Siemens-Allis R Series Guide

CONTENTS

TABLE

OF

CONTENTS

Introduction

General

Warranty

General

Description

Foundation

General

Indoor

Outdoor

Weights

of

Cubicles

Receiving

and

Handling

General

Identification

Inspection

and

Uncrating

Lifting

Switchgear

Use

of

Rollers

and

Jacks

Storage

Indoor

Switchgear

Outdoor

Switchgear

Installation

Introduction

Installing

Shipping

Sections

Setting

Shipping

Sections

Plumbing

and

Leveling

Instructions

Plumbing

Leveling

Indoor

Switchgear

Leveling

Outdoor

Switchgear

Installation

of

Traveling

Crane

Safety

Warning

Cleaning

Electrical

Connections

Primary

Connections

Bolted

Bus

Joints

Hardware

Note

Connection

to

Power

Transformer

Primary

Cable

Connections

Current

Transformers

Ground

Connections

Optional

Devices

Shutters

(

MOC

)

Switches

(

TOC

)

Switches

Key

Interlock

Drip

Resistant

Switchgear

(

Indoor

Option

)

Switchgear

Expanding

General

Indoor

Switchgear

Outdoor

Switchgear

Breaker

Preparation

and

Insertion

Preparation

Compartment

Identification

Placing

Breaker

in

Compartment

Racking

Breaker

Handling

Instructions

Drawout

Fuse

Carriage

(

3200

Amp

and

4000

Amp

)

Future

Breaker

Compartments

Inspection

and

Testing

Before

Energising

General

Inspection

Testing

Inspection

and

Testing

Before

Operation

Current

Transformers

Secondary

Load

Circuits

Control

Circuits

Watt

Meters

,

Watt

-

Hour

Meters

and

Directional

Relays

Static

Overcurrent

Trip

Devices

High

Potential

Tests

Phasing

-

Out

Maintenance

General

Time

Interval

Inspection

Cleaning

Insulation

—

Caution

Lubrication

Wiping

Electrical

Contacts

Mechanical

Devices

Circuit

Breakers

Relays

and

Instruments

Equipment

Surfaces

19

1

21

2

22

2

23

3

23

3

23

3

4

24

25

5

25

5

25

5

26

5

6

27

27

8

8

28

28

9

28

10

11

29

11

29

11

29

11

11

29

12

29

12

29

12

29

13

31

13

31

13

31

14

31

15

31

17

32

17

32

32

18

32

19

32

Courtesy of NationalSwitchgear.com

r

INTRODUCTION

Page

1

A

DANGER

GENERAL

This

manual

contains

instructions

for

receiving

,

handling

,

storage

,

installation

,

inspection

,

testing

and

maintenanceof

Siemens

-

Allis

low

voltage

metal

-

enclosed

switchgear

.

The

switchgear

described

herein

consists

of

the

600

volt

class

indoor

and

outdoor

designs

.

The

contents

of

this

manual

are

applicable

to

all

"

R

”

and

“

SR

”

switchgear

classes

arid

designs

unless

noted

otherwise

.

Siemens

-

Allis

low

voltage

switchgear

carries

letter

designations

as

follows

:

“

R

”

for

indoor

and

“

SR

”

for

outdoor

walk

-

in

(

NEMA

3

R

)

equipment

.

These

designations

may

appear

on

drawings

and

other

media

,

and

familiarity

with

them

will

simplify

communication

with

the

factory

.

Figures

1

and

2

show

typical

installations

.

Standard

construction

details

of

necessary

auxiliary

and

accessory

equipment

are

included

in

appropriate

sections

.

Instructions

for

spe

-

cial

mechanical

and

electrical

devices

,

as

specified

in

the

purchase

order

,

are

covered

by

supplementary

data

sub

-

mitted

with

this

instruction

manual

.

Ratings

described

in

this

manual

are

in

accordance

with

NEMA

,

IEEE

and

ANSI

standard

requirements

.

(

This

equipment

is

listed

with

Underwriters

Laboratories

,

Inc

.

)

Due

to

the

nature

of

this

product

,

there

is

inherent

danger

in

its

use

through

possible

exposure

to

high

electrical

voltage

.

Only

qualified

persons

thoroughly

familiar

with

these

instructions

should

be

allowed

to

operate

these

devices

.

Improper

use

or

procedures

can

result

in

serious

personal

injury

or

death

.

^

DANGER

No

attempt

to

operate

this

equipment

should

be

undertaken

without

fully

reading

the

instruction

manual

.

Operators

must

be

familiar

with

the

equipment

,

its

operation

,

and

have

read

these

instructions

prior

to

each

use

.

Failure

to

do

so

result

in

electrical

shock

or

burn

causing

may

death

or

serious

personal

injury

and

property

damage

.

Use

of

the

Siemens

-

Allis

equipment

must

be

restricted

to

qualified

personnel

.

A

qualified

person

is

one

who

is

familiar

with

the

installa

-

tion

,

construction

or

operation

of

the

equipment

and

the

hazards

involved

.

In

addition

,

this

quali

-

fied

person

has

the

following

qualifications

:

Is

trained

and

authorized

to

de

-

energize

,

clear

ground

and

tag

circuits

and

equipment

in

accor

-

dance

with

established

safety

practices

.

Is

trained

in

the

proper

care

and

use

of

protective

equipment

such

as

rubber

gloves

,

hard

hat

,

safety

glasses

or

face

shields

,

flash

clothing

,

etc

.

,

in

accordance

with

established

safety

practices

.

Is

trained

in

rendering

first

aid

.

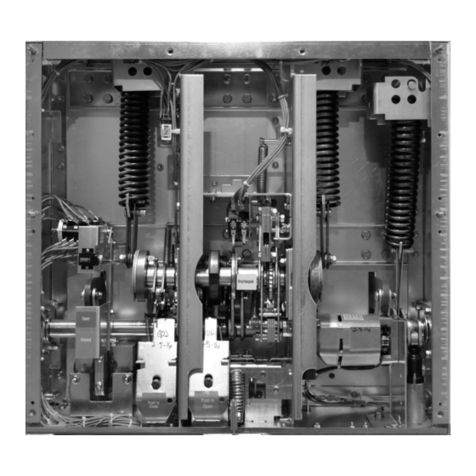

Figure

1

.

Picture

of

Typical

Low

Voltage

Indoor

Switchgear

Group

,

Type

“

R

”

Courtesy of NationalSwitchgear.com

INTRODUCTION

Page

2

WARRANTY

GENERAL

DESCRIPTION

For

warranty

coverage

,

see

sales

contract

.

Equipment

furnished

has

been

designed

to

operate

in

a

system

having

the

circuit

capacity

specified

by

the

purchaser

.

If

for

any

reason

the

equipment

is

used

in

a

different

system

,

or

if

short

-

circuit

capacity

of

the

system

is

increased

,

a

check

must

be

made

of

the

rating

of

the

switchgear

,

the

interrupt

-

ing

capacity

of

the

circuit

breakers

and

the

bus

capacity

.

Failure

on

the

part

of

the

user

to

obtain

approval

of

intended

changes

from

Siemens

-

Allis

may

be

cause

for

voiding

the

warranty

.

The

switchgear

described

in

this

manual

is

of

the

metal

-

enclosed

type

.

The

cubicles

described

are

comprised

of

full

depth

side

sheets

and

components

segregating

breaker

compartments

from

the

bus

section

,

from

each

other

and

from

compartments

containing

auxiliary

sec

-

ondary

equipment

.

In

addition

,

the

cubicle

and

intercubi

-

cte

bus

work

may

be

shielded

(

optional

)

from

the

primary

entrance

cable

area

with

segregating

barriers

.

Interlocks

are

provided

,

where

necessary

,

to

insure

proper

sequence

and

safe

operation

.

Indoor

switchgear

,

type

“

Ft

”

,

consists

of

one

or

more

cubi

-

cles

secured

together

as

a

single

group

.

It

is

completely

operational

when

installed

and

connected

to

customer

’

s

power

supply

.

When

connected

directly

to

a

power

trans

-

former

a

14

”

(

355.6

mm

)

wide

transition

section

may

be

provided

to

adjust

connections

to

the

proper

elevation

or

provide

space

for

incoming

metering

current

transformers

.

Circuit

breaker

compartments

are

provided

with

hinged

access

doors

for

installing

or

removing

circuit

breakers

.

Auxiliary

compartmentsare

designed

with

hinged

panels

for

mounting

of

instruments

,

relays

and

switches

.

Outdoor

switchgear

,

type

“

SR

”

,

is

similar

to

indoor

switch

-

gear

,

except

that

it

is

enclosed

in

a

weather

resistant

(

NEMA

3

R

)

steel

housing

.

The

equipment

is

designed

so

that

weather

conditions

will

not

affect

operation

of

the

switchgear

.

An

illuminated

service

aisle

is

provided

at

the

front

of

the

switchgear

allowing

inspection

and

mainte

-

nance

without

exposure

to

the

elements

.

An

access

door

is

provided

at

each

end

of

the

aisle

wall

with

panic

bar

latch

release

inside

the

aisle

.

The

rear

of

each

cubicle

is

equipped

with

a

door

for

access

to

the

primary

cable

entrance

area

and

secondary

terminal

blocks

.

These

doors

and

all

external

covers

are

secured

with

tamper

-

resistant

screws

.

