7

SECTION 1. INTRODUCTION

The purpose of this manual is to provide

assistance to operation and maintenance

personnel to reduce downtime and obtain

consistent performance.

This service manual contains thorough

installation and operation procedures, steps

for proper maintenance and repair, a trouble

shooting guide for assessing difficulties

promptly, an illustrated parts information

section, and engineering drawings for

fabricating special tools. It should be made

readily available to all those responsible for

the operation or servicing of the reverse

gear.

Performance characteristics and other

details may be obtained from the

engineering department of Capitol Gears,

Inc., St. Paul, Minnesota, U.S.A.

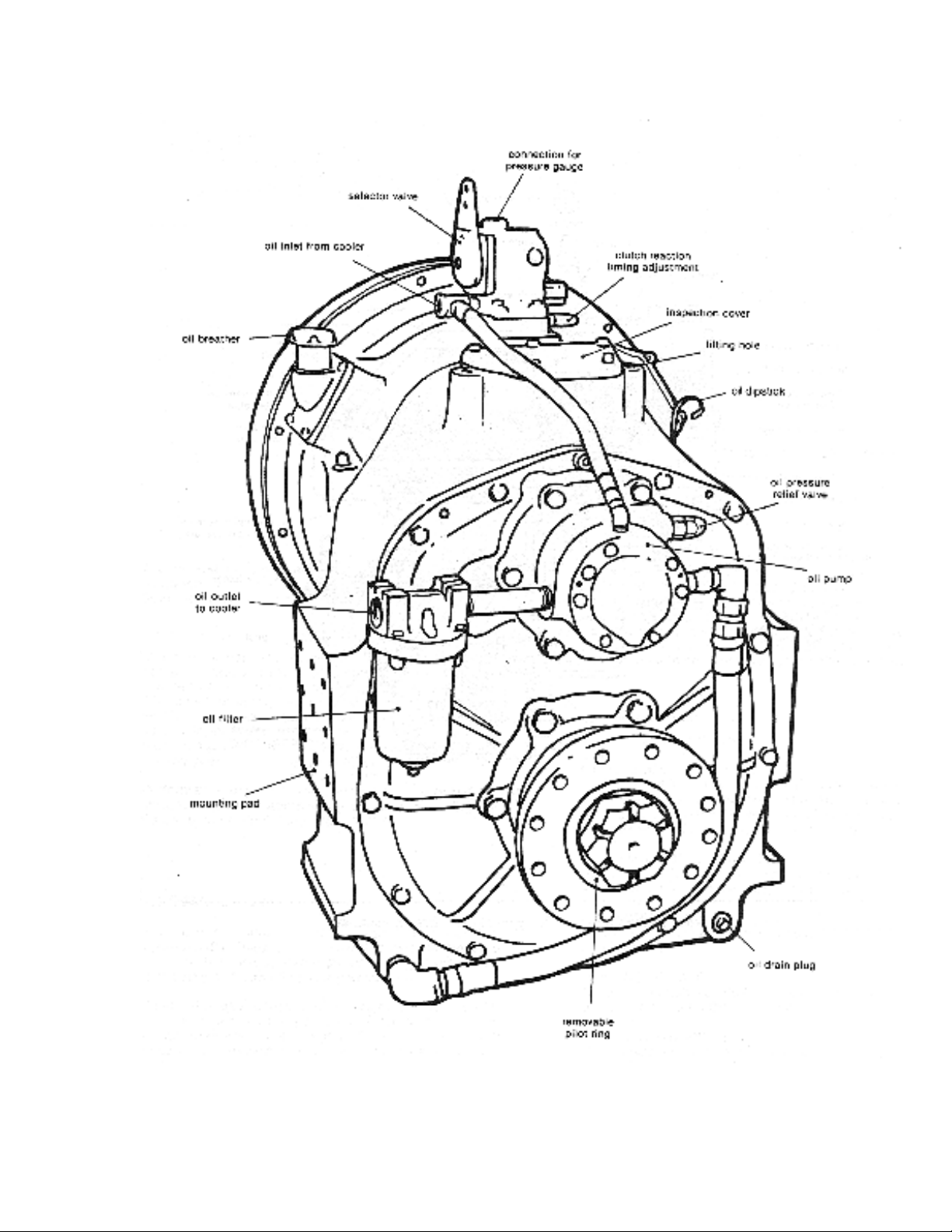

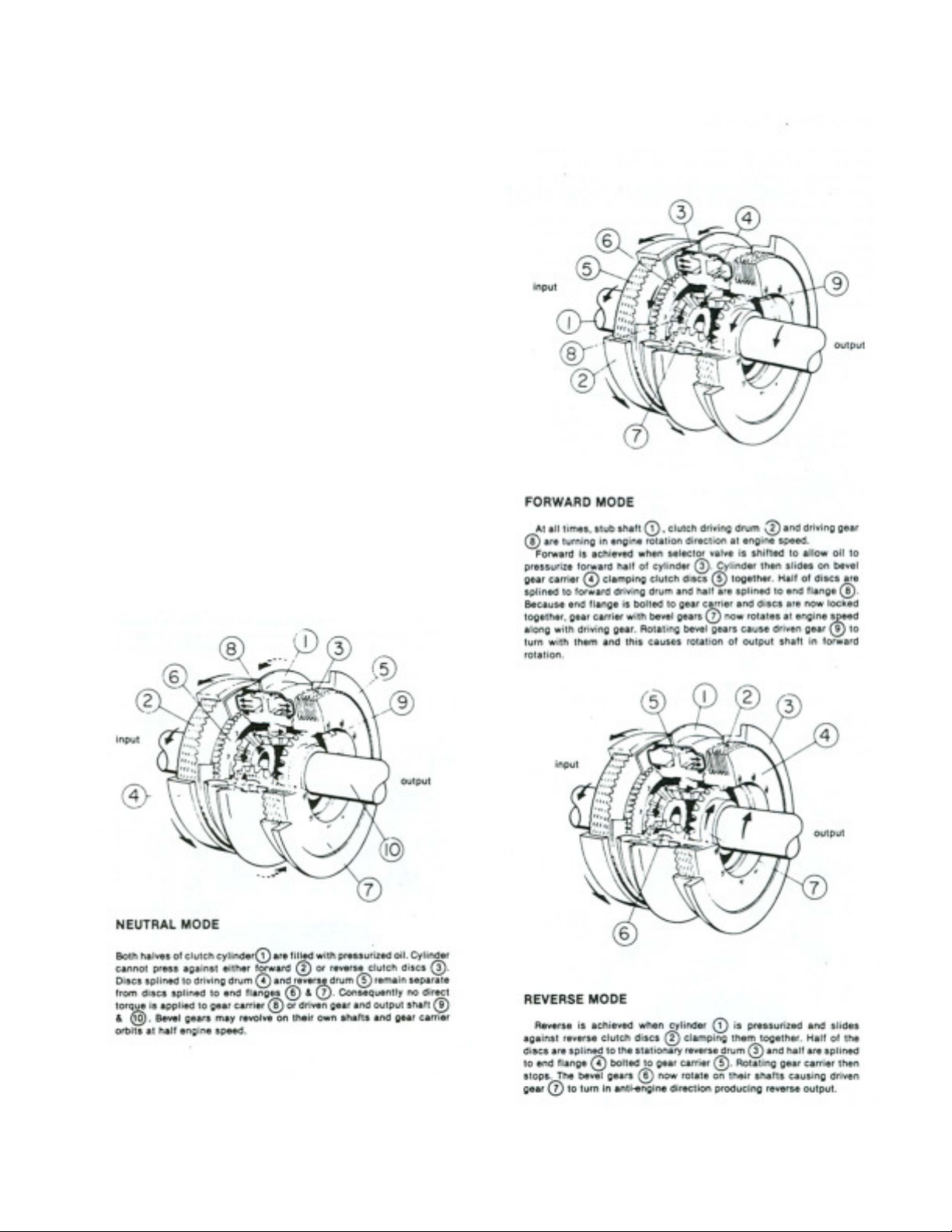

1.1 DESCRIPTION

The Capitol marine transmission is operated

hydraulically. The clutch is activated by high-

pressure oil and the gears, bearings and

clutch discs are lubricated and cooled by

low-pressure oil.

