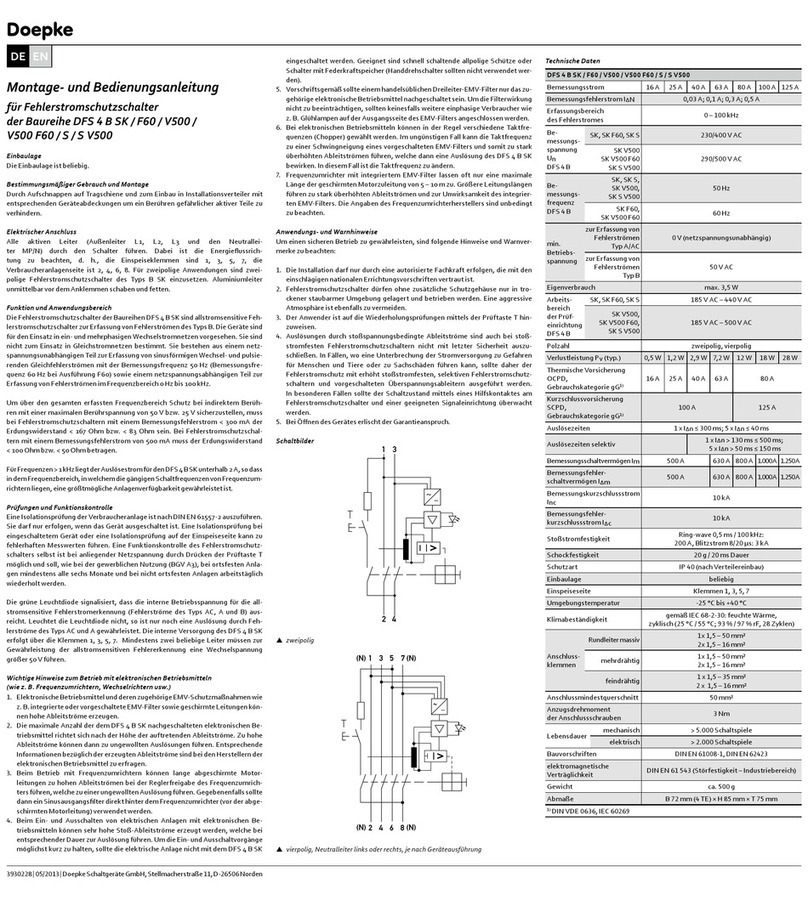

Technical data

DFS 4 A EV

Series

Number of poles

Tripping characteristics

Rated current

of test circuit

Active

additional

device

in sys. on

DC tripping

current

times (DC)

voltage

(DC detection)