Special

1

/

4

"

-

drive

sockets

for

these

screws

are

shipped

with

the

accessories

(

Part

No

.

15

-

171

-

404

-

051

)

.

Figure

2

.

Picture

of

Typical

Low

Voltage

Switchgear

Group

,

Type

“

SR

”

Courtesy of NationalSwitchgear.com

I

4

I

FOUNDATION

Page

3

horizontal

plane

within

1

/

16

"

(

1.6

mm

)

.

There

should

not

beany

projection

above

this

plane

within

the

area

covered

by

the

switchgear

.

If

the

customer

’

s

floor

or

sills

do

not

meet

this

requirement

it

will

be

necessary

to

use

shims

when

installing

the

switchgear

on

the

mounting

surface

.

GENERAL

Prior

to

installation

of

the

switchgear

,

careful

design

,

planning

and

construction

of

the

foundation

or

base

on

which

the

switchgear

will

rest

must

be

made

.

A

thorough

analysis

and

careful

construction

may

alleviate

many

problems

at

the

time

of

installation

.

It

is

important

that

a

true

and

level

surface

be

provided

,

with

the

structure

being

capable

of

supporting

the

weight

of

the

switchgear

and

other

related

equipment

.

OUTDOOR

Concrete

slab

,

sill

channels

,

piers

or

pilings

,

whichever

type

of

foundation

is

used

,

must

have

smooth

and

level

surfaces

and

be

in

the

same

horizontal

plane

within

1

/

16

"

(

1

6

mm

)

.

If

these

conditions

are

not

met

it

will

be

neces

-

sary

to

shim

when

installing

the

switchgear

.

The

use

of

a

transit

to

obtain

a

true

level

during

foundation

construc

-

tion

is

recommended

.

In

any

group

of

outdoor

switchgear

support

points

shall

be

at

each

end

and

at

the

division

of

every

second

or

third

cubicle

,

however

,

the

span

between

supports

shall

not

exceed

66

"

(

1514

mm

)

,

see

Figure

4

.

If

pilings

are

used

,

the

diameter

is

to

be

determined

by

INDOOR

As

it

is

difficult

to

obtain

a

true

and

level

floor

on

a

con

-

crete

slab

,

it

is

highly

recommended

that

3

"

(

minimum

)

sill

channels

be

grouted

in

as

shown

in

Figure

3

.

It

should

be

noted

that

the

surface

of

the

sills

is

slightly

above

floor

level

.

The

surfaceof

the

sills

must

be

level

and

in

the

same

Anchor

Bolts

Front

3.0

"

(

76.2

mm

)

33.68

"

(

860.5

mm

)

«

*

i

1

J

y

A

Floor

Line

-

»

I

/

T

*

A

,

•

i

V

1

*

>

J

9

.

62

"

(

15.7

mm

)

Dia

.

Holes

for

Anchor

Bolts

or

Welding

to

Sills

I

*

1.0

"

Max

.

(

25.4

mm

)

Cust

.

Floor

Must

Not

Project

Above

Top

of

Sill

Channels

.

50

"

(

12.7

mm

)

Dia

.

Anchor

Bolts

or

Sill

Furn

.

By

Cust

.

When

Req

'

d

.

(

See

Alternates

)

Side

View

Indoor

Bolting

Arrg

’

t

.

Weld

to

Floor

Steel

Drill

and

Tap

Floor

Steel

Alternates

vMrmv

5

~

7

\

/

*

•

m

*

;

%

Figure

3

.

Indoor

Anchoring

Courtesy of NationalSwitchgear.com

t

-

FOUNDATION

Page

4

restrictions

,

conduit

couplings

may

be

grouted

in

flush

with

foundation

,

and

conduit

nipples

added

after

switch

-

gear

is

in

place

.

Conduits

should

be

capped

during

con

-

struction

to

prevent

entry

of

dirt

,

moisture

and

vermin

.

When

“

J

”

bolts

or

other

types

of

anchor

bolts

are

grouted

in

foundation

they

must

be

located

exactly

as

shown

on

general

arrangement

drawing

.

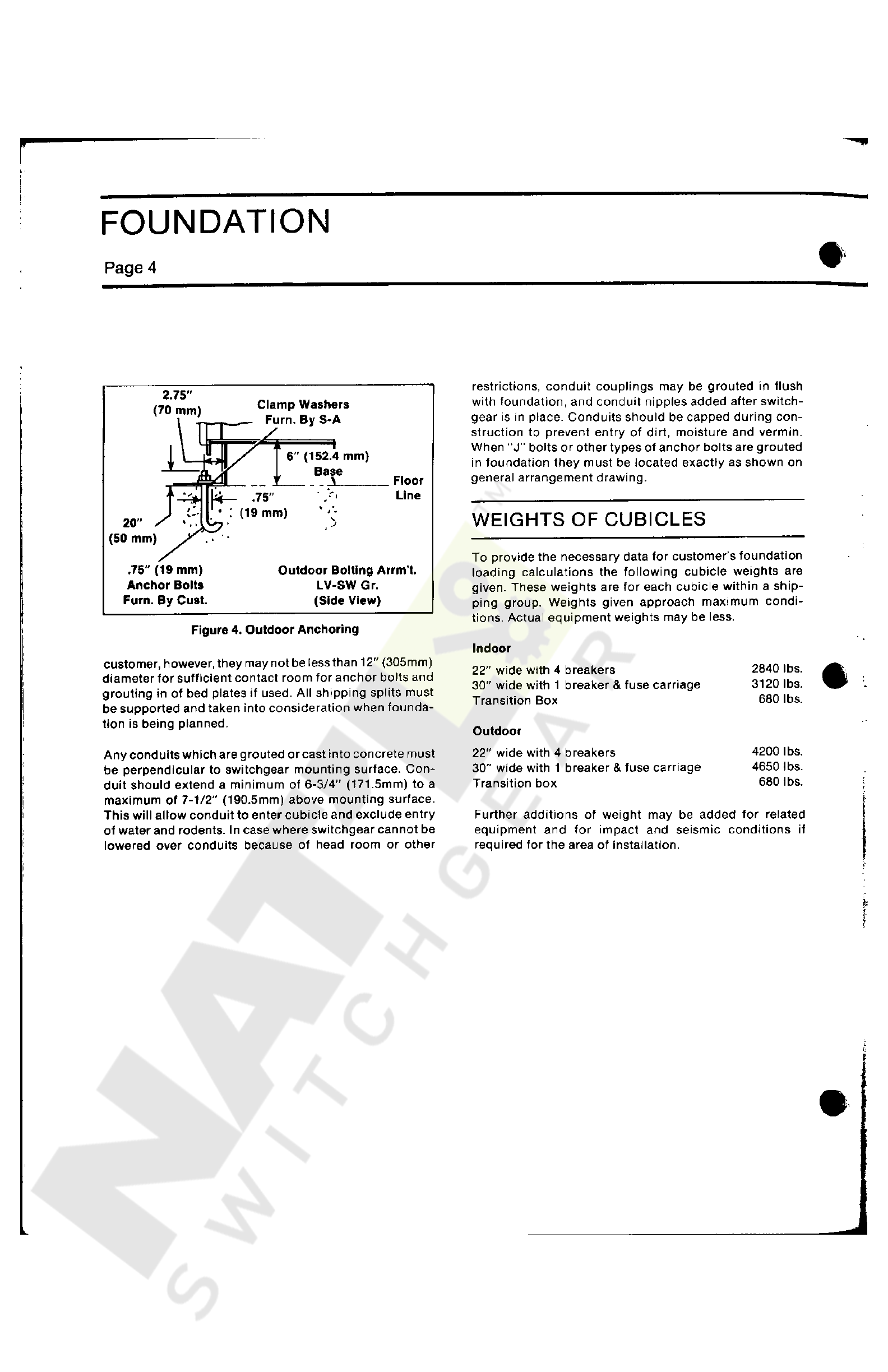

2.75

"

(

70

mm

)

Clamp

Washers

Furn

.

By

S

-

A

/

i

6

"

(

152.4

mm

)

Base

V

Floor

Line

\

|

4

—

•

:

(

19

mm

)

75

"

t

-

WEIGHTS

OF

CUBICLES

20

"

,

'

(

50

mm

)

To

provide

the

necessary

data

for

customer

’

s

foundation

loading

calculations

the

following

cubicle

weights

are

given

.

These

weights

are

for

each

cubicle

within

a

ship

-

ping

group

.

Weights

given

approach

maximum

condi

-

tions

.

Actual

equipment

weights

may

be

less

.

.

75

"

(

19

mm

)

Anchor

Bolts

Furn

.

By

Cust

.

Outdoor

Bolting

Arrm

’

t

.

LV

-

SW

Gr

.

(

Side

View

)

Figure

4

.

Outdoor

Anchoring

Indoor

22

"

wide

with

4

breakers

30

"

wide

with

1

breaker

&

fuse

carriage

Transition

Box

customer

,

however

,

they

may

not

be

less

than

12

"

(

305

mm

)

diameter

for

sufficient

contact

room

for

anchor

bolts

and

grouting

in

of

bed

plates

if

used

.

All

shipping

splits

must

be

supported

and

taken

into

consideration

when

founda

-

tion

is

being

planned

.

2840

lbs

.

3120

lbs

.

680

lbs

.

