CHNT Power NXM Series User manual

NO:2021.04

Standard:IEC/EN 60947-2

NXM Series

Moulded-Case Circuit-Breaker

User Instructions

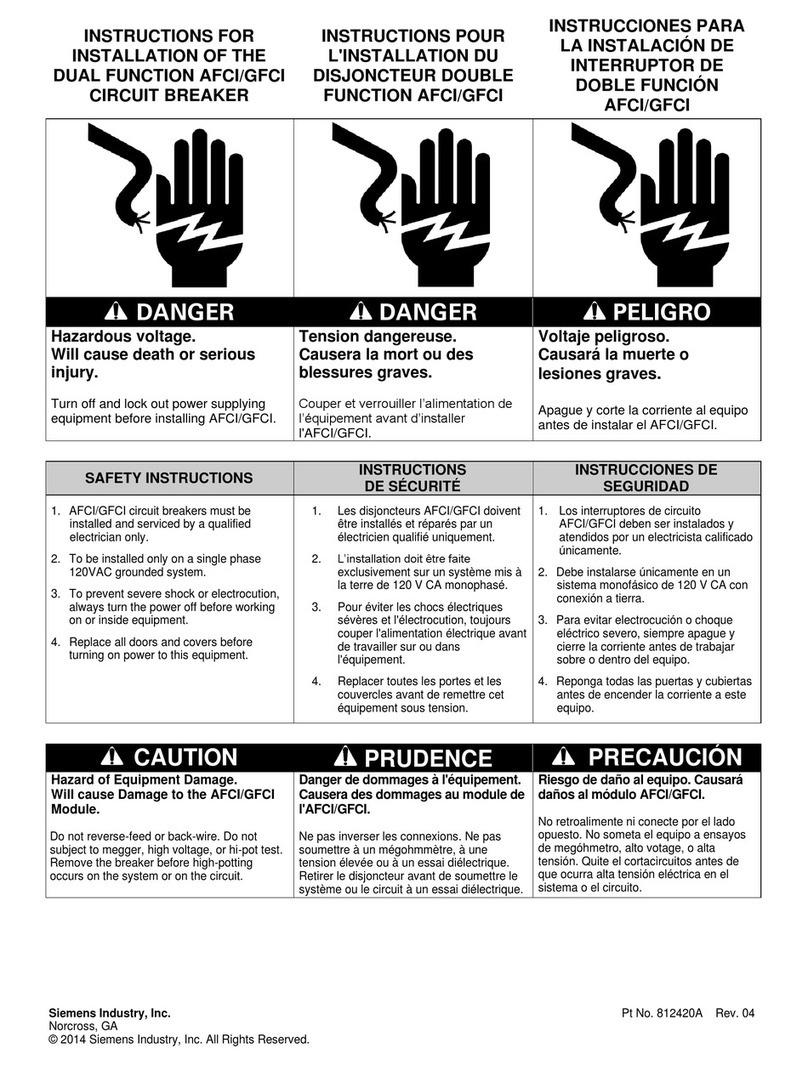

Safety Warning

1

2

3

4

Installation in any damp, condensed-phase environment with inflammable

and explosive gas is forbidden.Do not operate the product with wet hands.

You are prohibited from touching the conductive part when the product is

operating.

When the product is being installed or maintained, the power must be

switched off.

The product must not be installed in the place where gas medium can

corrode metal and damage insulation.

In order to avoid dangerous accidents, the installation and fixation of the

product must be carried out in strict accordance with the requirements of

the user instructions.

5

E M A

E U R

1

2

01

a) Ambient temperature for normal use: - 5 ℃ ~ + 40 ℃;

Note: if it is used within the range of - 35 ℃ ~ + 70 ℃, please consult with the

manufacturer

b) If the altitude exceeds 2000m, please consult with the manufacturer;

c) See the product sample for the inverse time lag, temperature compensation

curve and altitude derating curve of the product;

d) Pollution degree: degree 3;

e) Main circuit installation category: III;

f) Degrees of protection provided by enclosure: IP30 (except wiring terminals);

g) Rated insulation voltage Ui: 800V (NXM-63/160/125/250);

1000V (NXM-400/630/800/1000/1250/1600).