Internal con

sumption

Rated surge voltage capacity

Max. rated switching

capacity

Surge current strength

Rated insulation voltage

Rated frequency

Current heat loss per current

path

fuse

gG

Max. number of conductors

Connector

section

solid

stranded

Tightening torque

Installation position optional

Max. operating altitude

Mech. endurance

Electr. endurance

Storage temperature

Ambient

temperature

Standard

Resistance to climatic

changes

Shock resistance

>>

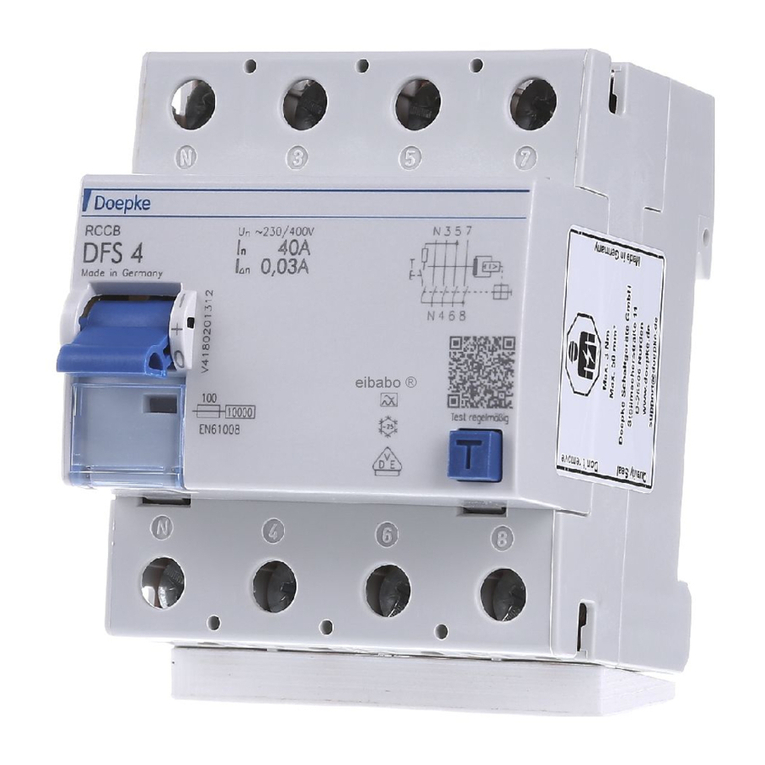

Mounting

distribution installation housing

Thermoplast

Protection class

Sealable Yes

Dimensions

Installation depth

Design requirements

Eective value of tripping threshold

Pulsating

Additional device

Additional device

Warranty

All professionally installed, unaltered devices are covered by warranty during the

statutory guarantee period from the day of purchase by the end user. The warranty

overloading or improper use. In the event of defects in workmanship or material,

which are discovered within the warranty period, the company will provide repair or

replacement free of charge. The warranty will be rendered null and void if the device

is opened without authorisation.

