TableofContents

Primary SafetyWarnings............................1-3

Pre-AssemblyInstructions................................3

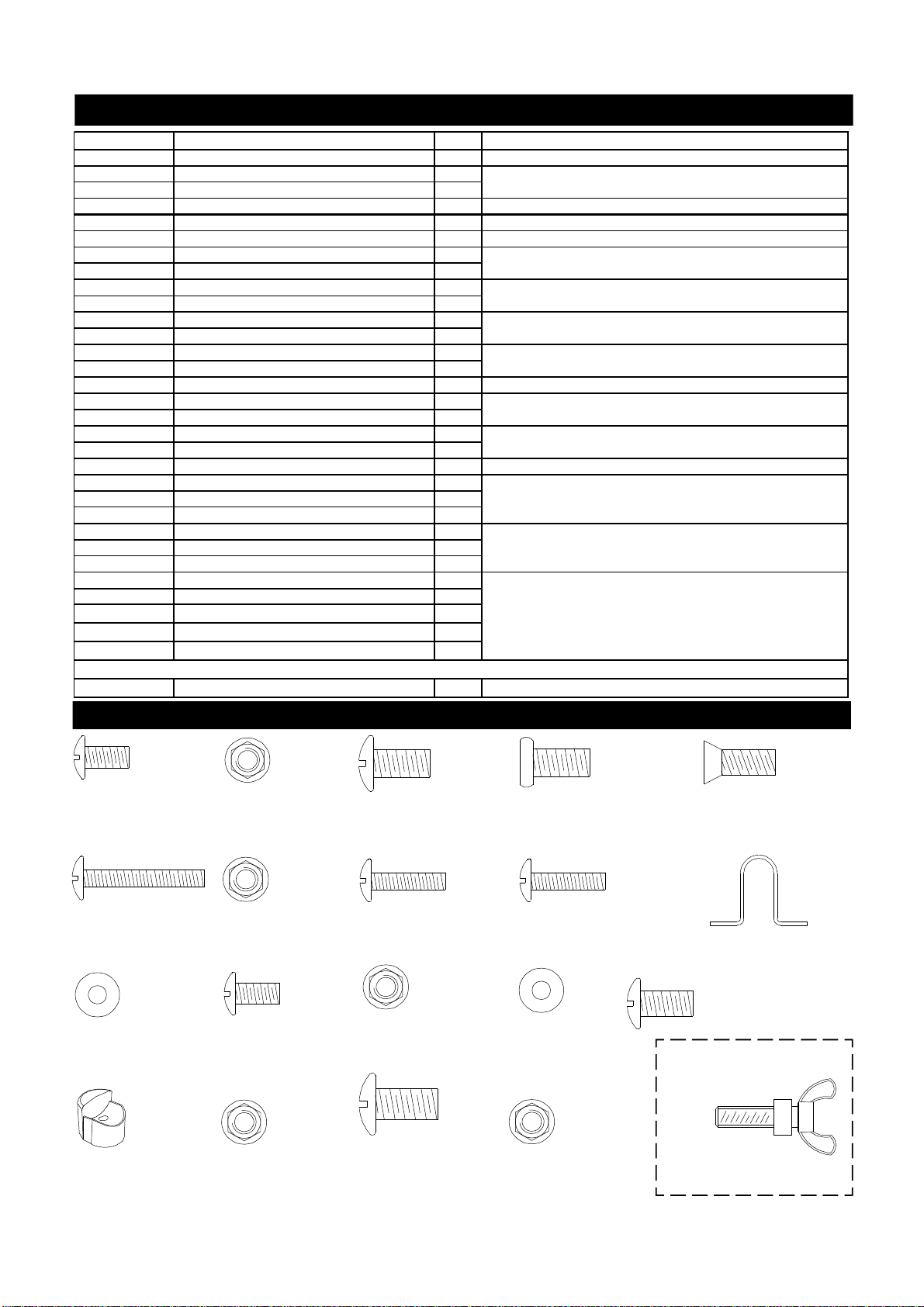

PartDiagramsandLists............................4-8

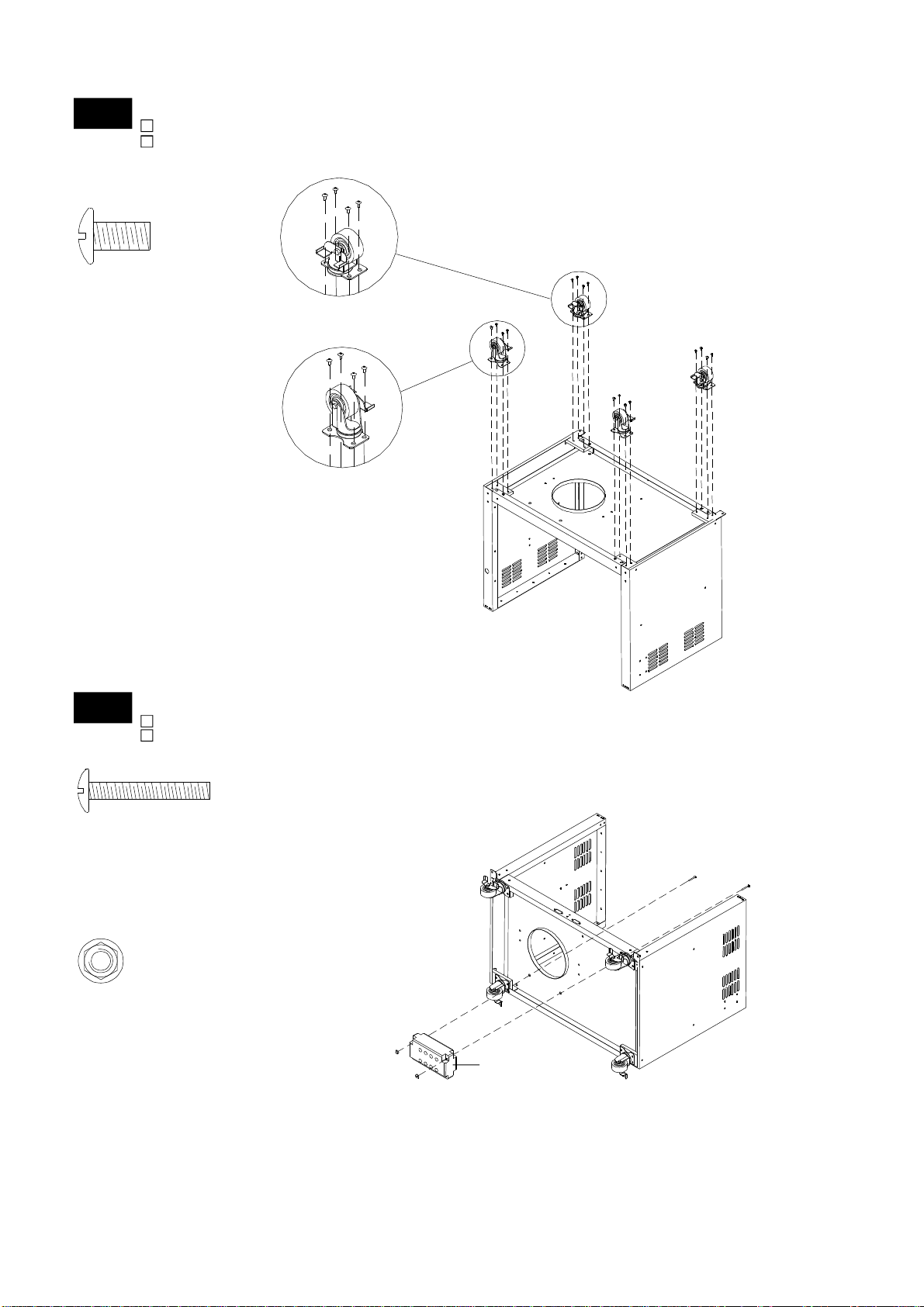

AssemblyInstructions.................................9-15

Use&CareInstructions:

•GasSafetyand LeakTests..............16-18

• NaturalGasConnection............................19

•LightingInstructions...................................20

•Troubleshooting...........................................21

CleaningandMaintenance.......................22-23

CookingGuide..........................................A1-A4

FrequentlyAsked Questions..................A5-A6

RepairProtectionAgreements......Back Cover

2

Donotstoreorusegasolineorother

flammableliquidsorvaporsinthe

vicinityofthisoranyotherappli-

ances.

AnLPcylindernotconnectedfor

useshallnotbestoredinthevicinity

ofthisoranyotherappliance.

1.

2.

•LPGmodelsmustbeusedwithLiquidPropane

Gasandtheregulatorassemblysupplied.Natural

GasmodelsmustbeusedwithNaturalGasonly.

Anyattempttoconvertthe grillfromonefueltype

toanotherisextremelyhazardousandwillvoidthe

warranty.

Keep gasregulatorhoseawayfromhotgrillsurfaces

anddrippinggrease.Avoidunnecessarytwistingof

hose.Visuallyinspecthosepriortoeachuseforcuts,

cracks,excessivewearorotherdamage.Ifthe hose

appearsdamageddonotuse the gasgrill. Call1-

877-934-7455foracertified replacementhose.

CaliforniaProposition65

Combustionbyproductsproduced when using this

productcontainchemicalsknowntotheStateofCalifor-

