CONTROL GROUP

10

8. Remove the winch controller handle from the assem-

bly.

9. Test fit the plastic console cover to the RH console.

NOTE: On EROPS tractors, the winch controller

assembly will be visible through the ashtray

opening in the plastic console cover. On OROPS

tractors, the winch controller assembly will not be

visible.

10. On OROPS tractors, mark the approximate location

where the winch controller handle, in its neutral posi-

tion, will protrude through the console cover. Cut a 3

in. (76 mm) diameter opening in the plastic cover

using a hole saw or suitable method.

11. Temporarily replace the winch controller handle into

the control assembly.

12. While ensuring the controller handle is in the neutral

position, center the gate plate (item 2) over the con-

troller handle as shown in View A. Once positioned,

use the gate plate as a template to transfer the mount-

ing hole locations (4 holes) to the plastic console

cover. Drill (4) 5/16 in. (8 mm) holes in the locations

marked. Also, be sure to remove any excess plastic

beneath the gate plate within the shift pattern.

13. Modify the cigar lighter boss as required to allow the

gate plate to fit flush to the top of the console cover.

14. Install the gate plate to the plastic cover with cap-

screw, washers and nuts (items 22, 23 and 24) as

shown in View A.

15. Re-install the controller handle into the control valve

assembly and tighten the jam nut.

16. Install the boot and boot retainer plate (items 26 & 27)

to the gate plate using self-tapping screws (item 25)

as shown in View B.

17. Stretch the top of the rubber boot over the rubber

bushing previously installed on the handle, and attach

the boot to the bushing to seal and retain the top of

the boot.

18. Affix the decal (item 4) to the console near the winch

controller, or to the inside of the window. The opera-

tor's view of the decal MUST be clear and unobstruct-

ed.

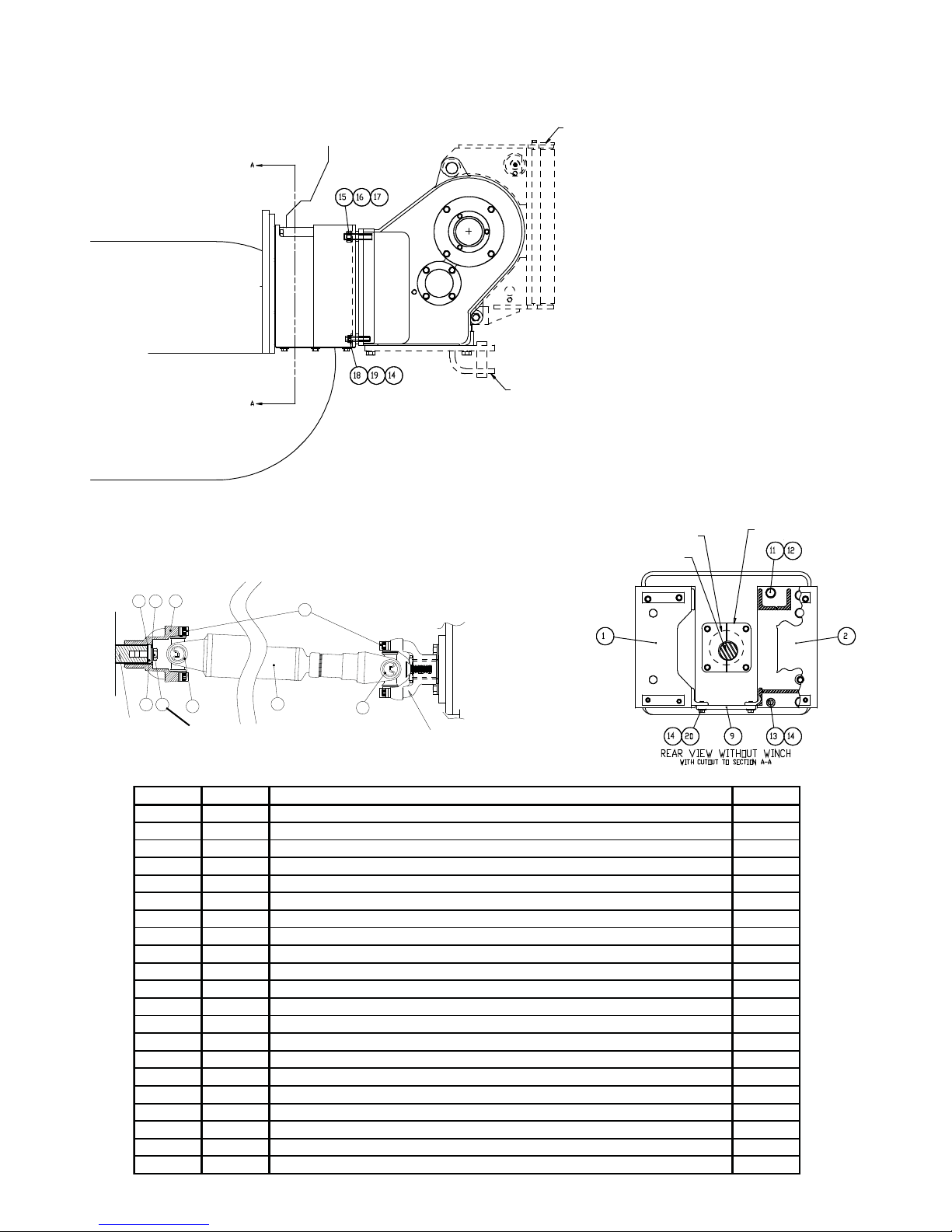

19. Install hydraulic fittings to the winch face and control

manifold, as shown in Detail “D”.

NOTE: If the winch is equipped Reel-Out, then

install the orifice plug (item 20) into the special

elbow (item 19) using Loctite 572 or equivalent.

20. Tilt the cab as outlined in the tractor manual.

21. Install the winch control hoses (item16) to the proper

ports as defined in Details “C” and “D”. Route the

hoses around the rear of the operator platform, down-

ward near the cab tilt hinge on the LH side of the trac-

tor, then back to the center of the tractor to pass under

the fuel tank to the winch. Ensure that the hoses will

not be stretched or pinched, or otherwise interfere in

any way with the tilting of the cab during regular serv-

icing.

22. Test the cab tilt function to validate the hose routing.

When satisfied, bundle and affix the hoses as appro-

priate using the tie straps (item 19).