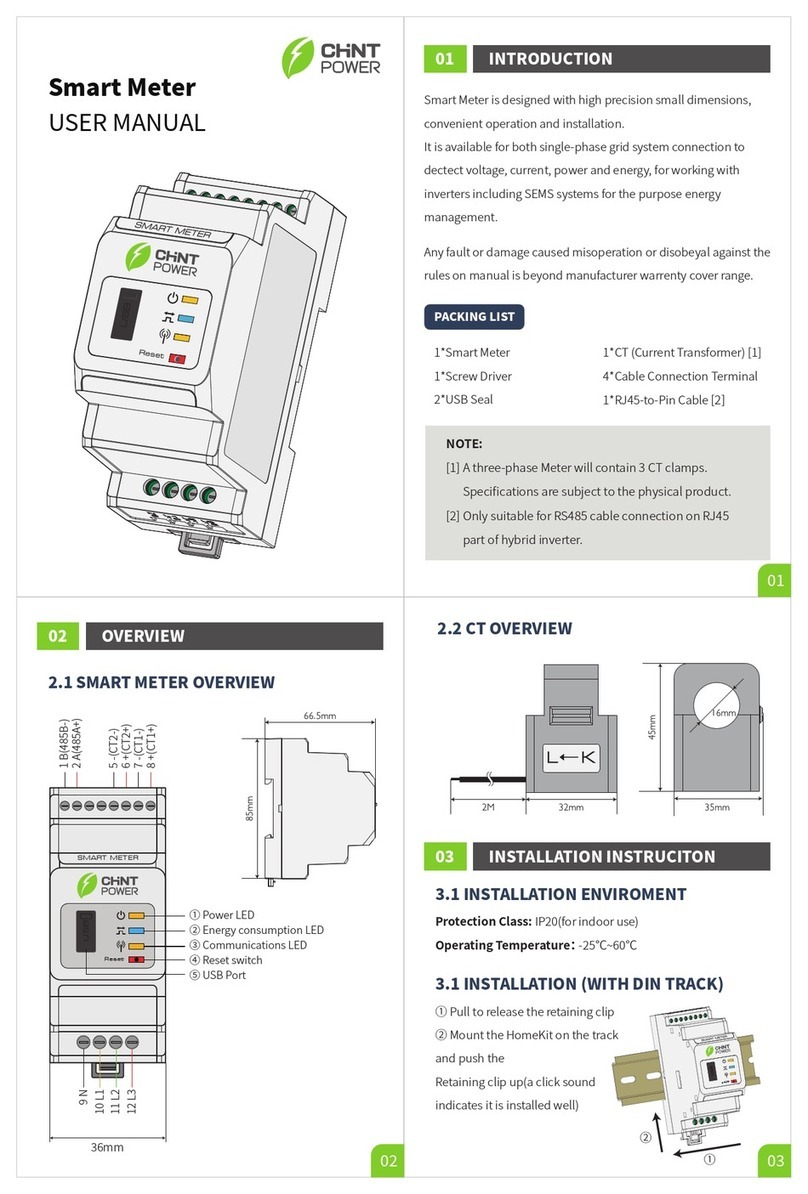

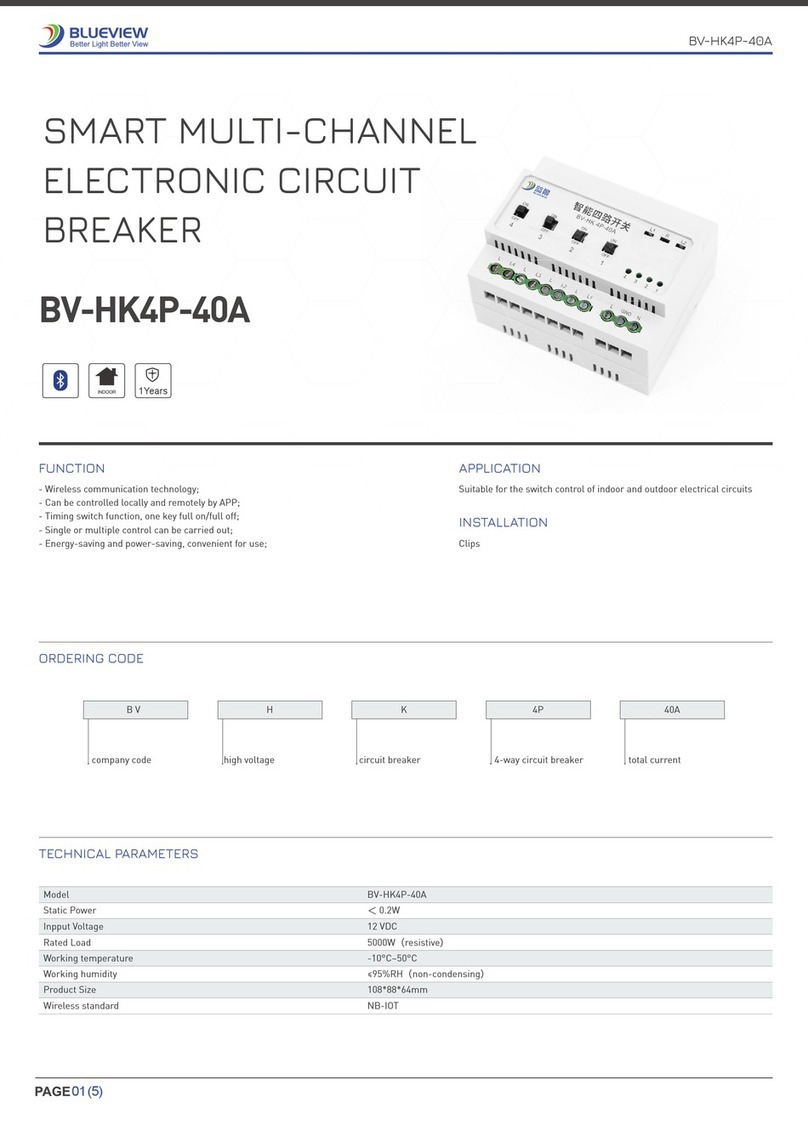

Use Information

Inspection and Test

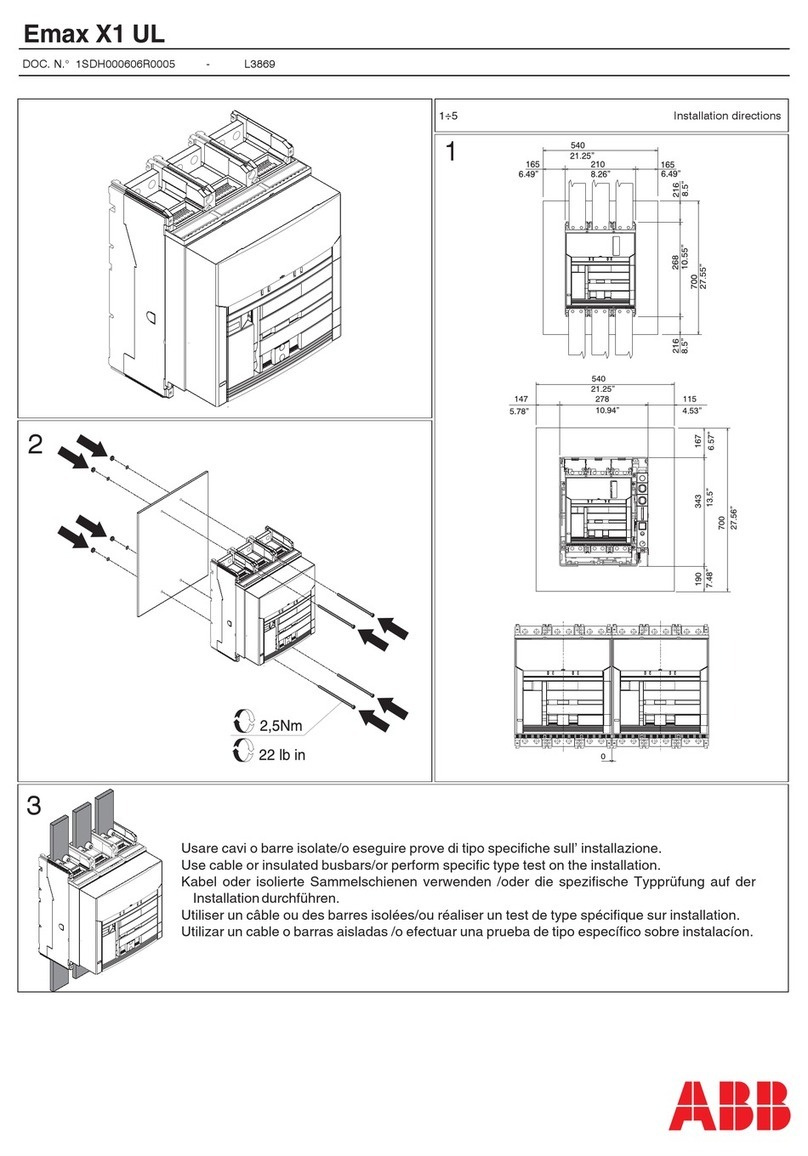

Figure 1 Inspection

Tool

Cross screwdriver

1. Determine

product

technical

parameters;

2. Only

qualified and

professional

technicians are

allowed for

installation,

operation and

maintenance.

Type Screw Nut Flat

gasket

Spring

washer

PCS

2P 3P 4P

NXM-63

NXM-125

S

H

M4×62

M4×72

M4×45

M4×45

M4×90

M5×75

M5×75

M6×90

M5×140

2

-

2

2

-

-

-

-

-

4

4

4

4

4

4

4

4

4

4

4

4

4

4

NXM-160

NXM-250

NXM-400、NXM-630

NXM-800

NXM-1000

NXM-1250、NXM-1600

S

H

02

Smin

Xmin

25min

Xmin

Ensure

minimum

installation

distance

Figure 2 Minimum installation distance

Unit: mm

Type

NXM-63

NXM-125

NXM-160

NXM-250

NXM-400

NXM-630

NXM-800

NXM-1000

NXM-1250

NXM-1600

S X

50 25

100 50

①

Re-

triping

②

Making

③

Breaking

④

Making

⑤

Tripping

CLICK!

