9

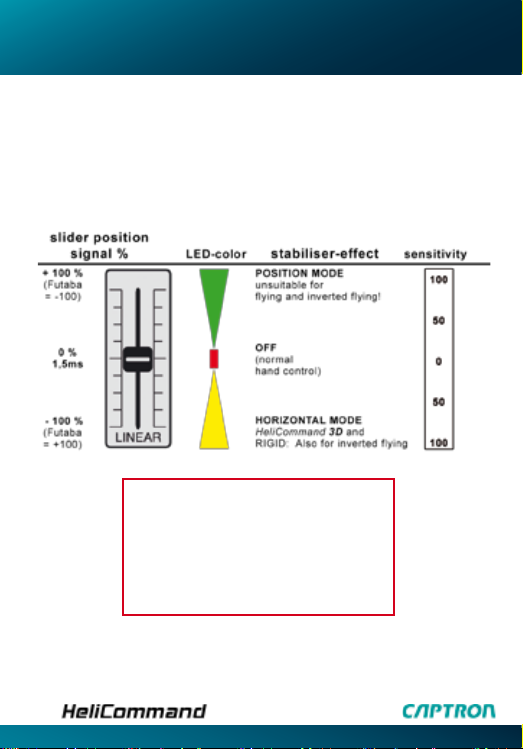

Basically, all versions (3A, 3D, Rigid) offers the following modes of operation:

LED red = stabilising functions switched off (= conventional)

LED yellow = horizontal mode

LED green = position mode

Horizontal mode („yellow“): moves the helicopter to the horizontal attitude if you

release the aileron (roll-axis) and elevator (pitch-axis) controls.

This works totally independently of the optical quality of the ground surface. For

indoor ying you should select this mode; if you do not wish to, please read the

notes on page 29.

Position mode („green“): in this mode the unit stabilises the model’s position as

well as its horizontal attitude. This is the most powerful stabilisation, and is ideal

for “automatic” hovering and slow circuits. It works most effectively at heights of

about 0.5 to 2 metres above a natural surface (grass, gravel etc.). If you release

the aileron and elevator controls, the system actively brakes the helicopter until it

is stationary; all the pilot has to control is the collective

pitch / throttle function. If the model exhibits any slow drift at the hover, this can

very easily be corrected manually. For slow circuits close to the ground, you can

set a forward speed by keeping a slight constant push on the elevator stick, then

direct the model using the tail rotor stick (just like steering a car).

For higher speed and for ying at heights above about 5 m, this mode would

tend to be a nuisance because of its corrective actions; in this case you should

switch to horizontal mode („yellow“).

The conguration for the above-described functions is possible without PC,

unless four head-servos are used.

RIGID mode: this is a fourth mode of operation only available with the

HeliCommand RIGID: it is designed for ybar-less rotor heads, stabilising and

maintaining the helicopter’s attitude (see page 5).

Rigid mode can be combined to working parallel with the three modes

described above. These options are explained on page 26.

In addition to the previously described stabilising functions, all HeliCommand

versions offer the following supplementary functions:

swashplate mixer, tail rotor gyro and automatic trim.

Description of facilities