Outdoor

22

"

wide

with

4

breakers

30

”

wide

with

1

breaker

&

fuse

carriage

Transition

box

4200

I

bs

.

4650

lbs

.

680

lbs

.

Any

conduits

which

are

grouted

or

cast

into

concrete

must

be

perpendicular

to

switchgear

mounting

surface

.

Con

-

duit

should

extend

a

minimum

of

6

-

3

/

4

"

(

171.5

mm

)

to

a

maximum

of

7

-

1

/

2

"

(

190.5

mm

)

above

mounting

surface

.

This

will

allow

conduit

to

enter

cubicle

and

exclude

entry

of

water

and

rodents

.

In

case

where

switchgear

cannot

be

lowered

over

conduits

because

of

head

room

or

other

I

\

Further

additions

of

weight

may

be

added

for

related

equipment

and

for

impact

and

seismic

conditions

if

required

for

the

area

of

installation

.

fc

r

?

L

.

Courtesy of NationalSwitchgear.com

RECEIVING

AND

HANDLING

Page

5

drawings

.

These

numbers

insure

that

all

components

,

applying

to

a

particular

substation

,

are

correctly

located

before

uncrating

.

When

there

are

multiple

shipping

sec

-

tions

each

may

be

identified

by

an

attached

tag

giving

a

drawing

number

which

also

appears

on

the

customer

'

s

copy

of

the

shipping

list

.

The

shipping

list

also

describes

the

content

of

the

crate

or

package

as

cubicle

or

unit

No

.

1

-

2

-

3

etc

.

Refer

to

general

arrangement

drawing

for

loca

-

tion

of

each

shipping

section

within

a

group

line

-

up

.

GENERAL

Each

shipping

section

of

switchgear

is

securely

blocked

and

braced

for

shipment

.

It

is

crated

,

boxed

or

covered

as

required

by

shipping

conditions

.

Whatever

method

of

shipment

is

employed

,

every

precaution

is

taken

to

insure

its

safe

arrival

.

If

special

handling

is

required

,

it

is

so

indicated

on

the

shipment

.

All

moving

parts

are

secured

,

however

,

relatively

delicate

instruments

are

included

which

requires

that

each

section

be

handled

carefully

until

installed

in

its

final

location

.

INSPECTION

AND

UNCRATING

Before

uncrating

inspect

for

splintered

crate

or

other

abuse

.

In

the

process

of

uncrating

nail

pullers

are

recom

-

mended

.

The

use

of

sledge

hammers

and

crow

bars

could

bend

or

damage

the

finish

of

the

switchgear

.

Check

ship

-

ping

manifest

to

be

certain

that

all

items

have

been

received

.

Do

not

destroy

any

packing

material

until

all

items

listed

on

shipping

manifest

have

been

accounted

for

.

Small

packages

of

parts

can

be

lost

in

packing

mate

-

rial

.

Do

not

remove

identification

tags

from

apparatus

until

the

switchgear

is

completely

installed

.

If

there

are

any

shortages

,

or

damage

not

previously

noted

,

make

certain

it

is

noted

on

the

freight

bill

and

contact

carrier

and

Siemens

-

Allis

sales

office

immediately

.

NOTE

When

circuit

breakers

are

shipped

installed

in

their

respective

compartments

,

they

are

se

-

cured

in

the

fully

connected

position

and

they

are

closed

.

A

bolt

is

placed

through

the

trip

button

to

prevent

accidental

tripping

during

shipment

.

See

Figure

26

.

IDENTIFICATION

In

the

case

of

load

center

substations

,

the

low

voltage

circuit

breakers

may

be

key

interlocked

with

the

trans

-

former

primary

switches

.

Check

substation

numbers

on

packaging

of

switchgear

and

primary

switches

with

those

noted

on

applicable

general

arrangement

and

floor

plan

There

are

a

number

of

methods

that

can

be

used

in

han

-

dling

the

switchgear

which

when

properly

employed

will

not

damage

the

switchgear

sections

.

The

handling

method

used

will

be

determined

by

conditions

and

avail

-

able

equipment

at

the

installation

site

.

Lifting

with

a

crane

is

the

preferred

method

of

handling

,

however

,

overhead

obstructions

or

low

ceilings

often

dictate

the

method

to

be

used

.

Roller

bars

,

jacks

or

fork

lift

trucks

may

be

used

prior

to

removal

of

wooden

skids

.

LIFTING

SWITCHGEAR

A

DANGER

HEAVY

LOAD

Observe

all

handling

instructions

in

this

instruc

-

tion

book

to

prevent

tipping

or

dropping

of

equipment

.

Failure

to

do

so

will

result

in

property

damage

,

personal

injury

and

/

or

death

.

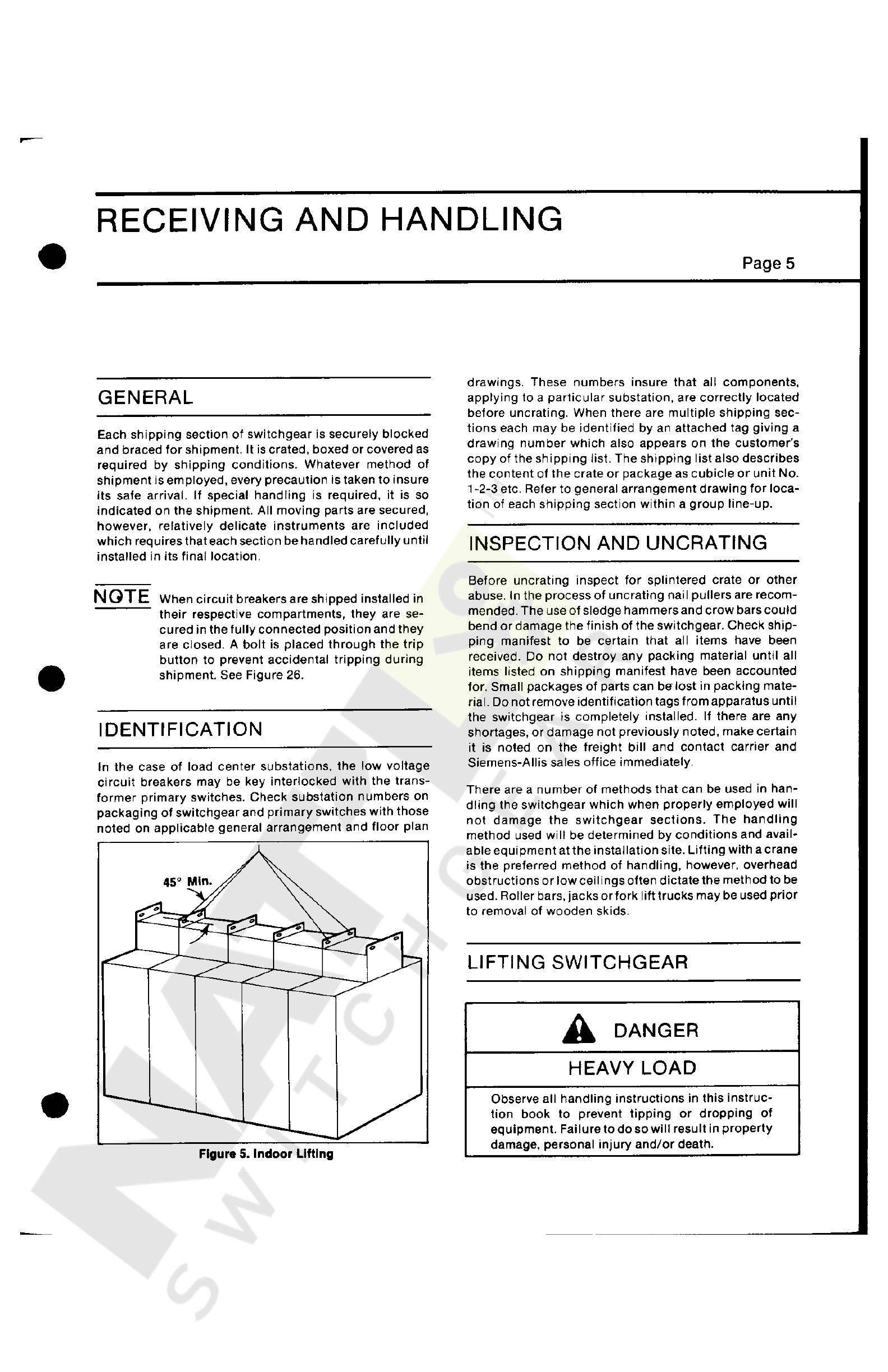

Figure

5

.