Figure 3 Test

3

Overall and Installation dimension

Under voltage

release

L

B

C

L1

E

J

E1

M

W3

W

F

2×φd

L

B

C

L1

E

J

E1

M

W4

W1

F

4×φd

A

2P 3P

Under voltage

release

Figure 4-1 NXM-63~250 front-panel wiring overall and installation dimension

03

Table 1 NXM-63 250 overall and installation dimension~

Figure 4-2 NXM-63~250 front-panel wiring overall and installation dimension

W3

L

B

C

L1

E

J

E1

M

W5

W2

F

6×φd

A1

Sectional view

of wiring

G

G1

H4

H3 H2

H1

Hmax

4P

Under voltage

release

Unit: mm

Overall

dimen-

sion

Dimen-

sion

Code

Specification

NXM-63S

NXM-125S

NXM-63H

NXM-125H NXM-160S NXM-160H NXM-250S NXM-250H

C

E

E1

F

G

G1

J

Hmax

H1

H2

H3

H4

L

L1

M

W

W1

86

55.5

27.5

23

17.5

8

17.5

88

51.7

24.5

29

16.5

7.5

25

102

56

30.5

29

23

10

25

90

71

64

21

21

100

81

74

31

31

96

75.5

62

112

91

77.5

98

77

62

23

123

102

87

24

135

121

49

56

78

24.5

24.5

155

135

50

63

90

24.5

165

145

101.5

78

105

04

Installa-

tion

dimen-

sion

W2

W3

W4

W5

A

A1

B

φd

103

25

50

75

25

50

117

4.2

120

30

60

90

30

60

130.5

4.5×6

140

35

70

105

35

70

126

4.5

Figure 5 NXM-400 1600 front-panel wiring overall and installation dimension~

L

B

C

L1

E

J

E1

M

W4

W1

F

4×φd

A

3P

W3

L

B

C

L1

E

J

E1

M

W5

W2

F

6×φd

A1

G

G1

4P

H4

H3 H2

H1

Hmax

Sectional view

of wiring

Under voltage release

Under voltage release

Table 2 NXM-400 1600 overall and installation dimension~

Unit: mm

Overall

dimen-

sion

Dimen-

sion

Code

Specification

NXM-400

NXM-630 NXM-800 NXM-1000 NXM-1250 NXM-1600

C

E

E1

F

G

G1

J

150

92

46

50

32.5

11.5

25

160

91

45

50

44.5

15

25

170

100

52

60

44.5

15

25

175

120

37.8

78

53

15

25

Dimen-

sion

Code

Specification

NXM-63S

NXM-125S

NXM-63H

NXM-125H NXM-160S NXM-160H NXM-250S NXM-250H

Table 1 (Continued)

05

W

P3

P2

P4

P1

W

φd1

W

W

M2

P2

P3

W W

Hmax

H1

H2

H3

H4

L

L1

M

W1

W2

W3

W4

W5

A

A1

B

φd

161

108.5

97.5

40.5

41.5

257

225

104

140

185

44

88

132

44

88

194

7

165

114

103.5

43

45

270

235

104

182

240

58

116

174

58

116

200

7

168

118

106

42

43

280

243

106

210

280

70

140

210

70

140

243

7.2

202

153

143

57

57

207

158

148

65

65

370

342

92.5

210

280

70

140

210

70

140

314

6

Installa-

tion

dimen-

sion

Figure 6 NXM-63~250 rear wiring

overall and installation dimension

Figure 7 NXM-400~800 rear wiring

overall and installation dimension

Dimen-

sion

Code

Specification

NXM-400

NXM-630 NXM-800 NXM-1000 NXM-1250 NXM-1600

Table 2 (Continued)

06

P6

P5

P6

P7

P5

P8

W

P2

P1

W

φd1

W

P10

L8

L4

L4

L7

L5

L5

L2

L6 L6

KK

Q

P9

4×φd2 6×φd2

Installation

diagram

Mounting plate hole

dimension (3P)

Mounting plate hole

dimension(4P)

