Limited

Constructions Characteristics

Constructions Characteristics

W Nmaster 2i

W Nmaster 2i

Basic Structure

W Nmaster2 WX series circuit breakers are available in Drawout & fixed versions. The

drawout version is mounted on a chassis & the fixed version is installed using fixing

brackets.

i

Drawout version

Fixed version

Chassis

Circuit breaker

Front cover

12 C&S Electric Limited

13

C&S Electric Limited

Constructions Characteristics

Constructions Characteristics

W Nmaster 2i

W Nmaster 2i

C&S Electric fully takes into account environmental requirements, starting right

from the design phase of every product through to the end of its service life:

the materials used for W Nmaster 2 are not potentially dangerous to the

environment

the production facilities are non-polluting in compliance with the ISO 14001

standard

the energy dissipated per pole is low, making energy losses insignificant

the materials are marked to facilitate sorting for recycling at the end of product

service life.

i

n

n

n

Conformity to RoHS Directive

C eompliance with nvironmental requirements

RoHS

Compliant

WiNmaster2 ACB is a product confirming to RoHS (Restriction of Hazardous

Substances) directive. That means, in conformity with EU Directive Lead (Pb), Cadmium

(Cd), Mercury (Hg), Hexavalent Chromium (Cr+6), Polybrominated Biphenyls (PBB) and

Polybrominated Biphenyl Ethers (PBDE) have not been used except for exempted

applications.

RoHS

Compliant

14 C&S Electric Limited 15

C&S Electric Limited

W Nmaster 2i

C&S Electric fully takes into account environmental requirements, starting right

from the design phase of every product through to the end of its service life:

the materials used for W Nmaster 2 are not potentially dangerous to the

environment

the production facilities are non-polluting in compliance with the ISO 14001

standard

the energy dissipated per pole is low, making energy losses insignificant

the materials are marked to facilitate sorting for recycling at the end of product

service life.

i

n

n

n

Conformity to RoHS Directive

C eompliance with nvironmental requirements

RoHS

Compliant

WiNmaster2 ACB is a product confirming to RoHS (Restriction of Hazardous

Substances) directive. That means, in conformity with EU Directive Lead (Pb), Cadmium

(Cd), Mercury (Hg), Hexavalent Chromium (Cr+6), Polybrominated Biphenyls (PBB) and

Polybrominated Biphenyl Ethers (PBDE) have not been used except for exempted

applications.

RoHS

Compliant

14 C&S Electric Limited 15

C&S Electric Limited

W Nmaster 2i

Connection installation

C ionnections for ease of different nstallation

C&S W Nmaster2 ACB meets your demands for high breaking capacity, fully line-up and

optimized panel size. Various accessories and horizontal connection methods realize

user friendly handling. This offers flexibility for construction of busbar as product is

available with horizontal terminal requirement meeting varied customer requirement for

termination. Such facility allows user to optimize the size of switchboards and busbar

connection.

W Nmaster2 ACB provides you total solutions with an advanced trip relay for

measurement, diagnosis, analysis and communication as well as protective functions for

absolute protective co-ordination and electric power monitoring system.

i

i

Breaker connection in Horizontal Type

18 C&S Electric Limited 19

C&S Electric Limited

Mixed typeVertical typeHorizontal type

Cradle terminal as per panel manufacturer

W Nmaster 2i

Connection installation

C ionnections for ease of different nstallation

C&S W Nmaster2 ACB meets your demands for high breaking capacity, fully line-up and

optimized panel size. Various accessories and horizontal connection methods realize

user friendly handling. This offers flexibility for construction of busbar as product is

available with horizontal terminal requirement meeting varied customer requirement for

termination. Such facility allows user to optimize the size of switchboards and busbar

connection.

W Nmaster2 ACB provides you total solutions with an advanced trip relay for

measurement, diagnosis, analysis and communication as well as protective functions for

absolute protective co-ordination and electric power monitoring system.

i

i

Breaker connection in Horizontal Type

18 C&S Electric Limited 19

C&S Electric Limited

Mixed typeVertical typeHorizontal type

Cradle terminal as per panel manufacturer

W Nmaster 2i

All accessories are common for entire range and now can be easily fitted from the front.

Therefore, it is now possible to convert Manual breaker to electrical breaker at site or

even in installation. All accessories (Shunt coil, UVT, closing coil, locks etc.) can now be

installed very easily from front after removing the top cover of ACB and all accessories

are clip-on require no screws for mounting and even motor drive require just one screw

for mounting on the ACB for easy access.

