Specifications

SAFE WORKING LOAD: 190 kg (30 Stone)

Stretcher Operation

1. The Stretcher is locked in the vertical position when the mechanism is at its

lowest point. This is a safety feature.

2. To drop the Stretcher down for use, power the mechanism upwards for a

couple of inches by pressing the ‘UP’ button on the handset, which releases it.

3. Lower cotside by raising both of the stainless steel catches

simultaneously (using both hands). The need for two-handed operation

prevents accidental dropping of the cotside and is a safety feature.

4. Position the service user onto the stretcher and raise cotside until it locks into

position.

5. Raise the stretcher up to a height suitable for the carer by pushing the ‘UP’

button.

6. Ensure that the waste funnel is positioned over a suitable drain or self-draining

area of floor.

7. After bathing re-adjust height of stretcher, lower cotside and transfer service

user.

8. The water-collector under the stretcher is attached with Velcro and may be

detached at the rear to become instead a unique curtain which hangs down to

help protect the carer.

SAFETY NOTE: Always ensure that the cotside is in place and secure during

showering.

We thank you very much for purchasing our product and hope that the following notes

will assist you in obtaining maximum benefit from it.

Code Stretcher

size

Lifts from

500 to 900

mm

Fixes to

wall, folds

away

Water

draining

facility

Padded base &

sides

SWS 140 1400 x 700

mm

SWS 160 1600 x 700

mm

SWS 180 1800 x 700

mm

SWS 181 1800 x 800

mm

SWS 100 Floor

Mounting

Frame

Servicing

We would recommend that the product is serviced annually by a qualified Care &

Independence engineer or one of their appointed agents.

Cleaning and Maintenance

After use, clean the unit, particularly the liner area with clean, warm water then an anti

-bacteria solution. If the unit becomes soiled, use of a non-abrasive cleaner then an

anti-bacteria solution is recommended. For institutional use we suggest that the

stretcher is cleaned after each person to avoid the risk of cross-infection. It is

suggested this be carried out using clean warm water, a non-abrasive cleaner then an

anti-bacteria solution.

Note that the waste funnel should be flushed clean with an anti-bacteria

solution after use.

Abbreviated Installation Instructions—if appropriate

ELECTRICAL SUPPLY: Please provide fused spur at high level either above shower

area or perhaps in adjoining room or corridor. This will be used to feed a transformer,

which is in a waterproof plastic box approx. 200mm x 150mm x 100mm, which will fix

to the wall at about 1200 mm above floor level immediately to the left or the right of

shower stretcher. The cable from the fused spur to transformer box will need to be

surface mounted in trunking.

FIXING: You need 1800mm of clear wall space, (1600mm for the WS160, 1400mm

for the WS140) measured left to right. Wall needs to be of solid construction and free

of surface mounted pipes, etc. The device rests on the floor and fixes to the wall with

up to 8 fixings which can be either expansion bolts or chemical fixings.

NOTE: Where the wall is not strong enough but the floor is solid, use Floor

Mounting Frame (code SWS 100) which transmits the load to the floor.

Offer up the mechanism to the wall and mark positions of holes. You must use 4

fixings (min. 10mm) through the upper wall-plate, and at least two through the lower

wall plate. The vertical component of the weight of the unit and patient is taken by the

floor.

Remove mechanism, drill holes and re-fit. Fit transformer box at a height of approx.

1200mm, higher if required, to either side of the mechanism. Remember that the

handset connects to this box and, although this has a generous length lead on it, the

box must be positioned close enough to the mechanism to allow the handset to be

held by the carer when standing at any likely position around the bed.