M1

W

6×φD4×φd3

W

3P

B

L2

8×φD 6×φd3

W W W

AA

4P

B

L2

N

A

P6

P8

Figure 8 NXM-1000 rear wiring

overall and installation dimension

Figure 9 NXM series rear wiring

mounting plate hole dimension

Figure 10 NXM series plug-in wiring overall and installation dimension

Figure 11 NXM-63/125/400/

630/800/1000 plug-in structure Figure 12 NXM-160 plug-in structure

Figure 13 NXM-250 plug-in structure

07

Table 3 NXM series back-panel wiring overall and installation dimension

Unit: mm

Dimen-

sion

Overall

dimen-

sion

Installa-

tion

dimen-

sion

Code

Specification

NXM-63

NXM-125 NXM-160 NXM-250 NXM-400

NXM-630 NXM-800 NXM-1000

W

P1

P2

P3

P4

P5

P6

P7

P8

P9

P10

M2

φd1

M1

φd2

φD

L2

B

L4

L5

L6

L7

L8

K

Q

A

Φd3

25

——

67.5

100.5

——

44.5

50.5

——

——

8.5

29.5

M8

——

M6

5.5

11.8

121

117

92

144

3P:80

4P:106

75

159

3P:50

4P:75

60

25

4.5

30

——

63.5

96.5

——

——

75

——

135

13

38

M8

——

M10

8

11

135

130.5

106

167

3P:94

4P:124

——

——

3P:60

4P:90

72

30

4.5

35

——

67.5

108.5

——

77

95

132

150

13

47.5

M10

——

M10

6

12

147

126

108

184

3P:107

4P:142

——

——

3P:70

4P:105

76

35

4.5

44

40

58

75

93

88

111

——

——

25

60

——

φ12

M10

9

33

225

194

168

283

3P:142

4P:187

169

281

3P:88

4P:132

145

44

7

58

46

66

77

99

92

110

——

——

23

60

——

φ16

M12

9

40

235

200

168

302

3P:178

4P:236

170

300

3P:100

4P:166

124

58

7

70

64

84

——

——

143.5

158.5

——

——

27

87

——

φ16

M12

12

40

243

243

177

309

3P:214

4P:284

181

305

3P:90

4P:185

146

70

7

08

Installation

M8×16 10N·m

4

12.5

14.5

25.5

M8-6H

40.5

7.5

φ8.2

Cross sectional area : s

s(b×c)≥70

c≤5

11≤X≤13

φ8.5

a≤7.5

b≤16

a≤7.5

φ8.5

b≤16

M6×12 4N m

·

φ6.5

φ8.2

7

Cross sectional area : s

NXM-63:s(b×c)≥16

NXM-125:s(b×c)≥50

c≤4

11≤X≤13

φ6.5

a≤8

b≤17.5

a≤7

φ6.5

b≤17.5

Connect to breaker

25.5

40

4

17 4

12.5

M8×16 12N·m

Connect to breaker

23.5

φ10.5

φ8.5

6

6

21

62

40

10

Cross sectional area : s

NXM-250: s(b×c)≥120

c≤8

11≤X≤13

φ8.5

a≤10

b≤23.5

a≤10

φ8.5

b≤23.5

4

Installation and Wiring

Figure 14 NXM-63/NXM-125 connecting plate and wiring dimension

Figure 16 NXM-250 connecting plate and wiring dimension

Figure 15 NXM-160 connecting plate and wiring dimension

Figure 17 NXM-400 connecting plate and wiring dimension

Connect to breaker

Installation

Installation

Connect to breaker

30.5

30.5

16

43

43

70

70

11.5

11.5

φ10.5

φ10.5

φ14

φ14

8

Cross sectional area : s

s(b×c)≥240

c≤13.5

19≤X≤21

φ10.5

a≤11.5

b≤30.5

a≤11.5

φ10.5

b≤30.5

M10×30 30N m

·

Installation

09

30.5

30.5

16

43

43

70

70

11.5

11.5

φ10.5

φ10.5

φ14

φ14

8c≤13.5

19≤X≤21

φ10.5

a≤11.5

b≤30.5

a≤11.5

φ10.5

b≤30.5

Cross sectional area : s

wire

1 wire

2 wires

Copper-bar

s(b×c)≥370 s(b×c)≥400

s(b×c)≥185 s(b×c)≥200

M10×30 30N m

·

Installation

Figure 18 NXM-630 connecting plate and wiring dimension

Figure 20 NXM-1000 connecting plate and wiring dimension

Figure 19 NXM-800 connecting plate and wiring dimension

Figure 21 NXM-1250/ NXM-1600 connecting plate and wiring dimension

Connect to breaker

43

50

8.5

58

90 15

φ17

φ14

10

43

50

58

90 15

φ17

φ14 c≤20

19≤X≤21

φ14

a≤15

b≤43

Cross sectional area : s

1 wire

2 wires

s(b×c)≥600

s(b×c)≥300

M12×35 40N m

·

Installation

Connect to breaker

24 24

45

38

15

30

82

82

52

52

2525

77

h

5×φ11

1530

5×φ11

15

77

50

52

15

30

24

22

45

82

15

74

Unit: mm

Rated current

1600A

1250A/1000A

h

20

15

50

1530

M10×45(1000、1250)