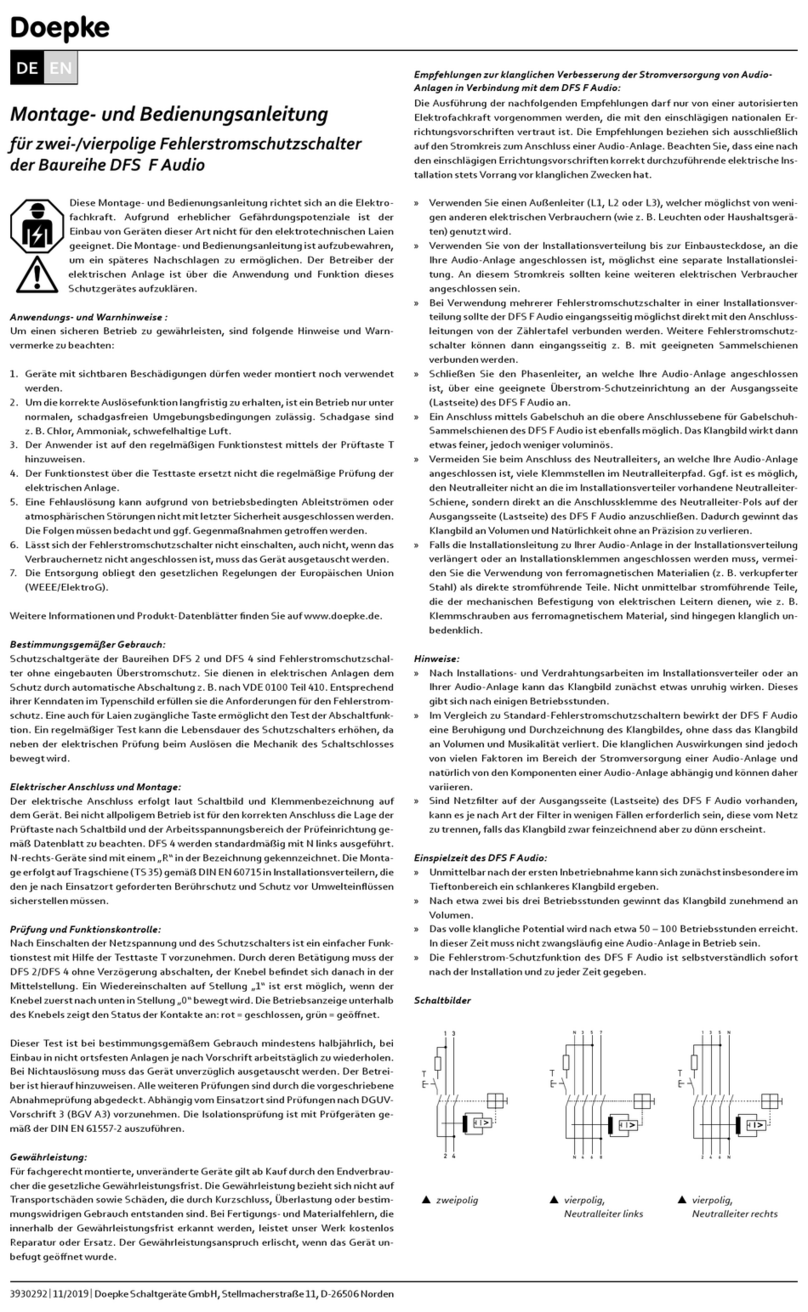

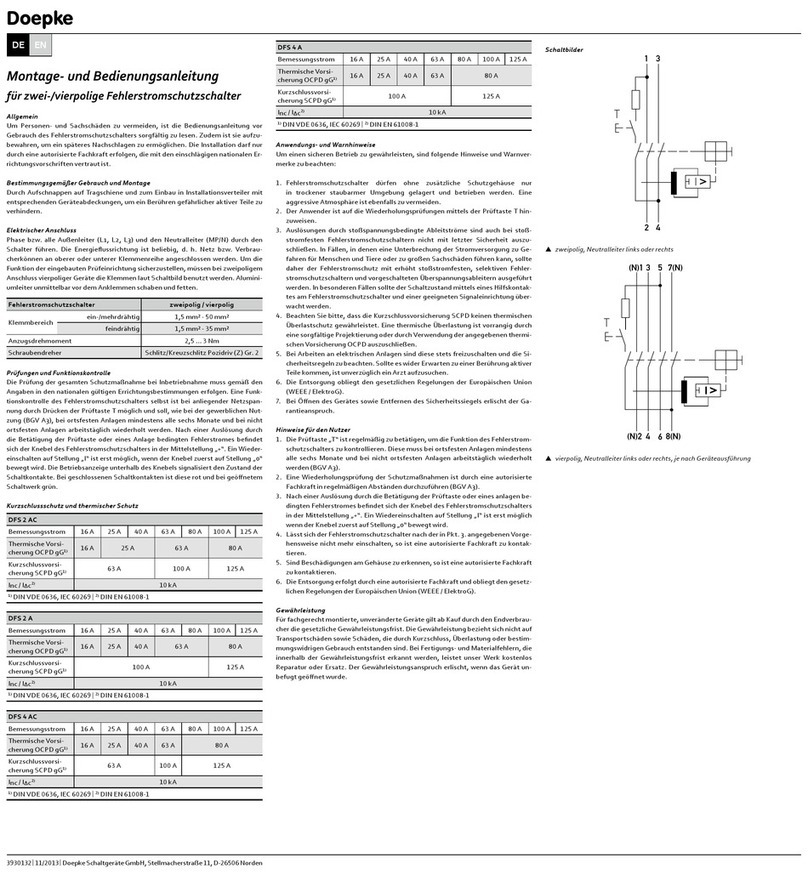

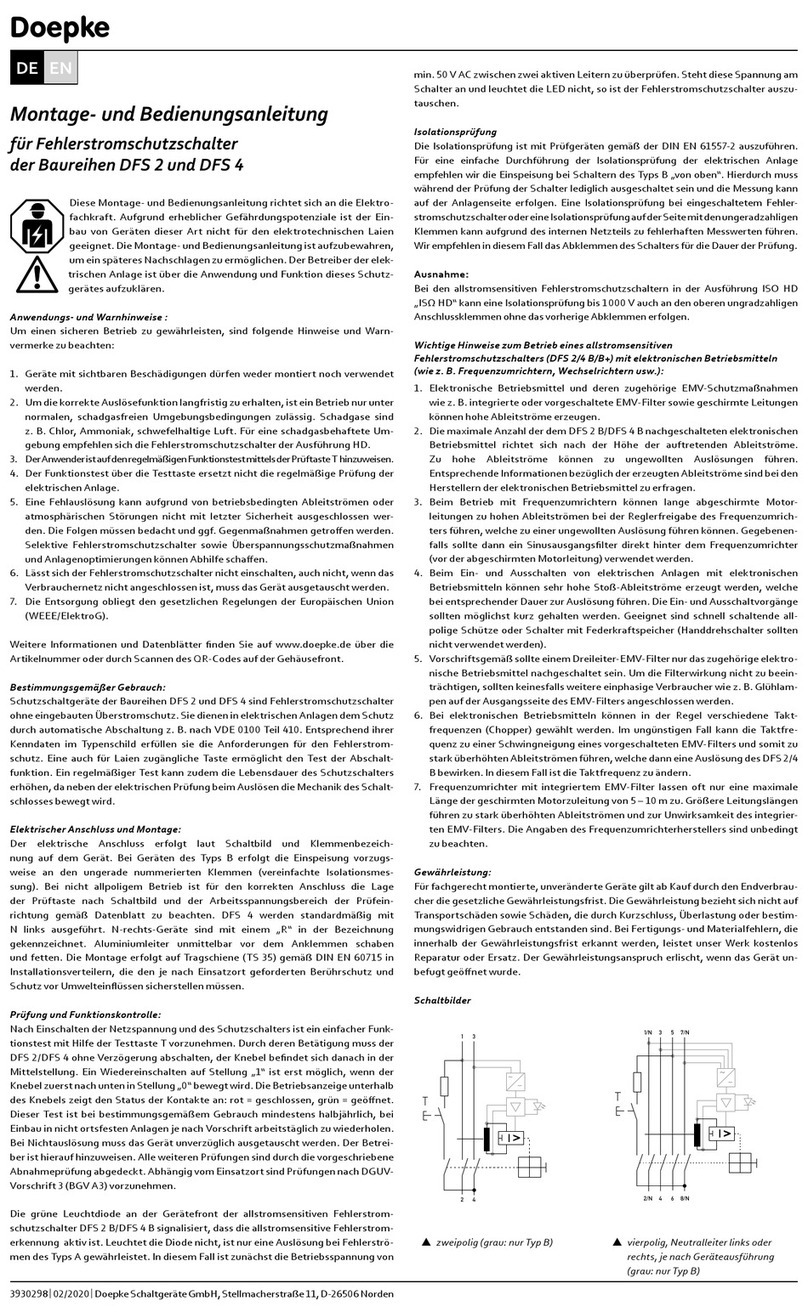

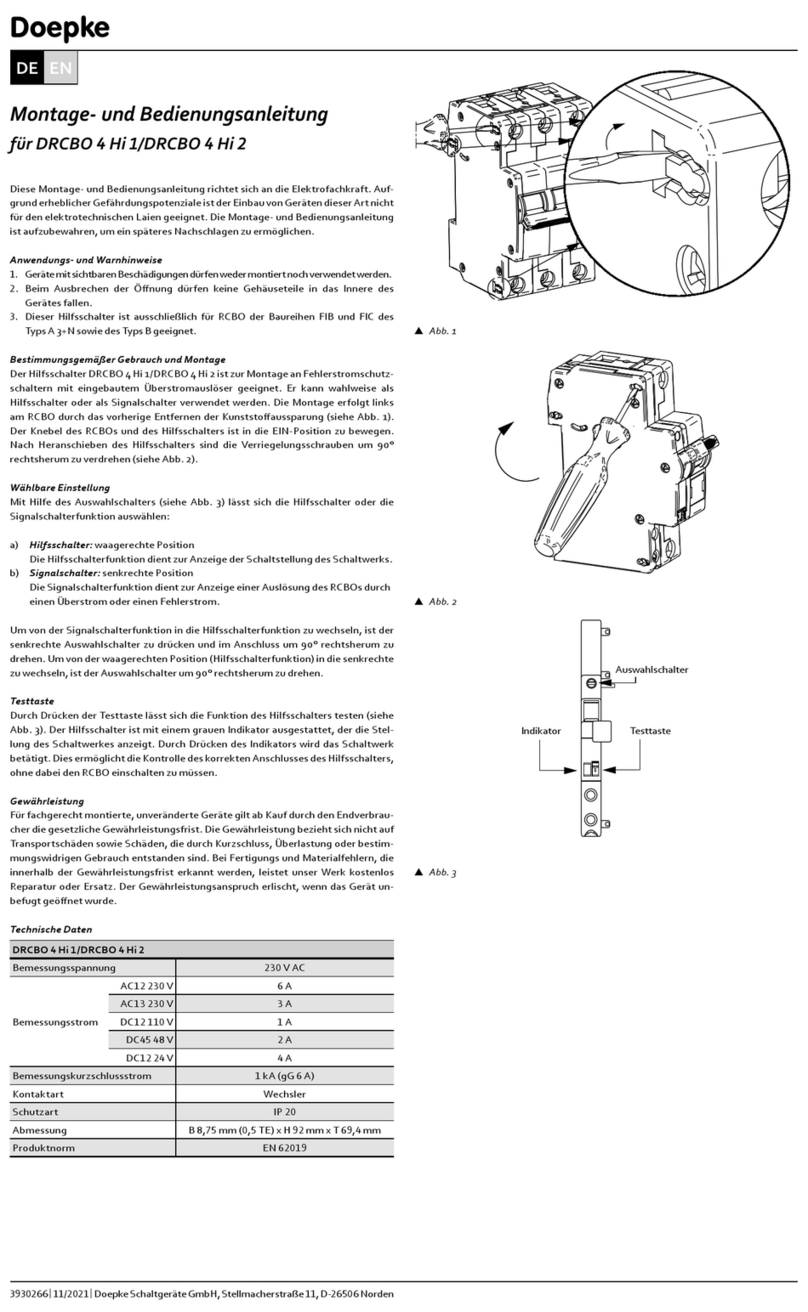

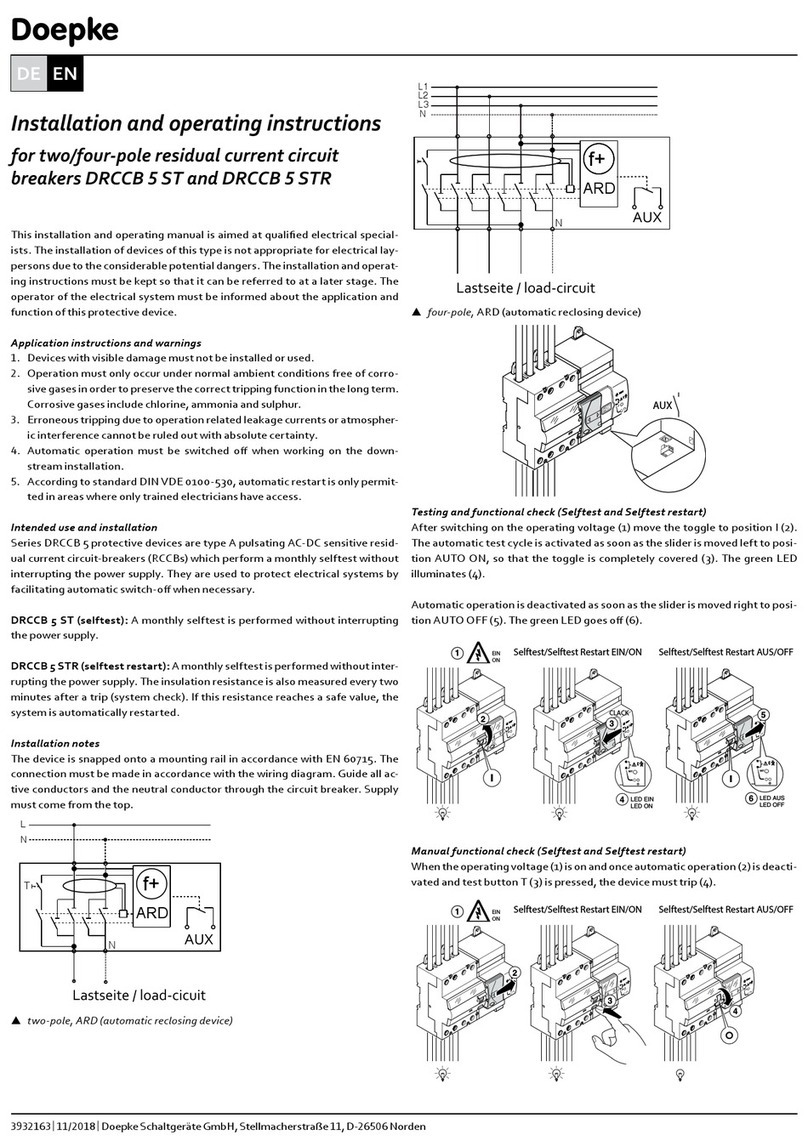