Indoor

Lifting

Courtesy of NationalSwitchgear.com

RECEIVING

AND

HANDLING

Page

6

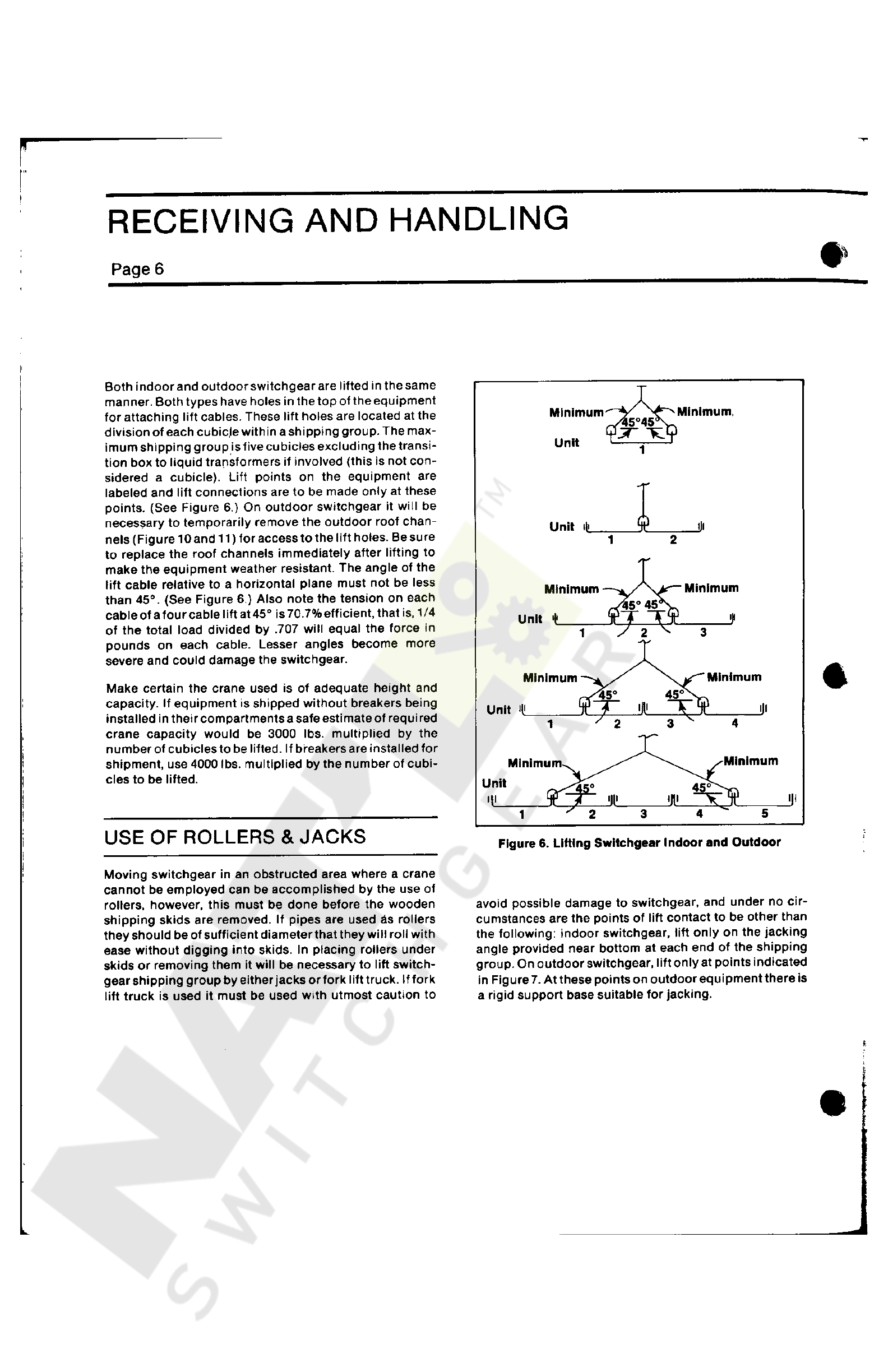

Both

indoorand

outdoorswitchgearare

lifted

in

the

same

manner

.

Both

types

have

holes

in

the

top

of

the

equipment

for

attaching

lift

cables

.

These

lift

holes

are

located

at

the

division

of

each

cubicle

within

a

shipping

group

.

The

max

-

imum

shipping

group

is

five

cubicles

excluding

the

transi

-

tion

box

to

liquid

transformers

if

involved

(

this

is

not

con

-

sidered

a

cubicle

)

.

Lift

points

on

the

equipment

are

labeled

and

lift

connections

are

to

be

made

only

at

these

points

.

(

See

Figure

6

.

)

On

outdoor

switchgear

it

will

be

necessary

to

temporarily

remove

the

outdoor

roof

chan

-

nels

(

Figure

10

and

11

)

for

access

to

the

lift

holes

.

Be

sure

to

replace

the

roof

channels

immediately

after

lifting

to

make

the

equipment

weather

resistant

.

The

angle

of

the

lift

cable

relative

to

a

horizontal

plane

must

not

be

less

than

45

°

.

(

See

Figure

6

.

)

Also

note

the

tension

on

each

cableof

afourcable

lift

at

45

°

is

70.7

%

efficient

,

that

is

,

1

/

4

of

the

total

load

divided

by

.

707

will

equal

the

force

in

pounds

on

each

cable

.

Lesser

angles

become

more

severe

and

could

damage

the

switchgear

.

Make

certain

the

crane

used

is

of

adequate

height

and

capacity

.

If

equipment

is

shipped

without

breakers

being

installed

in

their

compartments

a

safe

estimate

of

requi

red

crane

capacity

would

be

3000

lbs

.

multiplied

by

the

number

of

cubicles

to

be

lifted

.

If

breakers

are

installed

for

shipment

,

use

4000

lbs

.

multiplied

by

the

number

of

cubi

-

cles

to

be

lifted

.

USE

OF

ROLLERS

&

JACKS

Figure

6

.

Lifting

Switchgear

Indoor

and

Outdoor

Moving

switchgear

in

an

obstructed

area

where

a

crane

cannot

be

employed

can

be

accomplished

by

the

use

of

rollers

,

however

,

this

must

be

done

before

the

wooden

shipping

skids

are

removed

.

If

pipes

are

used

as

rollers

they

should

be

of

sufficient

diameter

that

they

will

roll

with

ease

without

digging

into

skids

.

In

placing

rollers

under

skids

or

removing

them

it

will

be

necessary

to

lift

switch

-

gear

shipping

group

by

either

jacks

or

fork

lift

truck

.

If

fork

lift

truck

is

used

it

must

be

used

with

utmost

caution

to

avoid

possible

damage

to

switchgear

,

and

under

no

cir

-

cumstances

are

the

points

of

lift

contact

to

be

other

than

the

following

:

indoor

switchgear

,

lift

only

on

the

jacking

angle

provided

near

bottom

at

each

end

of

the

shipping

group

.

On

outdoor

switchgear

,

lift

only

at

points

indicated

in

Figure

7

.

At

these

points

on

outdoor

equipment

there

is

a

rigid

support

base

suitable

for

jacking

.

f

Courtesy of NationalSwitchgear.com

TJ

1

»

<

l

#

1

STORAGE

Page

8

ble

oxidation

.

Do

not

lubricate

slide

rails

,

or

aluminum

hinge

gear

on

shutter

!

INDOOR

SWITCHGEAR

When

switchgear

is

not

to

be

erected

immediately

,

it

•

should

be

uncrated

and

inspected

for

damage

within

fif

-

teen

days

of

receipt

and

stored

in

a

clean

,

dry

location

.

Indoor

cubicles

are

neither

weather

resistant

nor

drip

re

-

sistant

;

therefore

,

they

should

be

stored

indoors

.

If

they

must

be

stored

outdoors

,

or

if

they

are

to

be

kept

in

a

humid

,

unheated

area

,

provide

adequate

covering

and

place

a

heat

source

of

approximately

500

watts

output

within

each

cubicle

to

prevent

condensation

.

Space

heat

-

ers

are

not

standard

equipment

on

indoor

switchgear

.

If

storage

is

for

an

extensive

period

of

time

lubricate

moving

parts

such

as

hinges

,

shutters

,

etc

.

to

protect

from

possi

-

OUTDOOR

SWITCHGEAR

When

storing

outdoor

switchgear

in

an

area

exposed

to

weather

or

humid

conditions

,

the

space

heaters

provided

must

be

energized

.

Access

to

heater

circuit

is

gained

through

rear

doors

.

See

wiring

diagram

for

terminal

identi

-

fication

.

If

storage

is

for

an

extensive

period

of

time

lubri

-

cate

moving

parts

such

as

hinges

,

shutters

(

but

not

the

shutter

hinge

gears

)

and

other

moving

parts

.

Do

not

lubri

-

cate

slide

rails

,

or

aluminum

hinge

gear

on

shutters

!

t

>

\

\

j

I

Courtesy of NationalSwitchgear.com

INSTALLATION

Page

9

installation

instruction

drawing

,

panel

arrangement

and

panel

arrangement

bill

of

material

,

nameplate

engraving

list

and

accessories

drawing

.

In

reading

this

instruction

book

special

attention

should

be

given

to

"

Foundation

”

already

covered

on

Pages

3

and

4

.

Check

the

foundation

whichatthistimeshould

be

complete

.

It

must

conform

to

the

requirements

described

in

this

book

and

the

general

arrangement

drawing

.

INTRODUCTION

Prior

to

installation

of

switchgear

read

this

instruction

book

and

drawings

mailed

at

an

earlier

date

,

such

as

general

arrangement

,

three

line

diagram

,

schematic

dia

-

gram

,

master

wiring

diagram

,

cubicle

wiring

diagram

,

S

«

e

Fig

.

6

for

Locating

Lifting

Cablet

Space

Available

In

Top

or

Bottom

of

Unit

*

For

Customers

Primary

and

Secondary

Cables

.

See

Instruction

Book

.