niatocausecancer,birthdefects,orotherreproductive

harm.

Brasscomponentsonthe grill,suchashosefittings,

propanecylindervalves(soldseparately)andburner

valvestems,containlead whichisknowntothe Stateof

Californiatocausecancer,birthdefects,orotherrepro-

ductive harm.

Neverusecharcoal orlighterfluidinthisgasgrill.

Failuretocomplywiththeseinstructionscouldresultin

agrease fireorexplosionthatcouldcause serious

bodilyinjury,deathorpropertydamage.

Beforeeachuseofyourgrill:InspecttheGreaseTray,

Grease HeatShieldand insideoftheGrill Bowltobe

surethereisno excessivegrease and debrisbuildup.

CleantheGrease Tray,Grease Heat Shieldand inside

oftheGrill Bowlfrequentlytoeliminategrease/debris

build-up and topreventgrease fires. Failuretocomply

withthese instructions couldresult inagrease fire

andeven asubsequentexplosion thatcouldcause

serious bodilyinjury,deathorpropertydamage.

•

•

•

•

!

Thisappliance,when installed,mustbe electri-

callygrounded inaccordancewithlocalcodes

or,inthe absenceoflocalcodes,withthe

National Electrical Code,ANSI/NFPA 70, orthe

Canadian Electrical Code,CSA C22.1.

Keep anyelectricalsupplycordand the fuel

supplyhoseawayfromanyheated surfaces.

•

•

WARNING !

DANGER

!!

1.

2.

3.

4.

Ifyousmell gas:

Shutoff gas totheappliance.

Extinguishanyopenflame.

Openlid.

Ifodorcontinues,keepawayfrom

theappliance andimmediatelycall

yourgas supplieroryourfire

department.

WARNING

! !

WARNING

! !

Never coverorwraptheCooking Grids,bottom

oftheGrill Bowl,Grease Traywithaluminumfoil

oranyothermaterialthatwill absorbgrease.

! !

WARNING