Wiring diagrams

N6

~

Vtwo-pole

~

Vfour-pole, neutral on left or right, depending on device version

Installation and Operating Manual

for two-/four-pole residual current circuit-breakers

in DFS 4 A EV model ranges

Intended use

vices that disconnect the switching contacts of the RCCB when smooth DC residual

currents > 6 mA are detected. They are only suitable as protective devices for the

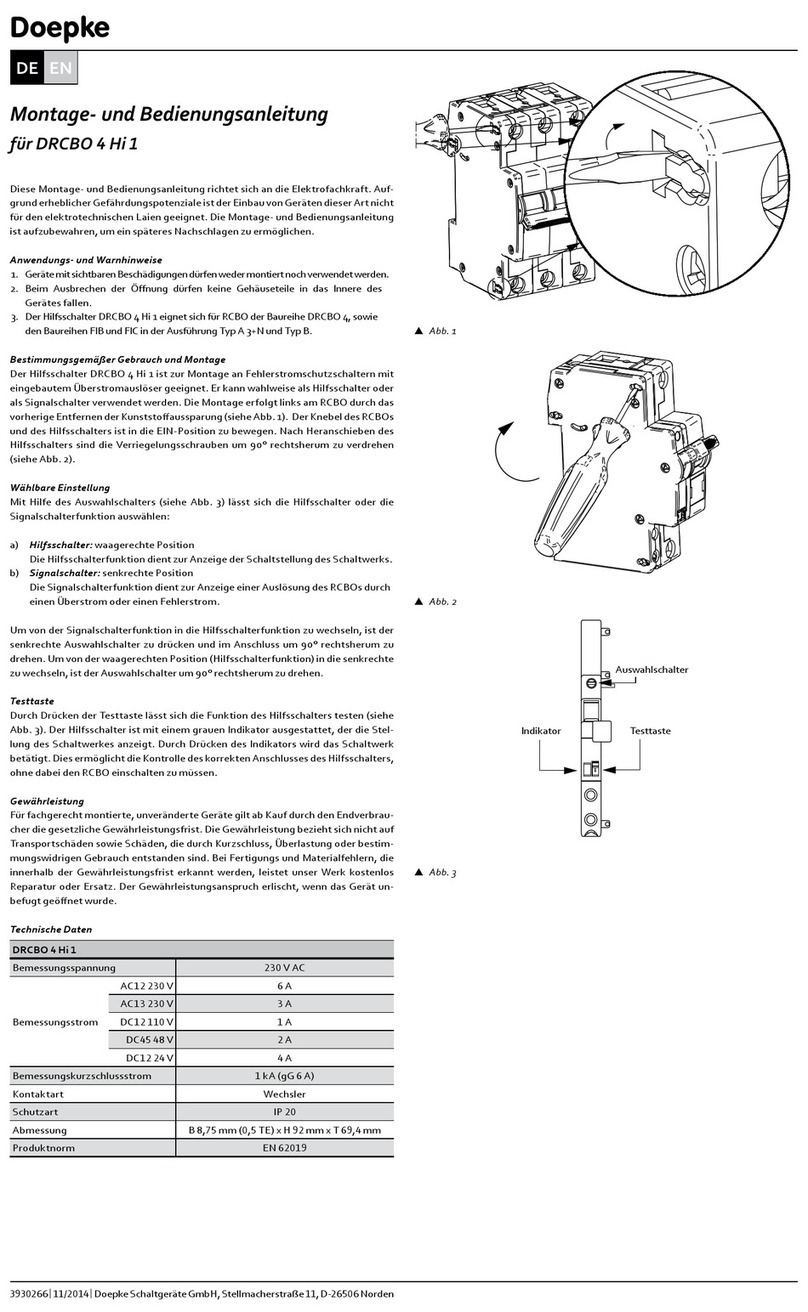

Mounting

Mounting is carried out by snapping onto a mounting rail for installation in distri

bution boards with suitable device covers to prevent contact with dangerous active

parts.