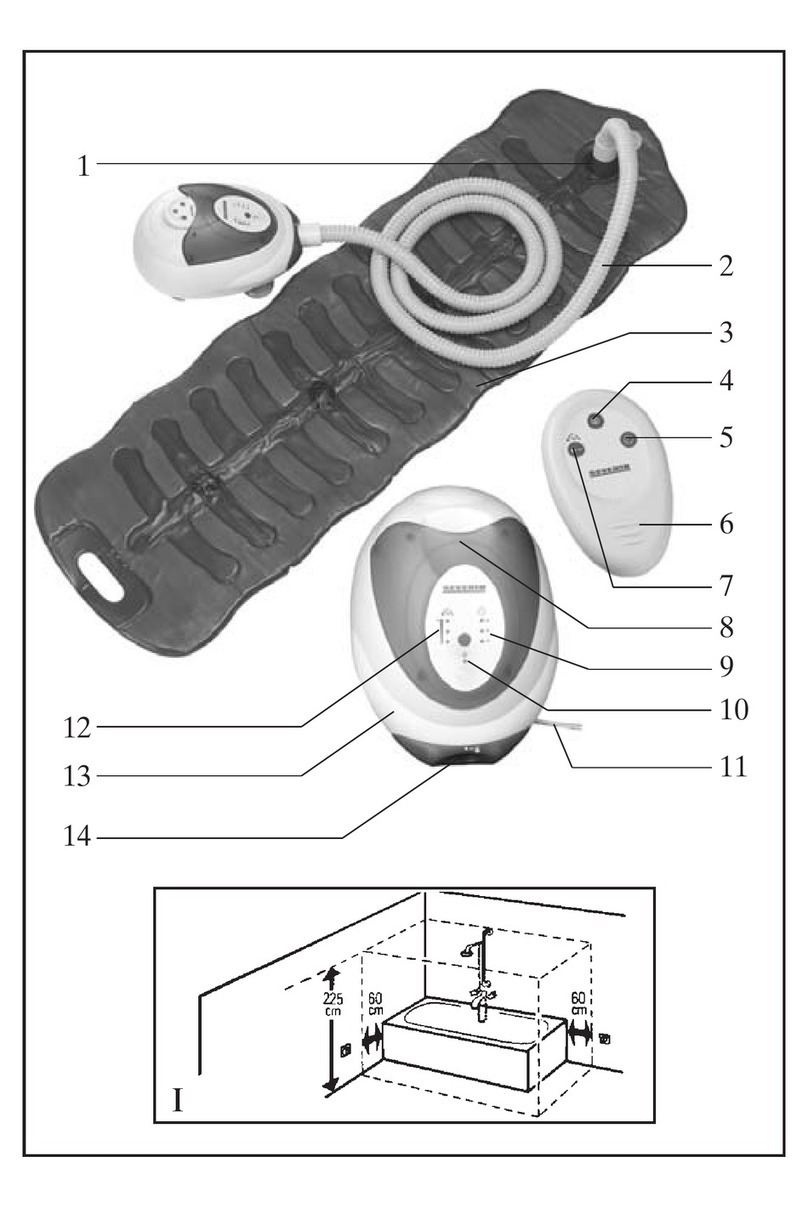

CONNECTING UP: The ¼ inch jack plug on the lead from the actuator plugs into the

water-protected socket on the side of the grey transformer box. Note that the plug

needs to be orientated correctly before it will push fully home. Look into the hole in the

box and determine the position of the lugs which protrude. These must line up with the

slots on the plug body. The plug body is a very tight fit into the hole. When it is fully

home, give it a twist to lock it in place. Test the motor (once mains is connected) for

operation – if motor does not move then the jack plug is probably not fully located.

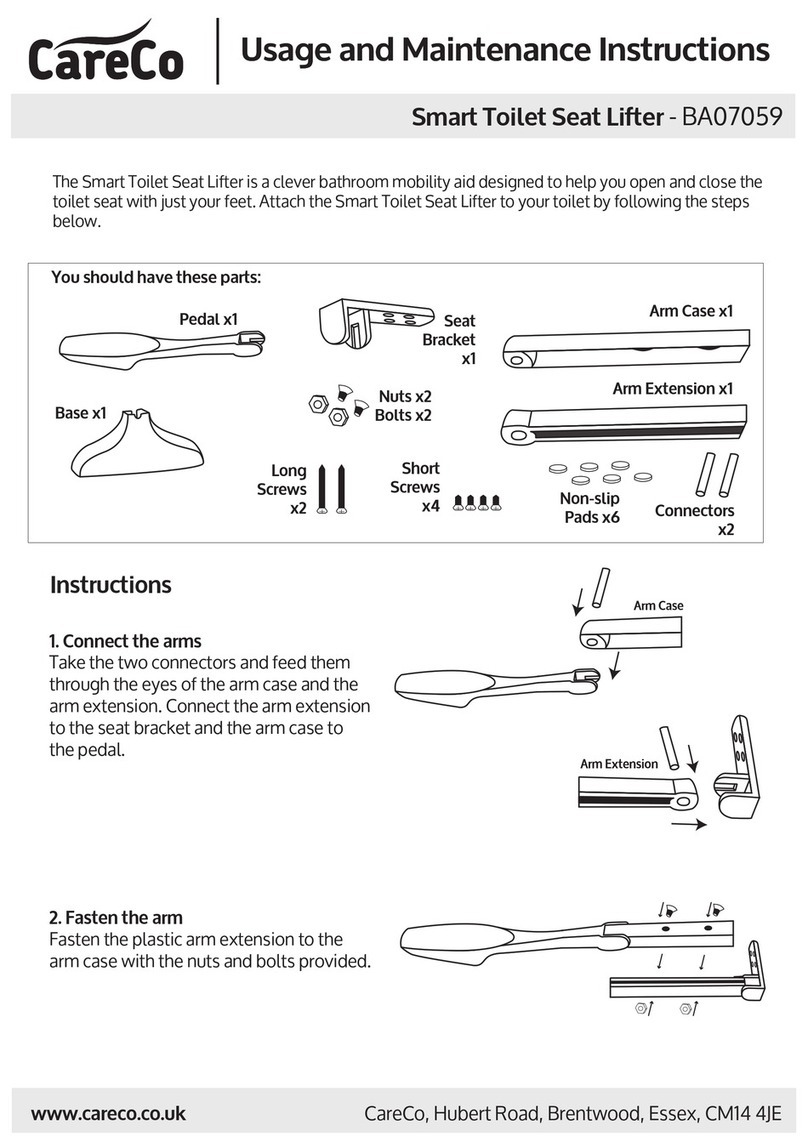

ASSEMBLY: The stretcher mounts to the mechanism using the short stainless steel

bolts, washers and the nylon bushes. Push these into the large holes in the support

arms from the outside towards the centreline.