Page 1

version 1.0.5.1 SCARAB YSiixKopta Airframe guide www.MultiCopterPilot.com

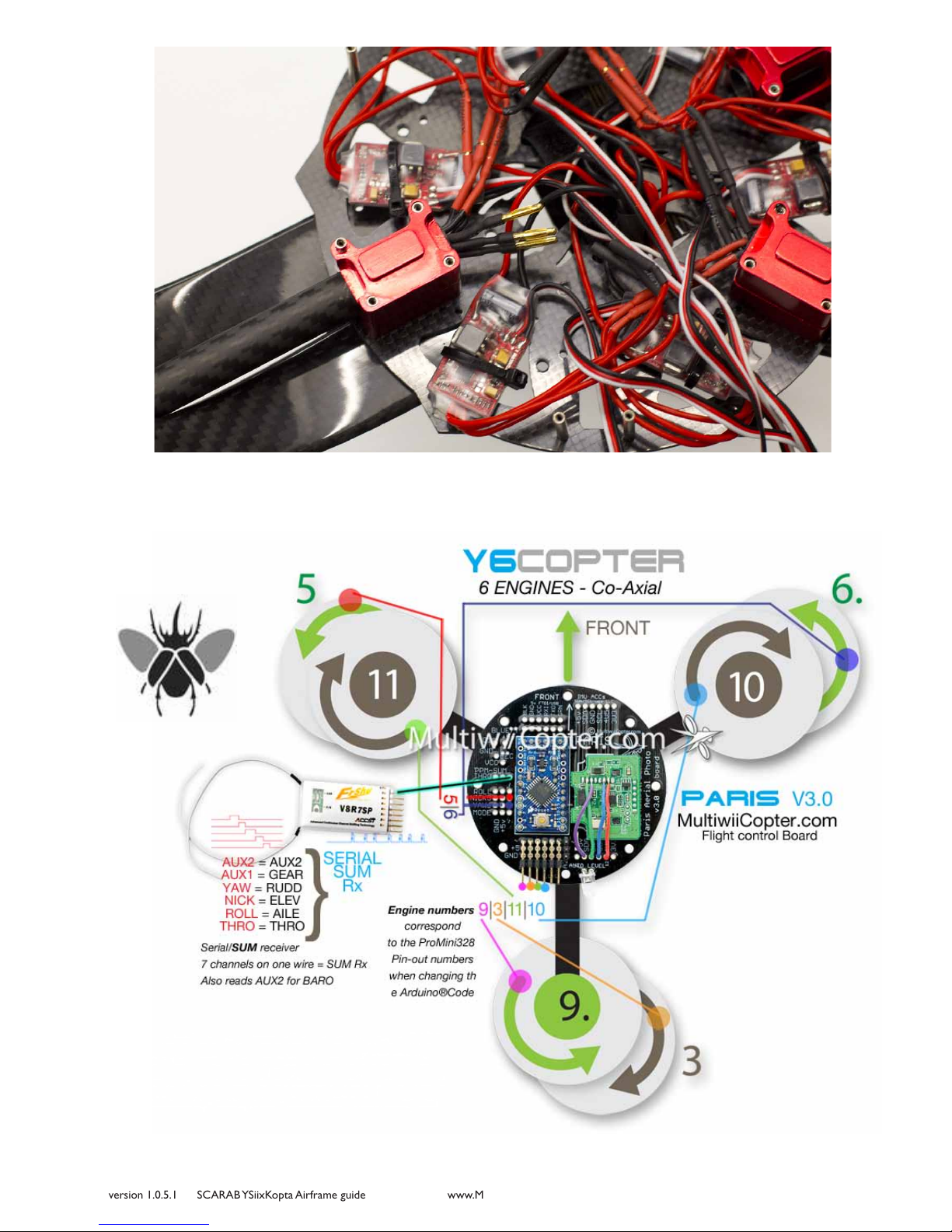

SCARAB YSiixkopta Airframe

The following is the recommended building tips for

assembling the airframe.

YSiixKopta SCARAB is designed for

10 amp ESCs x 6 - preferrably running 4S

775kv Motors between 35g - 75g

Wires - 20AWG wires LiPo 150-220g

4S 9050Triples

VERSION 1.0.5

BOOM LENGTH - Build light -> to fly - if necessary -

cut booms down to suit motors - small motors (29g)

- Medium (50-70g) = 260mm - heavy motors(75g+)

210mm ~ 230mm Balance props perfectly on a

magnetic balancer. then dynamic running them on a

hand rig. Mounting - use conter sunk screws on the

top motor direct to the Carbon mount . Mount the

LOWER motor to the X plate(that comes with your

motor) - use M3 bolts to secure the X. Do not pull on

the wires - any stress will damaged the motor internally.

SCARAB is designed to sacrifice the frangible

booms in the event of a crash and save the

motors,electronics and the mainframe from

impact G forces. Thin rounded booms are very

streamlined to prop wash and gives longer flight

times of 12-15mins. We expect the removable

boom to be used in most cases - for travel and for

modular replacement reasons. good connections

are vital. If a single connector fails or comes loose

- yourYSiix may crash - double check each one

For aYsiix you may need to revese the shaft -

remove the grub screw from the bell. tap the shaft

out with a 3mm tap - then I use a wood vice - I

turn the vice slowly to feed the shaft to the correct

distance. wiring - decide if you want removable

booms/plugs. or if you want to solder the wires to the

ESC? Solder wires are be less suitable for Travel-AP

- so each pilot takes his own Risk. Top motors wire

ends red - bottom mor wire ends black - to identify it

each motor exit wire location is different

(above left) - counter sink two matching holes

in the engine mount by aligning the wires to the

shaft side of the key shape - Attach the motor - use

Loctite on the screws and also on the shaft lock screw.

Slide the carbon boom over the completed assembly

including the wires - be sure not to cut the wires on

the carbon shaft ! see next page for photos

top engine red

bottom engine black