Customer

to

Oritt

Top

Plate

to

Suit

1.2

"

(

30.5

mm

)

Die

.

Lifting

Hole

*

TO

0

"

{

254

mm

)

25.94

(

651

9

mm

)

Ho

*

i

1

10.0

(

254

mm

|

Ref

.

>

96

2

"

(

2443

mm

)

Overall

—

W

y

vent

12.0

"

(

305

mm

)

Rear

Eat

i

26.0

’

MJ

;

'

(

370

mm

)

28.0

"

15.1

'

15.1

"

’

(

660.4

mm

)

e

”

(

355.6

mm

)

(

M

0.4

mm

)

14.0

"

(

363.5

mm

)

14

.

P

”

i

(

363.5

mm

)

,

.

14

,

y

,

12

'

(

30

5

mm

)

Rear

Door

:

1

14.0

'

53

(

355

6

mm

)

(

355

65

mm

)

(

355

-

6

mm

)

i

(

355.6

mm

)

J

-

Hinged

Rear

If

"

Dpor

(

Option

)

/

1 2

"

(

30.5

mm

)

Rear

Door

f

W A

»

*

1

60.0

'

(

1524

mm

)

Untl

Depth

Standard

23

5

'

30

-

0

'

(

762

mm

)

w

/

12

(

304.6

mm

)

Exttn

.

26

.

Q

'

(

660.4

mm

)

w

/

8

"

(

203

2

mm

)

Eaten

.

14

0

'

(

457

2

mm

)

w

/

0

Eaten

.

Rear

/

*

\

(

597

mm

)

Hot

si

Eaten

Exien

.

(

Opilon

)

r

T T

\

.

16.0

'

(

457

mm

)

I

J

102.0

'

(

2561

mm

)

Top

of

Holst

r

,

•

0

0

"

(

1524

mm

)

Standard

Unit

Depth

TK

I

o

S

*

c

Wir

.

O

Sac

-

oo

o

With

Breaker

in

Bo

Horn

Position

Cable

Space

Is

Obstructed

Here

Wir

.

Throat

I

I

i

Loc

.

Loc

.

I

i

7

J

.

2

"

(

IBS

9

mm

)

c

c

£

33.66

'

(

660.5

mm

)

3

=

J

D

i

4.8

~

42

"

(

1067

mm

)

V

MJn

—

ft

.

Space

Recommended

With

30

"

(

762

mm

)

Artie

Recom

—

»

Side

6

Rear

O

'

OJ

(

122

mm

)

12

"

34.64

(

865

mm

)

40.9

f

(

1039

mm

)

b

-

J

40.9

"

13.94

'

13

94

"

13.94

"

13.94

'

Rear

nr

(

1038.6

mm

)

"

*

j

Extension

<

354

mm

)

I

(

»

4

mm

)

(

354

mm

)

(

354

mm

)

f

I

i

I

t

Floor

t

J

.

I

'

“

4

J

I

I

Une

Front

Location

oi

Holes

In

Bottom

of

Units

for

Anchor

Bolls

—

See

Sotting

Arrangement

9.94

'

{

252.5

mm

)

9.94

"

(

252.5

mm

)

3

0

'

U

Customer

Conduit

1.5

'

1

Maximum

Above

Floor

J

1

A

(

76.2

mm

)

33

88

'

3.0

"

Hinged

Panels

(

880.5

mm

)

(

76.2

mm

)

(

139.7

mm

)

Side

View

w

/

Hotil

4

Anchor

Bolting

Floor

Plan

Figure

9

.

Typical

Indoor

Floor

Plan

and

Side

View

Courtesy of NationalSwitchgear.com

INSTALLATION

Page

10

INSTALLING

SHIPPING

SECTIONS

As

previously

covered

under

“

Foundation

,

”

mounting

sur

-

faces

,

sills

,

slab

,

piers

or

pilings

must

be

level

and

in

the

same

plane

.

Also

,

conduits

must

be

properly

located

and

perpendicular

to

such

a

degree

that

they

will

clear

the

floor

plate

cutouts

.

Mounting

surfaces

must

be

swept

free

of

stones

,

chips

and

other

debris

which

might

impede

rollers

or

leveling

of

switchgear

.

The

proper

method

of

installation

depends

on

whetherthe

switchgear

has

been

shipped

as

one

complete

group

,

or

in

two

or

more

shipping

sections

.

The

general

arrangement

drawing

will

indicate

the

shipping

sections

,

cubicle

num

-

bers

and

their

location

within

the

switchgear

line

-

up

.

Sec

-

tions

are

assembled

and

wired

in

accordance

with

the

arrangement

as

in

final

installation

.

!

11

?

.

315

"

(

2851

mm

)

Overall

See

Figure

6

for

Locating

Lifting

Cablet

$

0

*

e

»

Available

In

Toe

04

Bottom

ol

Unit

*

lor

Cuitom

*

Primary

and

1

aeon

dory

Cable

-

$

o

*

Instruction

Book

.

Cutlomor

lo

Drill

floor

Plate

or

Hoof

lo

lull

Shippin

?

Group

$

0.12

'

'

—

(

1427

mm

)

26.0

'

Shippfng

Group

sur

(

1324

am

)

-

220

"

11

-

0

"

(

558.8

mm

)

1

23

Diam

*

l

»

f

Lifting

Holes

in

floof

ol

Flange

Each

Unit

Accessible

With

Channel

Removed

Removable

Roof

Channel

v

I

11.12

“

(

282

mm

)

u

.

ir

(

3

$

4

mm

’

|

m m

)

11.0

'

6.0

'

9

(

203

mm

)

Aisle

Eilenelon

,

9.44

-

•

Cable

Spec

*

Top

(

240

mm

)

10.00

V

-

Cable

Spec

*

Bottom

(

2

S

4

nun

)

13.44

”

(

341

mm

)

14.00

"

9.44

"

_

1194

“

(

3032.8

mm

)

Overall

V

50

'

(

1270

mm

)

(

240

mm

)

10.0

P

"

(

254

mm

)

4

I

22

'

Holst

X

{

558.8

mm

)

2.0

"

*

—

>

(

Ui

mm

)

+

L

I

(

T

V

»

nt

^

f

T

Liquid

Filled

Transformer

Throat

J

Vant

Vent

14.8

"

(

1378

mm

)

31

(

78.2

mm

)

‘

Overhang

t A

L

A

N

j

/

\

L

JAL

j

/

f

\

/

'

'

7

r

*

.

7

t

Secondary

Wiring

Location

I s

3.0

'

A

14.0

{

76

2

mm

)

£

*

cc

*

a

V

0

E

N

C

as

(

355.8

mm

)

\

30.0

"

(

762

mm

)

Aisle

Recomm

,

Side

$

Rear

113.38

"

(

2880

mm

)

Unit

Depth

\

\

/

3

tf

J

T

42.06

'

(

1008

mm

)

Able

'

A

59.84

"

(

1522

mm

)

Inner

Unit

t

3.0

-

7

2.0

-

?

2

\

118.4

-

9.0

/

(

228.6

mm

)

110

-

0

"

(

2784

mm

)

(

78.2

mm

)

1.5

"

(

38

mm

)

(

50.8

mm

|

-

re

(

3033

mm

)

3.0

”

\

I

7

i

Over

(

78.2

mm

)

ee

st

st

Hoof

c

Captive

Temper

-

reslelenl

Hardware

on

Doors

I

A

With

Breaker

In

Bottom

Position

Cable

Space

Is

Obstructed

Mere

Front

Inner

Unit

See

Anchor

Bolling

Detail

Papa

4

c

c

c

D

=

3

3

Hang

Door

Handle

Ol

Oi

Ol

"

i

-

78.78

-

{

1850

mm

)

*

{

122

mm

)

i

i

.

25

-

Front

3.0

”

A

3

33

88

'

(

860.5

mm

)

i

l

(

6

35

mm

)

(

76

J

2

mm

)

Hinged

Inner

Panels

*

Floor

I

J

-

Line

.

75

'

.

75

"

78.81

“

(

2027

mm

)

1

(

19

mm

)

*

{

19

«

m

)

Suggested

Location

tor

Customer

*

Anchor

Boris

.

See

Bolting

Arrangement

and

Mote

.

II

Required

,

Additional

Boris

Other

Than

Location

Shown

Must

Be

Located

on

Unit

1.31

'

Base

11.0

'

*

r

w

Front

(

13.3

mm

)

i

(

279.4

mm

)

t

^

^

\

(

1024

mm

)

le

—

(

102

mm

)

V

Hinged

Door

Each

Unh

8.0

"

<

152.4

mm

)

Besa

f

Side

Section

With

Outdoor

Anchor

Bolting

J

A

J

"

s

"

I

4

“

Customer

ConduM

7

5

“

Maximum

Above

Floor

Line

(

102

mm

)

(

102

mm

)

Figure

10

.

Typical

Outdoor

Floor

Plan

h

*

Courtesy of NationalSwitchgear.com

!

INSTALLATION

Page

11

is

in

firm

contact

with

the

mounting

surface

.

In

the

absence

of

contact

,

shims

must

be

added

adjacent

to

the

anchor

bolt

holes

.

These

shims

will

prevent

distortion

of

the

section

when

anchor

bolts

are

drawn

tight

.

Shims

should

be

approximately

three

inches

square

with

a

thickness

determined

by

the

existing

requirement

or

attained

by

stacking

.