M10×55(1600)30N m

·

Installation

Connect to breaker

Cross sectional area : s

s(b×c)≥480 s(b×c)≥500

s(b×c)≥240 s(b×c)≥250

43

14

10

58

90

15

φ14

φ14

φ17

58

90

15

43

c≤12

19≤X≤21

φ14

a≤15

b≤43

a≤15

φ14

b≤43

M12×35 40N m·

Installation

Connect to breaker

wire

1 wire

2 wires

Copper-bar

10

Electric operating

mechanismRated

control supply voltage

K

A

Electric operating

mechanismRated

control supply voltage

ON ON

TRIPPED TRIPPED

OFF OFF

PUSH TO TRIP PUSH TO TRIP

OFF OFF

RESET RESET

K

T

A

B

B2

B1

S4

S2

S1

P2

P1

Uc (+)

OFF

ON

(-)

Motor

driven

mechanism

5

Attachment Information

Figure22 -Motor driven mechanism overall and installation dimension

Figure 23 -Wring of motor diven mechanism (AC)

Table 4 NXM series motor riven mechanism overall and installation dimension

Unit: mm

Dimen-

sion

Overall

dimen-

sion

Code NXM-63

NXM-125 NXM-160 NXM-250 NXM-400

NXM-630 NXM-800 NXM-1000 NXM-1250

NXM-1600

Specification

K

B1

B2

T

A

B

74

102

51

92

25

117

90

116

53

97

30

130.5

90

116

60.5

97.5

35

142

130

176

88

154

44

194

130

176

88

153

58

200

130

176

88

154.5

70

243

130

176

88

156

70

314

Installa-

tion

dimen-

sion

11

( L Other sizes can be selected through

consultation with the manufacturer)

Breaker

150Min

N

18

30.5

L

Power

supply

Loop of

switching

on

Loop of

switching

off

F14

F12

QF

F11

L1 L3 N

Breaker

L5

Tripper

Ctrl

Schematic diagram of

handle installation

45

°

53

φ36

10

77

NXM-63/125/160/250/

400/630/800/1000

NXM-1250/1600

2×φ5.5

Figure 24 Manual operation mechanism installation dimension

Table 5 NXM Series manual operation mechanism installation dimension

Unit: mm

Size

code NXM-63

NXM-125 NXM-160 NXM-250 NXM-400

NXM-630 NXM-800 NXM-1000 NXM-1250

NXM-1600

Specification

N

L

53.5 61.5 63.5 98 97 97 68.5

65 95

Figure 25 Wiring of special tripper

for prepaid electricity meter Figure 26 Wiring of auxiliary contact

12

UC2 UC1 P1 P2

C1 C2

Power

supply

B14

B12

QF

B11

Power

supply

UC

Figure 30 Flash barrier or protective guard

① Flash barrier

shall be installed

before operation.

② Check if the

wiring is correct.

③ After

installation, the

insulation

resistance to the

ground shall not

be less than

10MΩ.

Insert in the direction of the arrow

on the flash barrier

Figure 27 Wiring

of alarm contact

Figure 29 Wiring

of shunt tripper

Figure 28 Wiring of

under voltage tripper

6

Environmental Protection

In order to protect the environment, the product or product parts should be

disposed of according to the industrial waste treatment process, or be sent to the

recycling station for assortment, dismantling and recycling.

QC PASS

Test date: Please see The packing

ZHEJIANG CHINT ELECTRICS CO., LTD.

NXM Series

Moulded-Case Circuit-Breaker

IEC/EN 60947-2

Check 17

13

NXM Series

Moulded-Case Circuit-Breaker

User Instructions

Zhejiang Chint Electrics Co., Ltd.

Add: No.1, CHINT Road, CHINT Industrial Zone,North Baixiang,

Yueqing, Zhejiang 325603,P.R.China

E-mail: global-sales@chint.com

Website: http://en.chint.com

This manual suits for next models

10

Table of contents

Other CHNT Power Circuit Breaker manuals