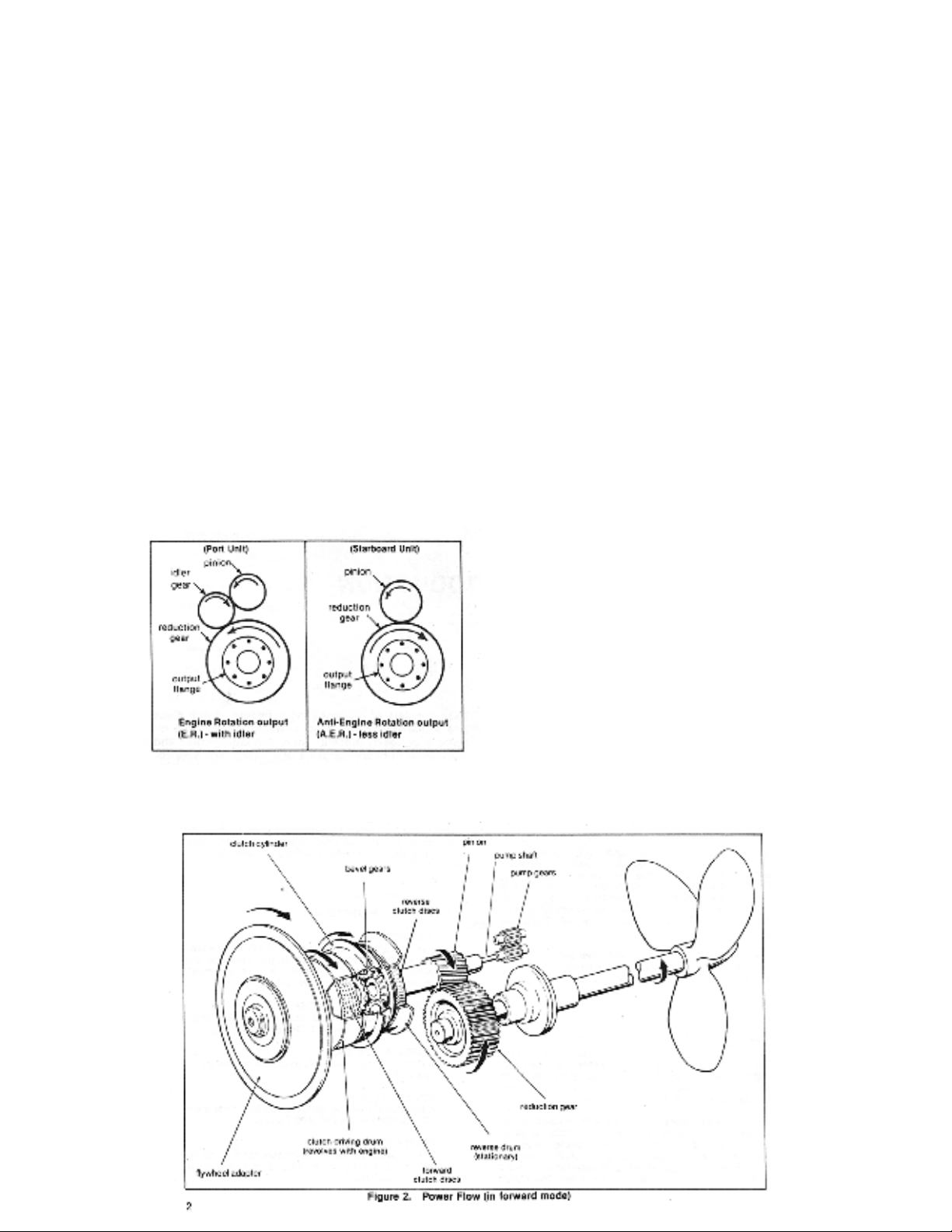

The marine gear consists of six major

groups of parts; adapter group, clutch pack,

oil pump, selector valve, pinion shaft and

reduction gear. The adapter parts vary

according to engine application and include

a flywheel adapter, drive flange, and oil dam

adapter to prevent engine contamination

and driving drum. The clutch pack consists

of reciprocating cylinders, clutch discs and a

planetary bevel gear reversing system. The

oil and pump supplies oil pressure for clutch

engagement and lubrication of bearings,

gears and clutch. The selector valve is used

to obtain forward, neutral or reverse. The

one-piece pinion and shaft drives the output

gear directly or through and intermediary

gear called and idler.

1.2 OPTIONAL EQUIPMENT

OIL COOLER

Various capacity oil coolers for salt or

fresh water are available depending on

engine size and are purchased

optionally. However, oil cooler must be

used with a capitol marine transmission.

HOSE AND FITTING PACKAGE

Kits that include the necessary hose and

fittings are available for use with capitol

oil coolers.

PROP COUPLING KIT

A prop shaft coupling kit is available to

meet most requirements

POWER TAKE-OFF

A one-way clutch may be furnished for

power take-off reduction gears ( HP

PTO series.)

INDEPENDENT MOUNT

For installations where the transmission

is not to be bolted directly to the engine,

a keyed input shaft is available.