Tighten

anchoring

hardware

,

and

check

for

level

.

If

line

-

up

consists

of

more

than

one

ship

-

ping

section

,

the

next

section

should

be

moved

into

place

being

certain

that

front

panels

are

in

line

with

those

of

the

first

section

.

Repeat

the

same

plumbing

as

done

on

the

first

section

;

insert

hardware

for

bolting

the

two

sections

together

,

but

do

not

tighten

.

Repeat

the

leveling

,

shim

-

ming

and

tightening

of

anchoring

hardware

as

on

the

first

section

.

Tighten

hardware

holding

the

two

shipping

sec

-

tions

together

.

Repeat

this

procedure

for

each

shipping

section

in

the

line

-

up

.

SETTING

SHIPPING

SECTIONS

After

checking

each

shipping

section

for

its

proper

loca

-

tion

sequence

,

as

shown

on

the

general

arrangement

drawing

,

move

the

first

section

of

the

switchgear

to

its

location

.

When

a

transformer

is

part

of

the

installation

and

in

its

correct

location

,

the

switchgear

is

positioned

next

to

the

transformer

as

shown

in

Figure

16

.

The

shipping

sec

-

tion

should

be

kept

high

enough

to

just

clear

any

conduits

and

then

moved

toward

the

transformer

to

the

dimensions

shown

on

the

general

arrangement

drawing

.

At

the

same

time

align

switchgear

with

the

anchor

bolt

locations

and

conduit

locations

below

.

With

all

points

aligned

and

with

conduit

caps

and

floor

plate

covers

removed

,

carefully

lower

the

section

to

its

permanent

location

.

It

is

important

that

the

first

section

be

accurately

positioned

and

leveled

as

each

successive

section

will

depend

on

the

first

.

PLUMBING

AND

LEVELING

INSTRUCTIONS

LEVELING

OUTDOOR

SWITCHGEAR

As

described

under

“

Foundation

,

"

Pages

3

and

4

of

this

instruction

book

,

the

floor

,

sills

,

piers

,

or

pilings

are

to

be

true

and

in

a

level

plane

,

and

within

the

area

of

the

switch

-

gear

in

the

case

of

a

slab

or

floor

there

are

no

projections

such

as

pebbles

in

the

concrete

protruding

above

this

plane

.

This

being

accomplished

there

should

not

be

any

problem

in

plumbing

or

leveling

the

switchgear

.

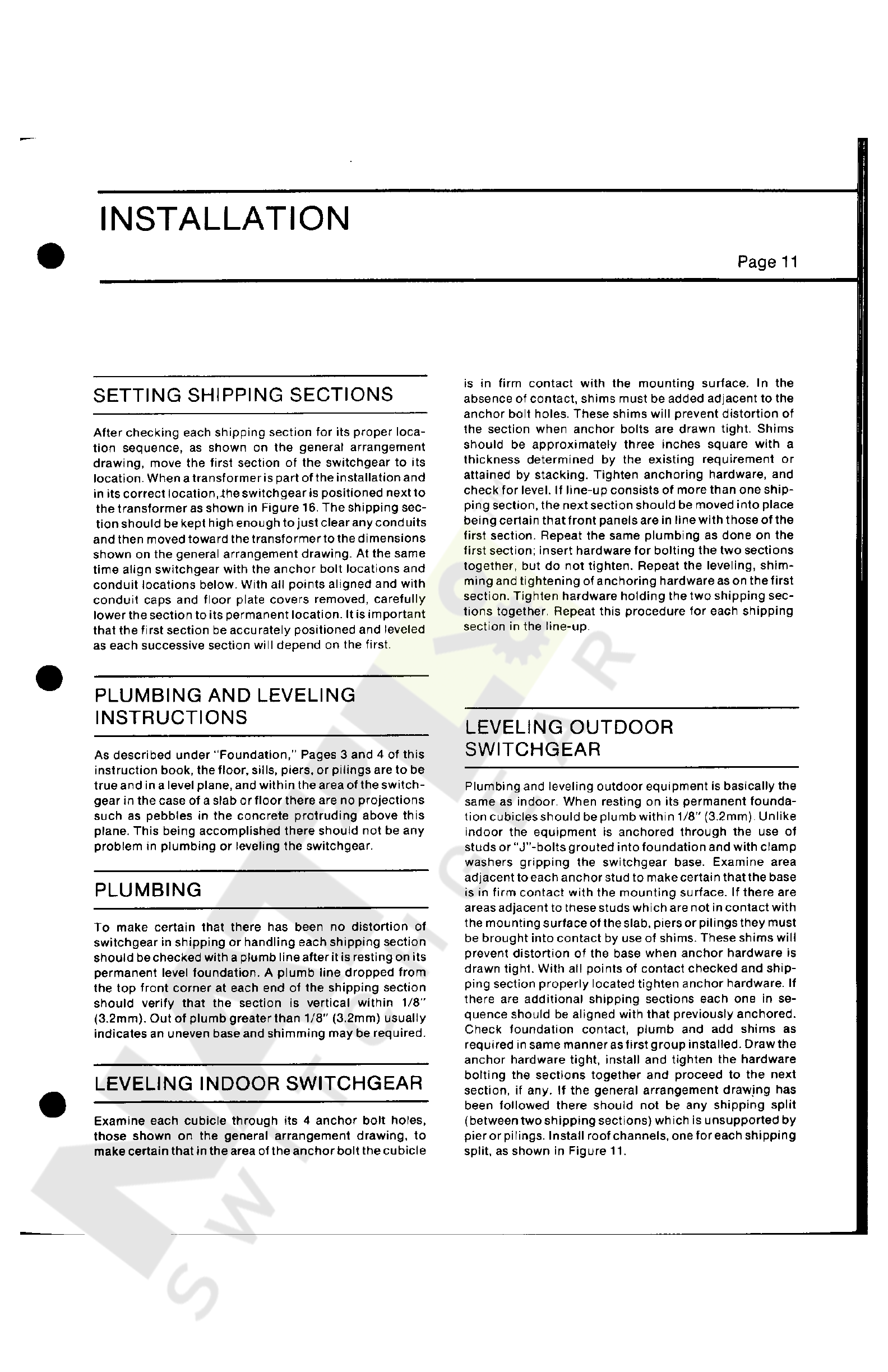

Plumbing

and

leveling

outdoor

equipment

is

basically

the

same

as

indoor

.

When

resting

on

its

permanent

founda

-

tion

cubicles

should

be

plumb

within

1

/

8

"

(

3.2

mm

)

.

Unlike

indoor

the

equipment

is

anchored

through

the

use

of

studs

or

“

J

”

-

bolts

grouted

into

foundation

and

with

clamp

washers

gripping

the

switchgear

base

.

Examine

area

adjacent

to

each

anchor

stud

to

make

certain

that

the

base

is

in

firm

contact

with

the

mounting

surface

.

If

there

are

areas

adjacent

to

these

studs

which

are

not

in

contact

with

the

mounting

surface

of

the

slab

,

piers

or

pilings

they

must

be

brought

into

contact

by

use

of

shims

.

These

shims

will

prevent

distortion

of

the

base

when

anchor

hardware

is

drawn

tight

.

With

all

points

of

contact

checked

and

ship

-

ping

section

properly

located

tighten

anchor

hardware

.

If

there

are

additional

shipping

sections

each

one

in

se

-

quence

should

be

aligned

with

that

previously

anchored

.

Check

foundation

contact

,

plumb

and

add

shims

as

required

in

same

manner

as

first

group

installed

.

Draw

the

anchor

hardware

tight

,

install

and

tighten

the

hardware

bolting

the

sections

together

and

proceed

to

the

next

section

,

if

any

.

If

the

general

arrangement

drawing

has

been

followed

there

should

not

be

any

shipping

split

(

between

twoshipping

sections

)

which

is

unsupported

by

pier

or

pilings

.

Install

roof

channels

,

one

for

each

shipping

split

,

as

shown

in

Figure

11

.

PLUMBING

To

make

certain

that

there

has

been

no

distortion

of

switchgear

in

shipping

or

handling

each

shipping

section

should

be

checked

with

a

plumb

Iine

after

it

is

resting

on

its

permanent

level

foundation

.

A

plumb

line

dropped

from

the

top

front

corner

at

each

end

of

the

shipping

section

should

verify

that

the

section

is

vertical

within

1

/

8

"

(

3.2

mm

)

.

Out

of

plumb

greater

than

1

/

8

"

(

3.2

mm

)

usually

indicates

an

uneven

base

and

shimming

may

be

required

.

LEVELING

INDOOR

SWITCHGEAR

Examine

each

cubicle

through

its

4

anchor

bolt

holes

,

those

shown

on

the

general

arrangement

drawing

,

to

make

certain

that

in

the

area

of

the

anchor

bolt

the

cubicle

Courtesy of NationalSwitchgear.com

INSTALLATION

Page

12

Stop

Angle

1

Stop

Angle

Track

©

©

.

'

Jt

?

L

CT

'

1

Figure

11

.

Outdoor

Roof

Channels

R

.

H

.

End

Unit

L

.

H

.

End

Unit

INSTALLATION

OF

TRAVELING

CRANE

%

Figure

12

.