E I o mase of nstallation, peration and aintenance

Charging handle

Operational position indication

UVT Delay Block

Closing coil

Shunt coil

UVT coil

Spring Charging Motor

Pad Lock position

Auxiliary terminal shield

Auxiliary terminal

2

3

1

4

5

6

7

8

9

3

6

2

9

1

7

8

Internal configuration

External configuration

Fixed type ACB

Trip relay

ON button

OFF button

Operational position indication

Charge handle

Rated name plate

Charge/Discharge indicator

Front facia

Auxiliary terminal shield

2

3

1

4

5

6

7

8

8

5

7

2

3

6

1

Auxiliary Contact group

Arc chute

Switch Body

Intelligent release

Spring charging motor

Electric motor

Charging handle

Closing coil

Shunt coil

UVT

UVT Delay block

2

3

1

4

5

6

7

8

9

10

11

1

2

4

9

9

4

10

3

5

10

20 C&S Electric Limited 21

C&S Electric Limited

External configuration

4

5

6

7

8

9

10

11

W Nmaster 2iW Nmaster 2i

All accessories are common for entire range and now can be easily fitted from the front.

Therefore, it is now possible to convert Manual breaker to electrical breaker at site or

even in installation. All accessories (Shunt coil, UVT, closing coil, locks etc.) can now be

installed very easily from front after removing the top cover of ACB and all accessories

are clip-on require no screws for mounting and even motor drive require just one screw

for mounting on the ACB for easy access.