Electrical connection

be used. Scrape and grease aluminium conductors immediately before connection.

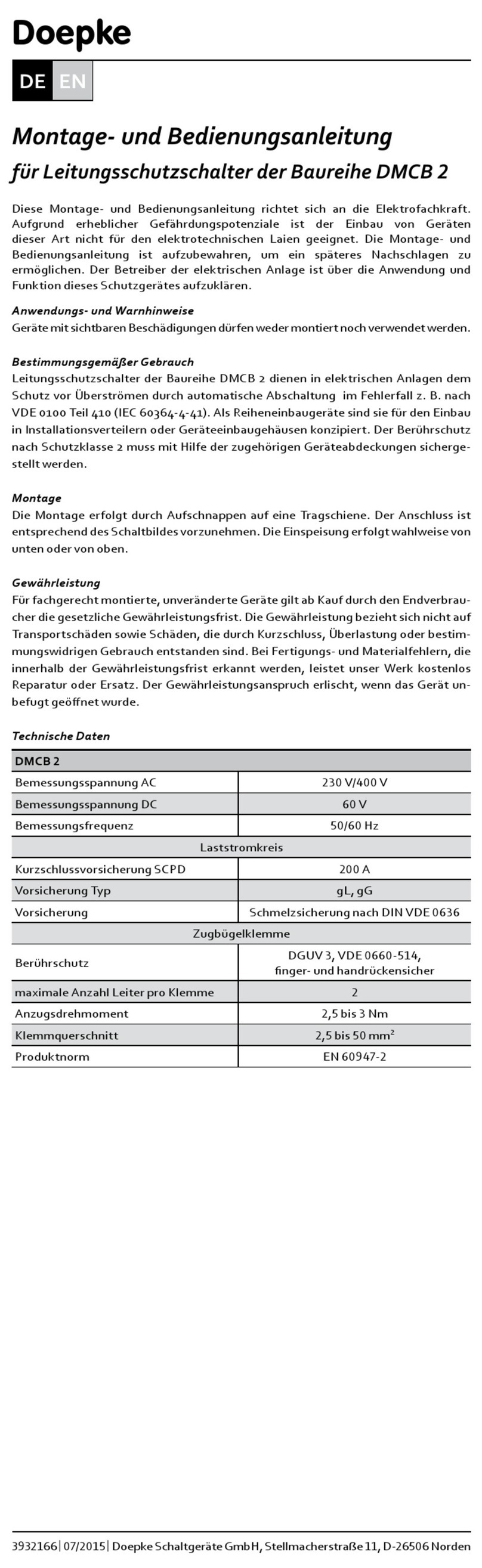

Integrated additional device

The integrated additional device, which depends on the auxiliary voltage, detects

smooth DC residual currents. If these currents exceed 6 mA, the additional device

dicates that the additional device is active. The additional device is supplied via an

must be present at these terminals for the additional device to function properly. If

the LED does not illuminate, then only tripping via type A residual currents is still

guaranteed.

Testing and functional check

An insulation test of the user equipment is to be carried out in accordance with DIN

ing when the device is switched on or insulation testing on the input side may lead

breaker itself is possible with connected mains voltage by pressing the test button T

the case of stationary systems and should be repeated every working day in the case

Application instructions and warnings

The following notes and warnings must be observed in order to ensure safe opera

Installation may only be carried out by an electrician who is familiar with the rel

evant national installation regulations.

atmosphere must also be avoided.

The user must be made aware of repeat testing using the test button T.

thermal overload protection. Thermal overloading must be ruled out as a matter

Trips due to leakage currents caused by surge voltage cannot be completely ruled

out. In cases where an interruption of the power supply may lead to potential

dangers for humans and animals or serious damage to property, residual current

protection should be implemented by means of increased surge current strength,

Important information on tripping with pulsating DC residual currents (type A)

Pulsating DC residual currents also contain a constant part (DC) in addition to

tween a pure smooth DC residual current and the constant (DC), spectral part

of a pulsating DC residual current and thus evaluates these in the same way.

If the additional device is active, pulsating DC residual currents will therefore

Doepke

||

DE EN