Traveling

Crane

DANGER

SAFETY

INSTRUCTIONS

HEAVYWEIGHTS

>

Before

any

work

is

done

within

the

cubicle

compartments

make

certain

primary

circuits

are

de

-

energized

,

tested

,

grounded

,

tagged

or

properly

identified

,

and

released

for

work

in

an

authorized

manner

.

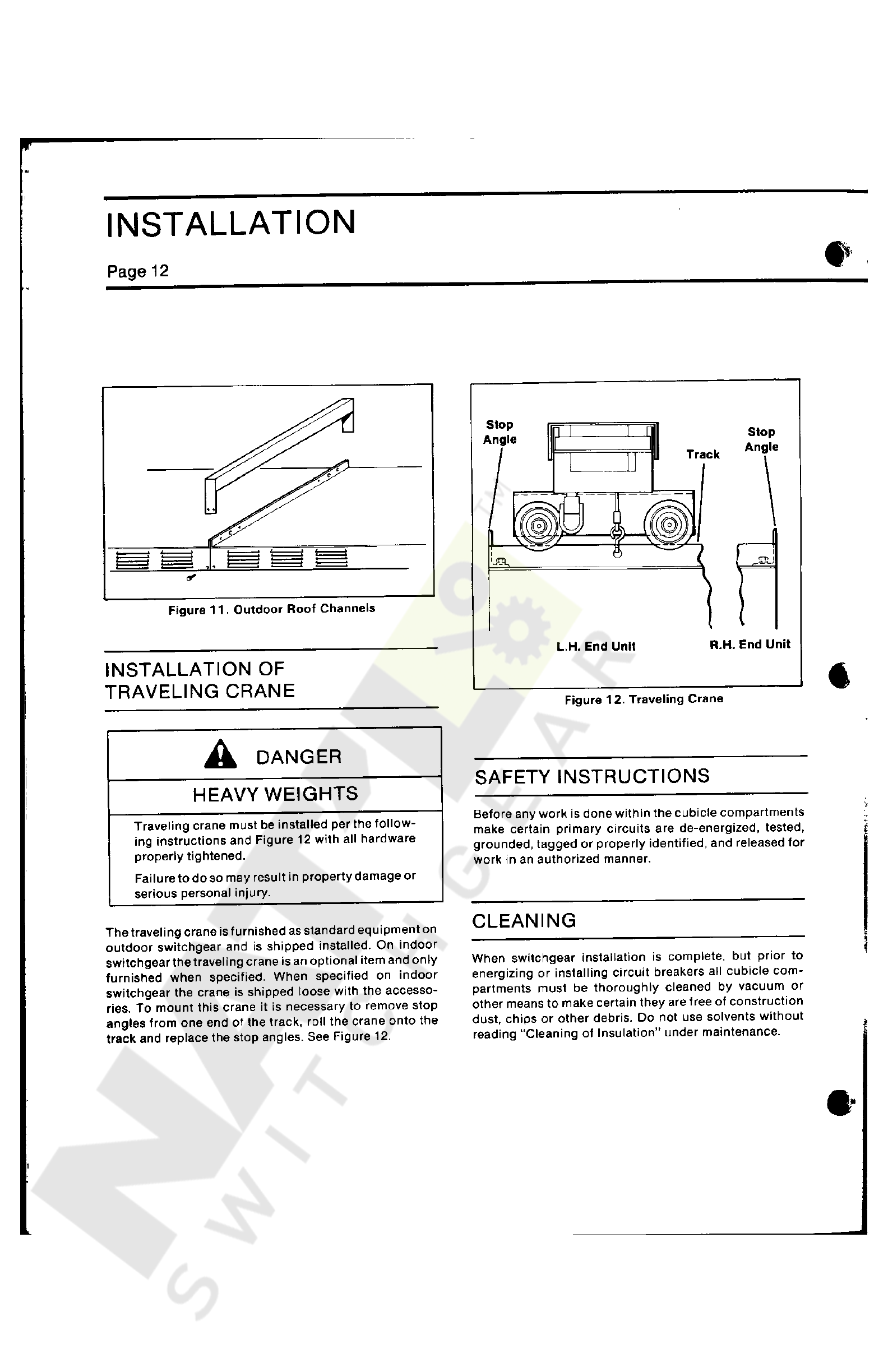

Traveling

crane

must

be

installed

per

the

follow

-

ing

instructions

and

Figure

12

with

all

hardware

properly

tightened

.

Failure

to

do

so

may

result

in

property

damage

or

serious

personal

injury

.

Jf

CLEANING

The

traveling

crane

is

furnished

as

standard

equipment

on

outdoor

switchgear

and

is

shipped

installed

.

On

indoor

switchgearthe

traveling

crane

is

an

optional

item

and

only

furnished

when

specified

.

When

specified

on

indoor

switchgear

the

crane

is

shipped

loose

with

the

accesso

-

ries

.

To

mount

this

crane

it

is

necessary

to

remove

stop

angles

from

one

end

of

the

track

,

roll

the

crane

onto

the

track

and

replace

the

stop

angles

.

See

Figure

12

.

1

When

switchgear

installation

is

complete

,

but

prior

to

energizing

or

installing

circuit

breakers

all

cubicle

com

-

partments

must

be

thoroughly

cleaned

by

vacuum

or

other

means

to

make

certain

they

are

free

of

construction

dust

,

chips

or

other

debris

.

Do

not

use

solvents

without

reading

“

Cleaning

of

Insulation

"

under

maintenance

.

t

Courtesy of NationalSwitchgear.com

ELECTRICAL

CONNECTIONS

Page

13

1

.

All

surfaces

must

be

free

of

dust

,

dirt

,

and

other

for

-

eign

material

.

2

.

Do

not

use

any

abrasive

cleaner

on

plated

contact

surfaces

.

Cleaning

normally

is

not

necessary

and

should

not

be

done

unless

parts

are

badly

tarnished

.

If

cleaning

is

necessary

,

use

a

mild

cleaner

and

thor

-

oughly

rinse

parts

to

remove

all

residue

.

3

.

Assemble

all

joints

with

parts

dry

.

Do

not

use

any

grease

or

oxide

preventing

compounds

even

where

aluminum

buses

are

used

.

Aluminum

buses

and

con

-

nectors

requiring

bolted

connections

are

tin

plated

and

can

be

applied

directly

to

other

tin

plated

alumi

-

num

parts

or

silver

plated

copper

bars

without

the

use

of

an

oxide

preventing

compound

.

4

.

For

method

of

bolting

joints

,

see

Figure

14

,

and

follow

hardware

tightening

instructions

.

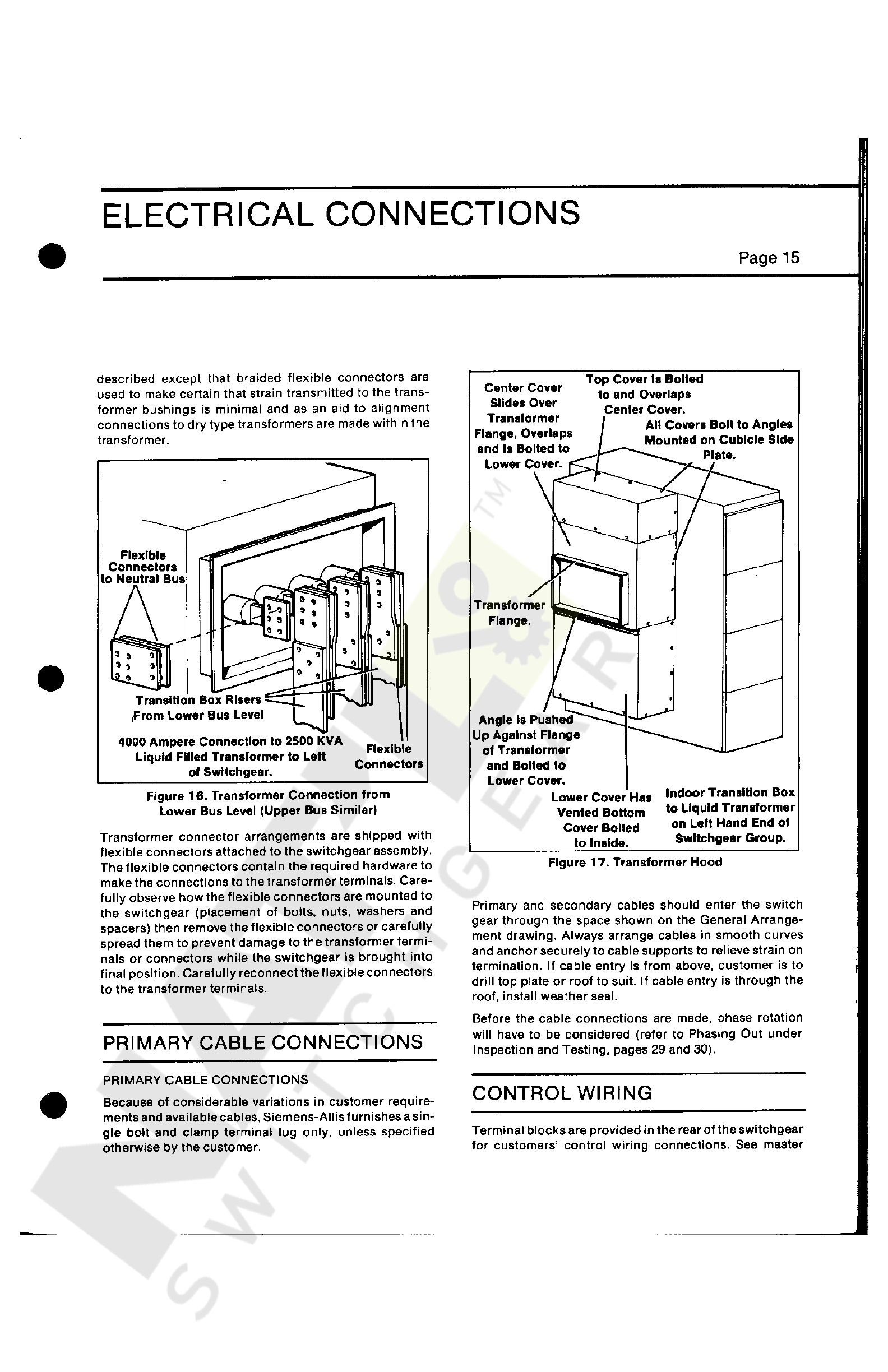

PRIMARY

CONNECTIONS

BUS

BARS

AND

CONNECTORS

Bus

bars

,

risers

and

various

connectors

may

be

of

alumi

-

num

or

copper

as

required

by

the

specification

of

each

order

(

Fig

.