E I o mase of nstallation, peration and aintenance

Charging handle

Operational position indication

UVT Delay Block

Closing coil

Shunt coil

UVT coil

Spring Charging Motor

Pad Lock position

Auxiliary terminal shield

Auxiliary terminal

2

3

1

4

5

6

7

8

9

3

6

2

9

1

7

8

Internal configuration

External configuration

Fixed type ACB

Trip relay

ON button

OFF button

Operational position indication

Charge handle

Rated name plate

Charge/Discharge indicator

Front facia

Auxiliary terminal shield

2

3

1

4

5

6

7

8

8

5

7

2

3

6

1

Auxiliary Contact group

Arc chute

Switch Body

Intelligent release

Spring charging motor

Electric motor

Charging handle

Closing coil

Shunt coil

UVT

UVT Delay block

2

3

1

4

5

6

7

8

9

10

11

1

2

4

9

9

4

10

3

5

10

20 C&S Electric Limited 21

C&S Electric Limited

External configuration

4

5

6

7

8

9

10

11

W Nmaster 2iW Nmaster 2i

Table of contents

Popular Circuit Breaker manuals by other brands

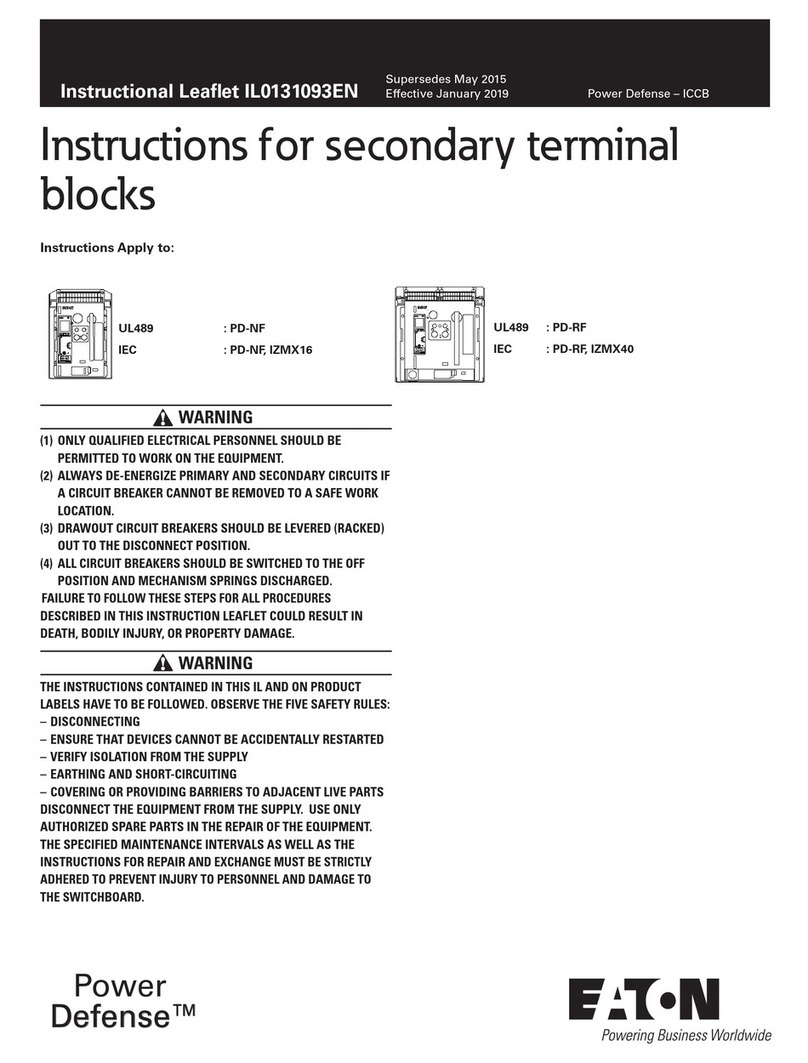

Eaton

Eaton Power Defense PD-NF Instruction leaflet

Siemens-Allis

Siemens-Allis R Series Installation, operation & maintenance instructions

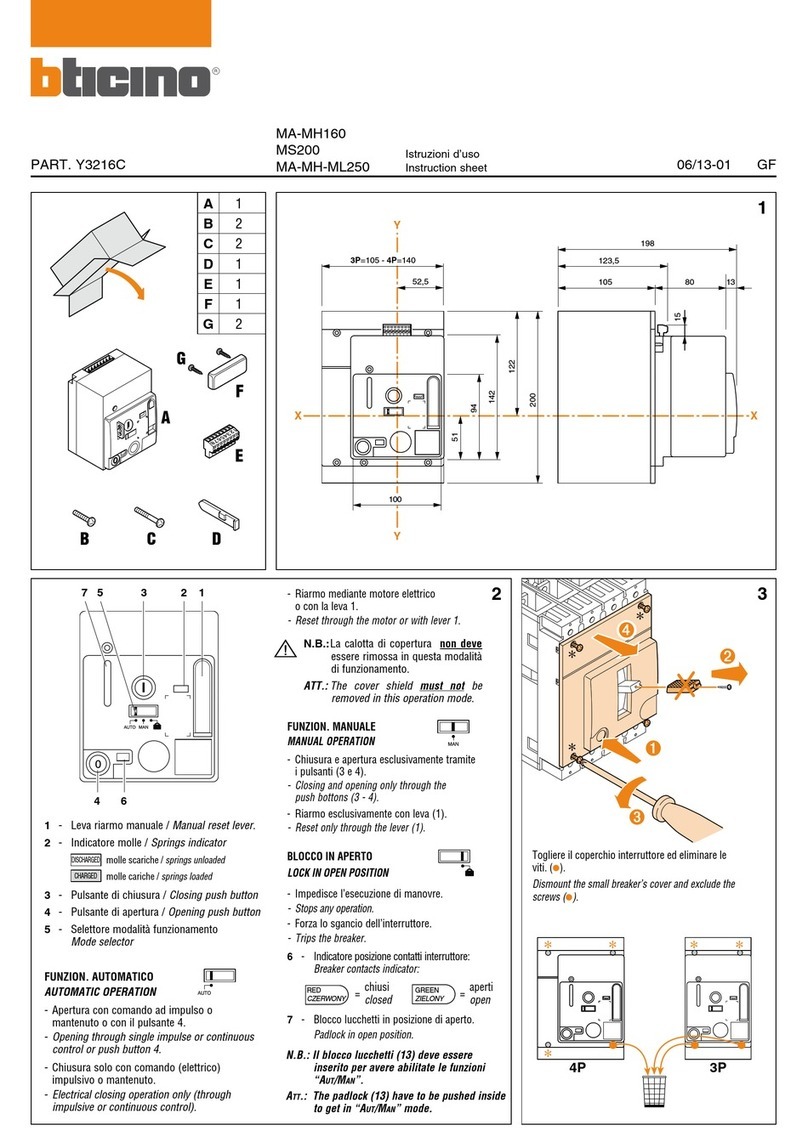

Bticino

Bticino MA-MH160 instruction sheet

Siemens

Siemens 3AH3 operating instructions

Allen-Bradley

Allen-Bradley 140G Series quick start guide

CHNT Power

CHNT Power NXM Series User instructions