13

)

.

When

the

specification

calls

for

aluminum

all

bus

and

connector

joints

with

exception

of

shipping

splits

,

neutral

bus

,

primary

contacts

and

termination

points

joining

other

equipment

are

of

welded

construc

-

tion

.

Each

weldment

has

been

carefully

designed

to

meet

the

temperature

rise

limitations

as

set

forth

by

ANSI

Standards

,

C

37.20

.

At

shipping

splits

and

termination

points

the

tin

plated

aluminum

bars

have

holes

for

1

/

2

"

hardware

for

coupling

of

splice

plates

or

connectors

to

other

equipment

.

When

the

specifications

require

a

copper

bus

system

all

joints

are

of

bolted

construction

,

and

com

-

pletely

assembled

at

factory

except

for

shipping

split

spli

-

ces

and

termination

points

to

other

equipment

.

Contact

areas

are

silver

plated

and

may

be

coupled

to

tin

plated

aluminum

bars

or

to

other

silver

plated

copper

bars

.

HARDWARE

NOTE

All

bus

joint

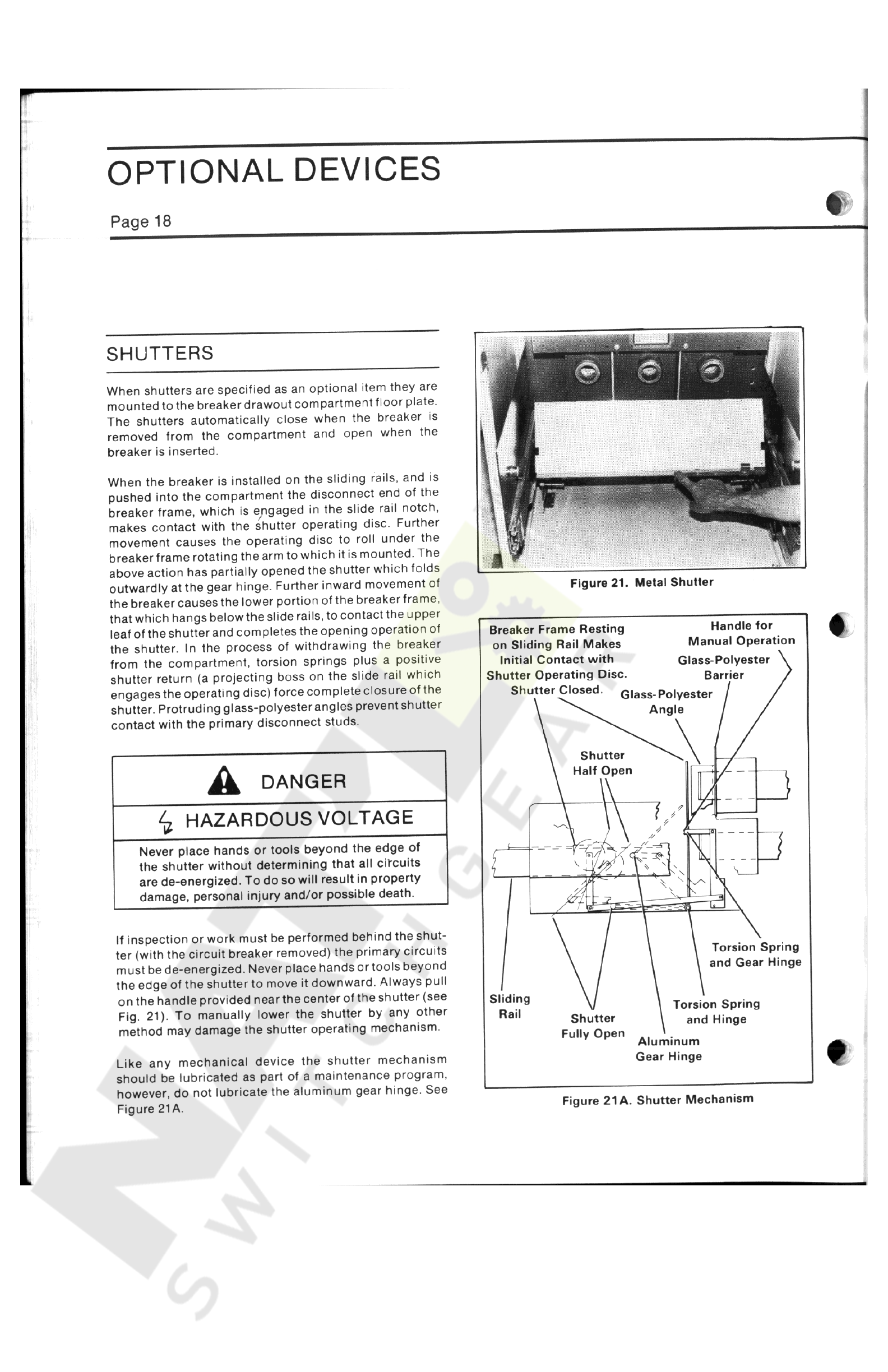

hardware

furnished

is

zinc

plated

,

dichromate

treated

high

strength

steel

.

Cap

screws

are

1

/

2

-

13

SAE

Grade

5

,

nuts

are

SAE

Grade

2

,

hexagon

,

heavy

.

Sizes

and

grades

other

than

above

are

not

to

be

used

.

Tighten

1

/

2

-

13

hardware

to

within

a

torque

range

of

50

-

75

ft

.

lbs

.

(

67.8

to

101.7

N

m

)

.

Should

specifications

call

for

special

hard

-

ware

as

silicon

bronze

or

stainless

steel

consult

factory

for

BOLTED

BUS

JOINTS

When

bus

joints

are

field

assembled

the

following

proce

-

dure

shall

be

followed

for

both

copper

and

aluminum

conductors

:

Figure

13

.

Bus

and

Risers

Courtesy of NationalSwitchgear.com

f

ELECTRICAL

CONNECTIONS

Page

14

proper

torque

range

.

For

copper

arrange

hardware

as

shown

in

Figure

15

with

flat

washer

on

each

side

of

joint

and

lockwasher

between

the

flat

washer

and

the

nut

.

When

aluminum

bus

or

a

mixture

of

aluminum

and

copper

bars

is

involved

the

lockwasher

and

flat

washer

under

the

nut

are

replaced

by

a

single

"

Belleville

”

spring

washer

.

The

concave

side

of

this

spring

washer

is

placed

against

the

bus

or

splice

plate

.

Torque

requirements

are

the

same

as

described

above

.

Do

not

exceed

the

torque

range

given

.

Forces

within

this

range

will

produce

a

low

resis

-

tance

joint

without

cold

flow

of

material

(

Fig

.

15

)

.

Shipping

Split

FRONT

OF

UNIT

Spiice

Bar

Plan

View

A

jflk

Bus

Bar

TOT

2

"

Bolt

Cft

Gnd

.

Bus

Bar

Gnd

.

Splice

Splice

Bar

NOTE

All

hardware

furnished

is

plated

,

high

strength

steel

.

Capscrews

are

1

/

2

-

13

SAE

Grade

5

.

’

Hex

nuts

are

SAE

Grade

2

.

*

Do

not

use

metric

hardware

Bus

Bar

3

w

Bus

Bar

i

3

”

Bolt

CQi

(

Cb

Gnd

.

Bus

Bar

Gnd

.

Splice

Cap

Screw

Flat

Washers

f

Splice

Bar

Bus

Bars

Bus

Bar

Lock

Washer

Silver

Plated

Copper

I

j

^

Gnd

.

Splice

TOJ

4

"

Bolt

Flat

Washer

n

Gnd

.

Bus

Bar

Cap

Screw

Tin

Plated

Aluminum

{

Belleville

Washer

Nut

Bus

Bar

Flat

Washer

Silver

Plated

Copper

Neutral

Bus

Cap

Screw

ns

m

Splice

Bar

Gnd

.

Splice

a

jfl

7

f

I

Tin

Plated

Aluminum

Gnd

.

Bus

Bar

Belleville

Washer

Nut

Bus

Bar

&

Figure

15

.